An Algorithm for Determining the Offset of Strip Using Contact Shape Roller

A contact and offset technology, applied in the field of steel rolling, can solve problems such as production, equipment and instrument damage, broken belt accidents, etc., and achieve the effect of stable rolling and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

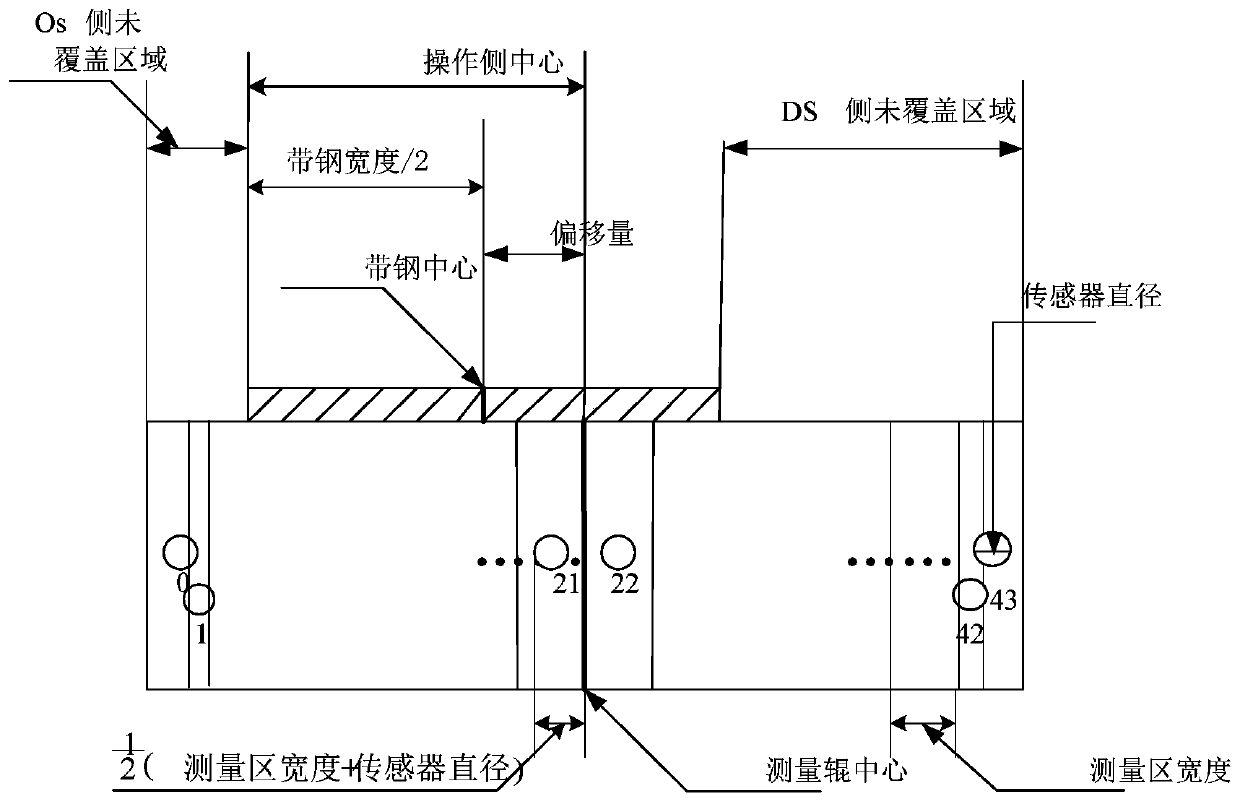

[0036] Such as figure 1 As shown, an algorithm for determining the offset of the strip by using the contact shape roll is suitable for multi-stand 6-high or 4-high rolling mills, and has the function of intermediate roll shifting. At the same time, the shape roller is a contact type shape measuring roller, and the measuring roller is segmented.

[0037] Described method comprises the following steps:

[0038] An algorithm for determining strip offset using contact shape rolls, comprising the following steps:

[0039] Step 1. Determination of minimum radial force

[0040] Step 101, installing contact-type flat rolls at the outlet of the strip cold rolling mill;

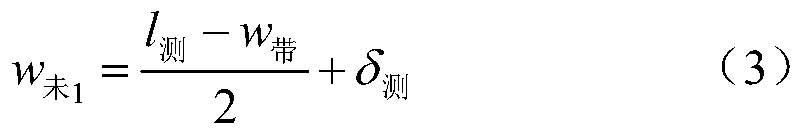

[0041] In step 102, the radial force of multiple measurement points detected by the contact plate shape roller is smoothed, as shown in formula 1

[0042] f 平滑 (i) =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com