Patents

Literature

45results about How to "Efficient rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

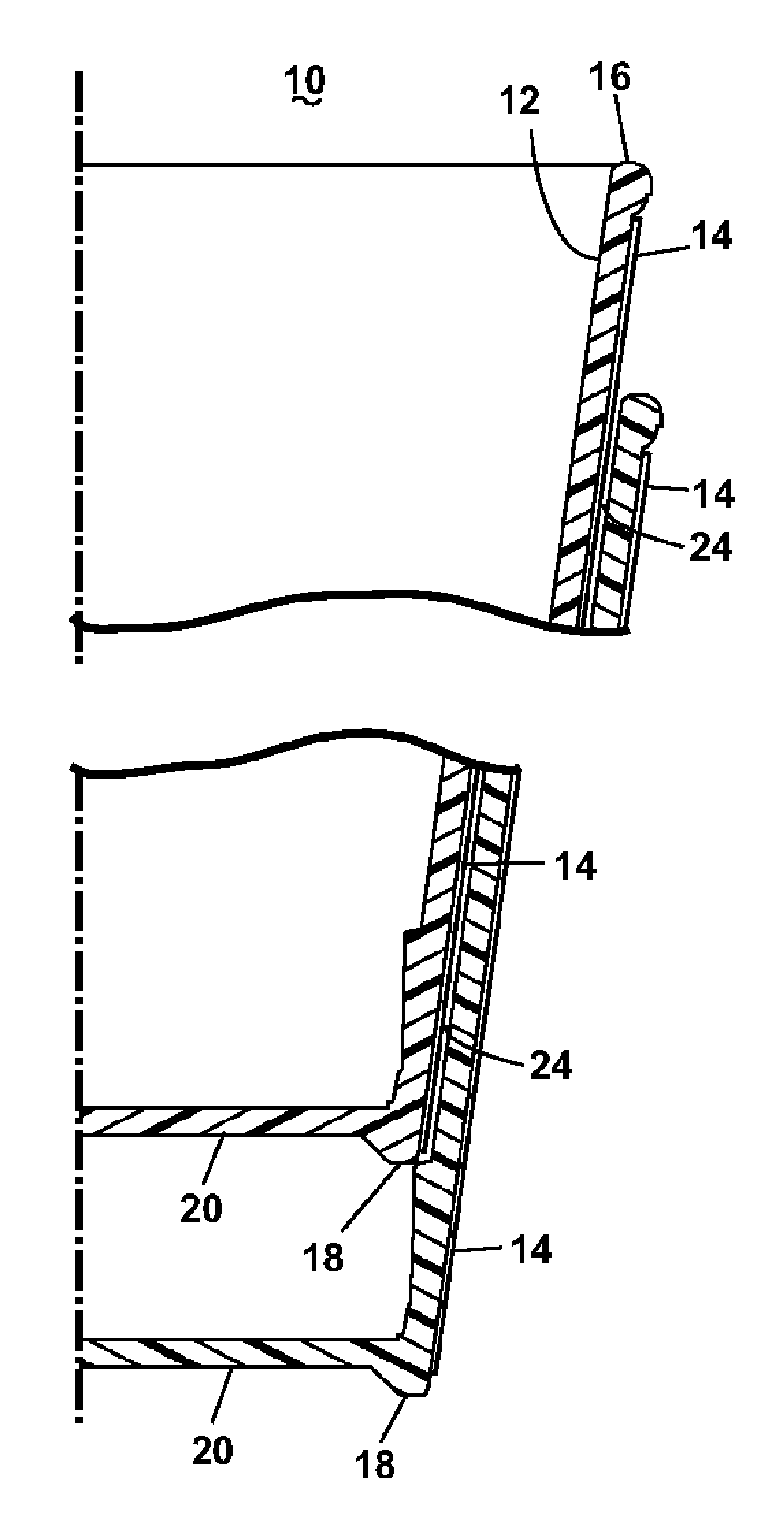

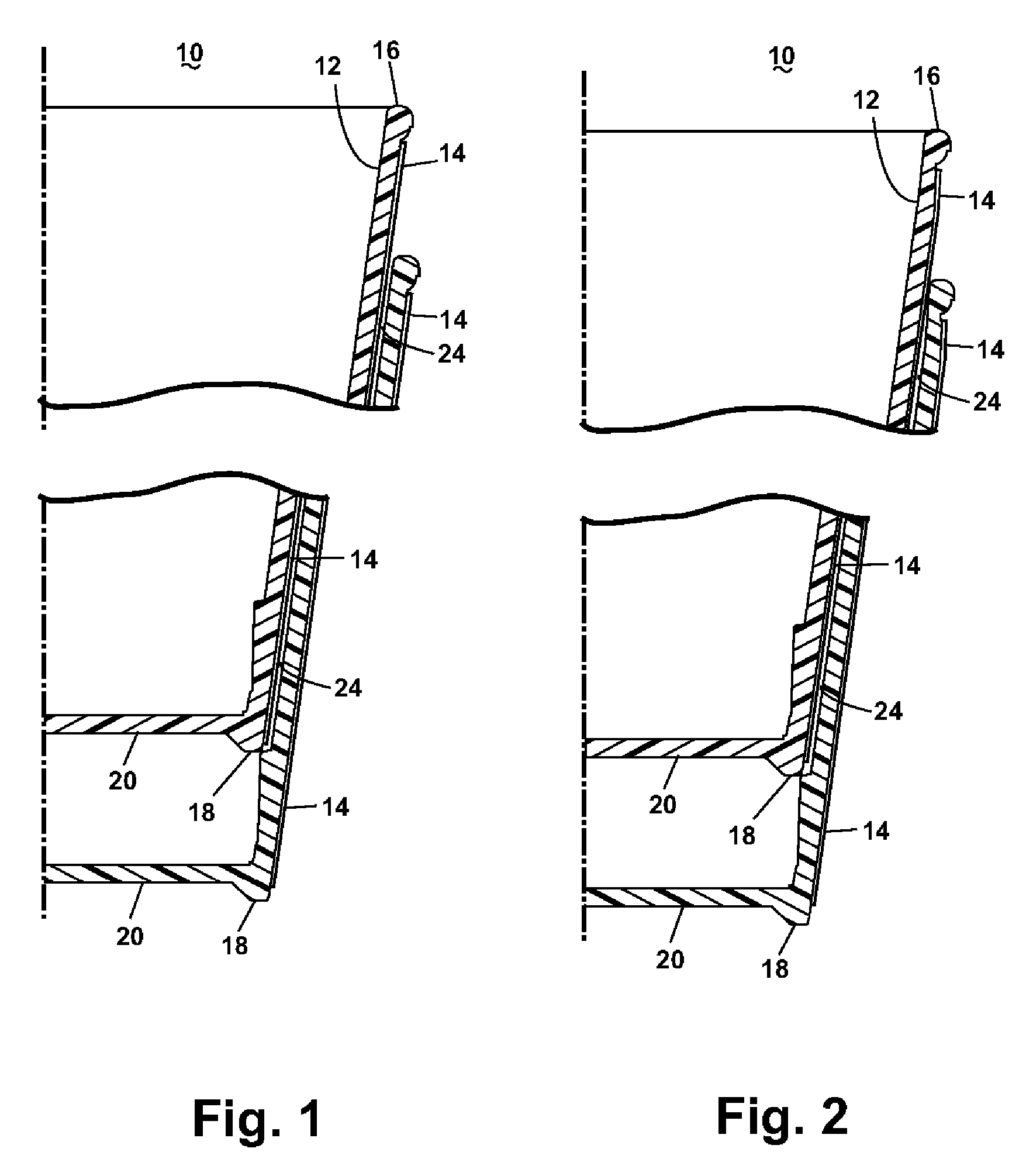

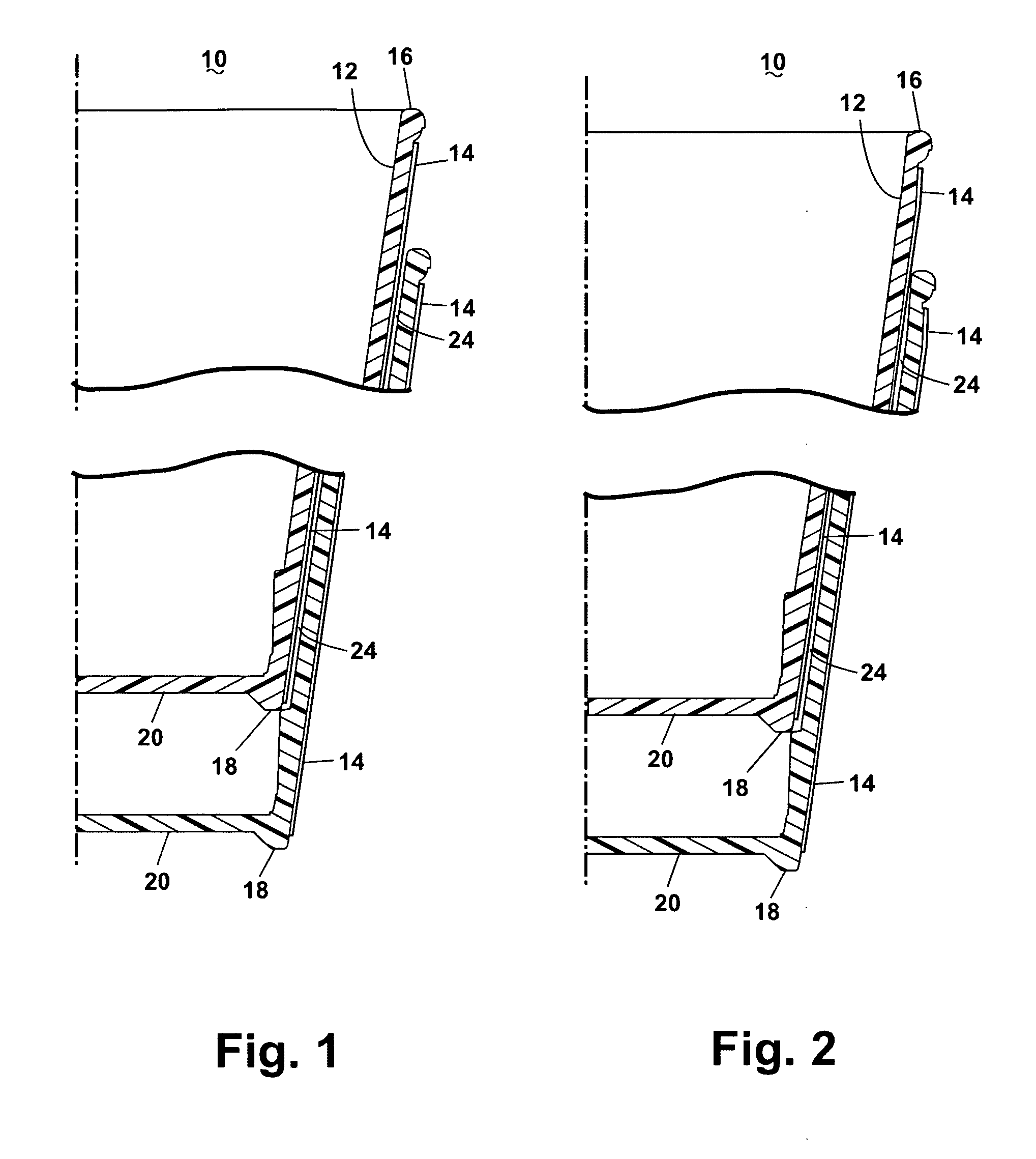

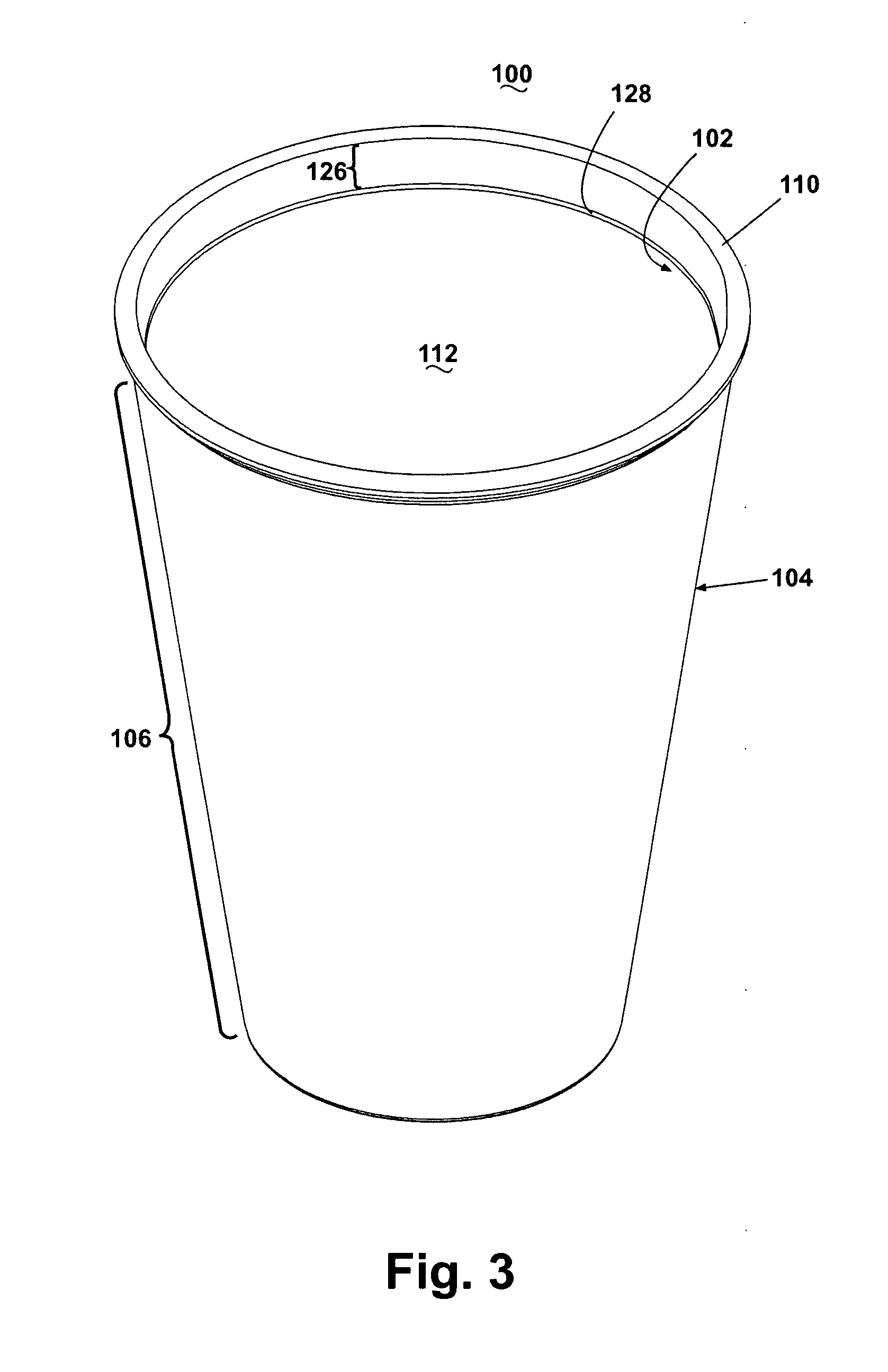

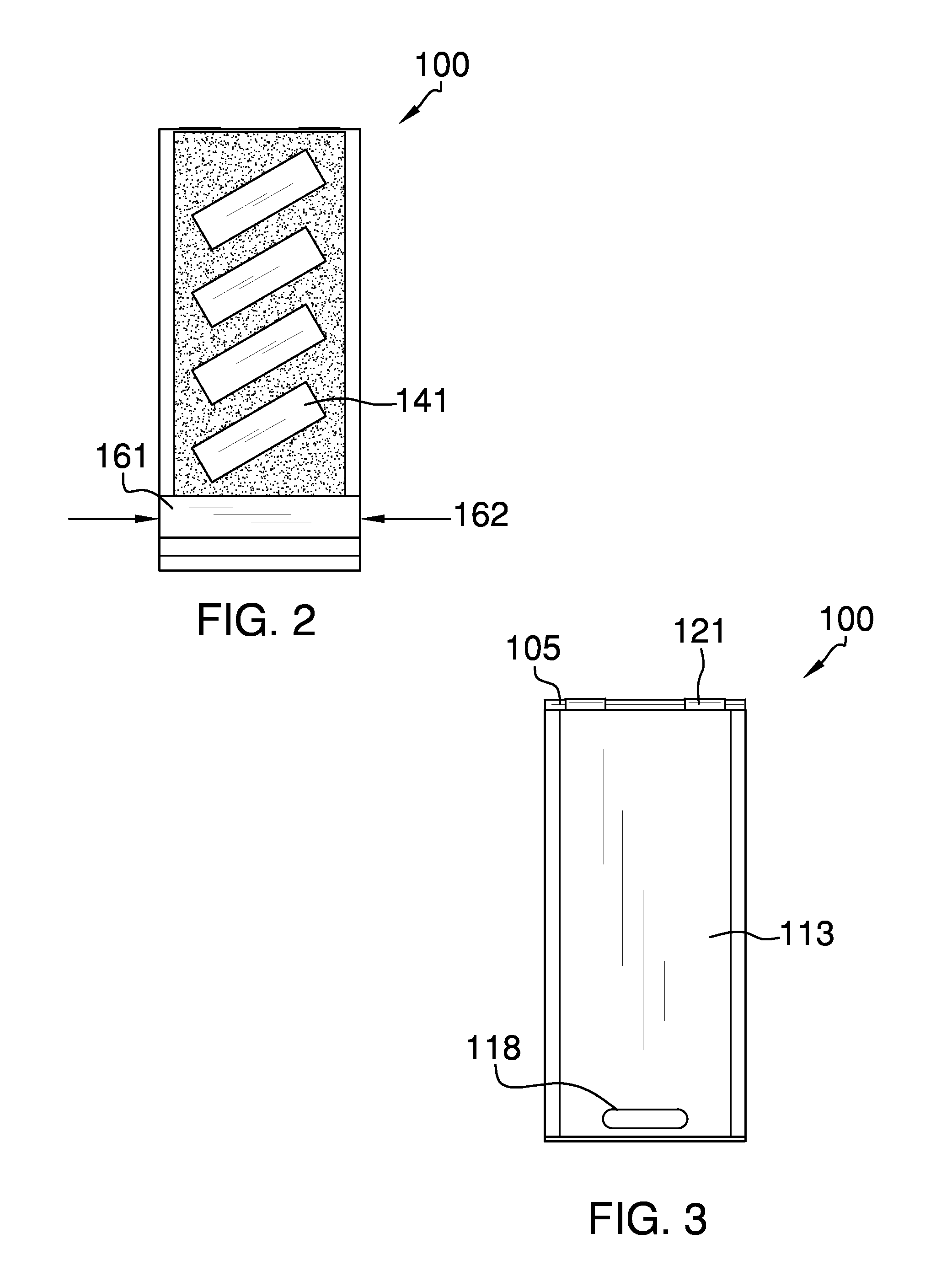

Paper wrapped foam cup and method of assembly

ActiveUS20050227029A1Efficient rollingDomestic cooling apparatusLighting and heating apparatusPulp and paper industryVisual appearance

A commercially viable paper wrapped foam cup comprising a taper portion that prevents the shrinkage-induced curling from interfering with the un-nesting of nested paper wrapped foam cups. The paper wrapped cup further comprises a fillet for strengthening the cup foot to retard shrinkage-induced curling of the foot. The paper wrapper has abutting to overlapping opposing ends to completely hide the foam cup to enhance the visual appearance of the cup. The overlapping portions of the paper wrapper are not bonded to each other to prevent wrinkling of the paper wrapper as the cup shrinks. A machine and corresponding method provide for automatically supplying foam cups and paper wrappers, wrapping the paper wrapped cup, and stacking the wrapped cups.

Owner:DART CONTAINER

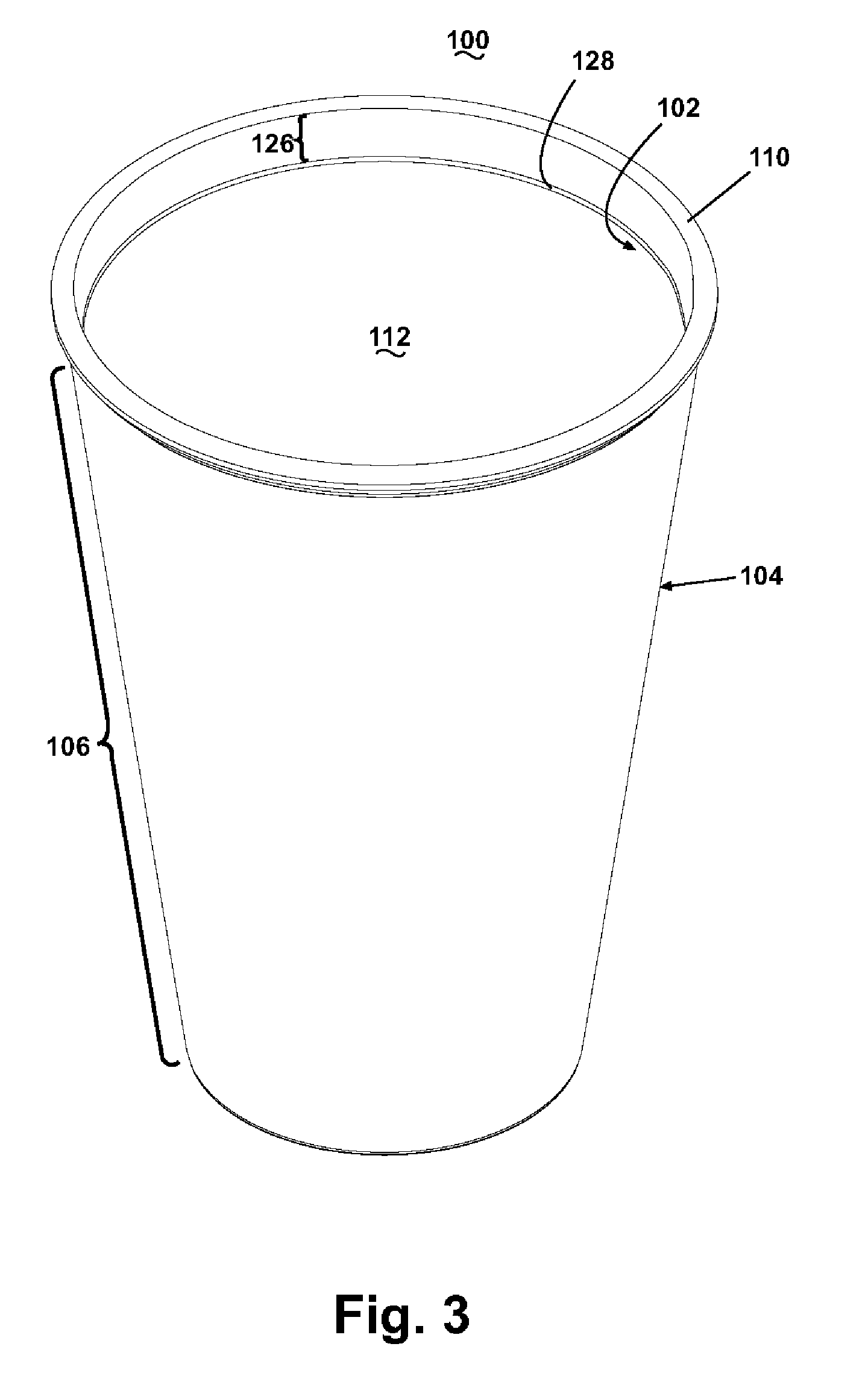

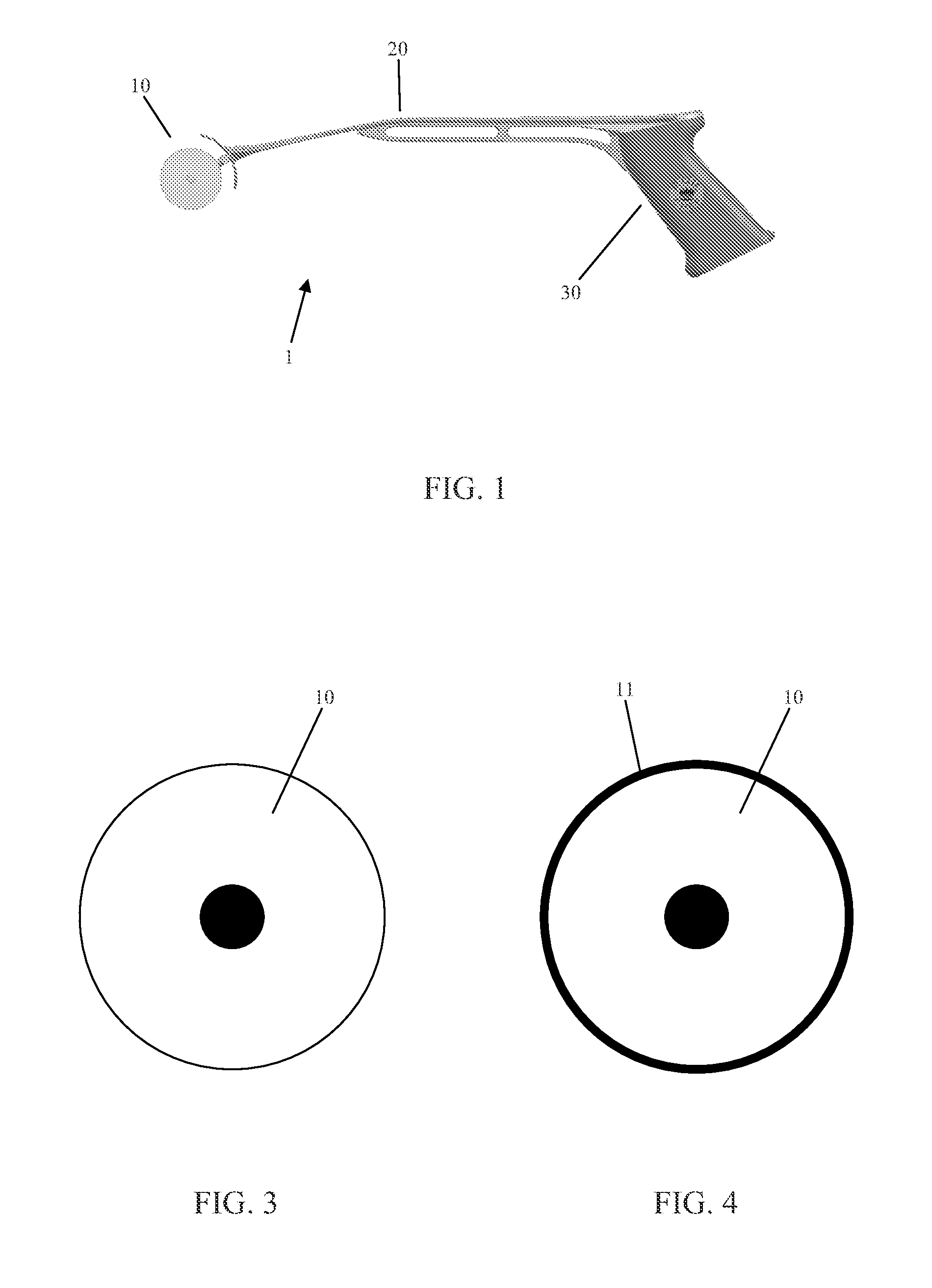

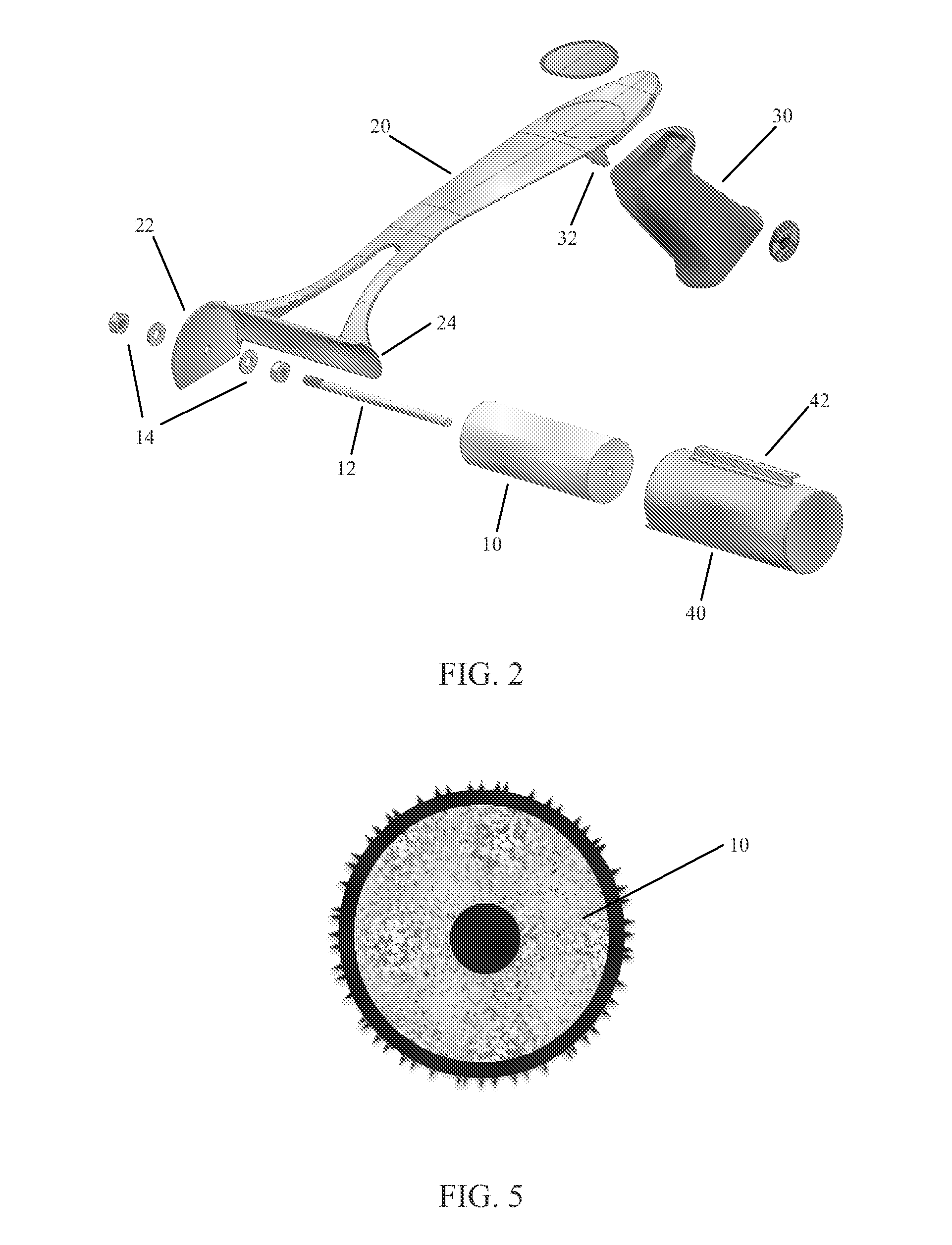

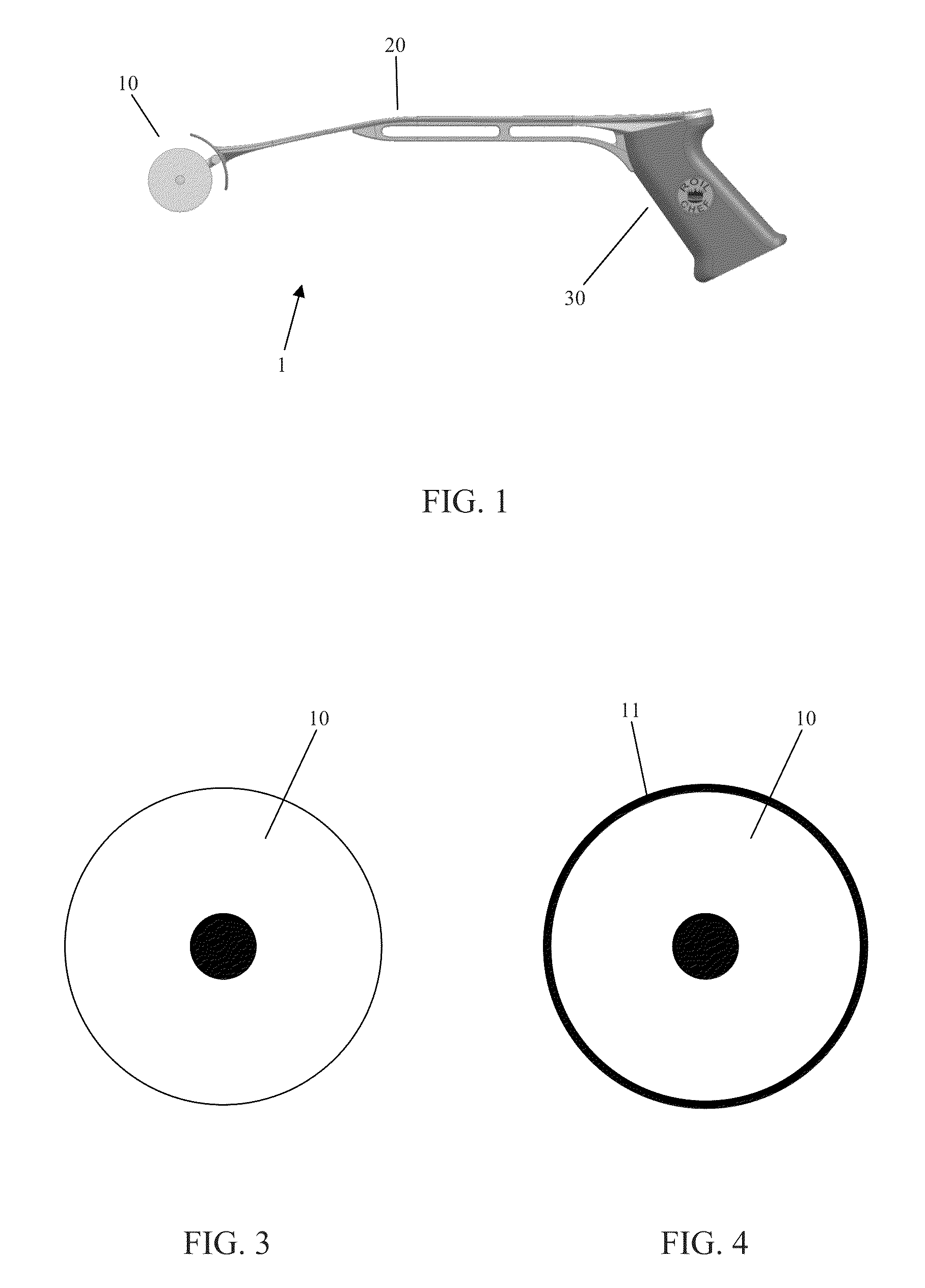

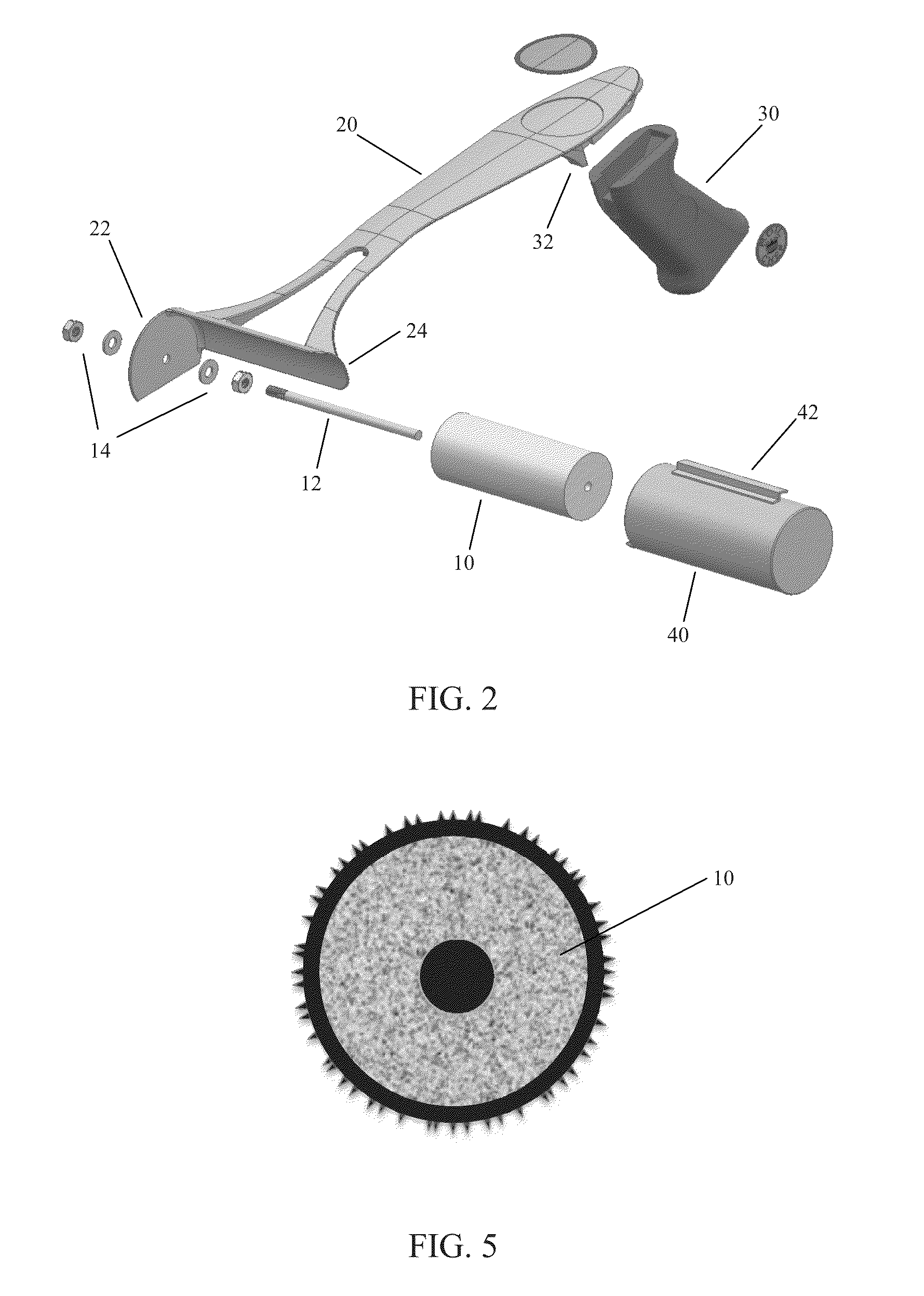

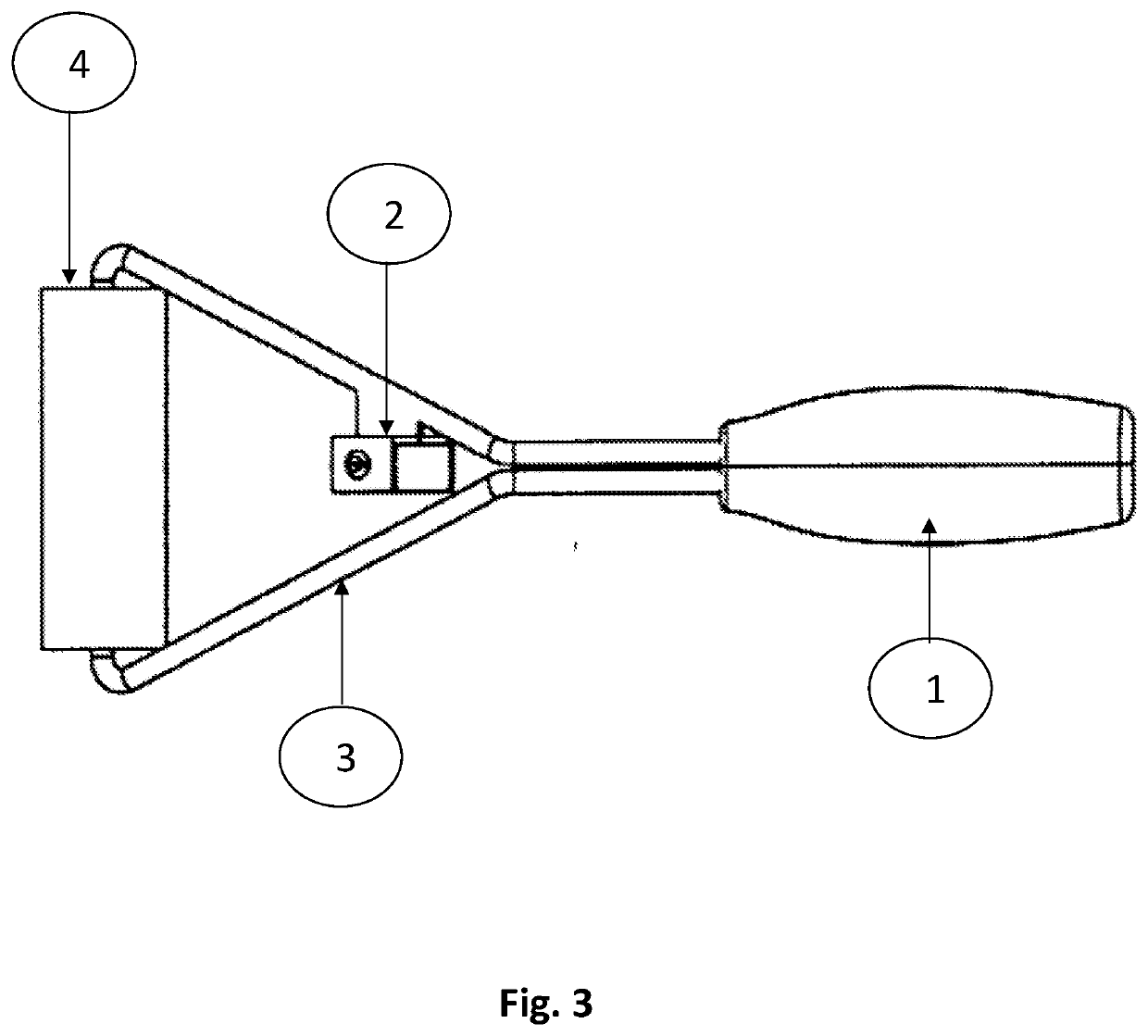

Grill Oiler

InactiveUS20120063836A1Efficient rollingEasily replaceableLiquid surface applicatorsCarpet cleanersLubricationIrrigation

A non-drip applicator that allows easy lubrication and seasoning of barbecue grilling grates or griddle cooking surfaces in an easy, fire safe, and efficient manner is described and claimed. The tool includes a body, an applicator, and, optionally, an irrigation system. The applicator may retain a supply of cooking oil therein, or cooking oil may be transferred to the applicator via the irrigation system. The application of pressure to the applicator by pressing it against the grill cooking elements causes cooking oil to be transferred from the applicator to the cooking elements. The applicator may be rotatably connected to the tool body, allowing the user to oil the grill by rolling the applicator along the grill cooking elements.

Owner:GILBERT PERFORMANCE DESIGN

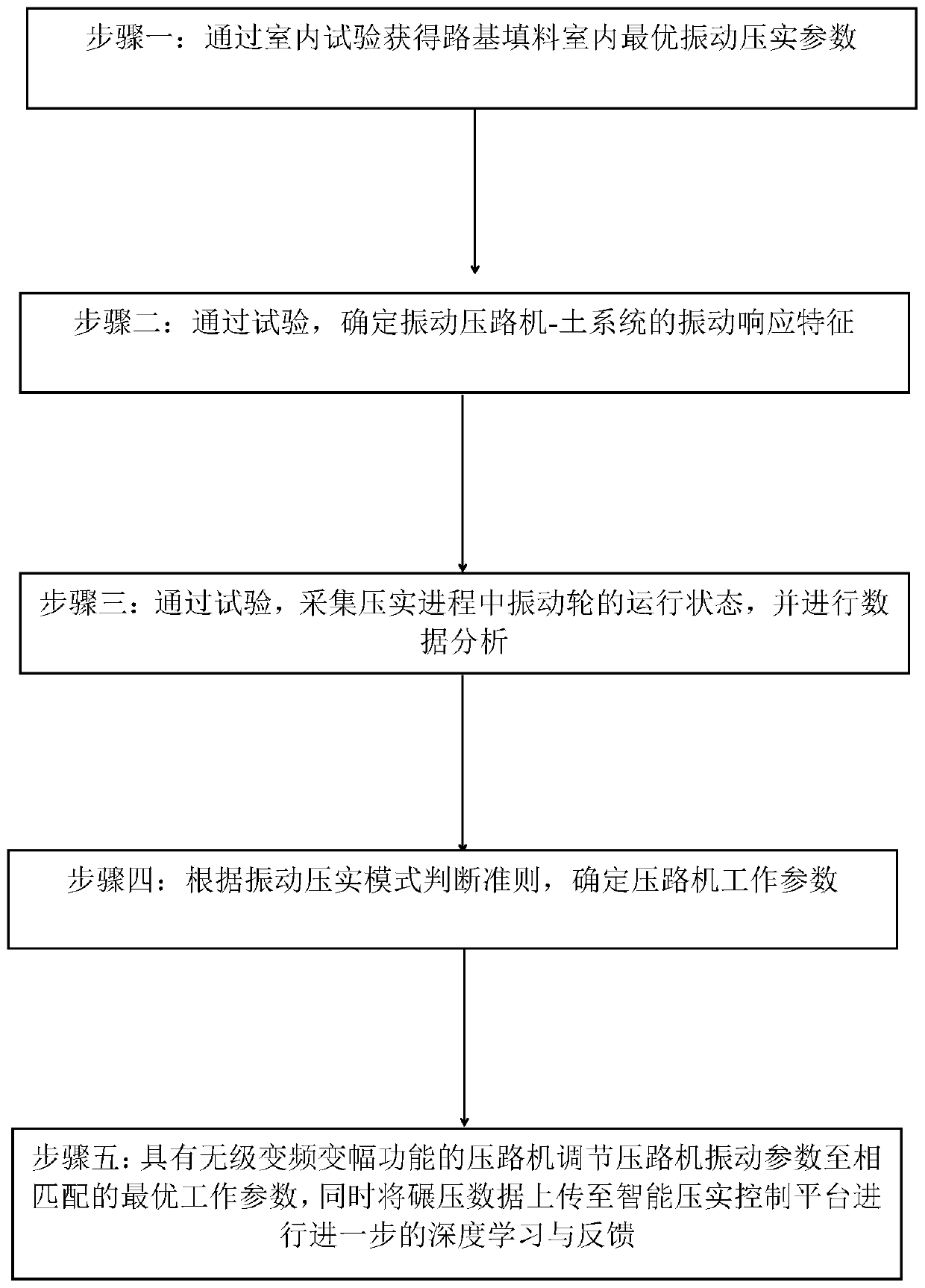

Intelligent frequency and amplitude modulation rolling method for vibratory roller

InactiveCN109881566AIntelligent rollingEfficient rollingRoads maintainenceAmplitude functionEngineering

The invention discloses an intelligent frequency and amplitude modulation rolling method for a vibratory roller, which comprises the following steps, step 1: obtaining the optimal vibration compactionparameters of a roadbed packing room through laboratory tests; step 2: determining the vibration response characteristics of a soil system of the vibratory roller; step 3: collecting the running state of vibration wheels in the compaction process through tests and analyzing the data; step 4: according to the criterion of a vibration compaction mode, determining the working parameters of the roller; step 5: adjusting the vibration parameters of the roller to the matching optimal working parameters by the roller with an electrodeless variable frequency and amplitude function and uploading the rolling data to the intelligent compaction control platform for further deep learning and feedback. Based on the vibration response characteristics of the roller and the judgment criterion of the optimal working parameters, the intelligent frequency and amplitude modulation rolling method for the vibratory roller automatically adjusts the vibration parameters of the roller to the matching optimal working parameters according to the compaction state of the roadbed filling, and develops a prototype to achieve the intelligence and high efficiency rolling of the roadbed filling.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

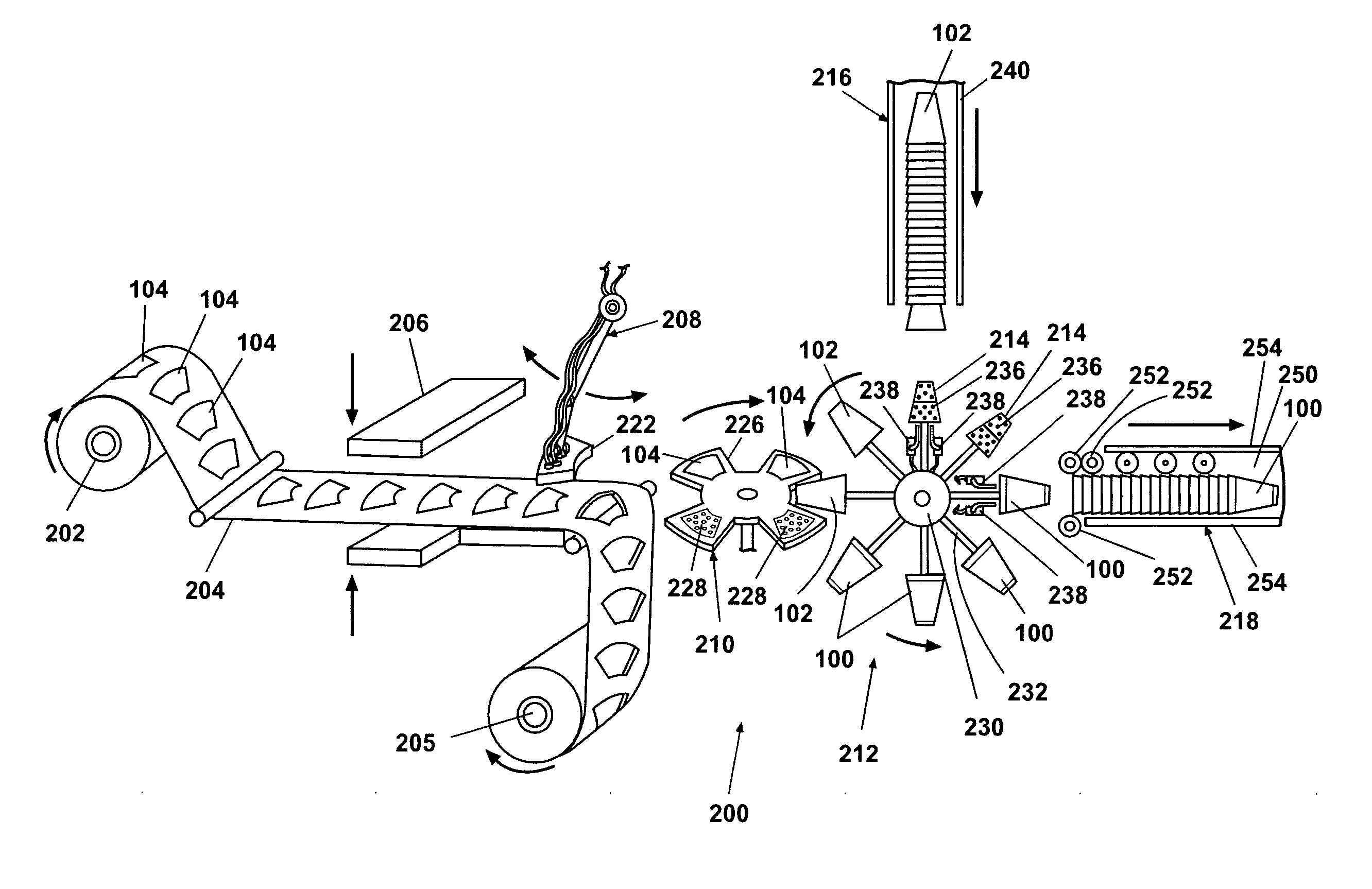

Paper Wrapped Foam Cup and Method of Assembly

ActiveUS20080098698A1Efficient rollingDomestic cooling apparatusPackaging cigarettePulp and paper industryVisual appearance

A commercially viable paper wrapped foam cup comprising a taper portion that prevents the shrinkage-induced curling from interfering with the un-nesting of nested paper wrapped foam cups. The paper wrapped cup further comprises a fillet for strengthening the cup foot to retard shrinkage-induced curling of the foot. The paper wrapper has abutting to overlapping opposing ends to completely hide the foam cup to enhance the visual appearance of the cup. The overlapping portions of the paper wrapper are not bonded to each other to prevent wrinkling of the paper wrapper as the cup shrinks. A machine and corresponding method provide for automatically supplying foam cups and paper wrappers, wrapping the paper wrapped cup, and stacking the wrapped cups.

Owner:DART CONTAINER

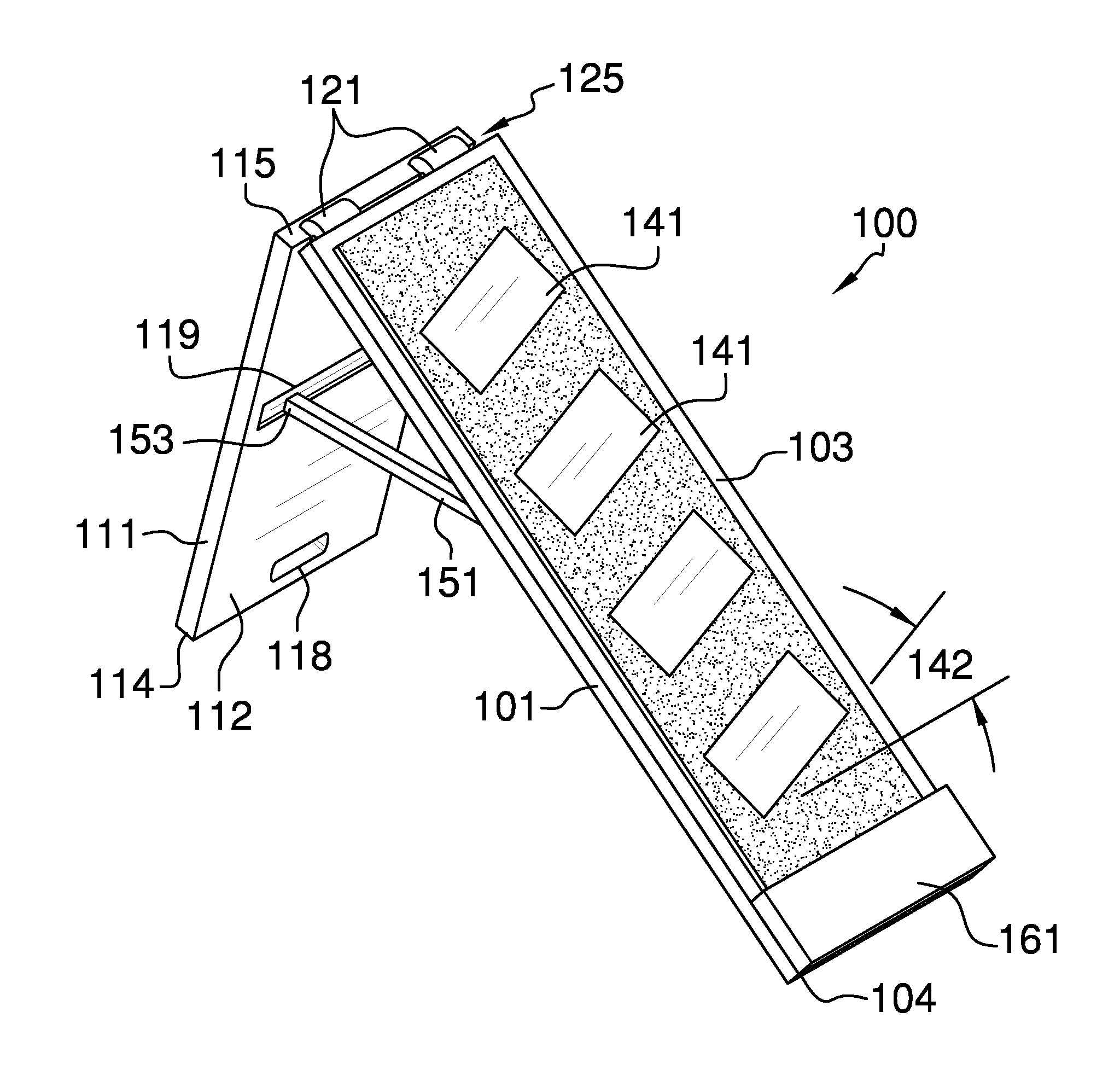

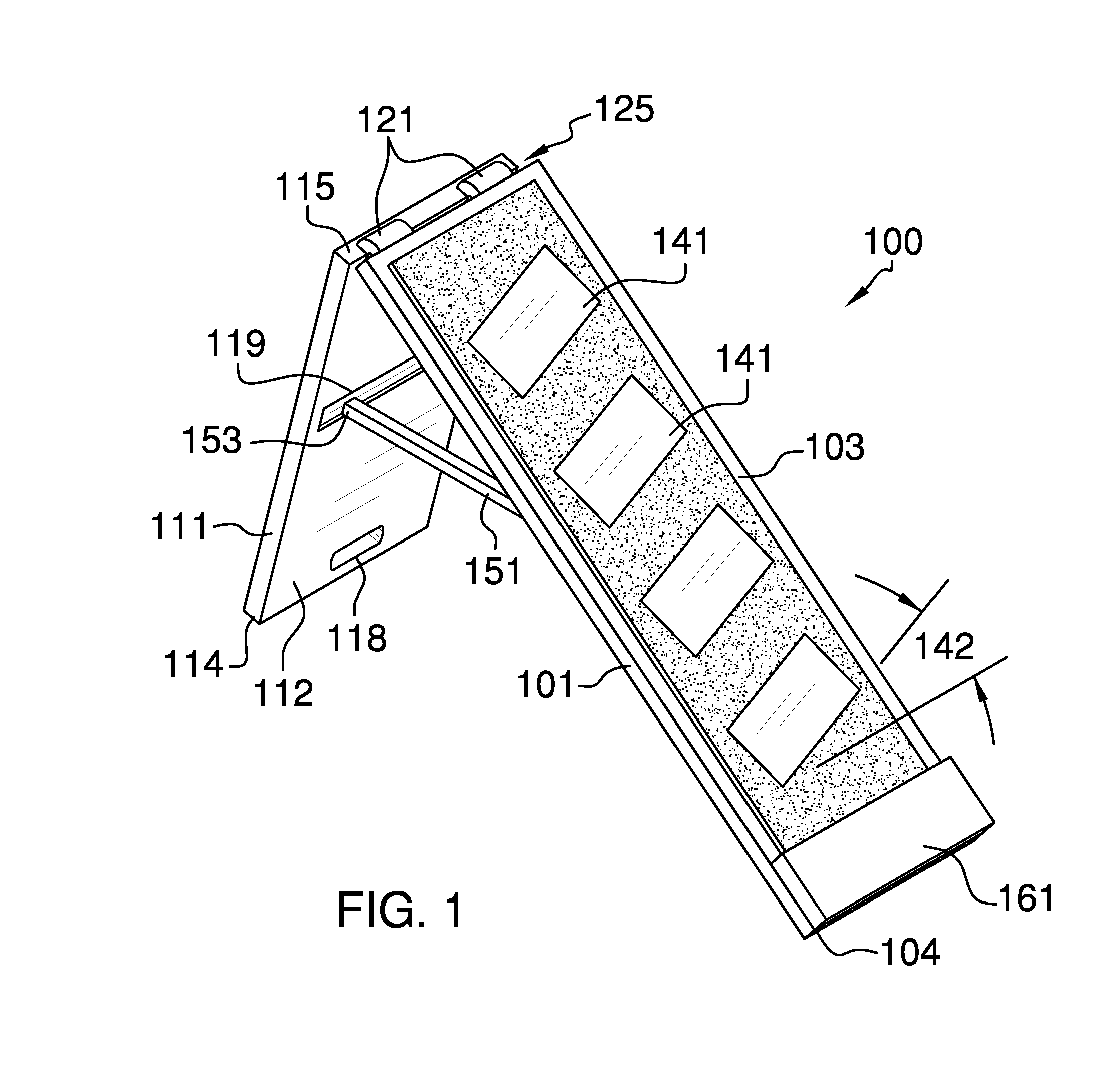

Tire unloading ramp

InactiveUS8695141B1Easy erectionEfficient rollingRefuse receptaclesLoading/unloading vehicle arrangmentAcute angleHinge angle

The tire-unloading ramp is a specially designed ramp that is ideally suited for rolling a tire away from the ramp when unloading a stack of tires. The tire-unloading ramp includes a back member and a front member that are connected to one another via a hinge member. The front member is longer in length than the back member, and forms an acute angle with respect to the ground surface. Moreover, the hinge member enables an acute angle to form between the front member and the back member, and is located at an apex of the tire-unloading ramp. A support member is able to rotate from against a rear surface of the front member, and engage a support member notch located on a rear surface of the back member.

Owner:VILLAREAL BRAULIO

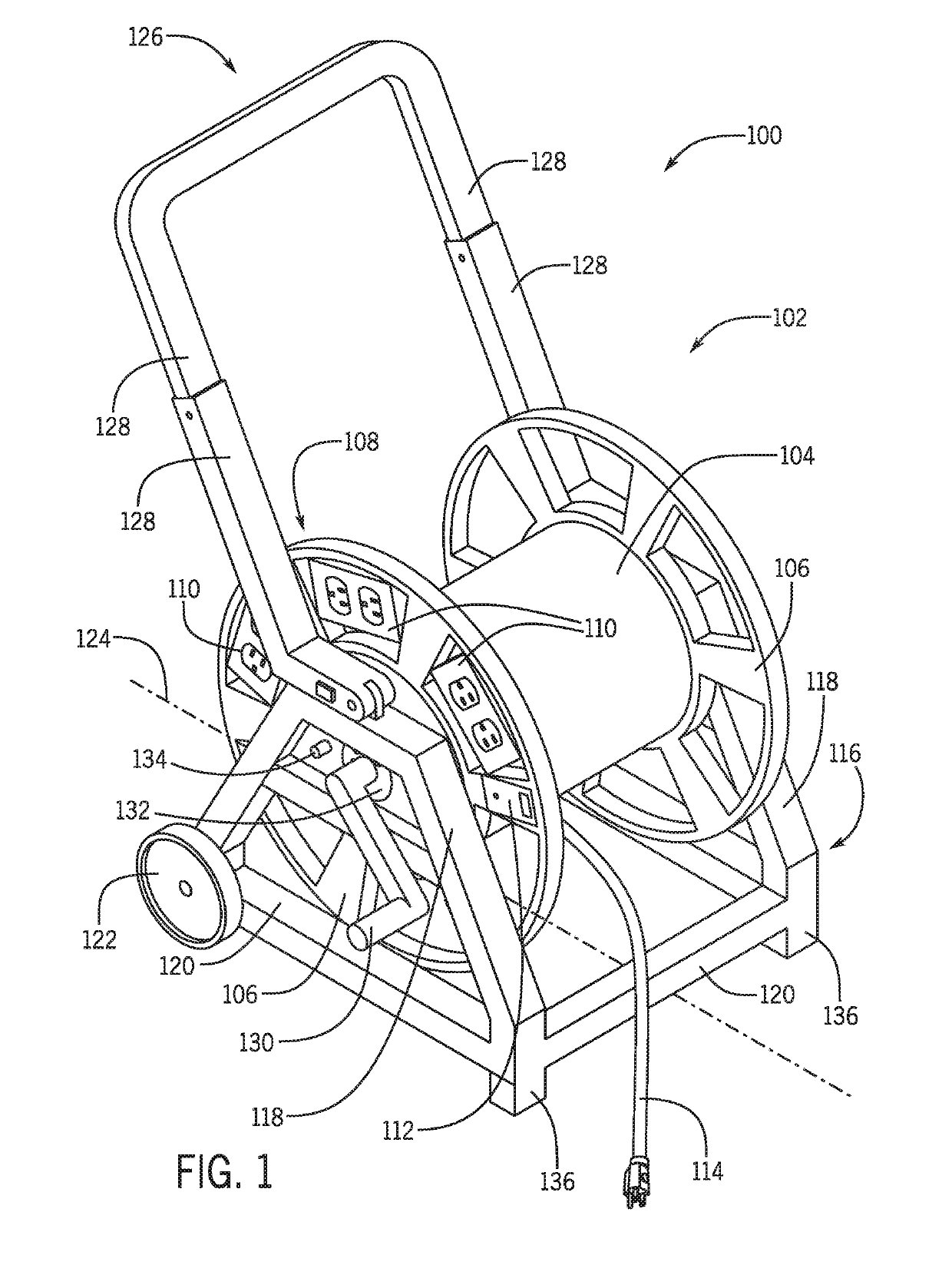

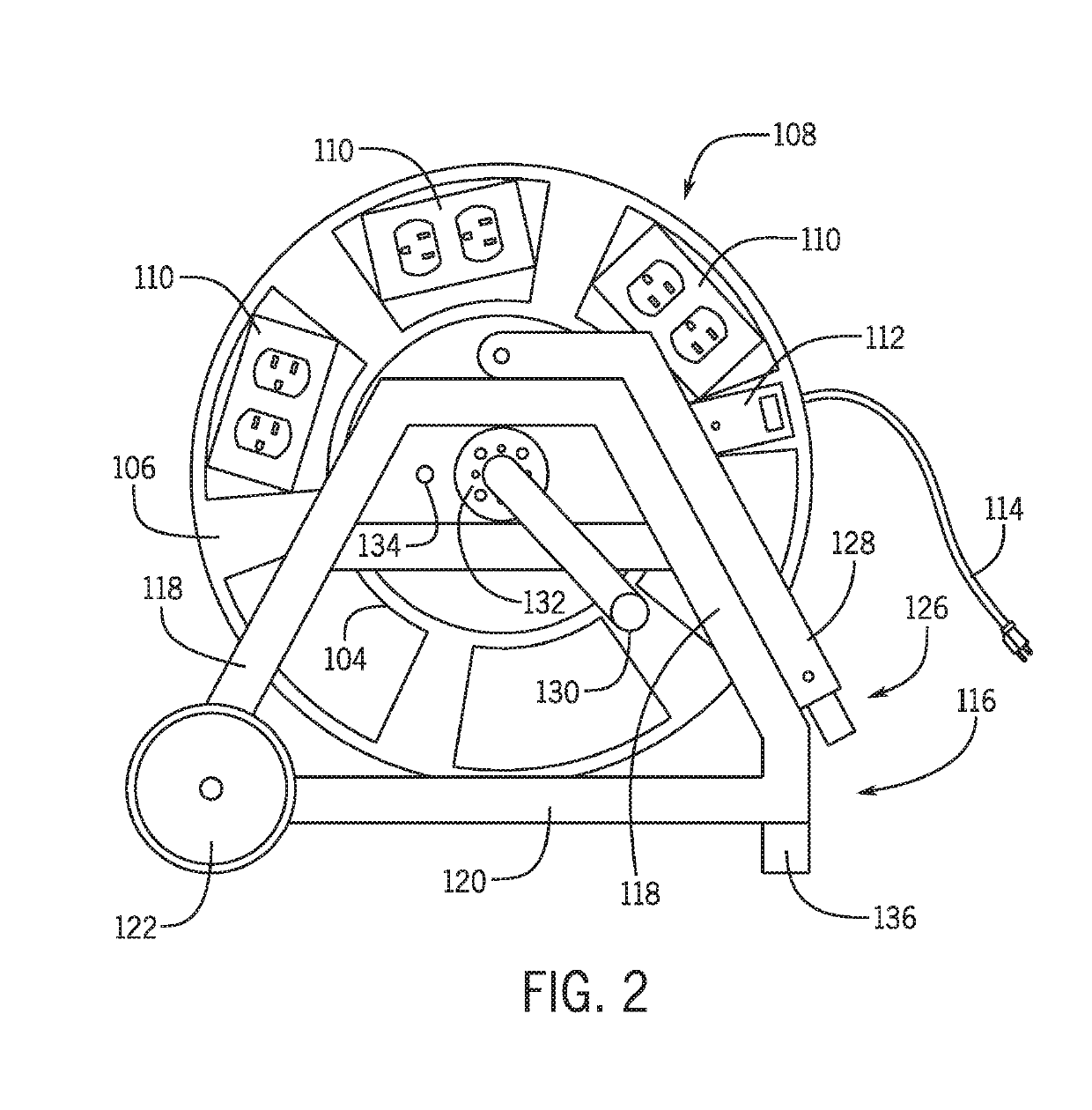

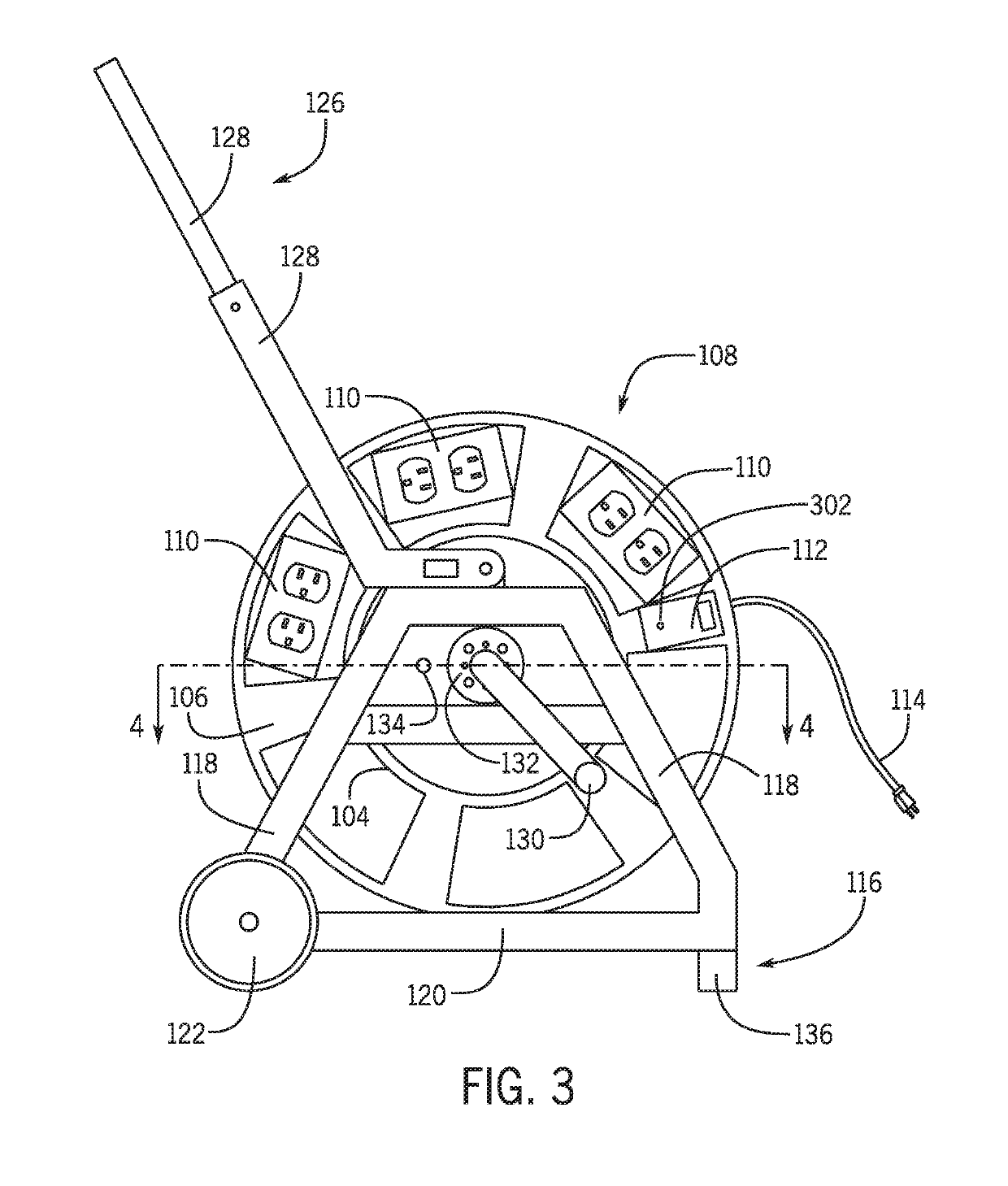

Cart for storing, transporting, and organizing a long electrical cord and a plurality of electrical outlets

ActiveUS20190115742A1Efficient rollingArrangements using take-up reel/drumElectricityPower switching

A cart for storing and transporting an electrical cord of up to 500 feet in length to be unwound over a parcel of ground. The cart includes a cord spool having a pair of circular spool sides together bounding space for storing the electrical cord. The cart also has a plurality of female electrical sockets, a circuit breaker, a power on-off switch, a power-on indicator light, and a short male cord to plug into a power cord to provide power to the female electrical sockets. The cart also has a support frame to rotatably support the cord spool, and a pair of wheels to roll across the parcel of ground while supporting the electrical cord. Also included is a frame handle to enable a user to tilt the support frame onto the pair of wheels, and for pushing or pulling the cart over the ground while unwinding the electrical cord.

Owner:MAGNO RALPH CARL

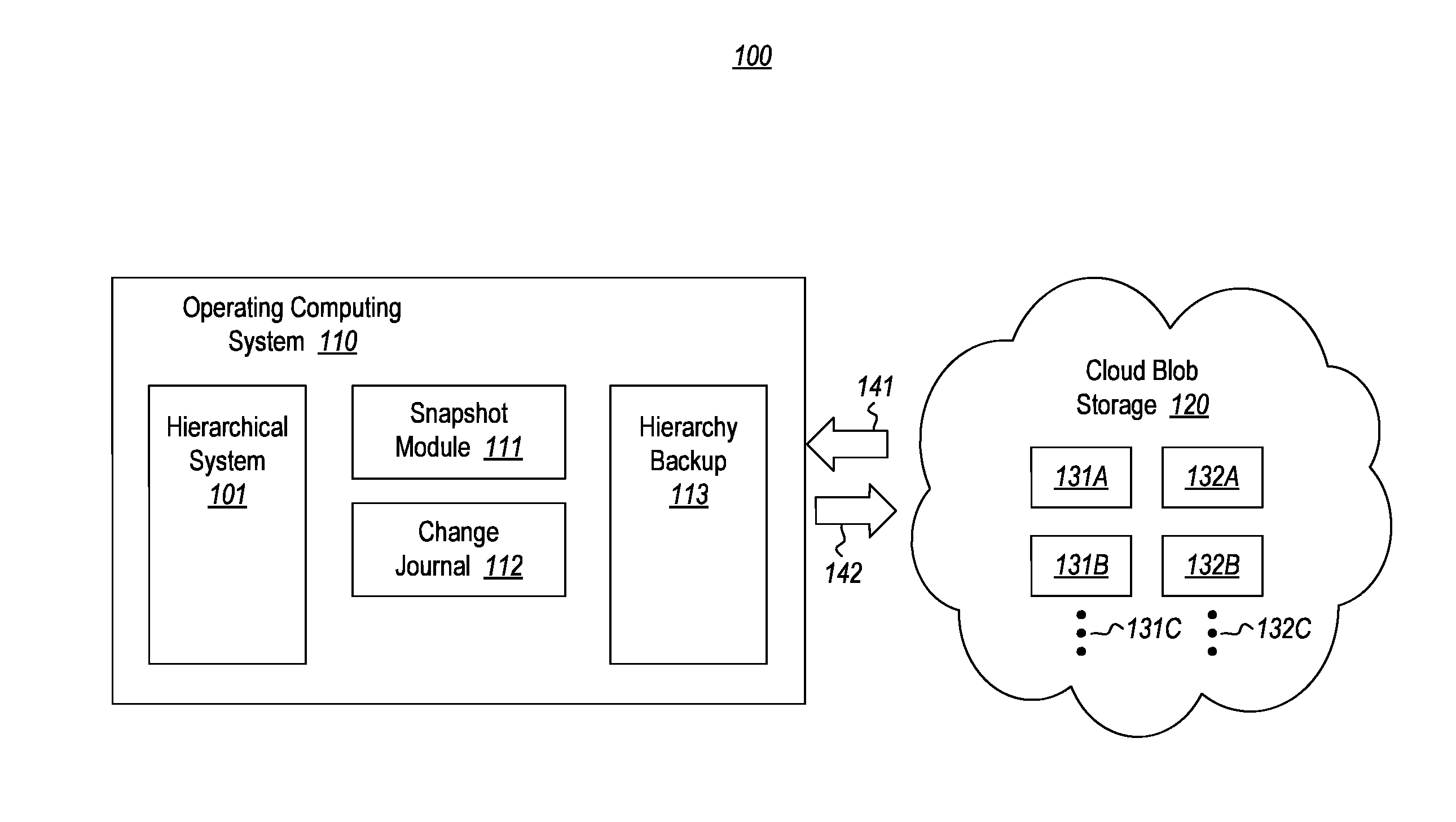

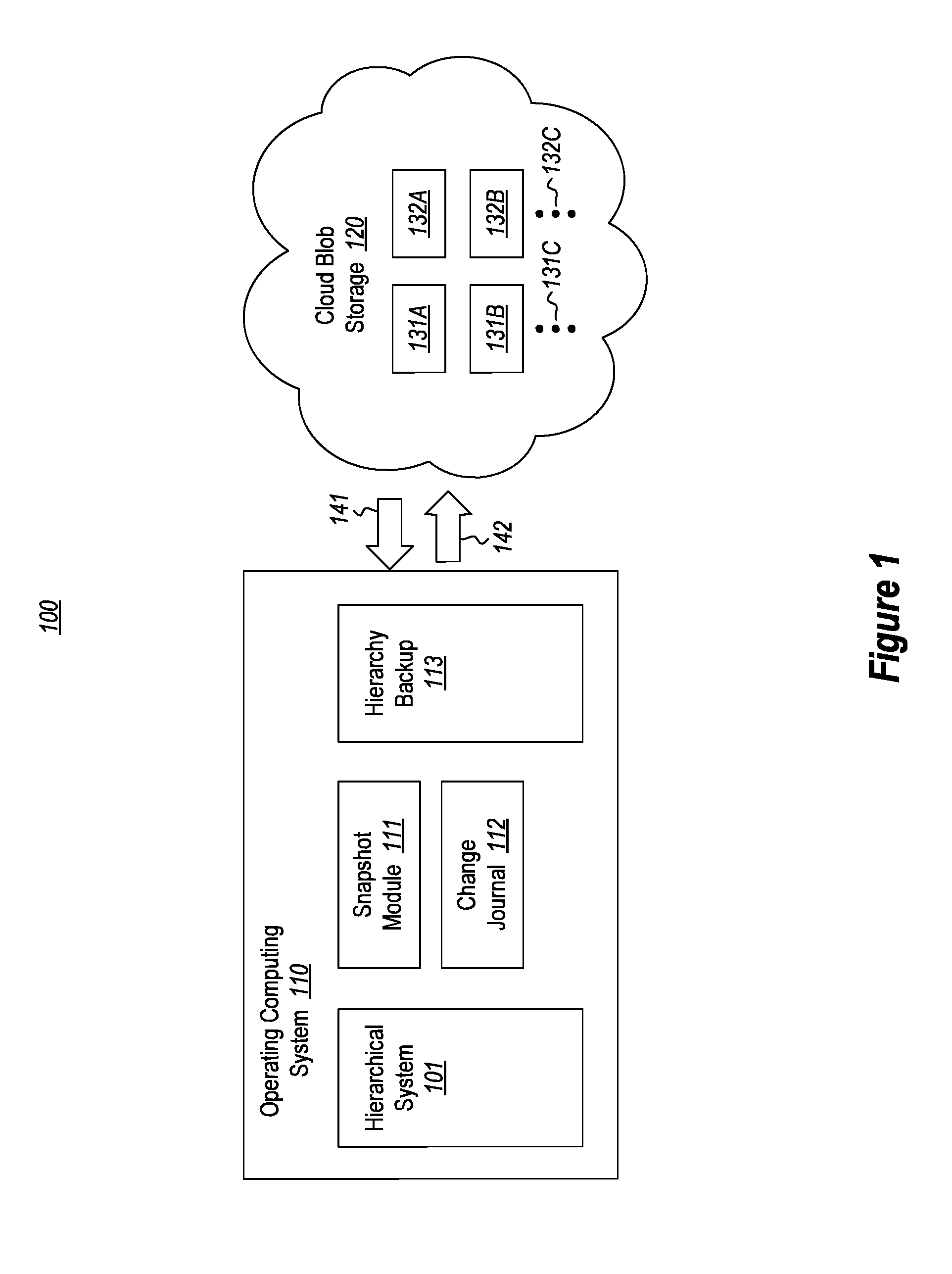

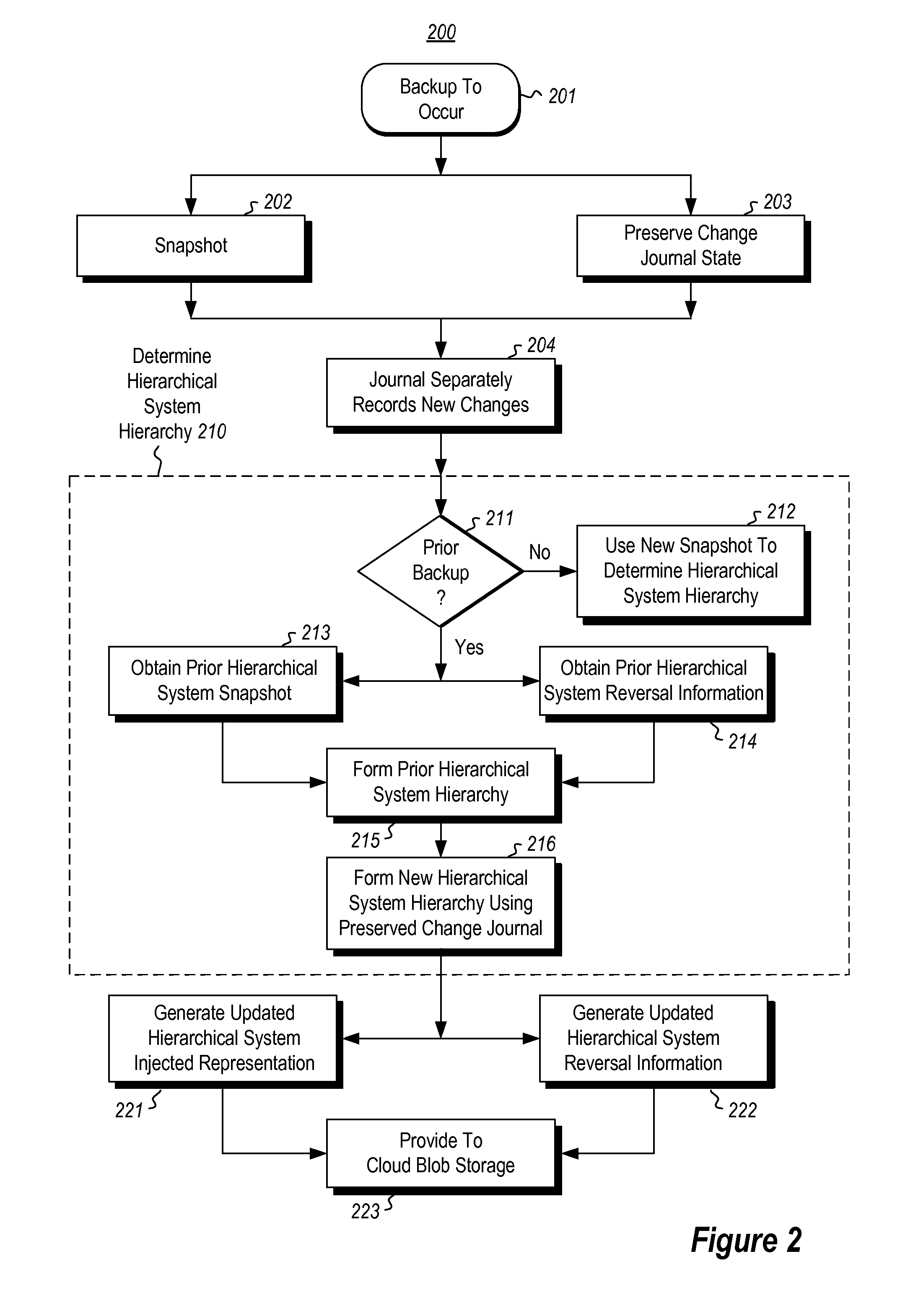

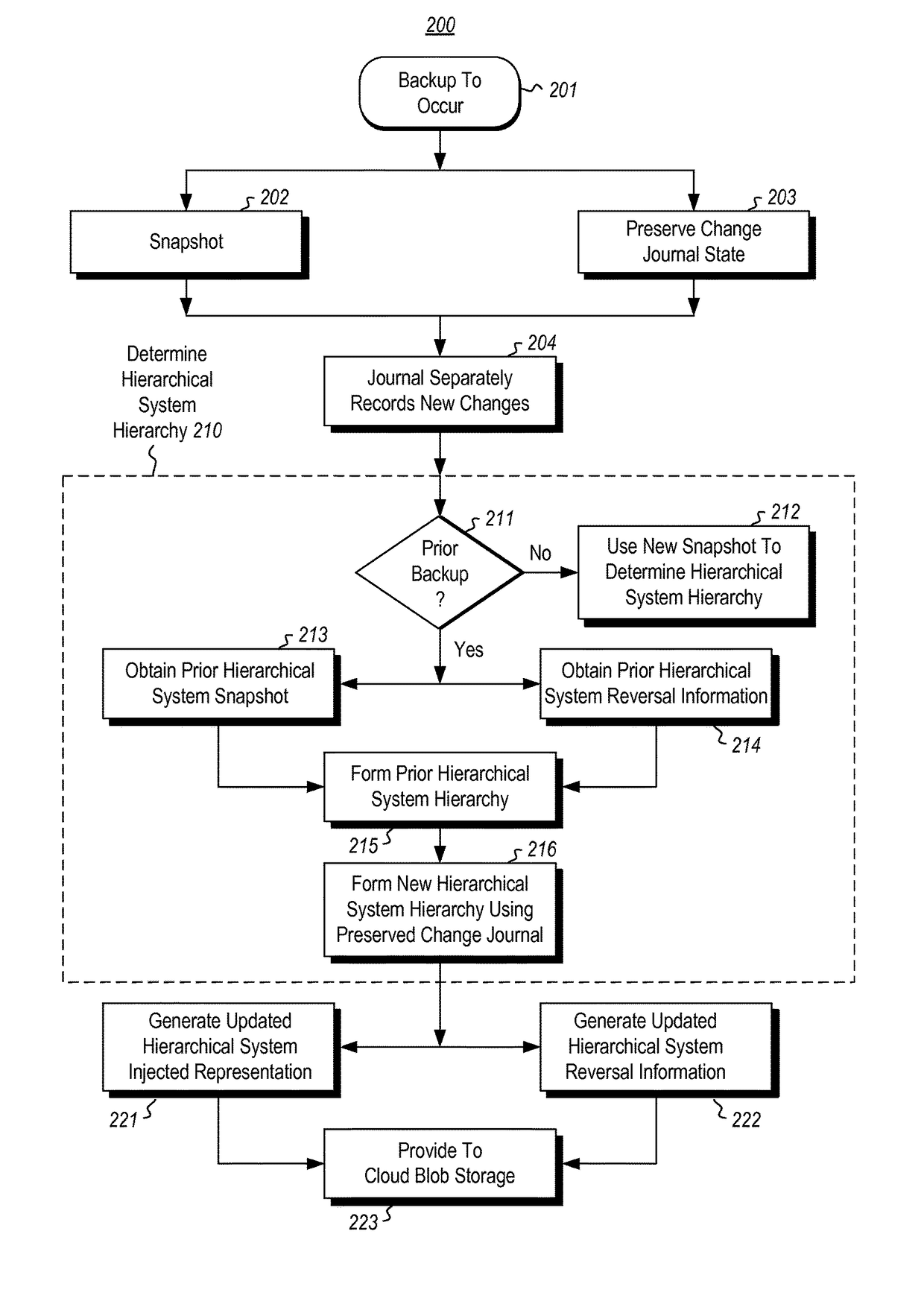

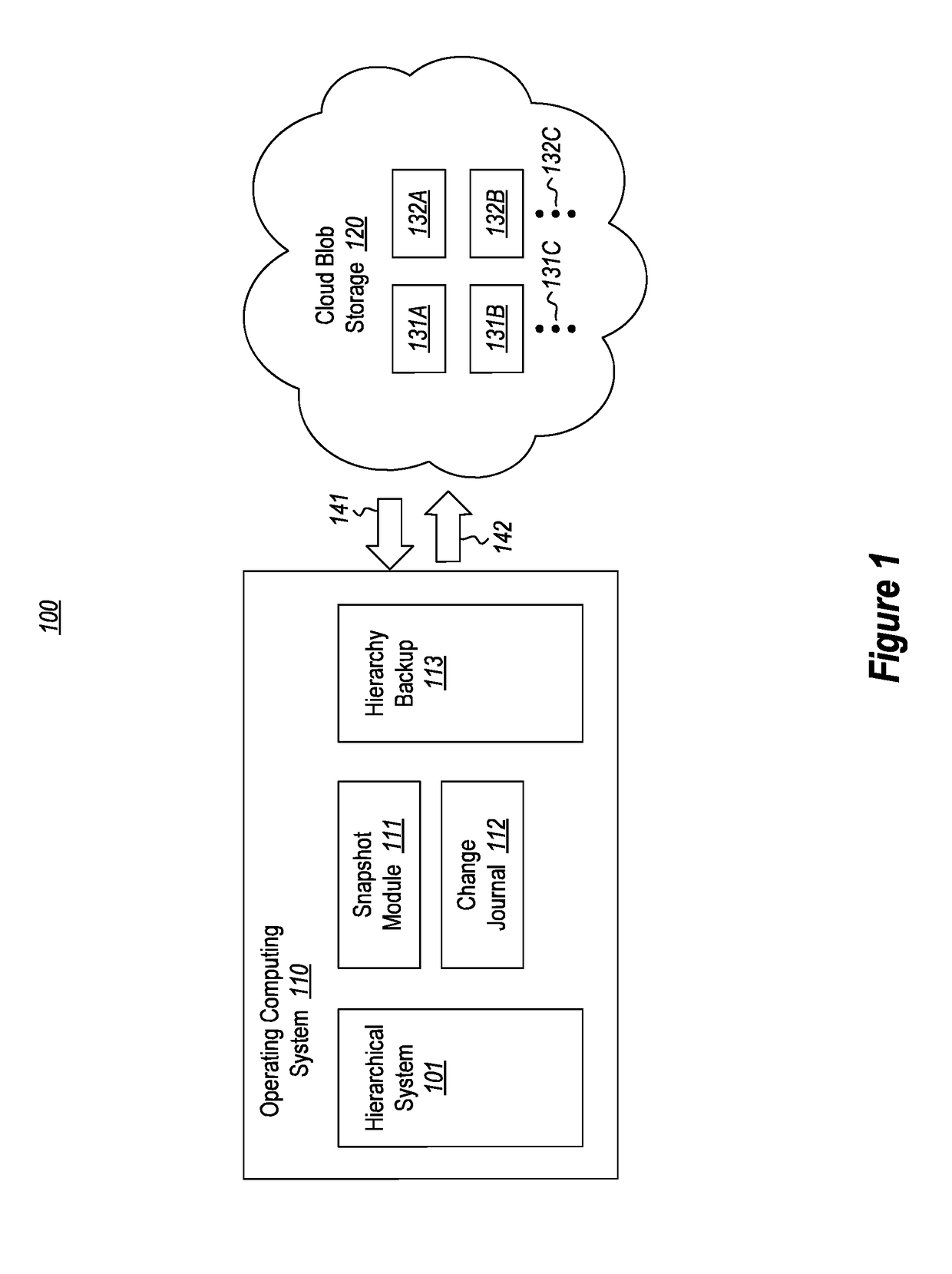

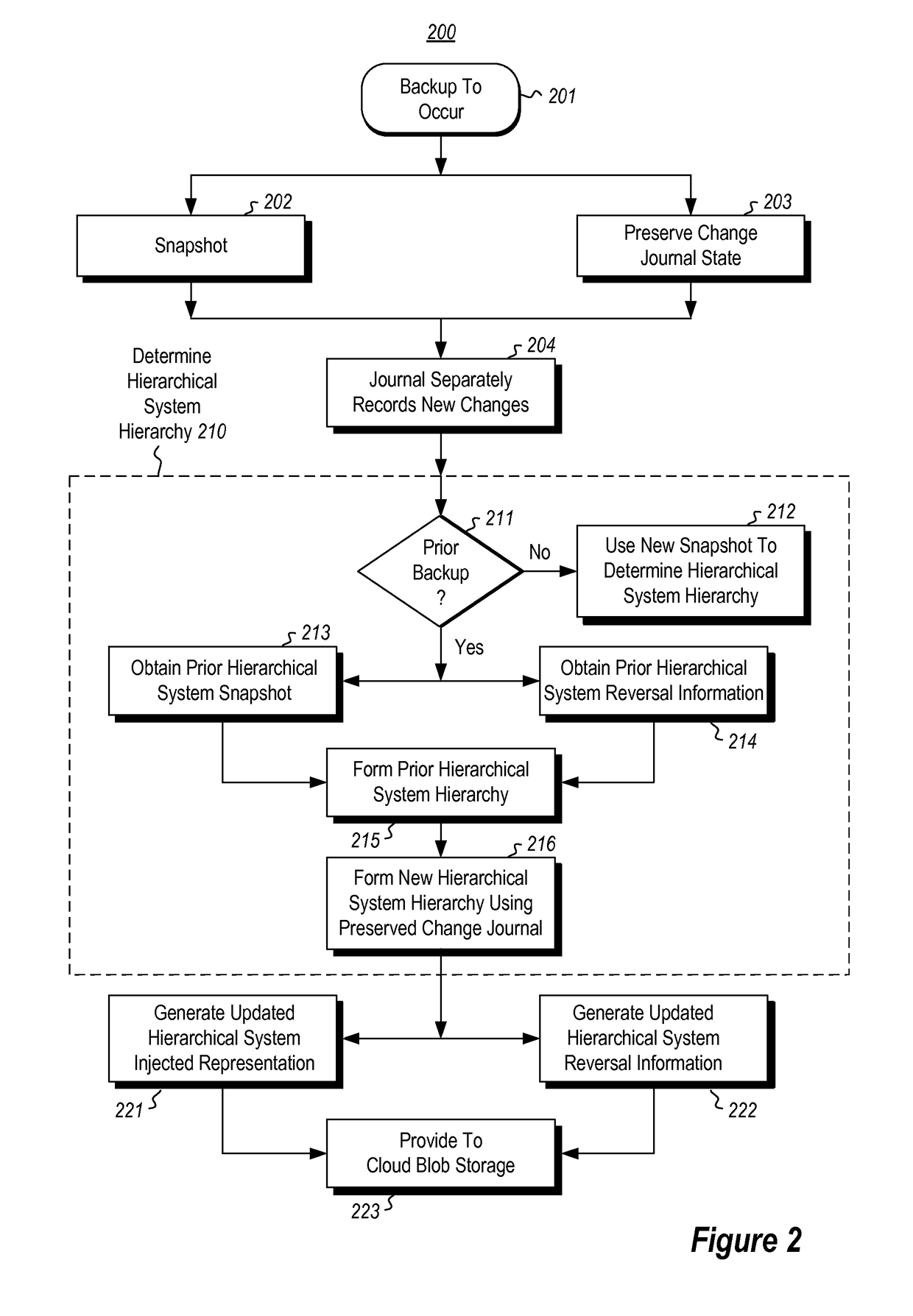

Cloud-based hierarchical system preservation

ActiveUS20160224433A1Improve the level ofEfficient and fast construction bottomDigital data information retrievalSpecial data processing applicationsCloud baseFile system

The efficient backing up of a hierarchical system in cloud blob storage. The hierarchical structure of the system as it existed at a prior instance in time is reconstructed. A change journal that represents changes in the file system that prior instant in time is then used to formulate an updated file system hierarchy as it exists at a second instant in time. An updated injected representation of the file system, and updated file system reversal information is then formulated and provided to cloud blob storage. The injected representation of the file system is a one-to-one function of the content of the file system, in that the reversal information can be used to recover the content of the file system. Injected representations of various nodes in the system hierarchy may also be remotely stored.

Owner:MICROSOFT TECH LICENSING LLC

Grill oiler

InactiveUS8961054B2Efficient rollingImprove the lubrication effectLiquid surface applicatorsCarpet cleanersEngineeringCooking oil

Owner:GILBERT PERFORMANCE DESIGN

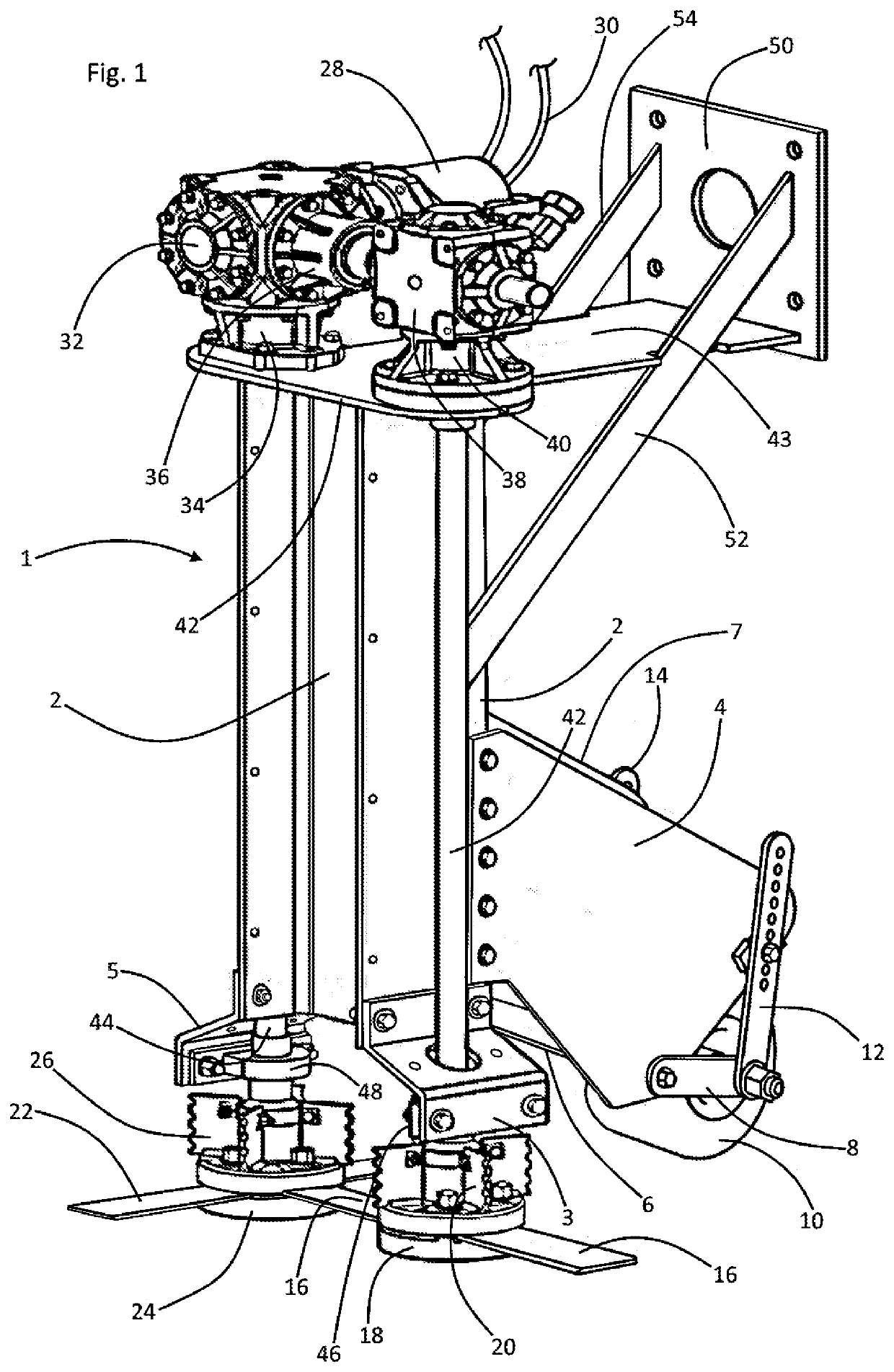

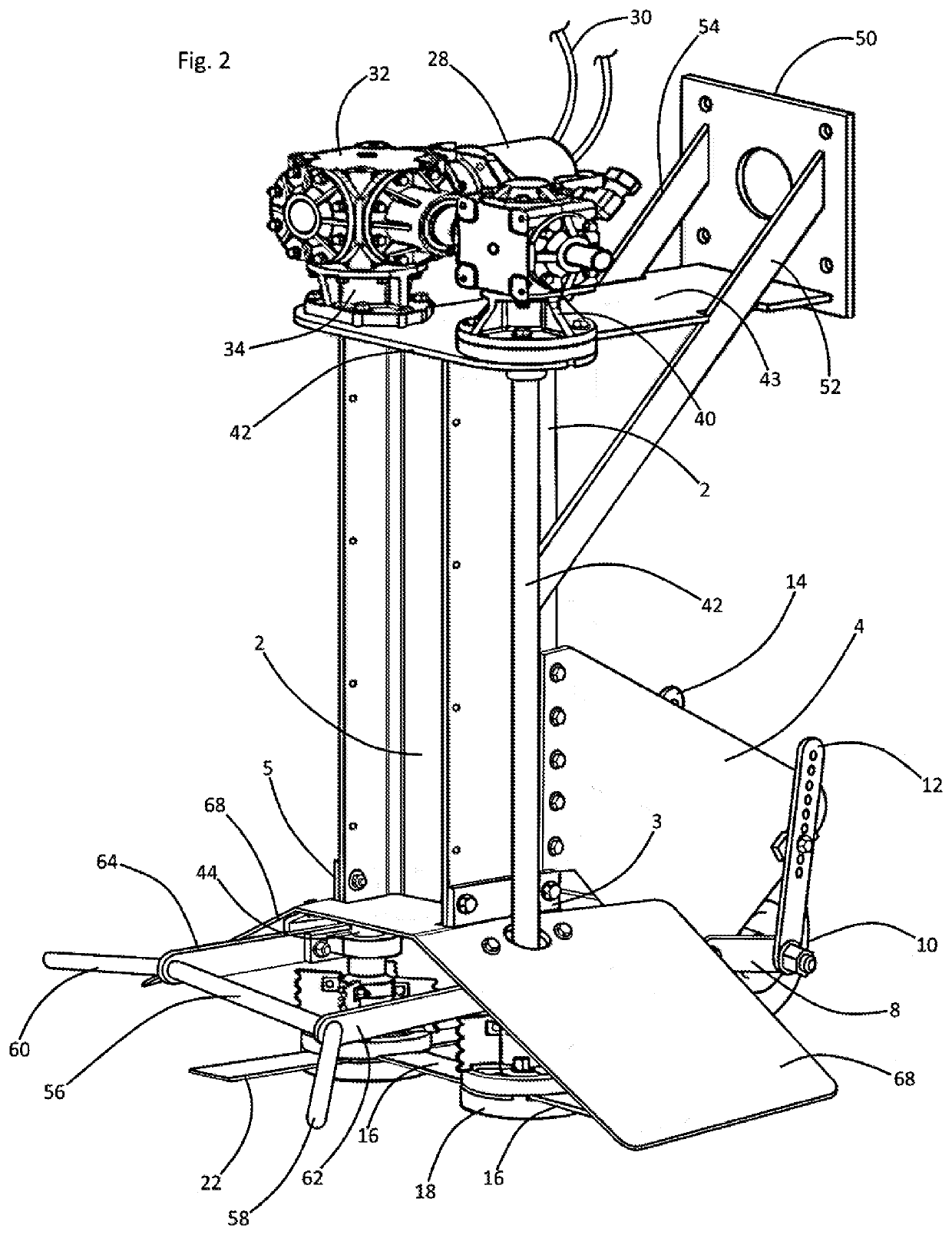

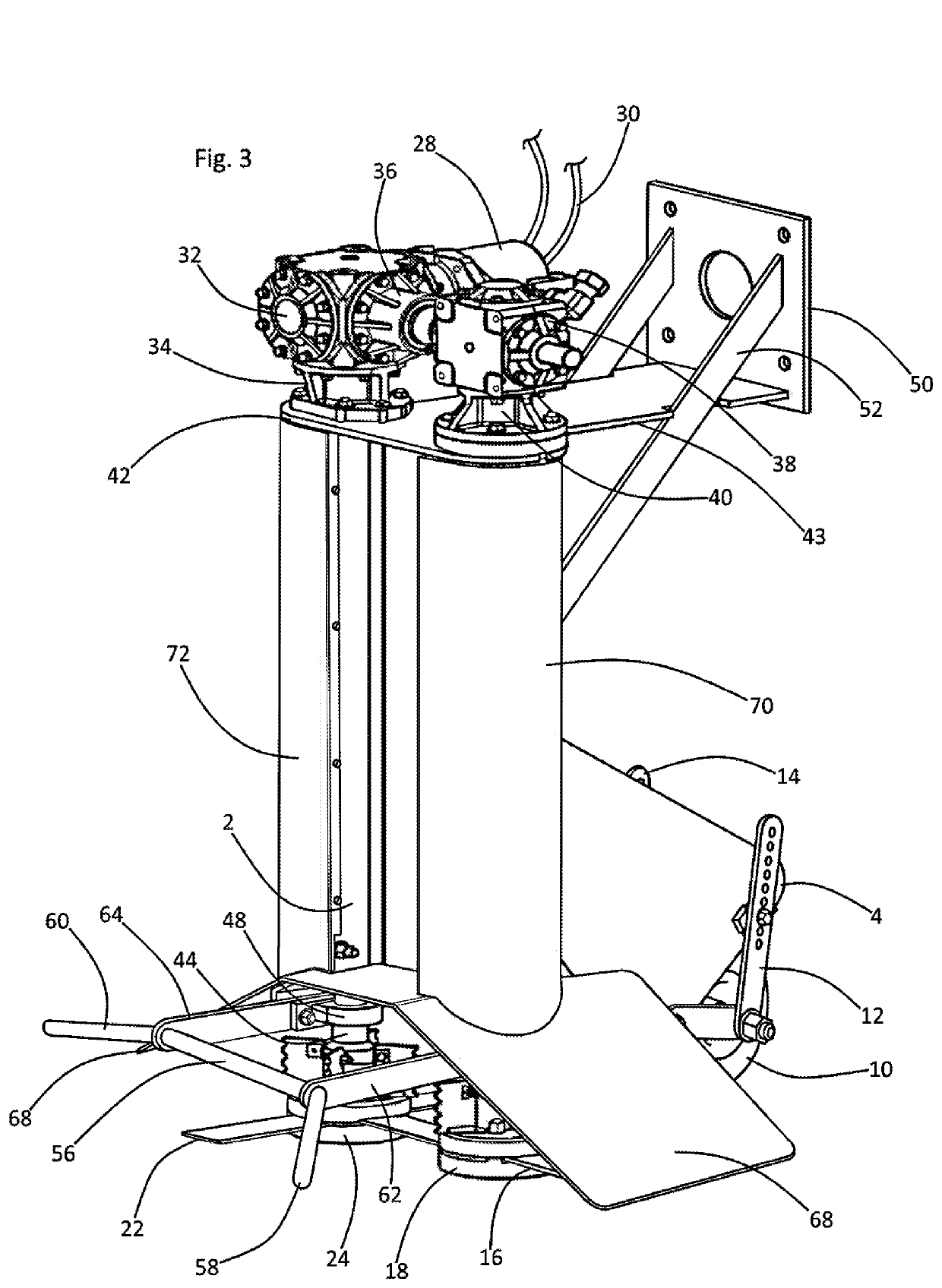

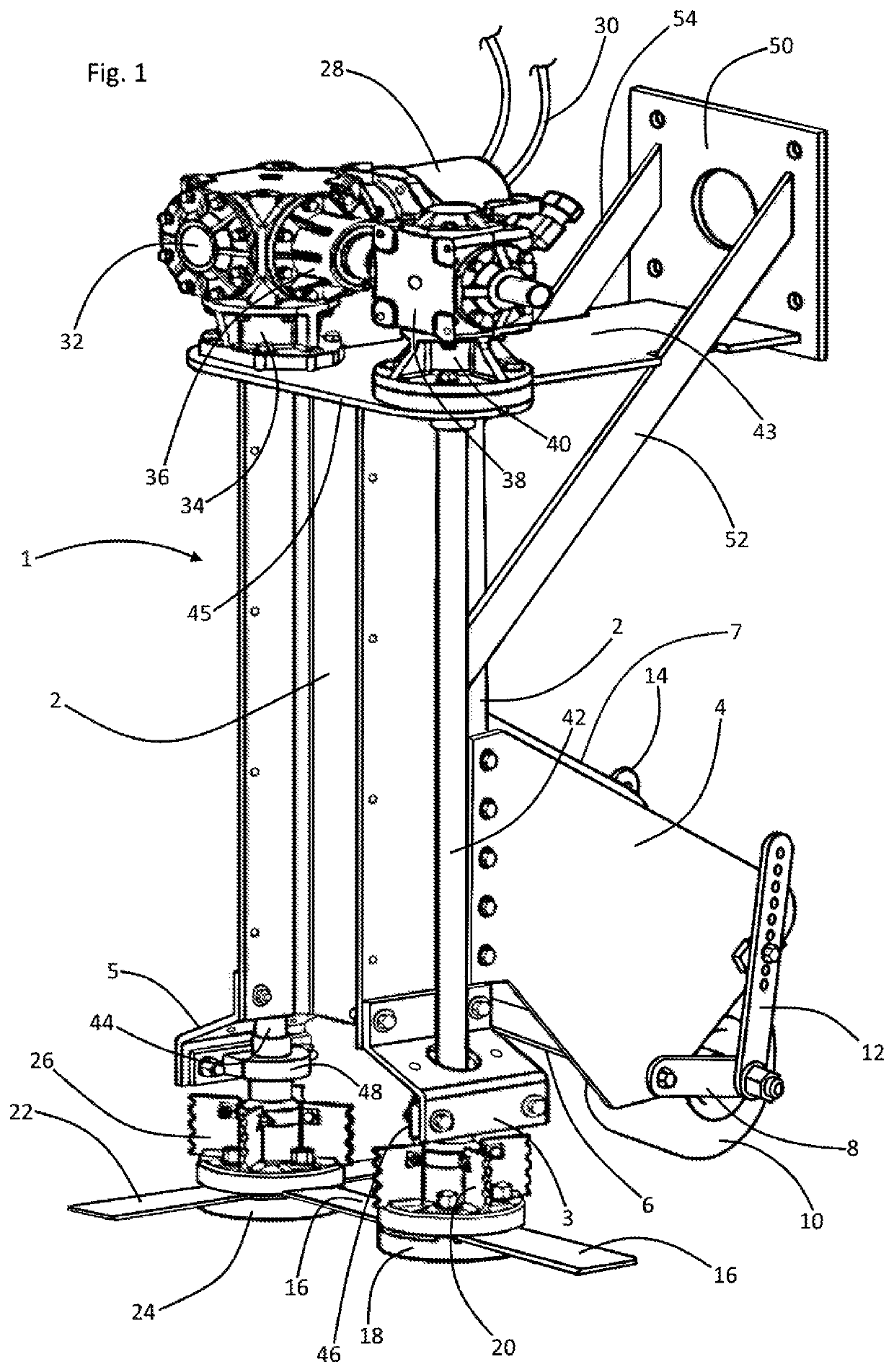

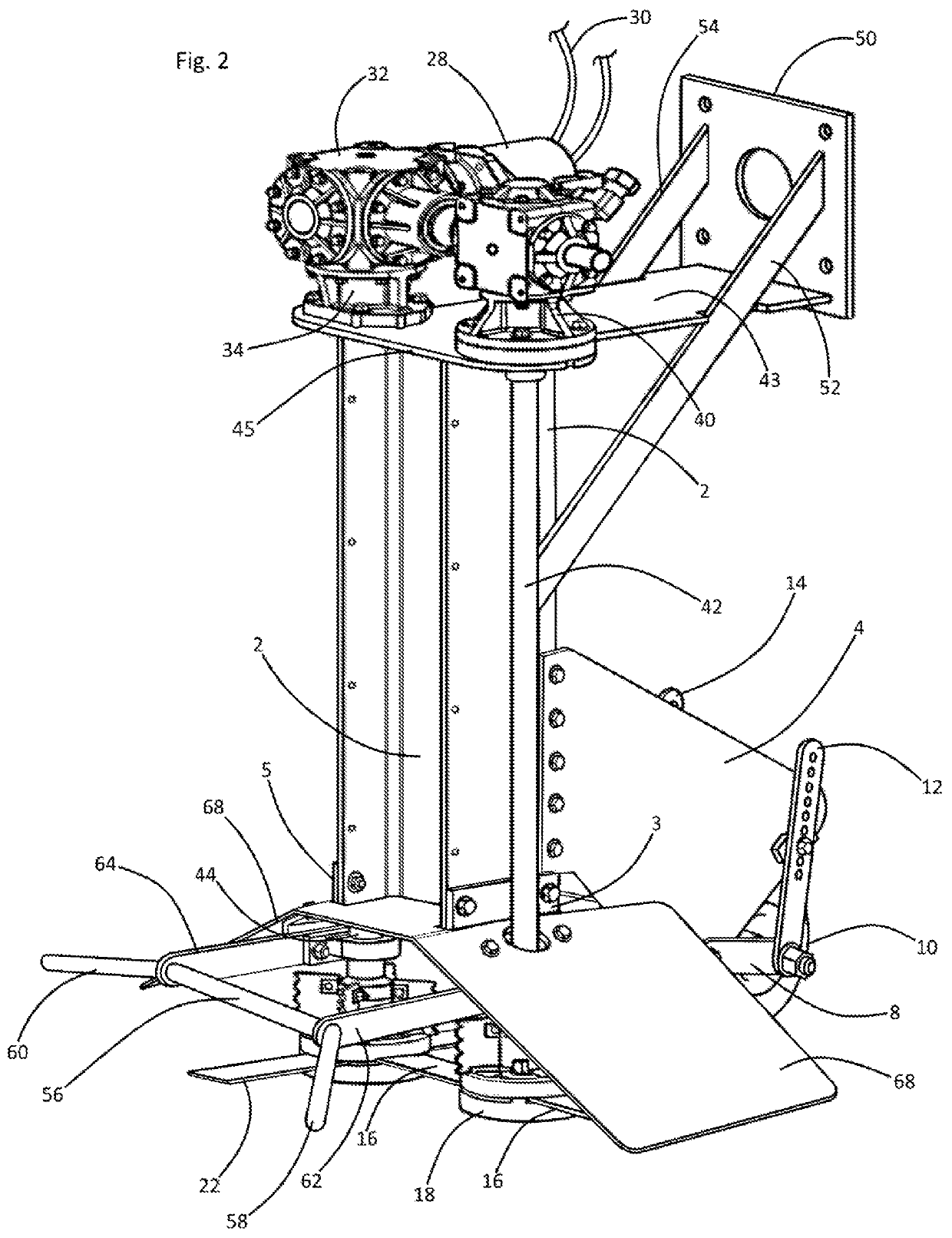

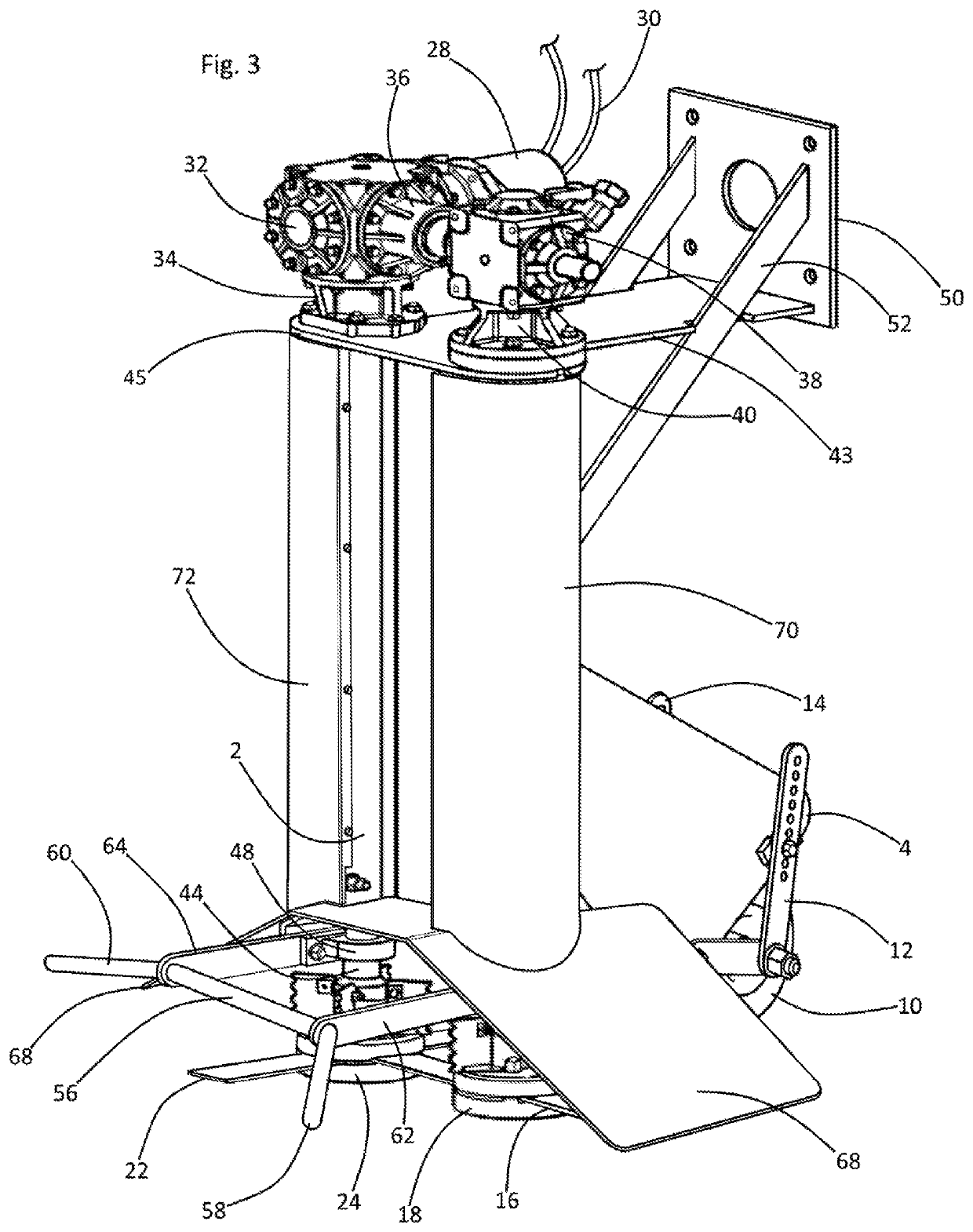

Crop Row Mower

A crop row mower incorporating an “L” member having a column and having a foot, the column having upper and lower ends, and the foot having a distal end; a wheel connected operatively at the distal end of the foot; a first rotary blade mounted at the lower end of the column; a hydraulic motor mounted at the upper end of the column; a first drive shaft extending along the column, the first drive shaft operatively interconnecting the hydraulic motor, and the first rotary blade; and a mounting bracket fixedly attached to the column's upper end, wherein the mounting bracket is adapted for pushing or pulling the “L” member in a proximal direction.

Owner:BUTTON BARBARA J

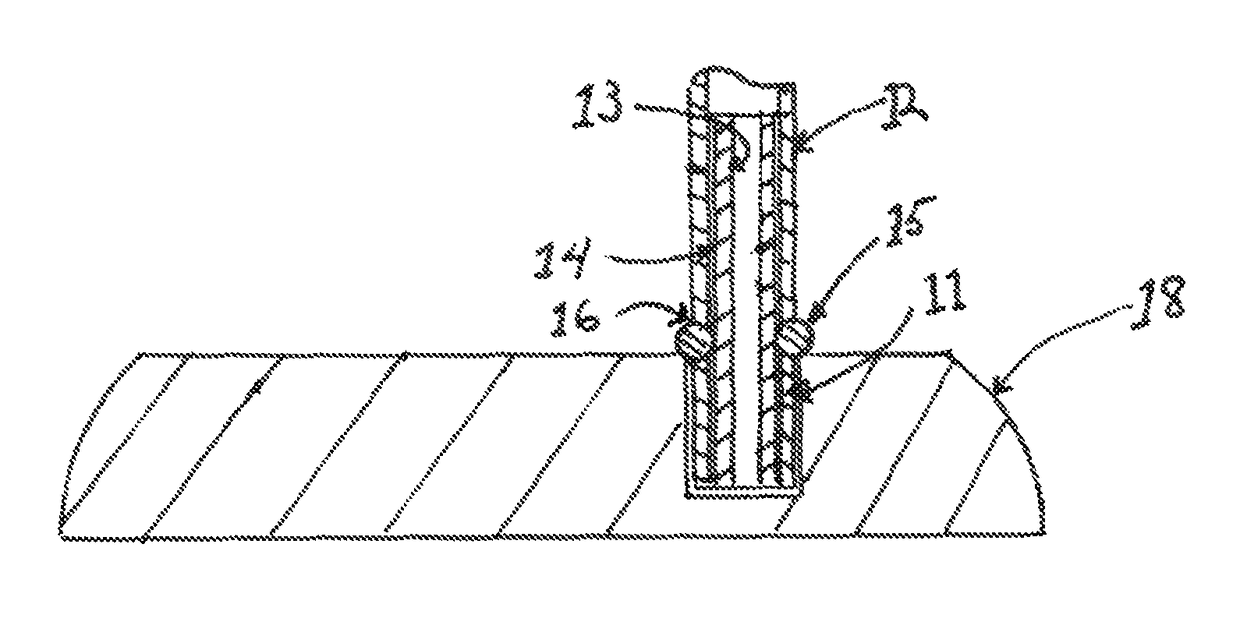

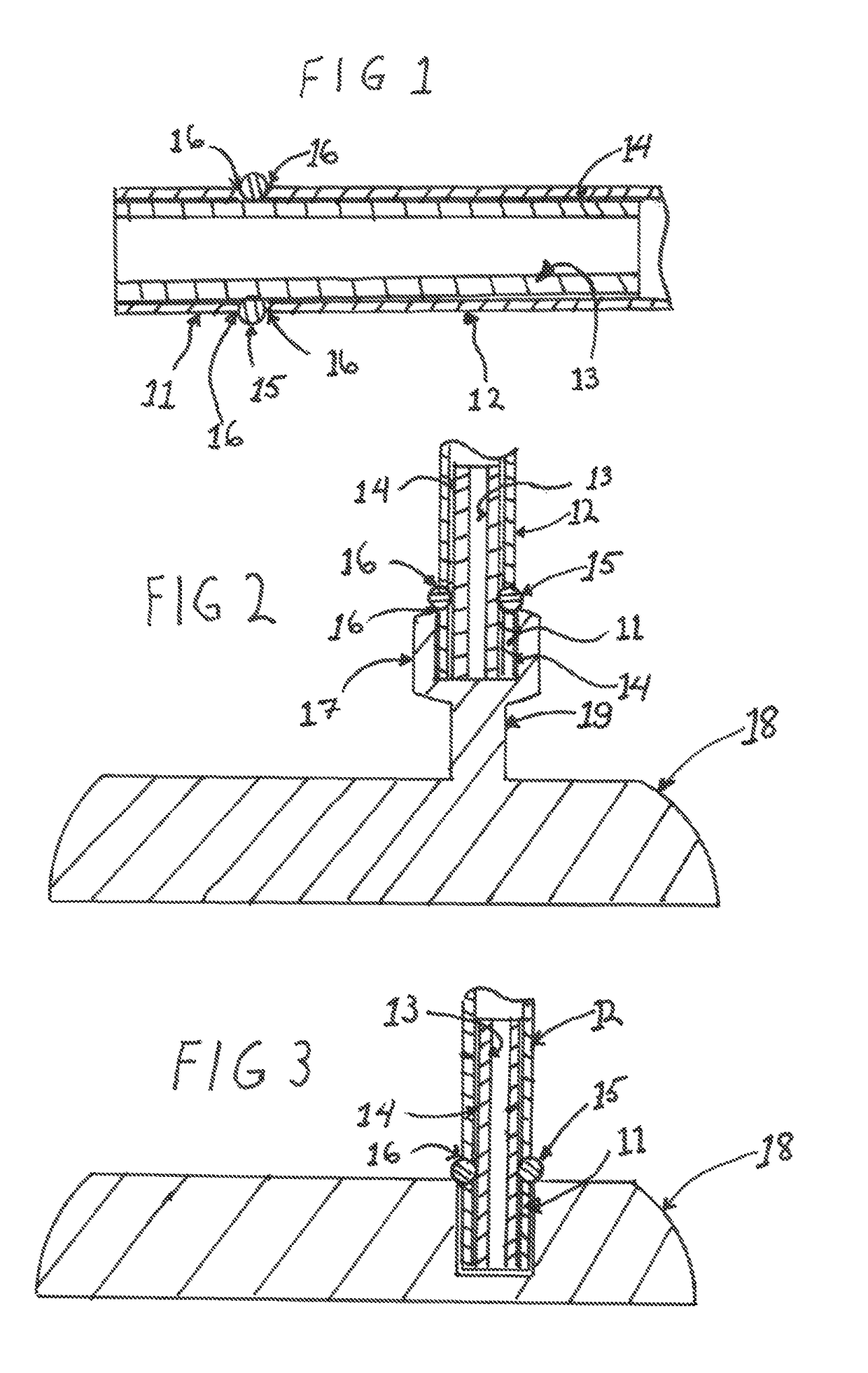

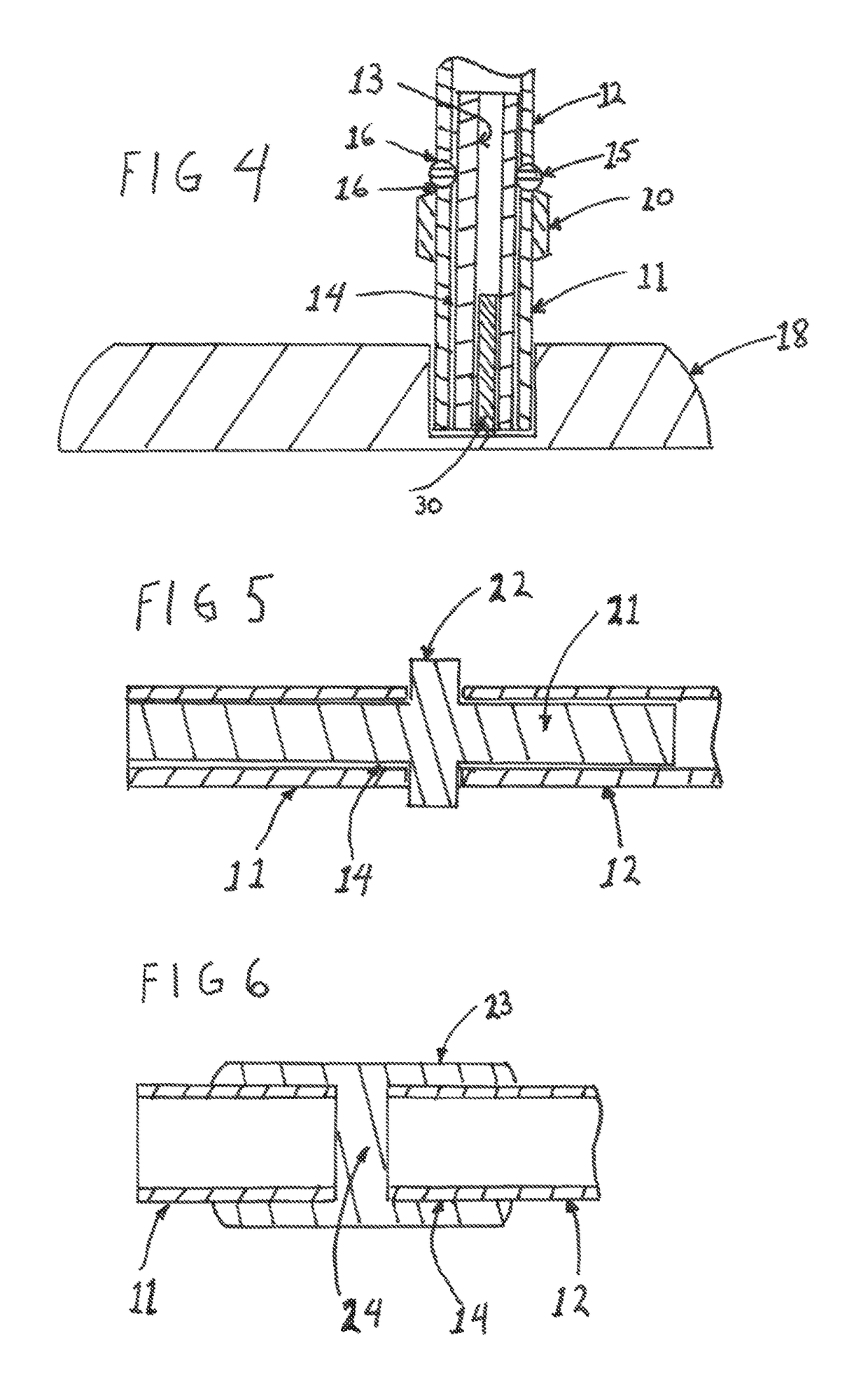

Golf shaft flex connection

A shaft insert (or external connecting segment) with greater flexibility than the substrate shaft allowing for a more flexible zone in an area of separation between two separated portions of the substrate shaft. The flexible connection is intended to be installed between two segments of the separated substrate shaft primarily on a golf putter with the flexible connection within 5 inches of the base of the club in total compliance with USGA (United States Golf Association) Rule 2, Appendix II. 2. b. requiring any change from the continuous shaft be within 5 inches of the club base. The shaft flex connection is designed to be symmetrical around its cross section with equal flexibility and torsional displacement in all directions in compliance with USGA Rule 2, Appendix 2. c. requiring golf shafts to be equally flexible with equal torsional displacement in all directions. The preferred embodiment of the invention utilizes a flexible tube for which the outside diameter is slightly smaller than the inside diameter of the substrate shaft. The substrate shaft is separated at the top of the hosel of the club and joined by fixing the tube (with epoxy or other adhesive) in each section of the separated sections of the substrate shaft whereby the separation is maintained at a fixed distance by installing an O ring or other spacer over the insert tube and between the two segments of the substrate shaft.

Owner:FOSTER JOHN THOMAS

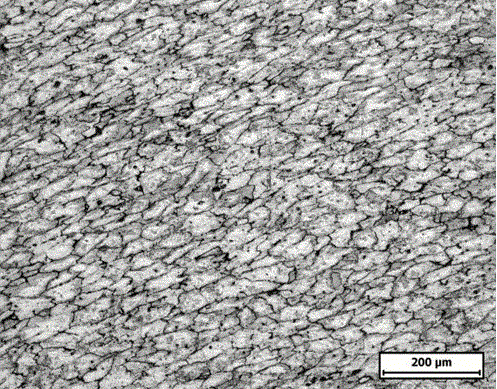

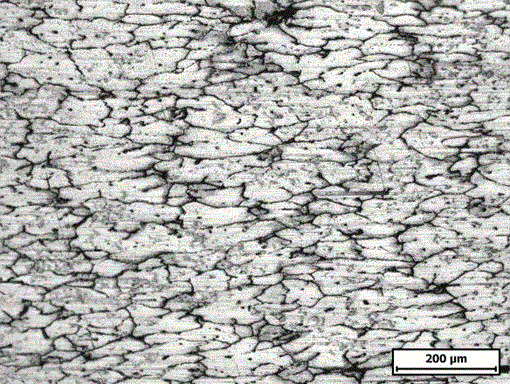

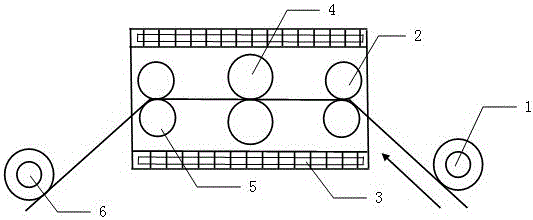

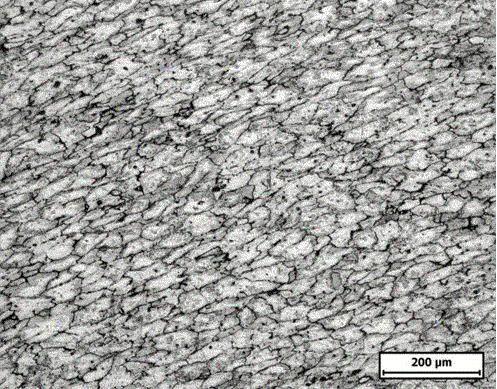

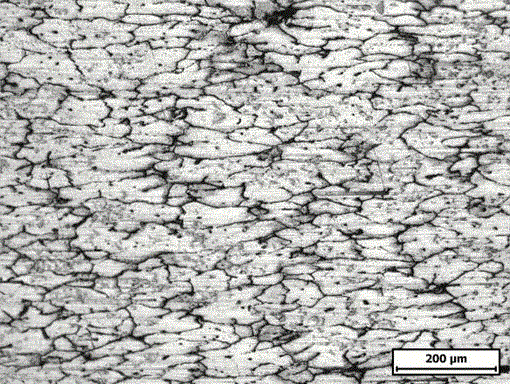

Method for rolling high-strength hard aluminum alloy

ActiveCN105107843AAchieve synergyPlay a synergistic roleMetal rolling arrangementsSingle passRolling mill

The invention relates to a novel method for rolling high-strength hard aluminum alloy. The method is characterized in that a strong magnetic field is applied when aluminum alloy is rolled, resistance to deformation of material can be reduced through the strong magnetic field, and the performance of deformation of material can be raised. Ultrathin and high-performance aluminum alloy can be produced through controlling intensity of magnetic induction of the strong magnetic field, the action time of the strong magnetic field, the rolling temperature, the rolling speed and proper reduction. The method is advantageous in that single pass reduction can be distinctly increased, the rolling efficiency of the high-strength hard aluminum alloy can be raised, the power consumption of a rolling mill is reduced, and the cost is saved. In addition, compared with a common rolling method, resistance to deformation of material is reduced, the grains are refined, the texture is uniformed, a part of the residual stress can be eliminated, defects caused by rolling can be reduced, and the yield during a rolling process can be raised by adopting the method to roll, so a thinner and better product can be achieved.

Owner:常州市凯宏铝业有限公司

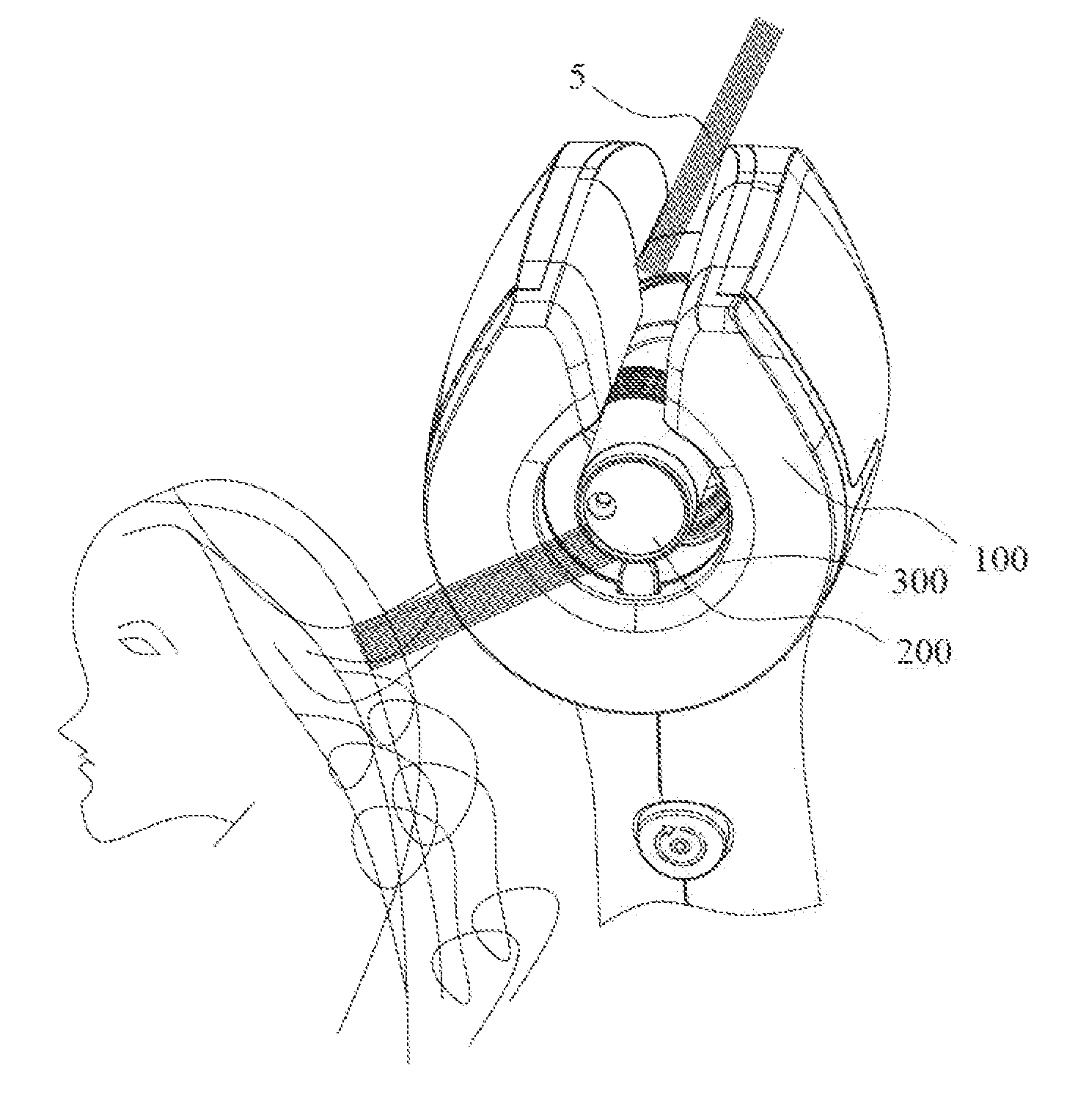

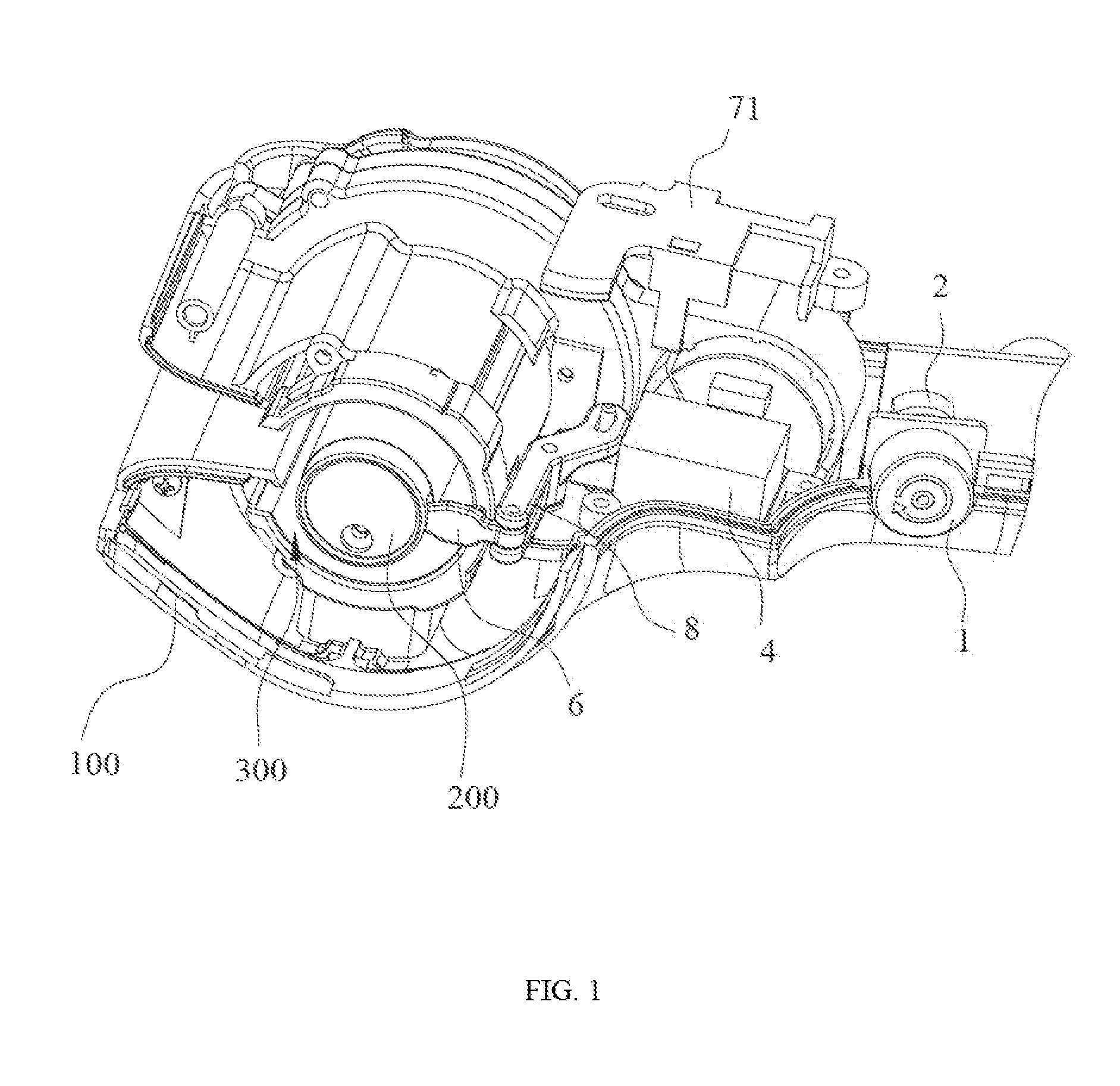

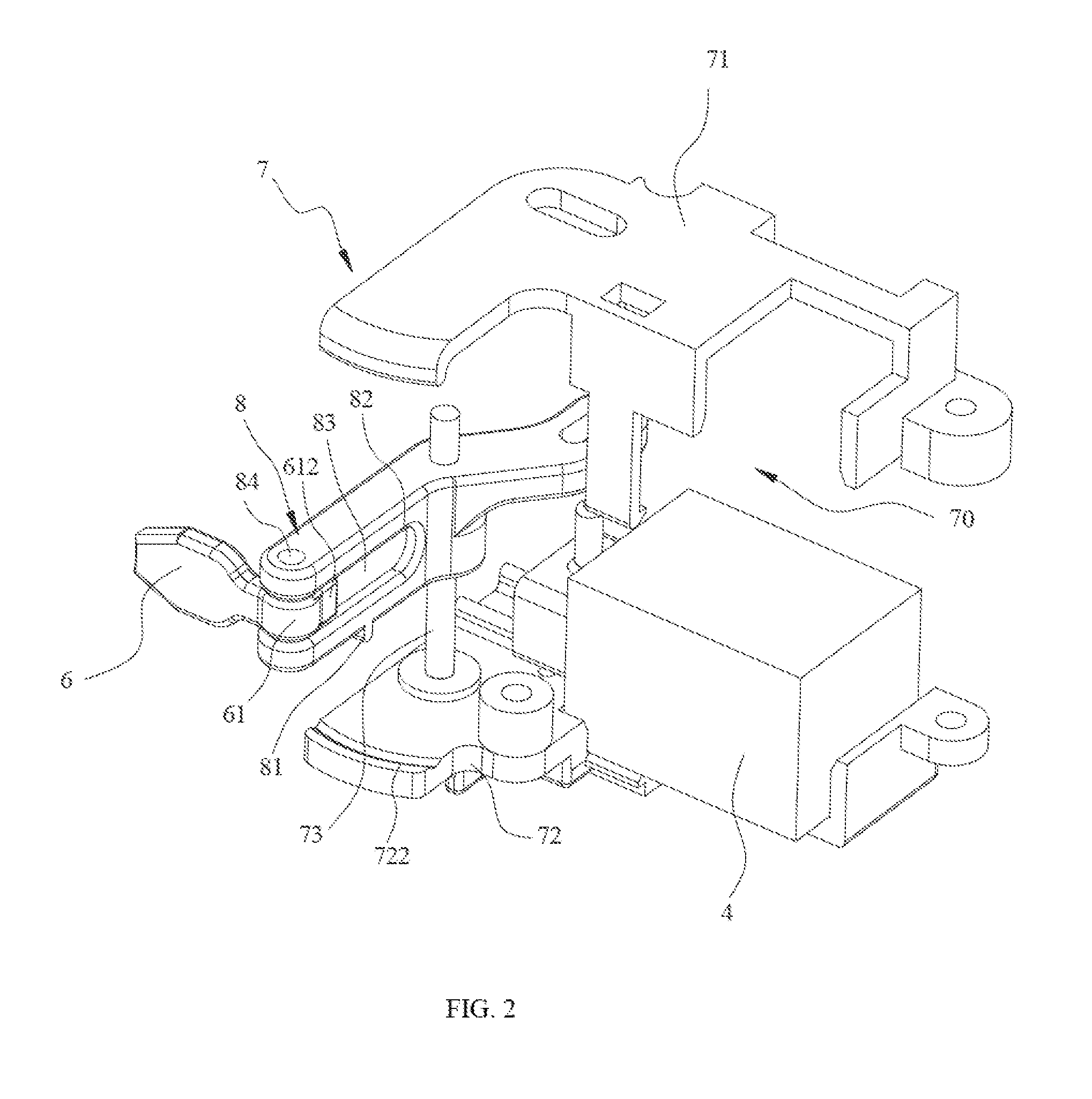

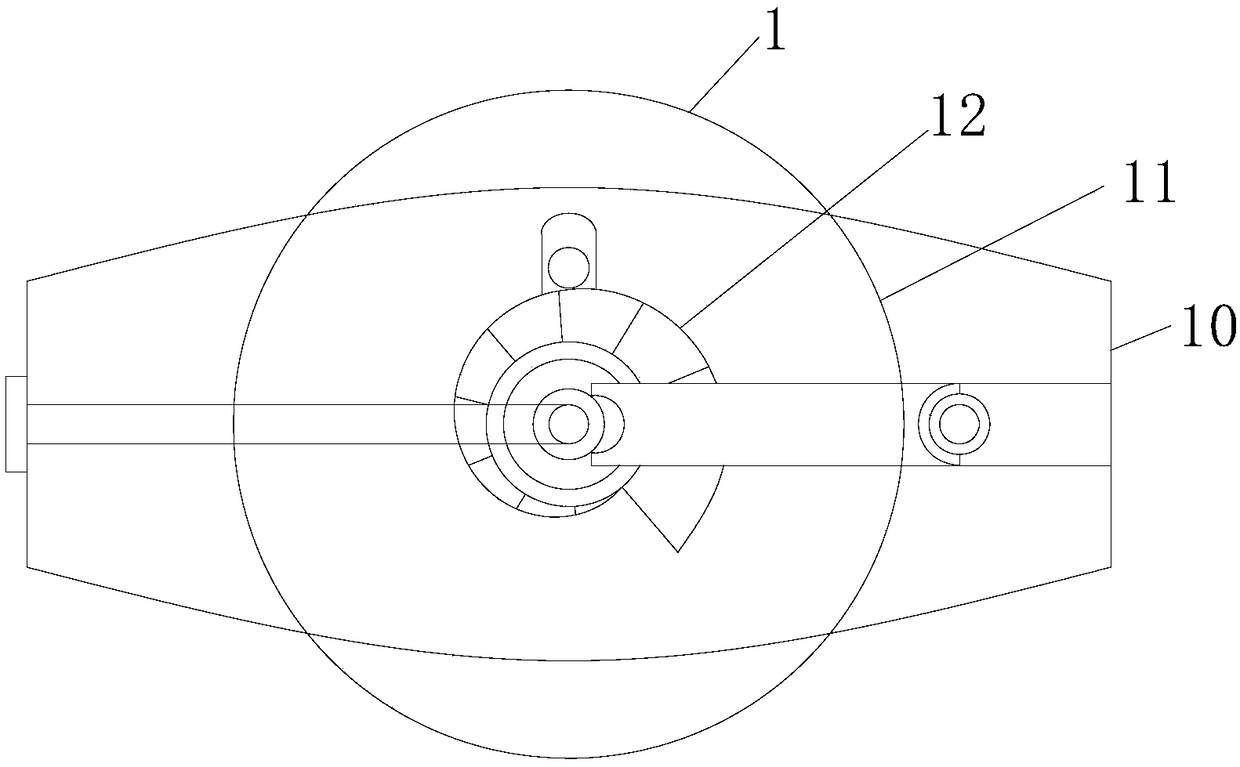

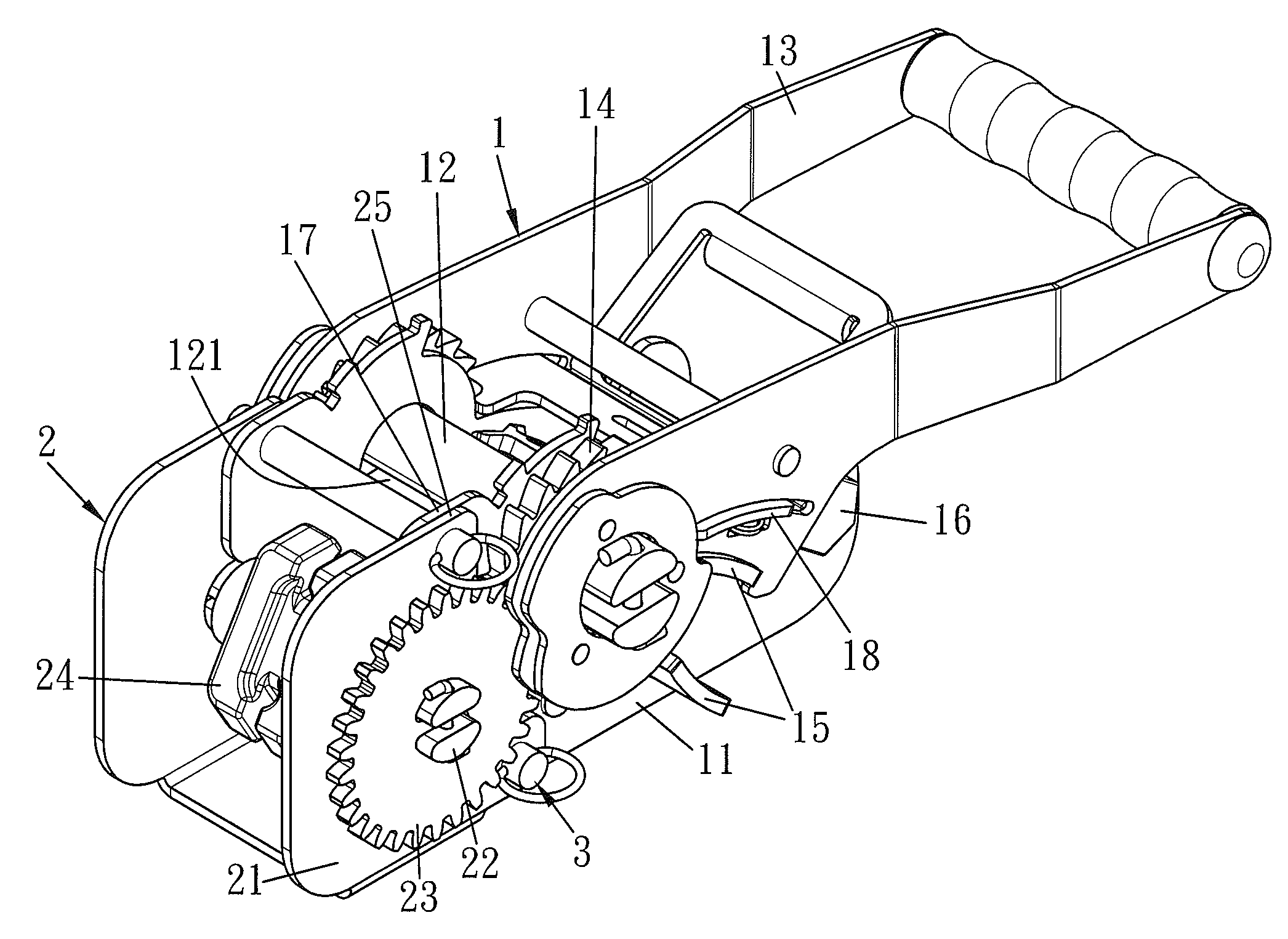

Baffle Plate Mechanism for a Hair Curler

ActiveUS20160073755A1Roll hair efficientlyEfficient rollingCurling-ironsCurling-tongsElectricityEngineering

A baffle plate mechanism for a hair curler, mounted between a shell and a heating roller of the hair curler, comprises a button extending out of the shell; a push switch mounted in the shell and connected to the button; a telescope apparatus mounted in the shell; wherein the telescope apparatus includes a movable push rod and an electromagnet for driving the movable push rod to do a telescopic movement when electricity is applied; the movable push rod penetrates the electromagnet; the electromagnet is coupled electrically to the push switch; and a baffle plate coupled to an end of the movable push rod and opposite to the heating roller.

Owner:SHENZHEN FENDA ELECTRICAL

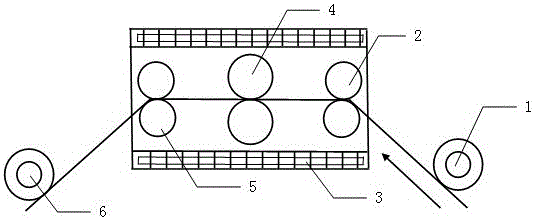

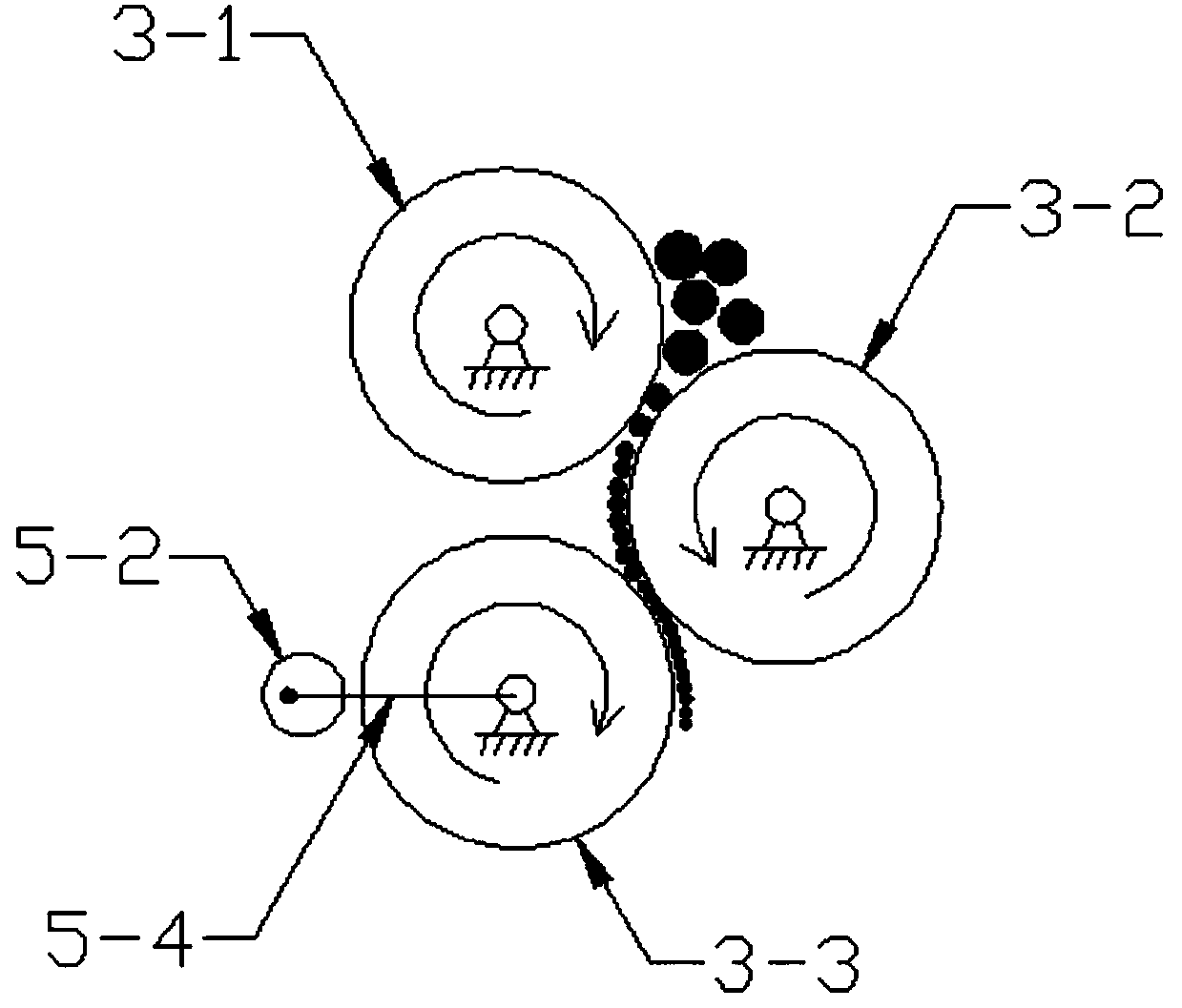

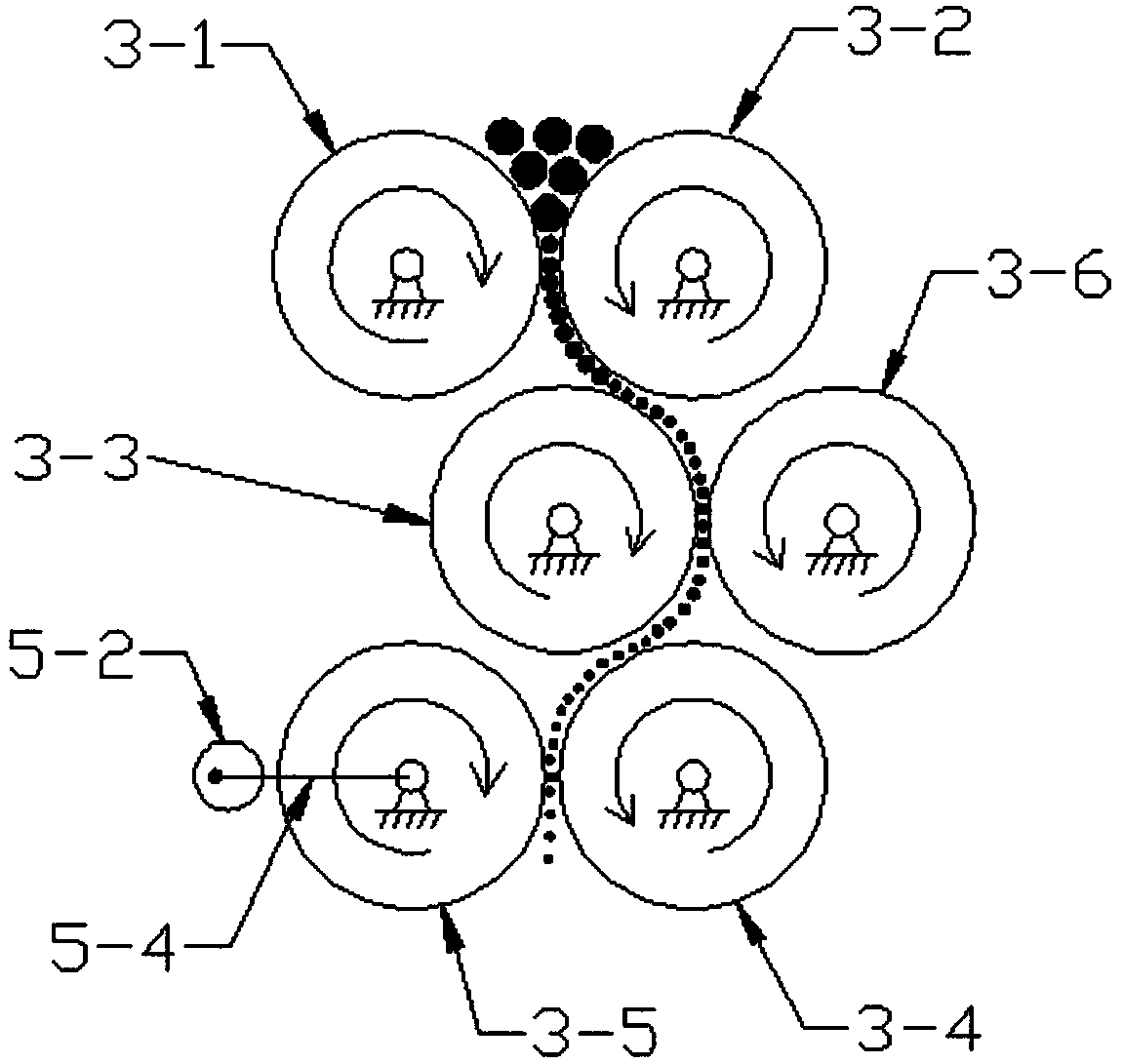

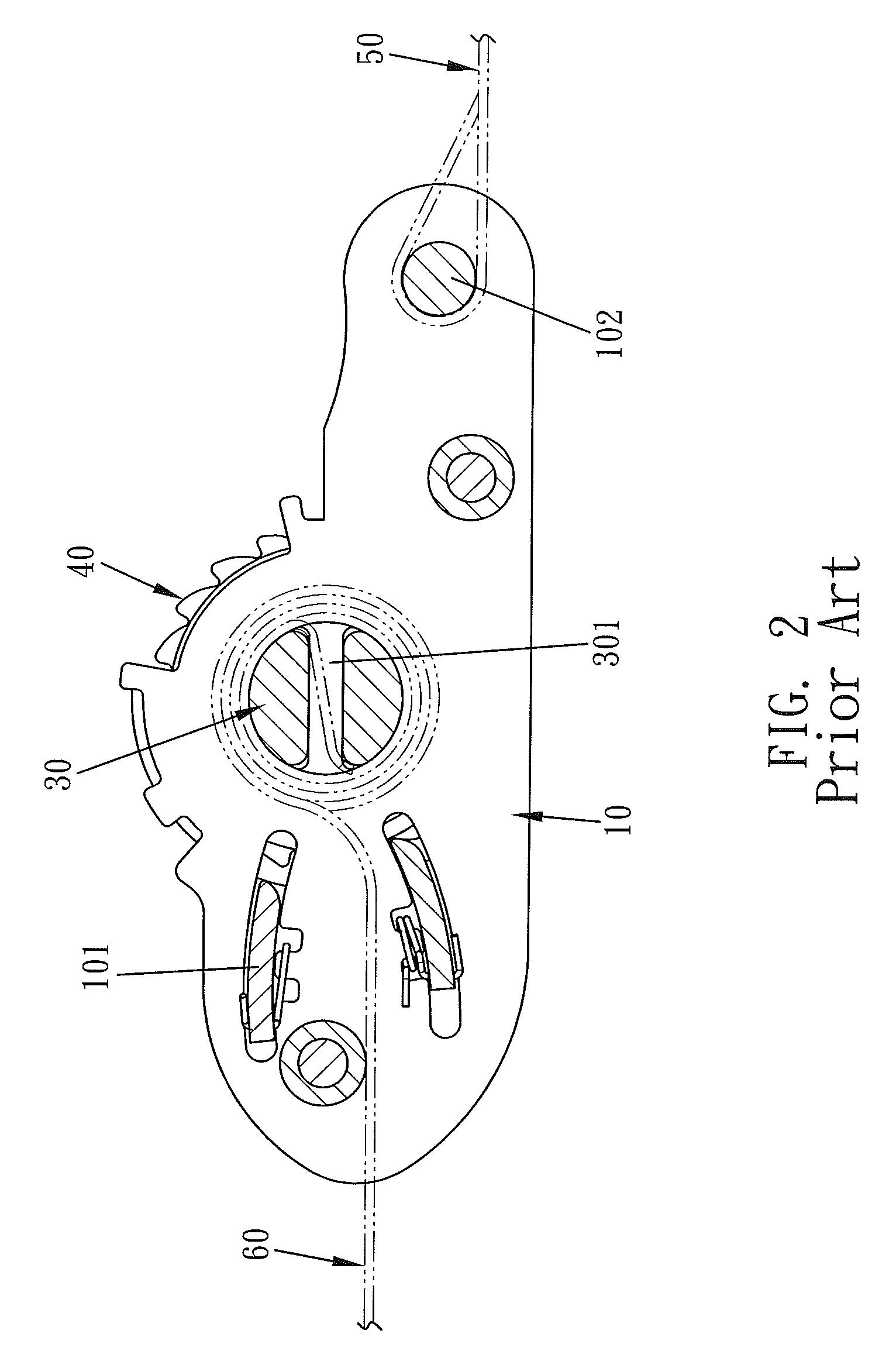

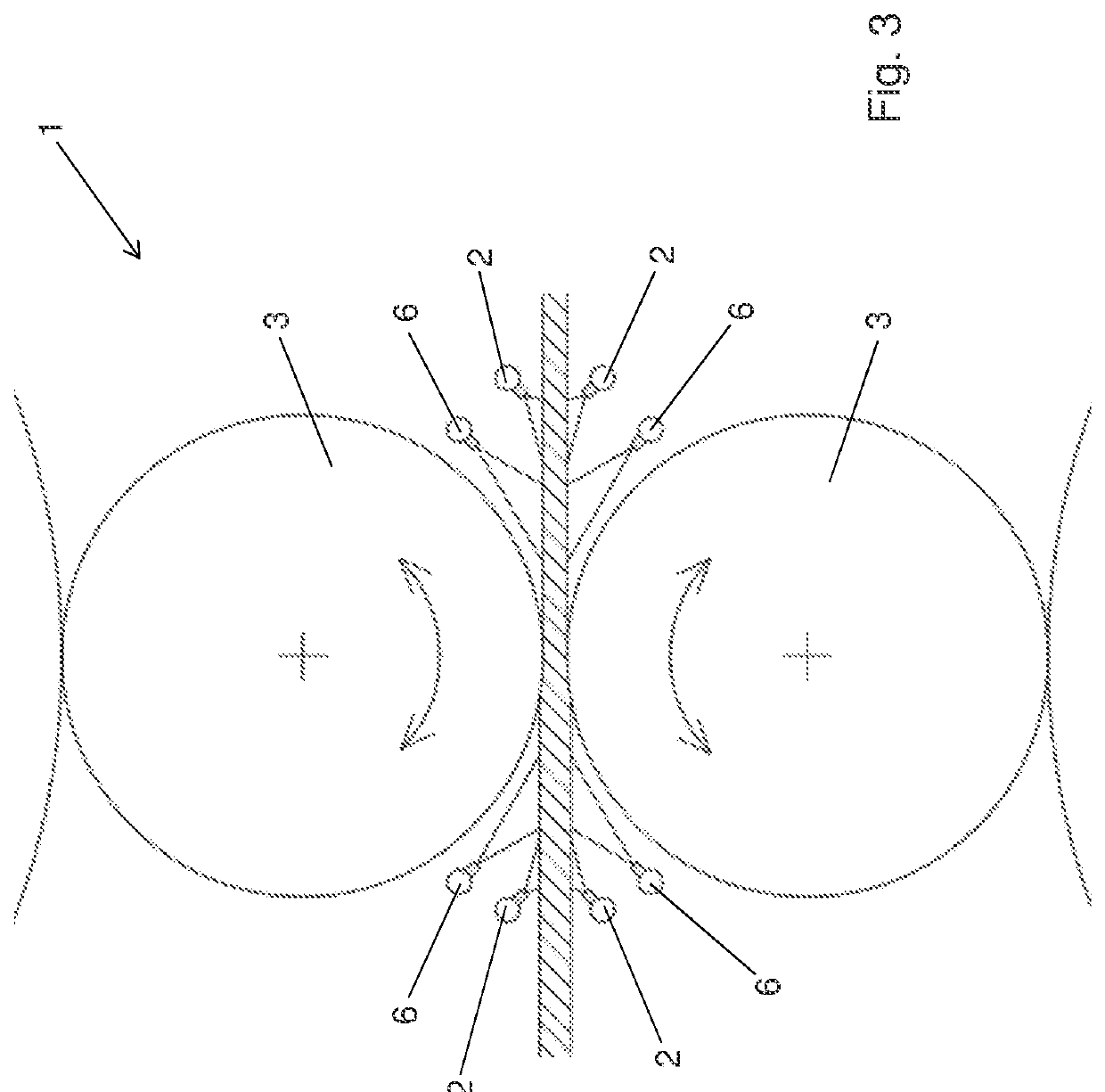

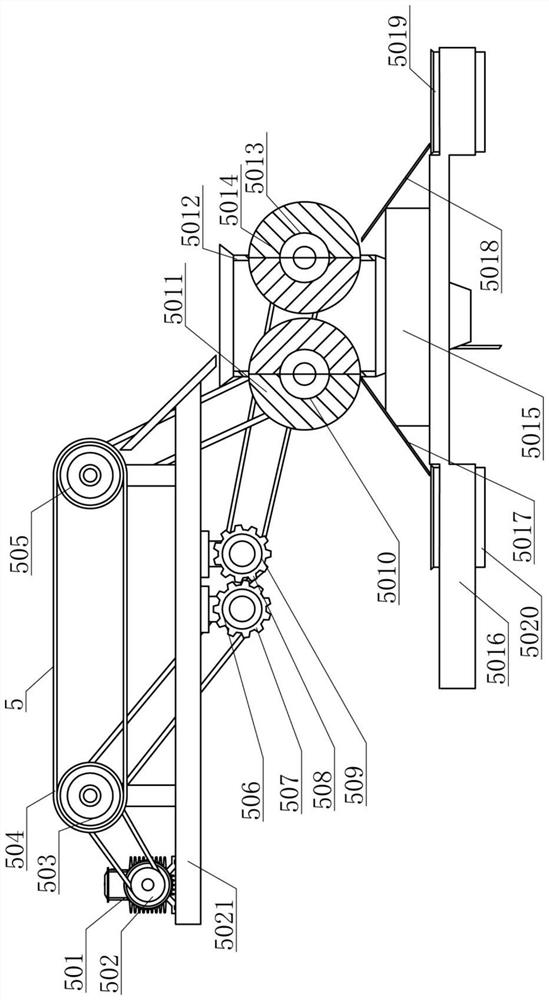

Apparatus capable of continuously rolling and breaking

InactiveCN107638902AEfficient rollingImprove controllabilityGrain treatmentsGear wheelControllability

The present invention relates to the technical field of rolling and breaking tools, more particularly to an apparatus capable of continuously rolling and breaking. According to the present invention,with the apparatus, a material can be automatically and directly subjected to the next rolling and breaking from the previous rolling and breaking so as to effectively perform the multiple continuousrolling and breaking on the material, such that the final thickness and the final particle size of the rolled and broken material can be regulated so as to enhance the controllability of the materialrolling and breaking; and a roller set comprises a plurality of rollers, the plurality of the rollers are rotatably connected to a rack, a transmission mechanism comprises a plurality of gears, the plurality of the gears are respectively and fixedly connected to the plurality of the rollers, the roller set is positioned inside the rack, a motor and the transmission mechanism are positioned on theouter portion of the rack, and the output shaft of the motor is fixedly connected to the first roller of the roller set.

Owner:王勇

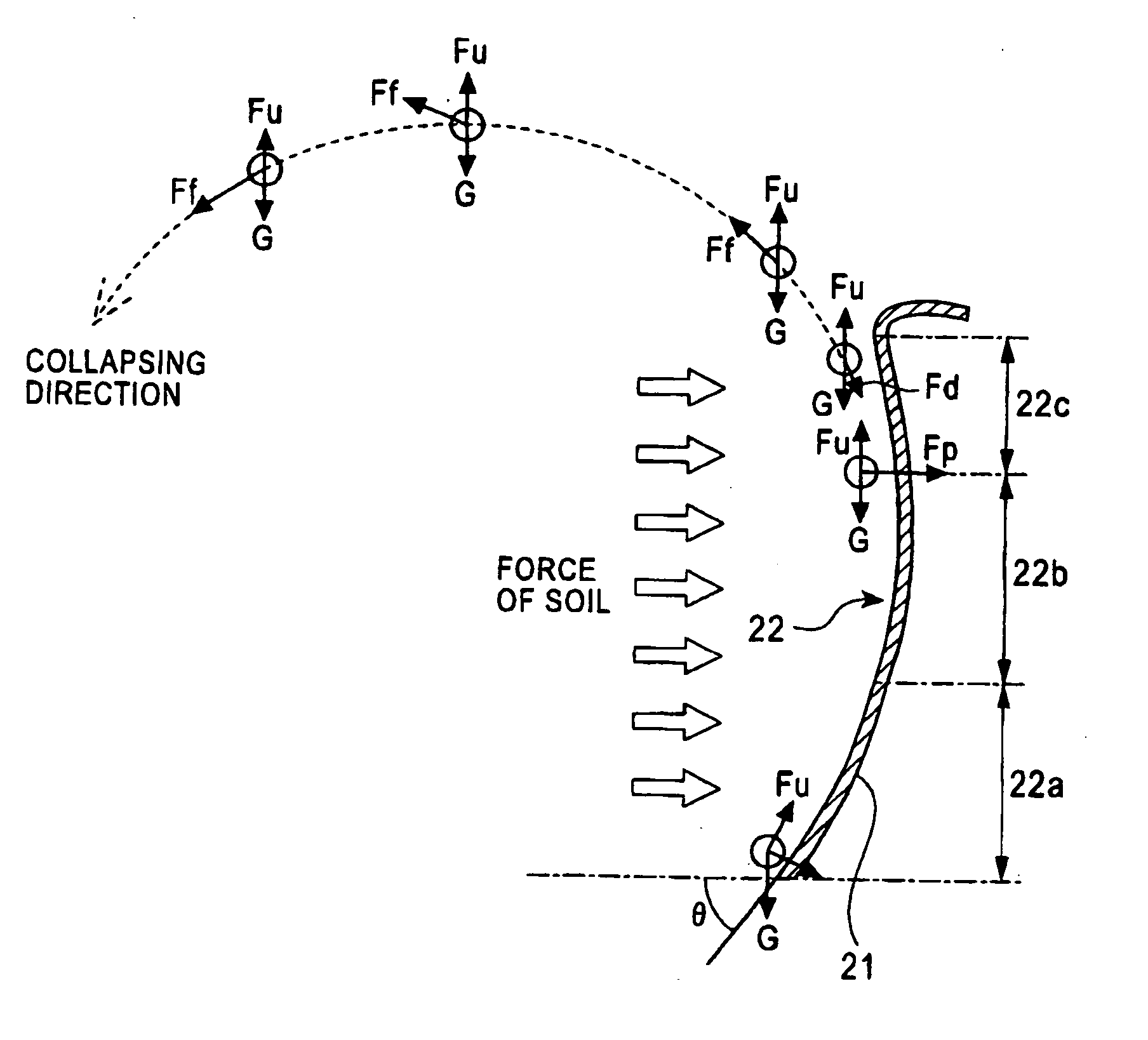

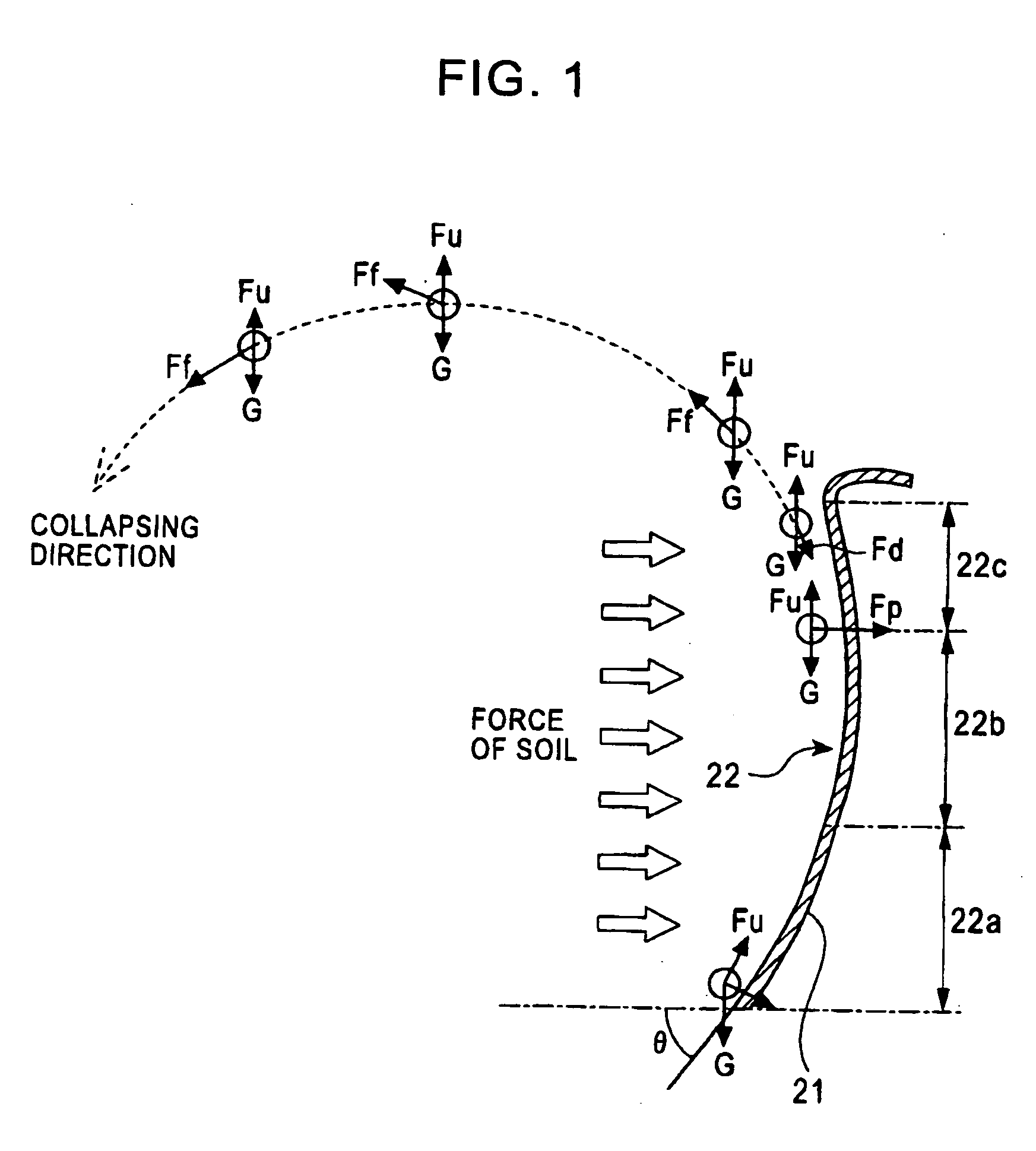

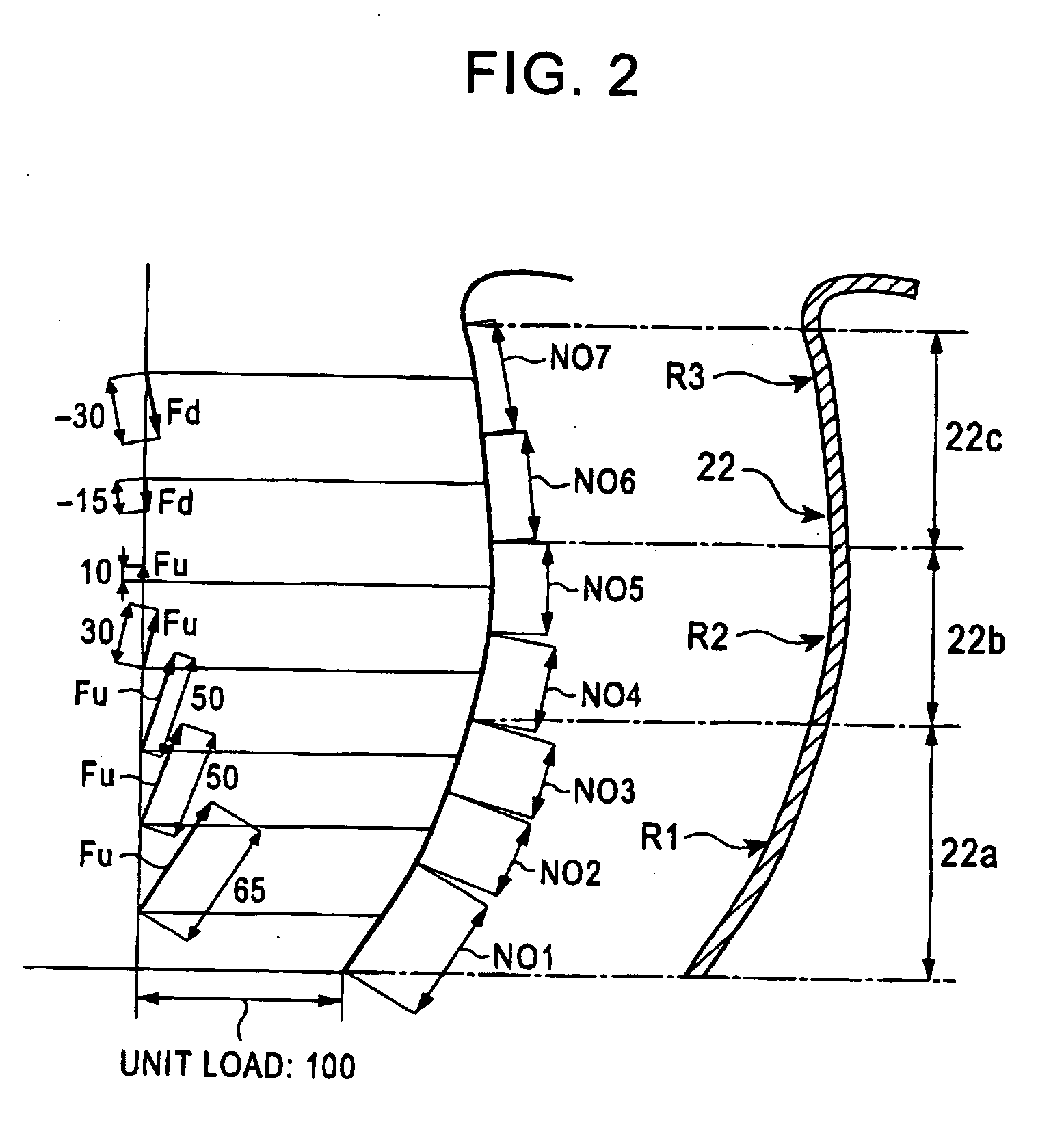

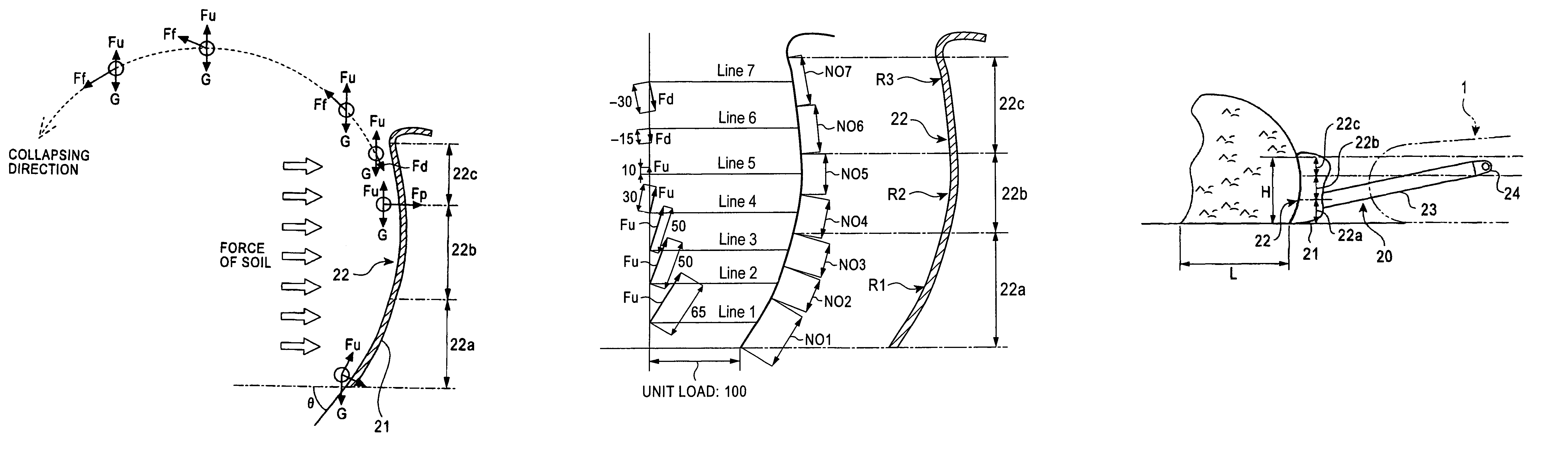

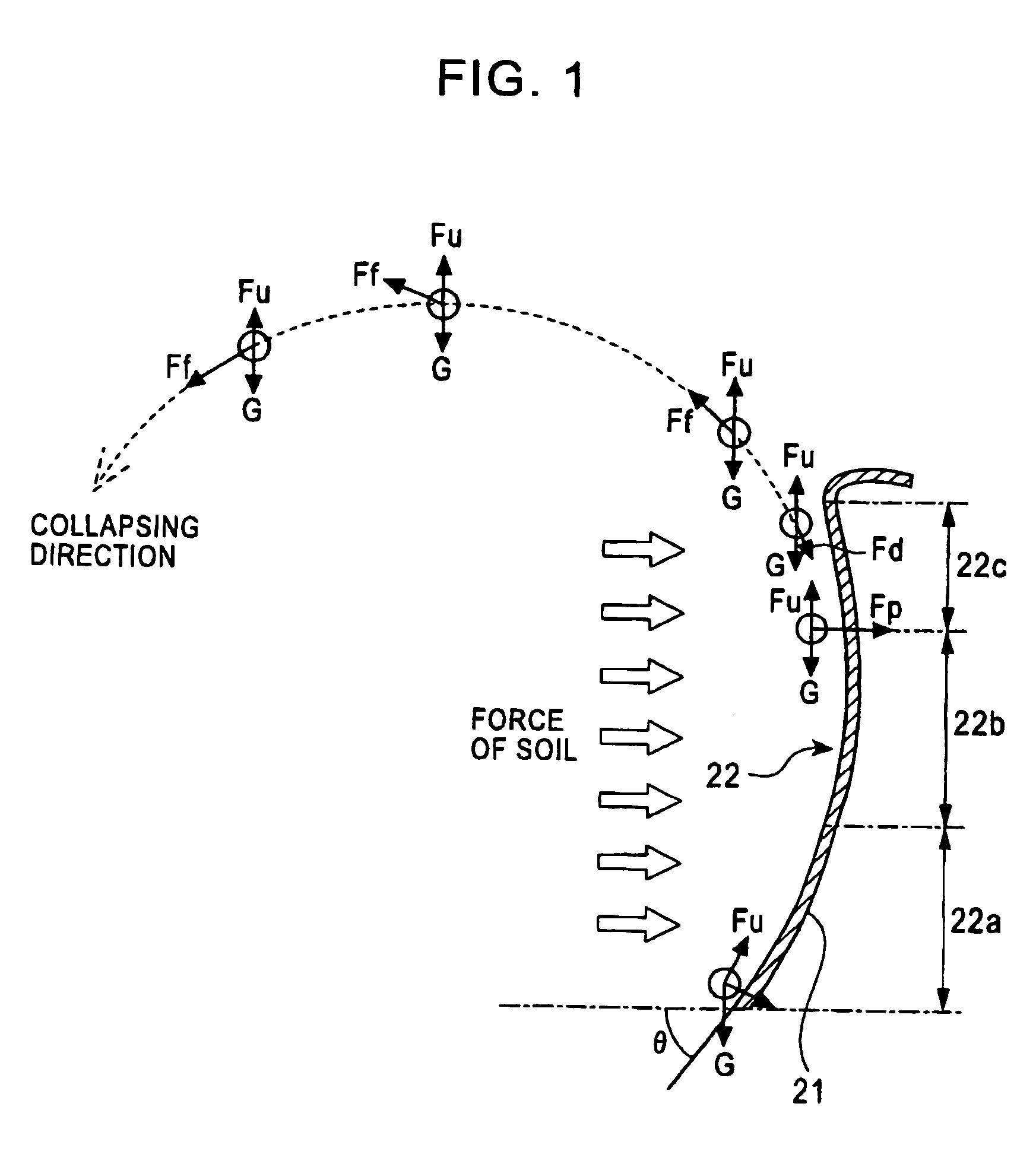

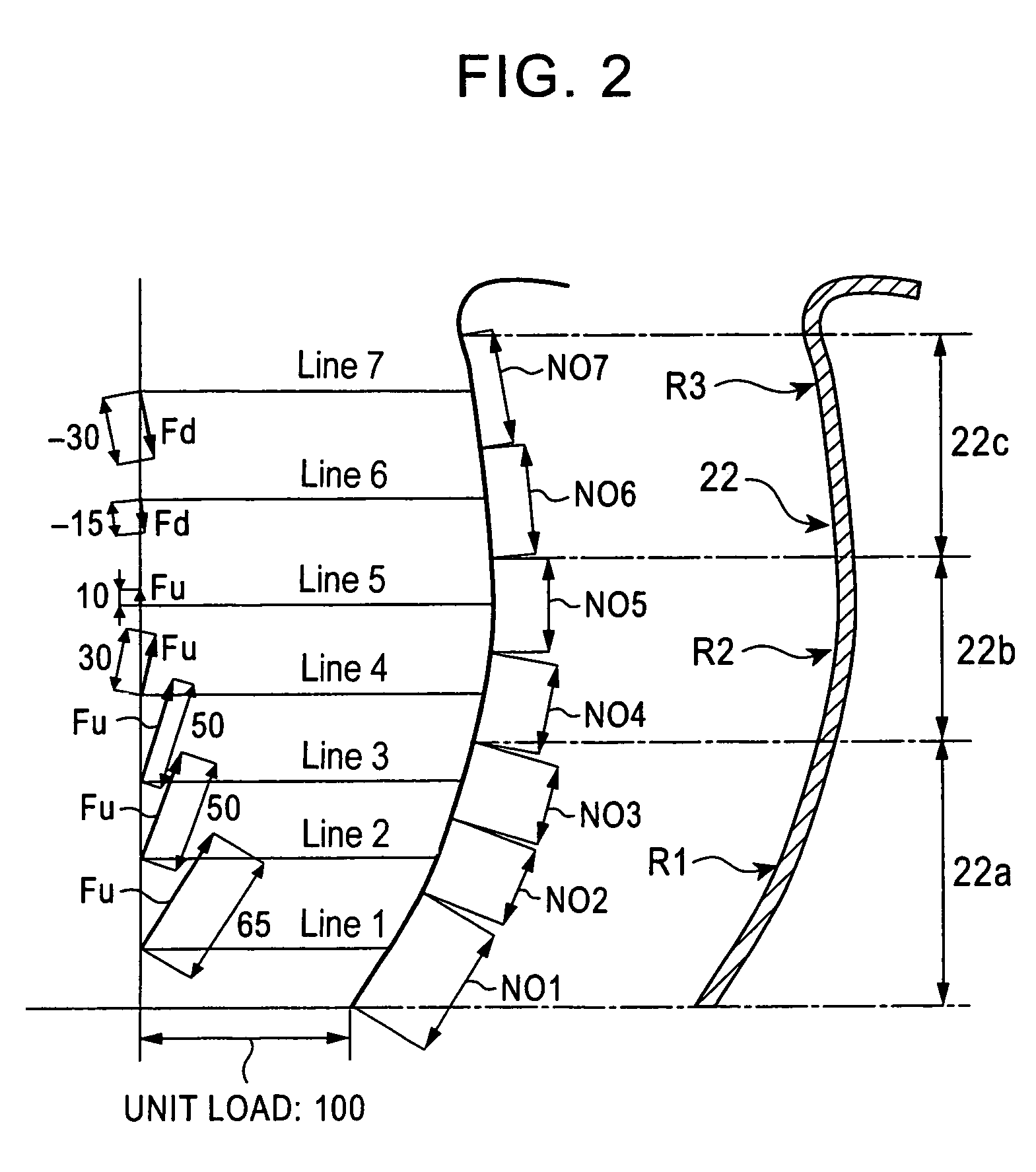

Excavator

InactiveUS20050230129A1Improve efficiencyDirt can be rolled efficientlyMechanical machines/dredgersSnow cleaningEngineeringExcavator

In an excavator, a blade surface for performing an earth removal operation while a blade is set in contact with the ground satisfies the following conditions: A) upward pushing force components Fu that push dirt upward along the blade surface are generated; B) an upper part of the blade surface has a release surface portion in which a forward-upward release force that rolls the dirt pushed upward by Fu forward is generated; C) when downward pressing force components Fd are generated in response to the generated release force, a total downward pressing force ΣFd>a total upward pushing force ΣFu; and D) if each Fu is given a positive value and if each Fd and a reduced amount of each Fu caused when the dirt hits the release surface portion are given negative values, a value of force at an endmost section of the release surface portion is positive.

Owner:KOBELCO CONSTR MASCH CO LTD

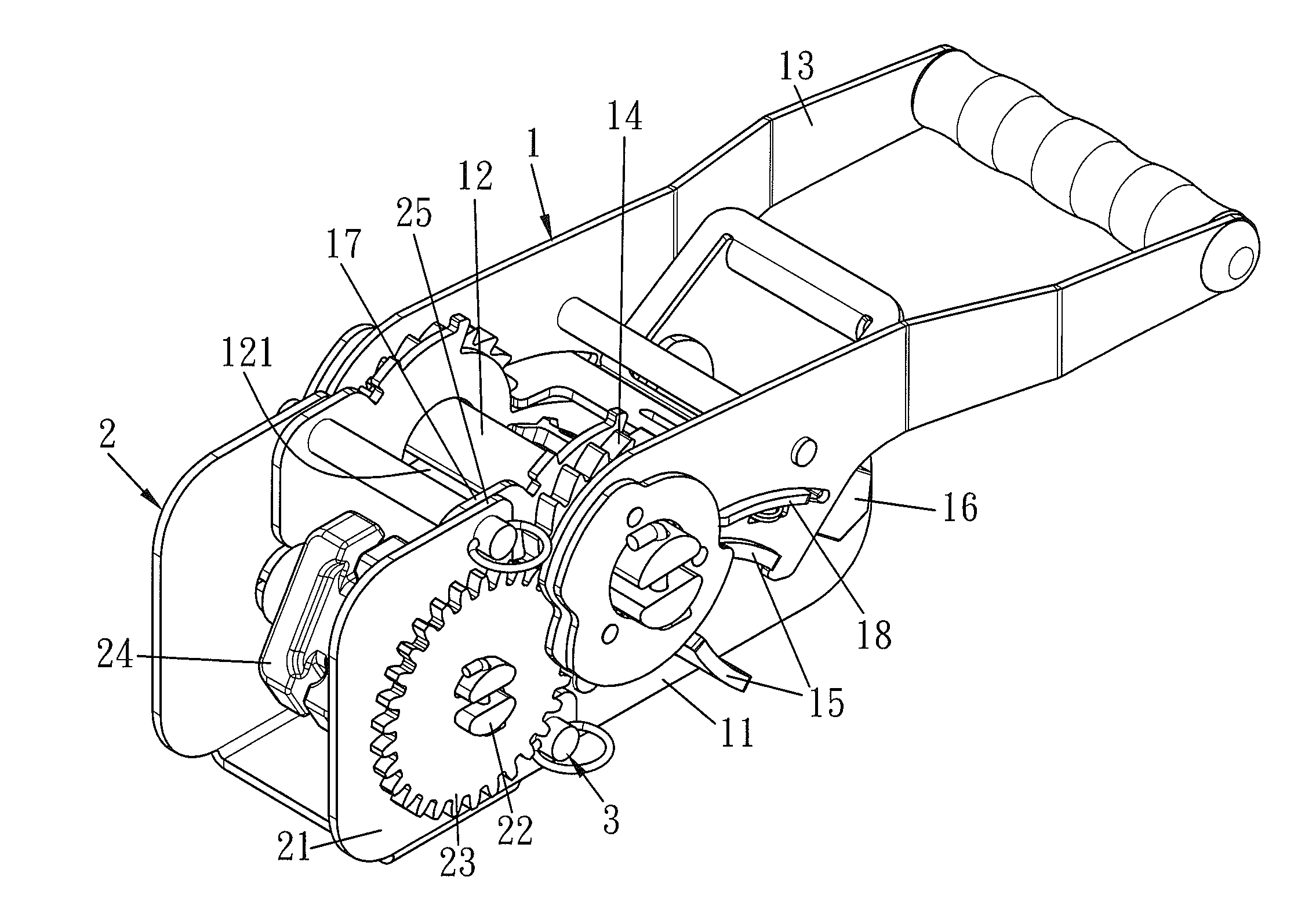

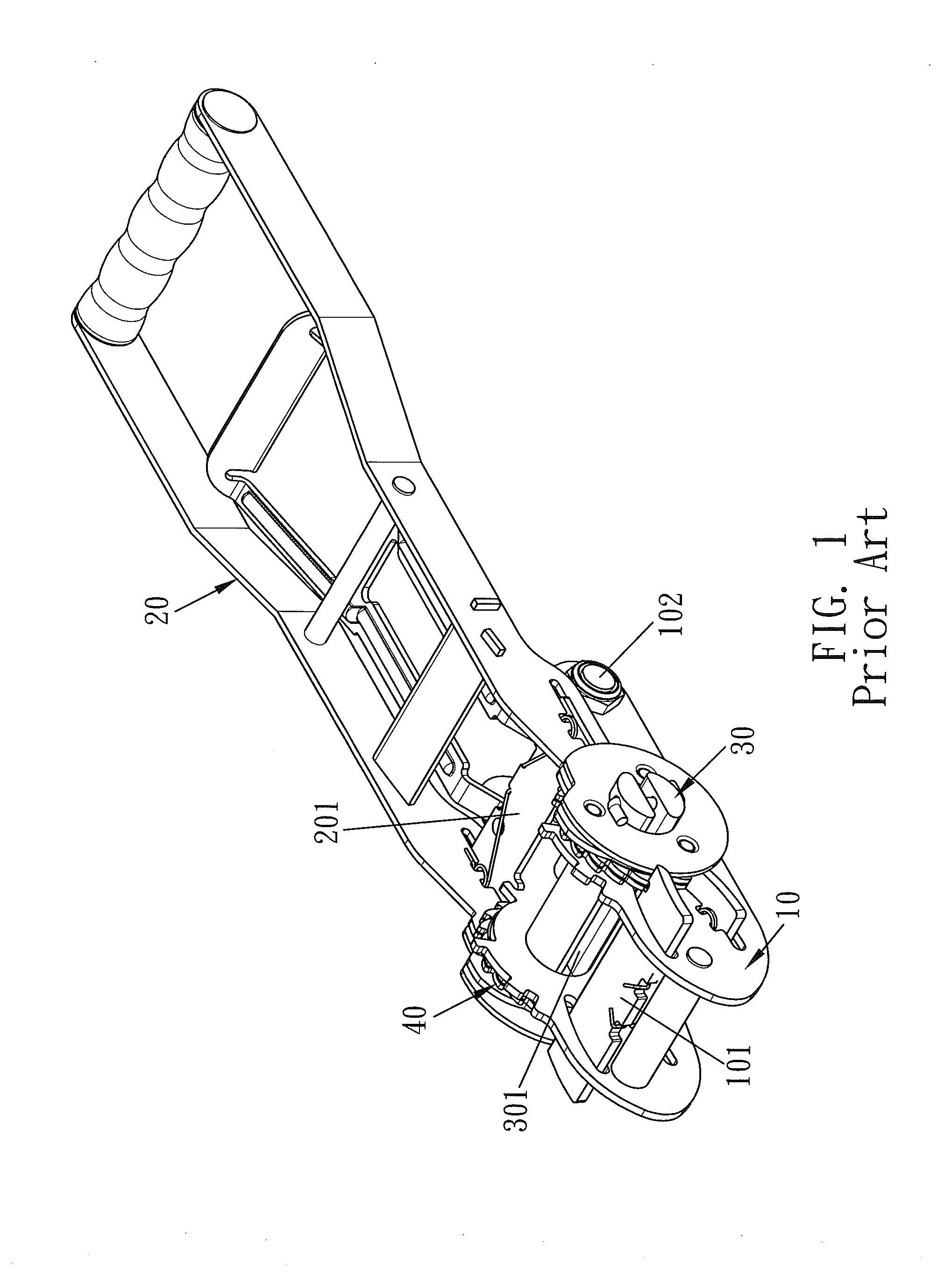

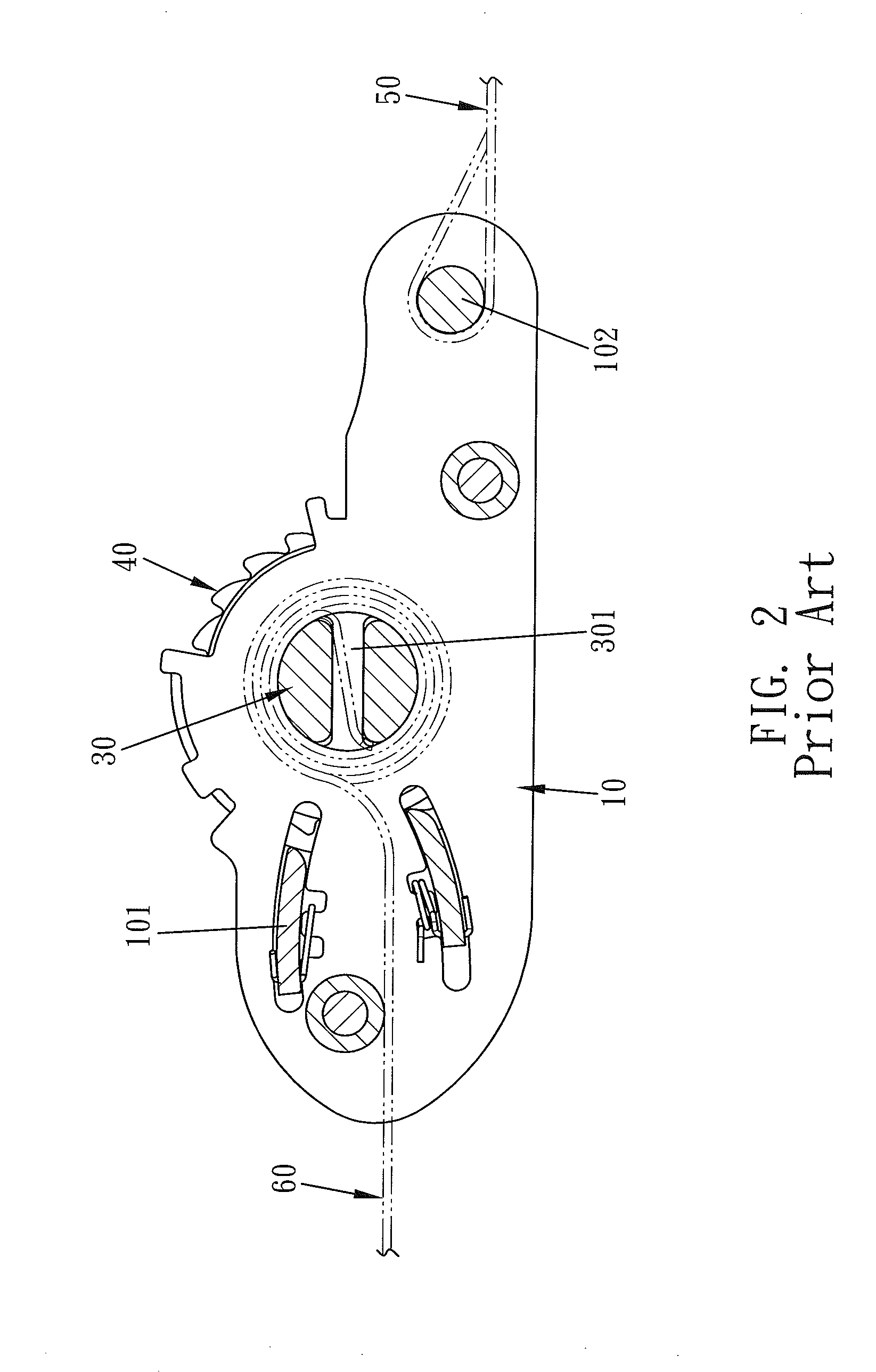

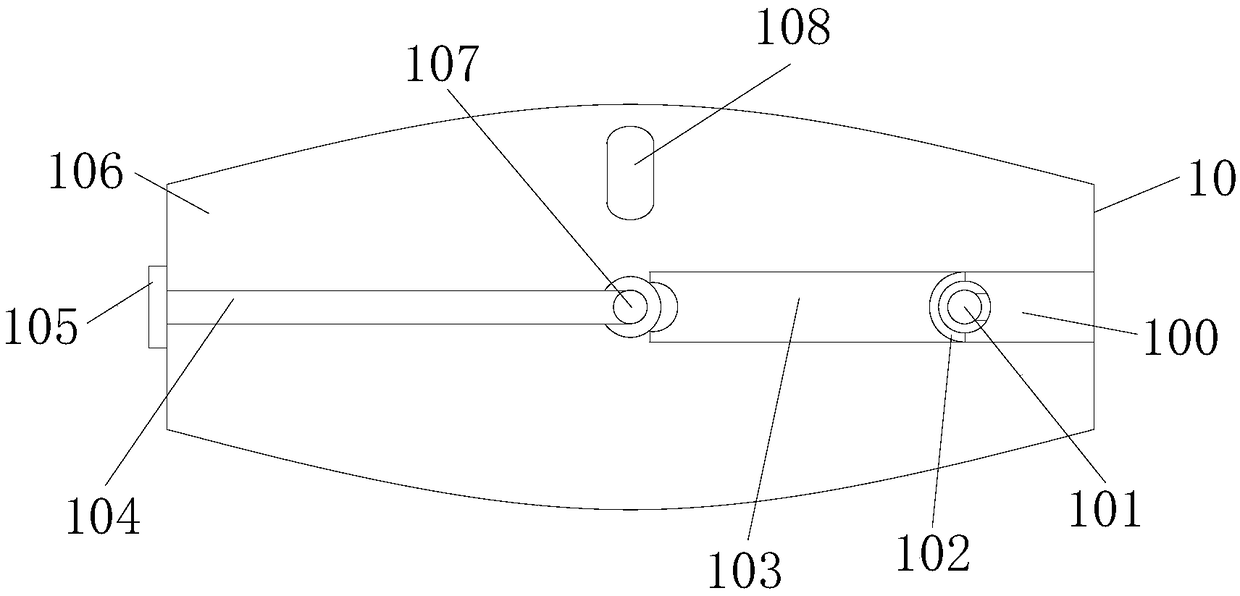

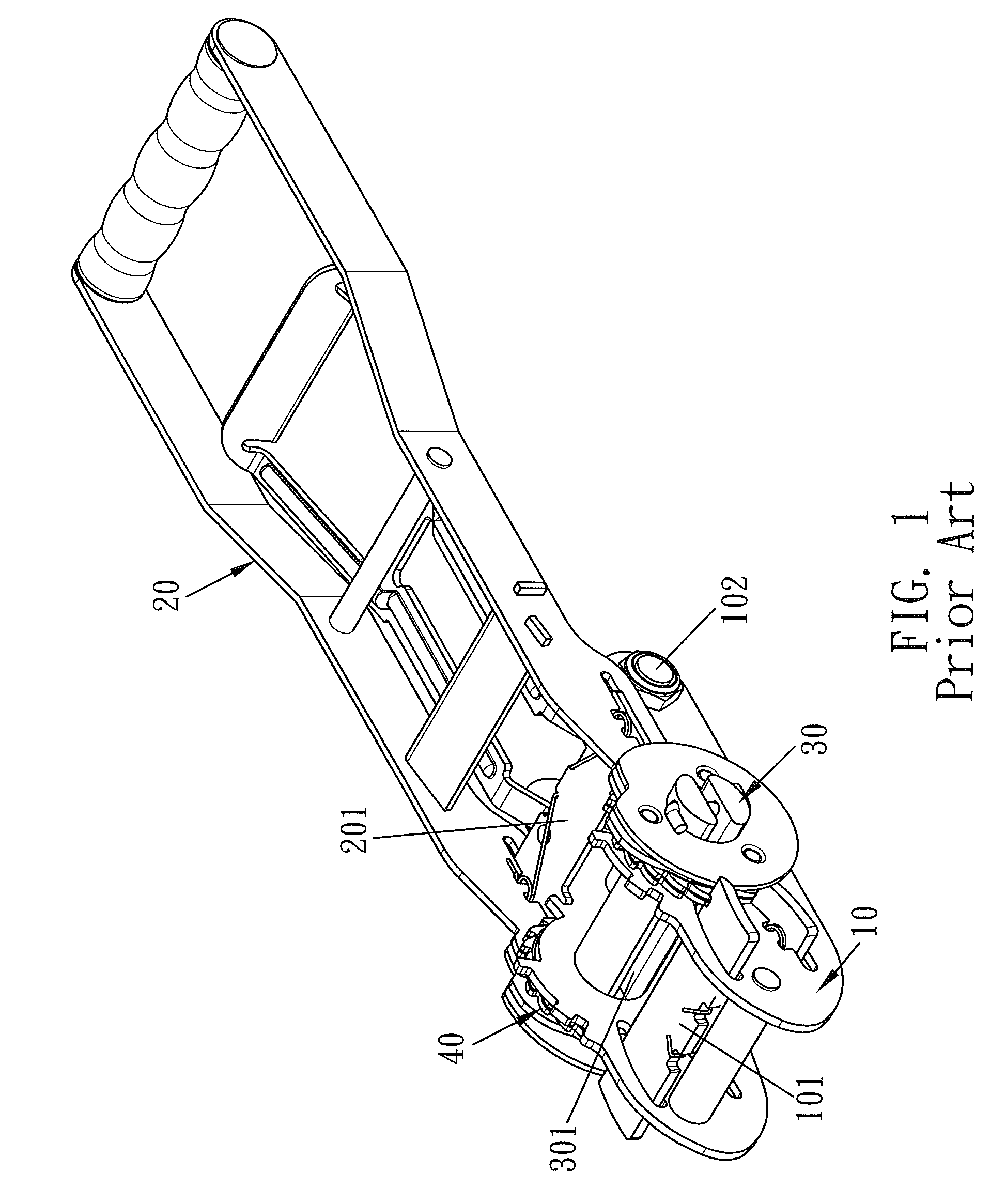

Hand Puller with Rope Reel

A hand puller with a rope reel contains a body and a reel. The body includes a fixing holder, a first rotary shaft, a rotating handle, two ratchet wheels, and at least one stopping piece. The rotating handle having a pushing plate, and the first rotary shaft has two driving gears. The reel includes a seat, a second rotary shaft, two driven gears, and a chain roller. The body includes a first connecting portion with plural holes, and the seat has a second connecting portion and a plurality of apertures. The reel and the body are movably coupled together, the second connecting portion of the reel is aligned and overlapped with the first connecting portion of the body, and at least one pin is inserted into at least one opening of the first connecting portion and the plurality of apertures of the second connecting portion.

Owner:WIN CHANCE METAL

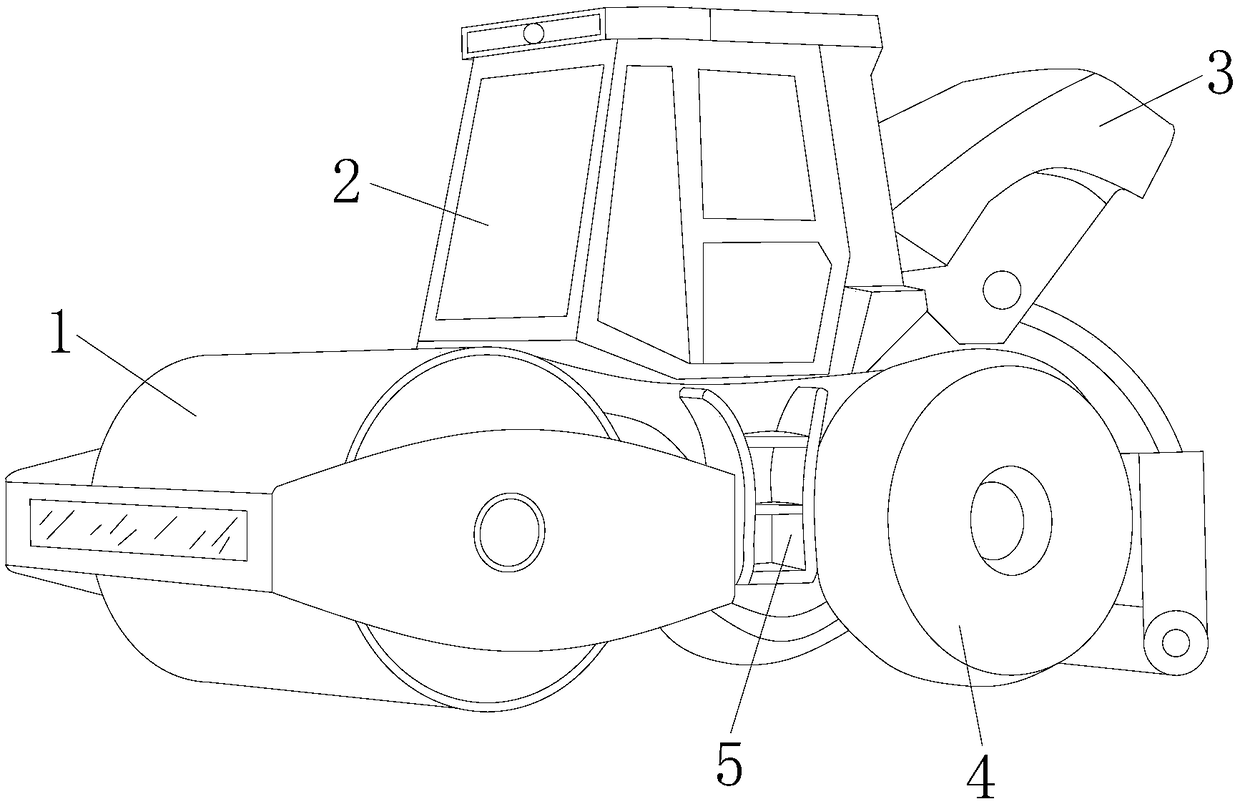

Road roller for adjusting heights of steel wheels on basis of detected road surfaces

The invention discloses a road roller for adjusting heights of steel wheels on basis of detected road surfaces. The road roller structurally comprises a steel wheel structure, a control room, a rear cover, a rear wheel structure and an engine base, wherein the control room is locked with the engine base; the rear cover is in shaft connection with the engine base; the steel wheel structure and therear wheel structure are mounted on the engine base; the steel wheel structure consists of a surrounding frame structure, a steel wheel structure and a rotation screw mechanism, which are located at asame axis; the steel wheel structure is in shaft connection with the surrounding frame structure; and the rotations screw structure is in shaft connection with the surrounding frame structure. The road roller is capable of realizing efficient grinding through reducing the height of the steel wheel structure for higher unsurfaced roads with more pile solids and raising or keeping the height of thesteel wheel structure for the sunken unsurfaced roads with less pile solids, improving the running speed to ensure the compaction quality and efficiency and decreasing the grinding times; and meanwhile, auxiliary wheels are added on the tires to reduce the pressure applied on the ground by the rear wheels, so that the grinding quality is further improved.

Owner:南安市劲沣电子科技有限公司

Crop row mower

Owner:BUTTON BARBARA J

Hand puller with rope reel

Owner:WIN CHANCE METAL

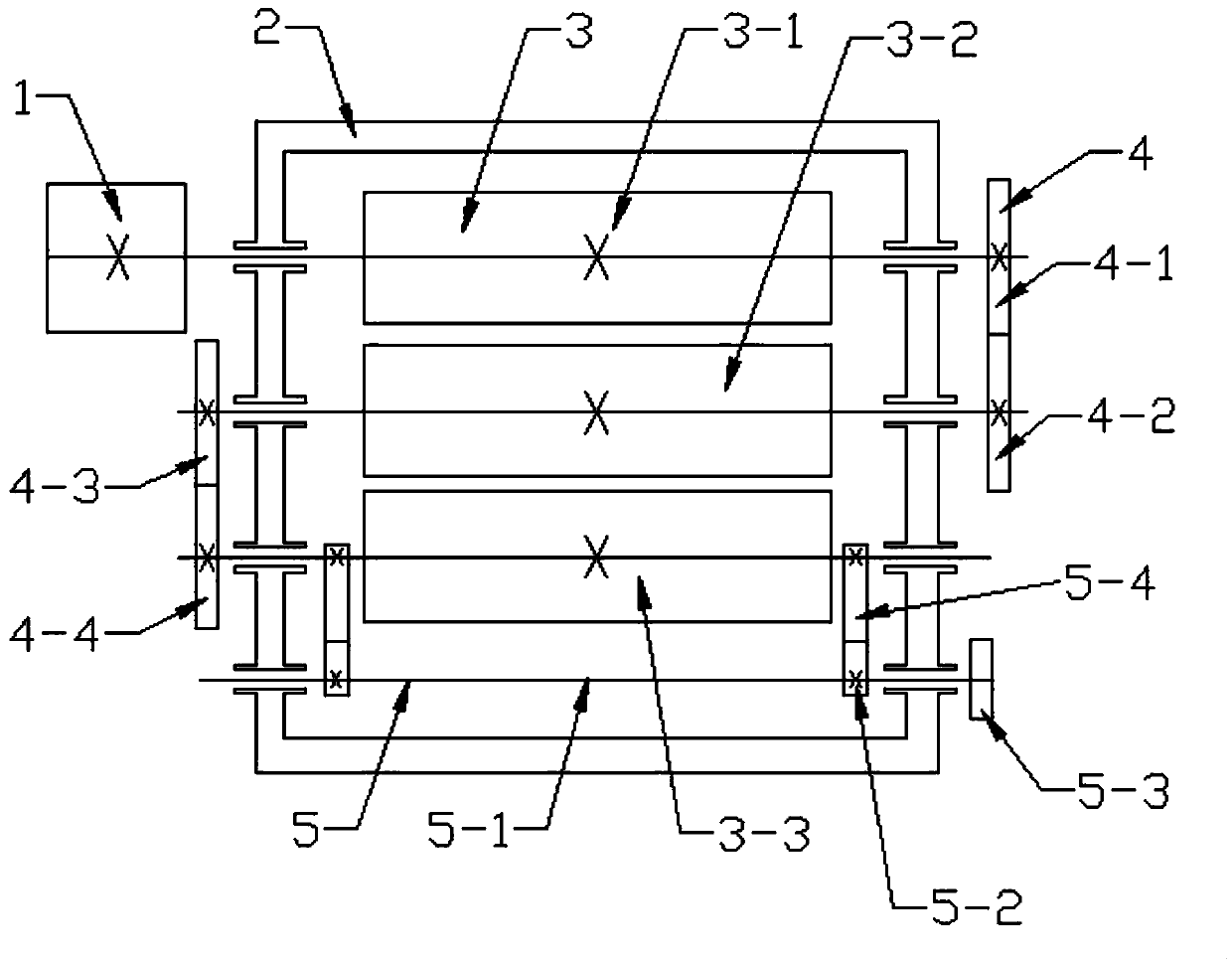

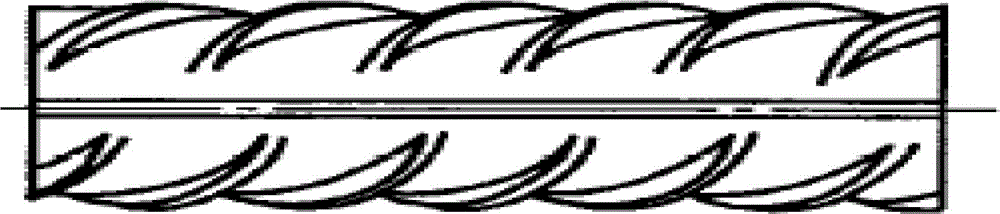

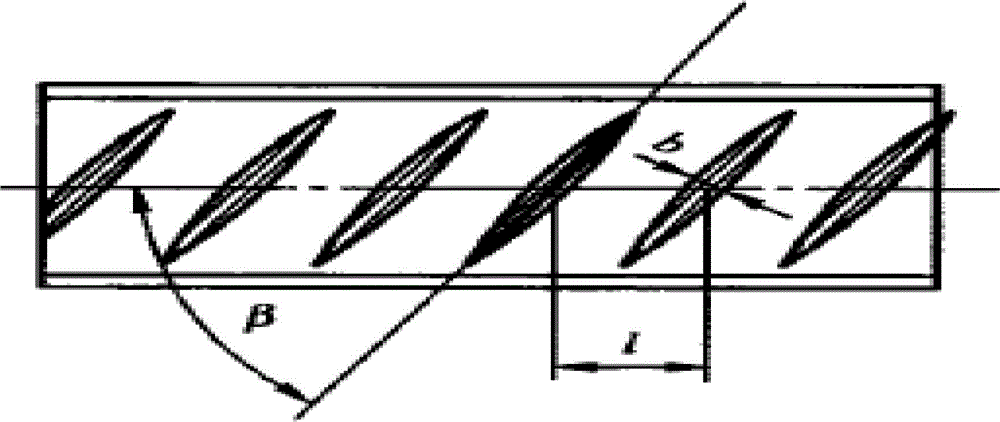

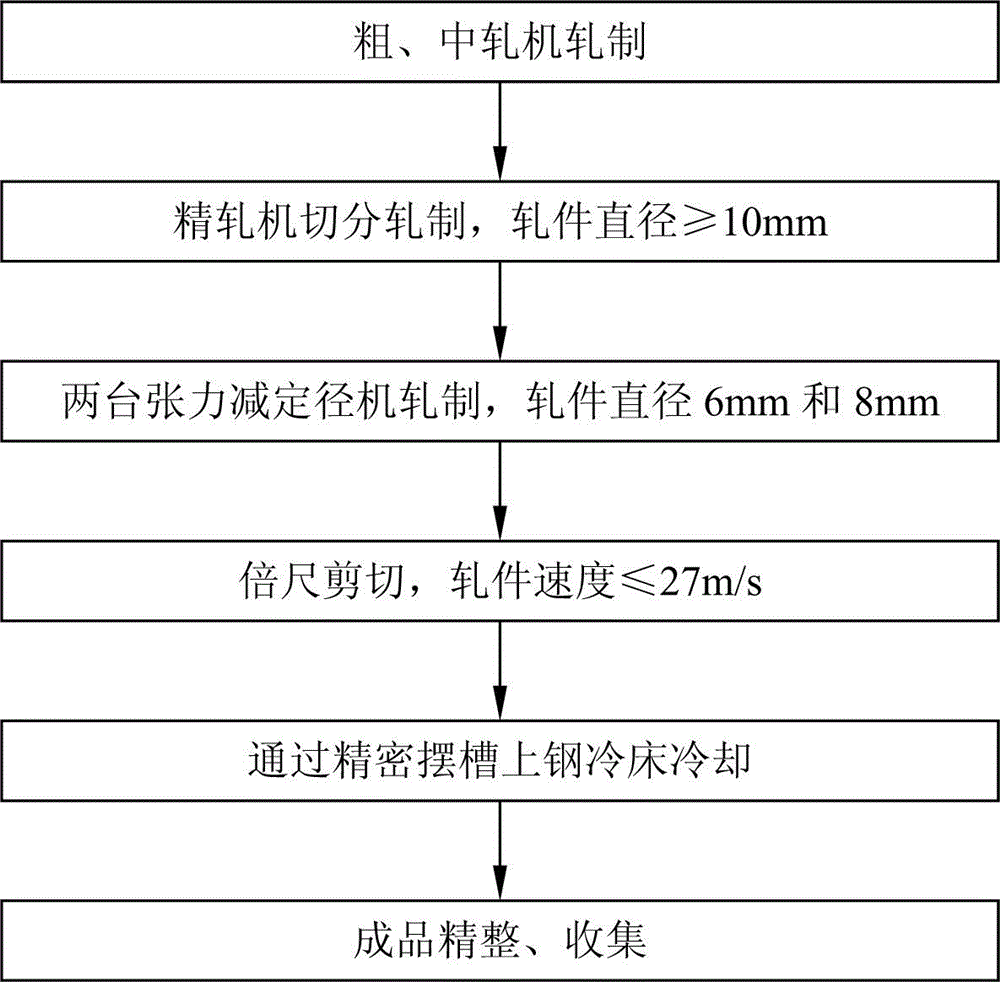

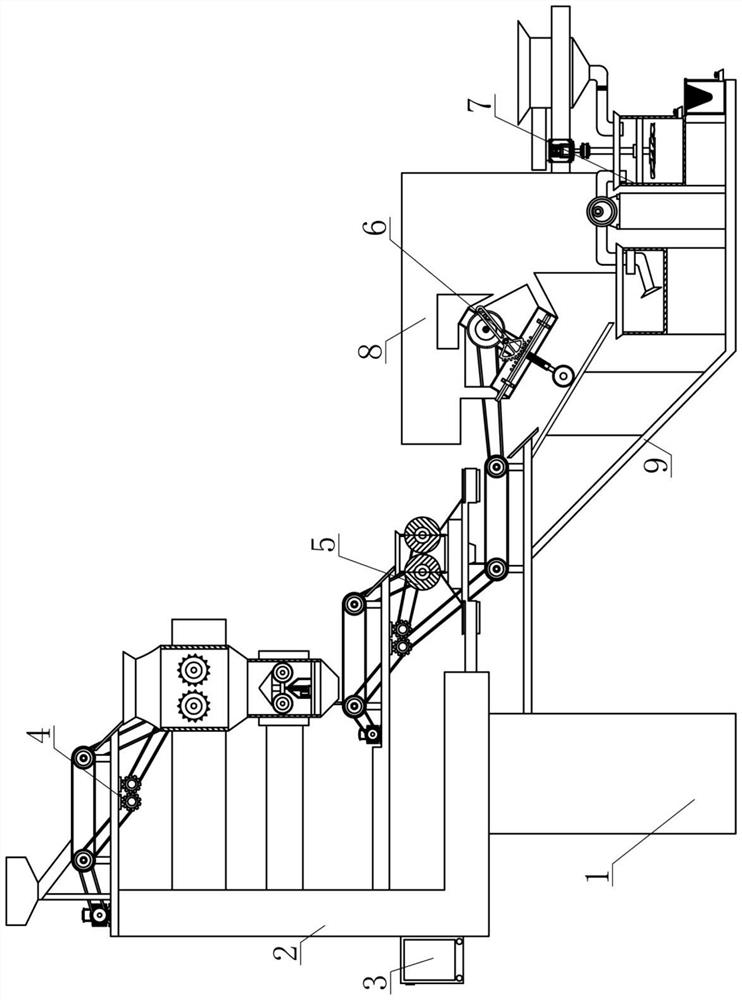

Rolling method for small-sized straight bar ribbed round steel

ActiveCN105268739ARolling precisionEfficient rollingCooling bedsMetal rolling arrangementsSizingMaterials science

The invention relates to the field of metal rolling of rolling of workpieces with special section shapes, in particular to a rolling method for small-sized straight bar ribbed round steel. The rolling method for the small-sized straight bar ribbed round steel is characterized by comprises the following steps that a, slitting rolling is conducted through a finishing mill; b, two tension reducing sizing mills are used for rolling; c, a high-speed flying shear is used for shearing; d, rapid braking is achieved through a braking clip tail roller; and e, the steel is input into a cooling table through a feeding device to be cooled. The rolling method for the small-sized straight bar ribbed round steel is high in rolled piece quality and precision, high in production efficiency and broad in application range.

Owner:BAOSTEEL ENG & TECH GRP

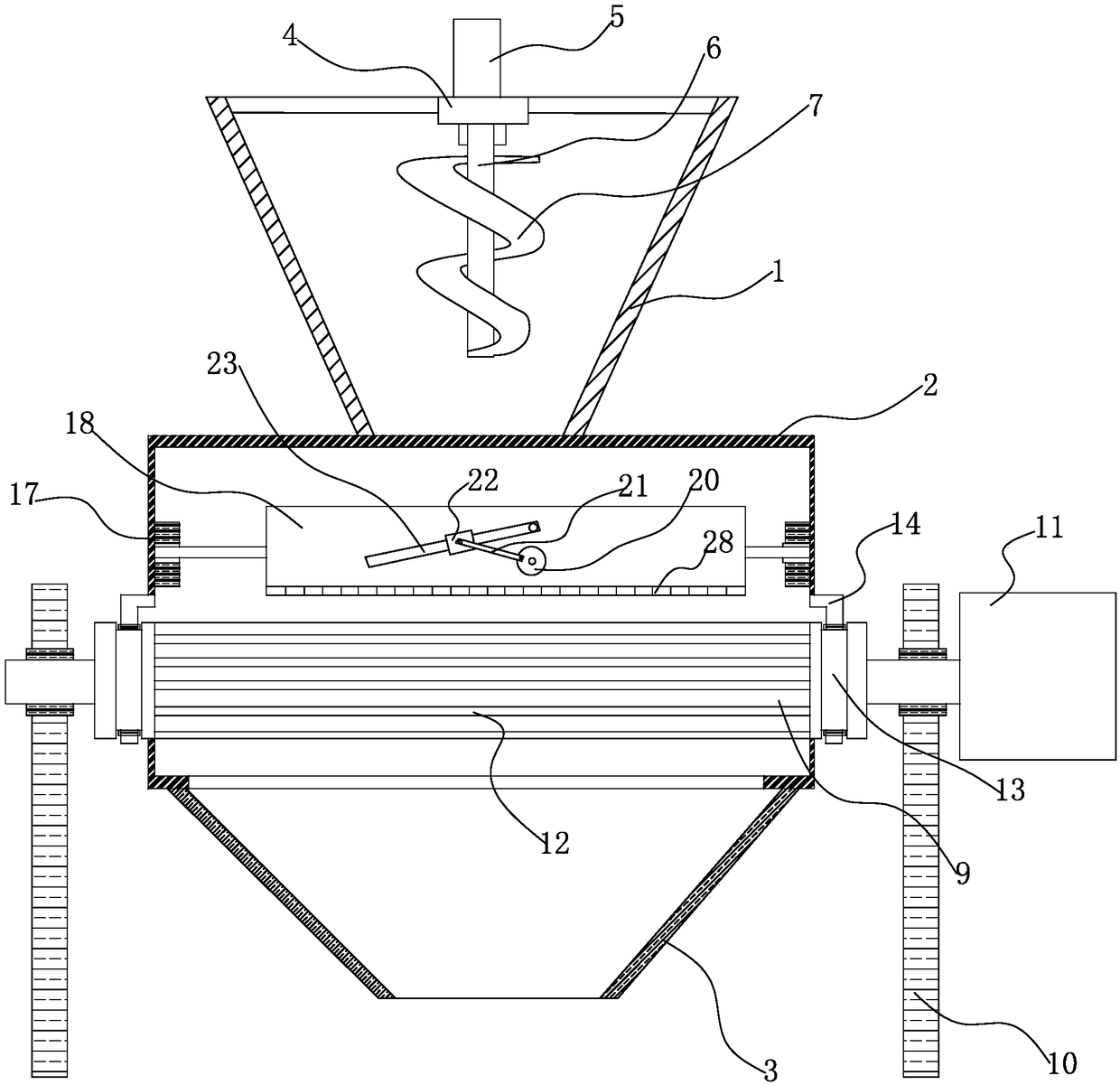

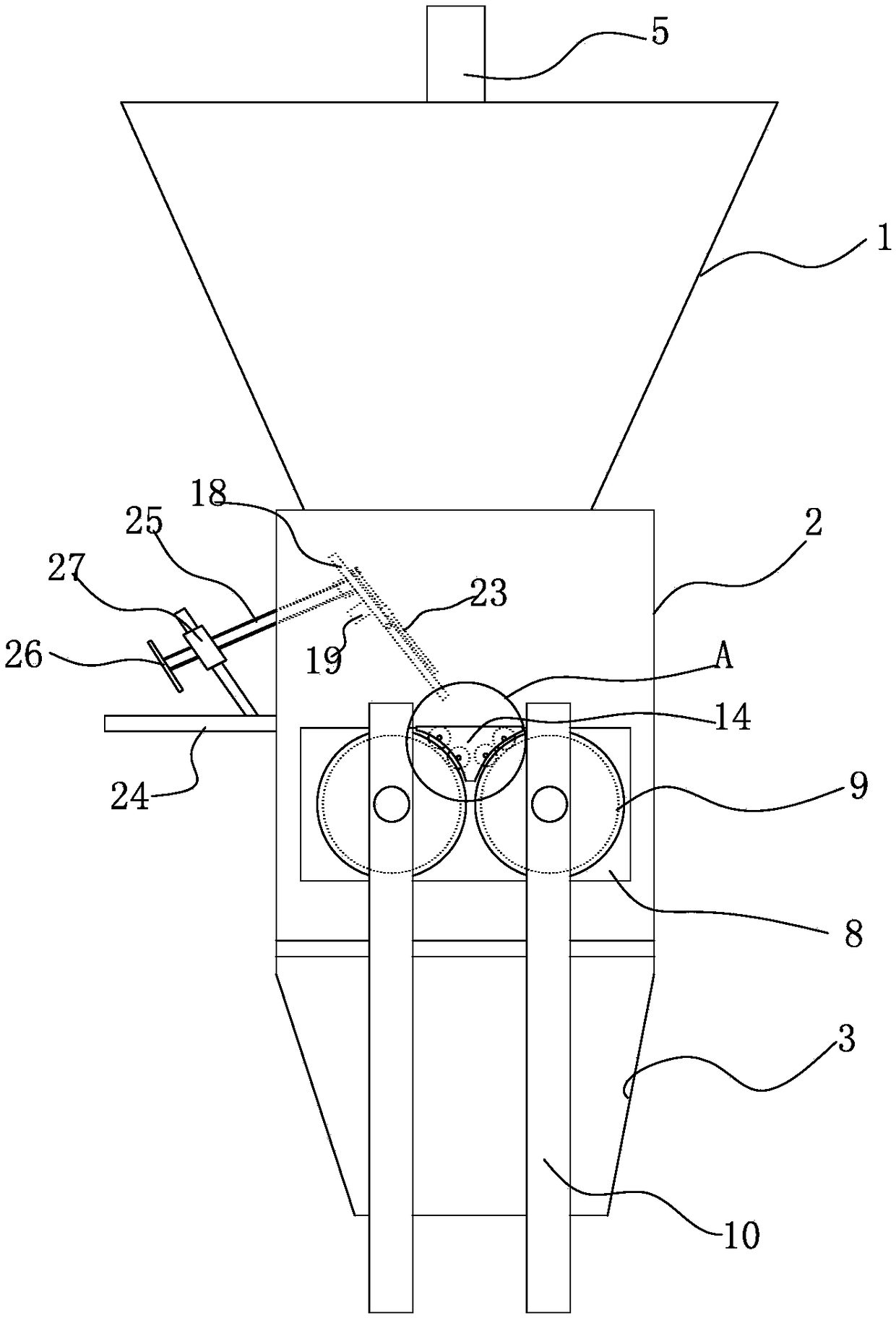

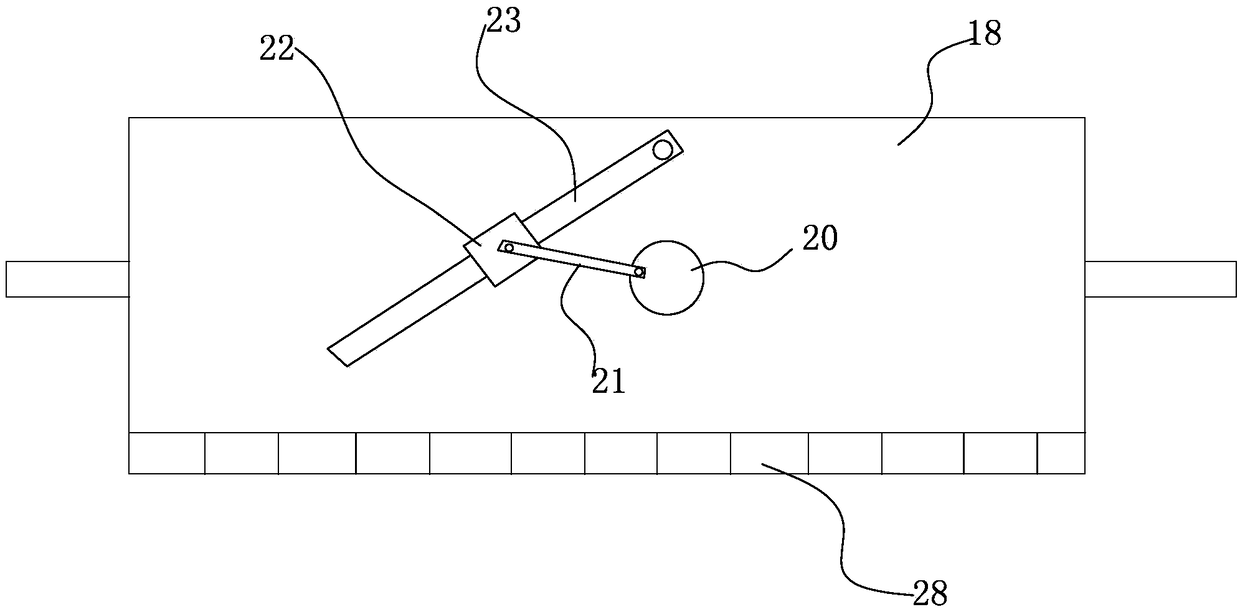

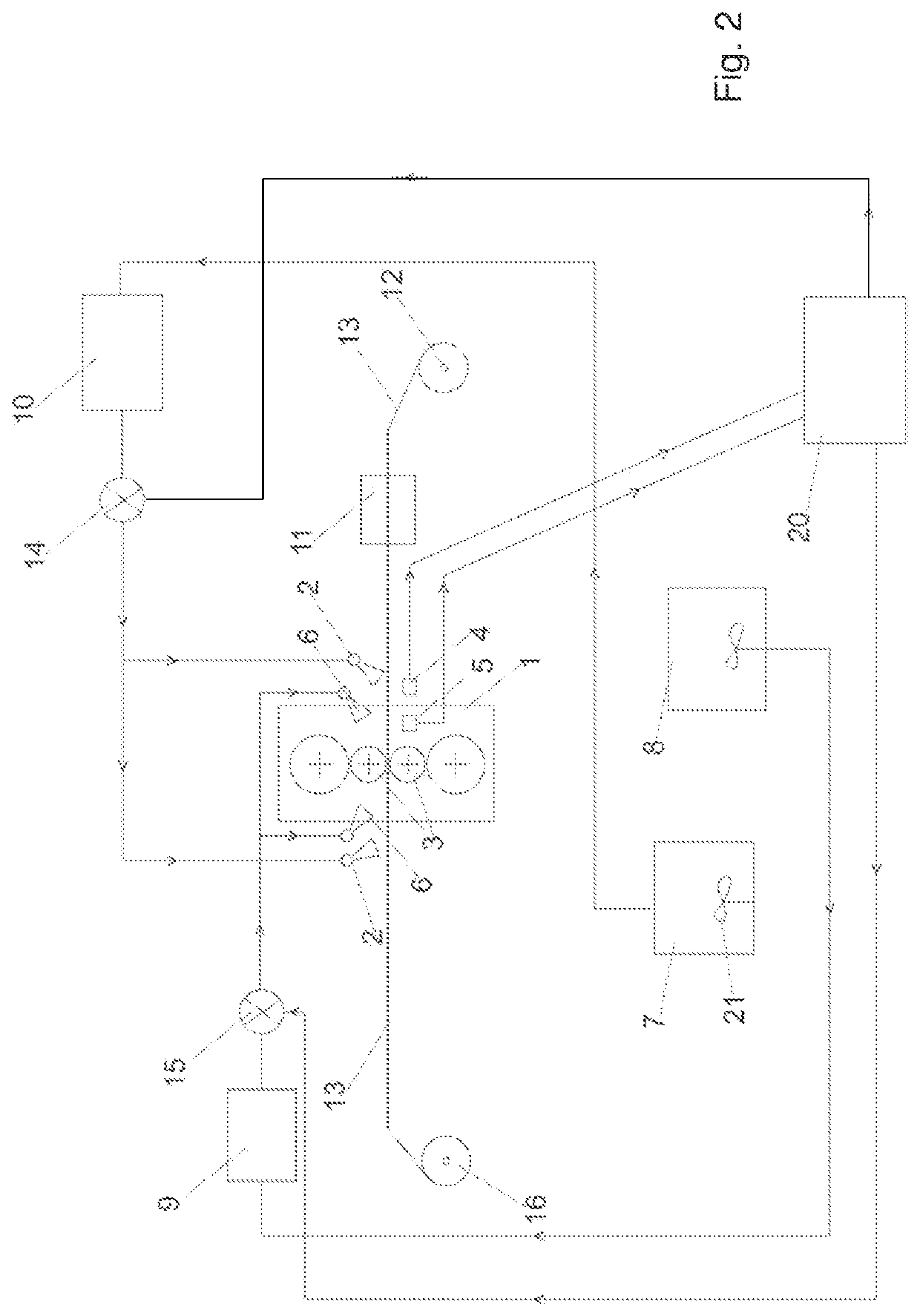

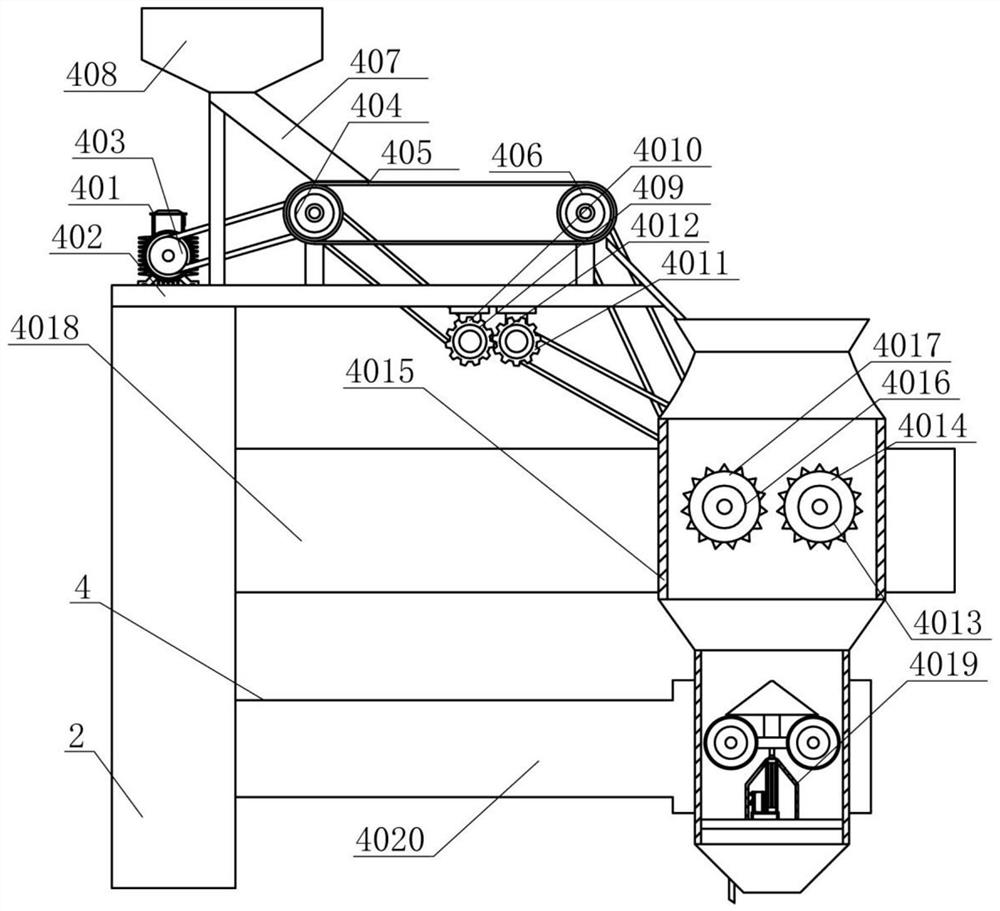

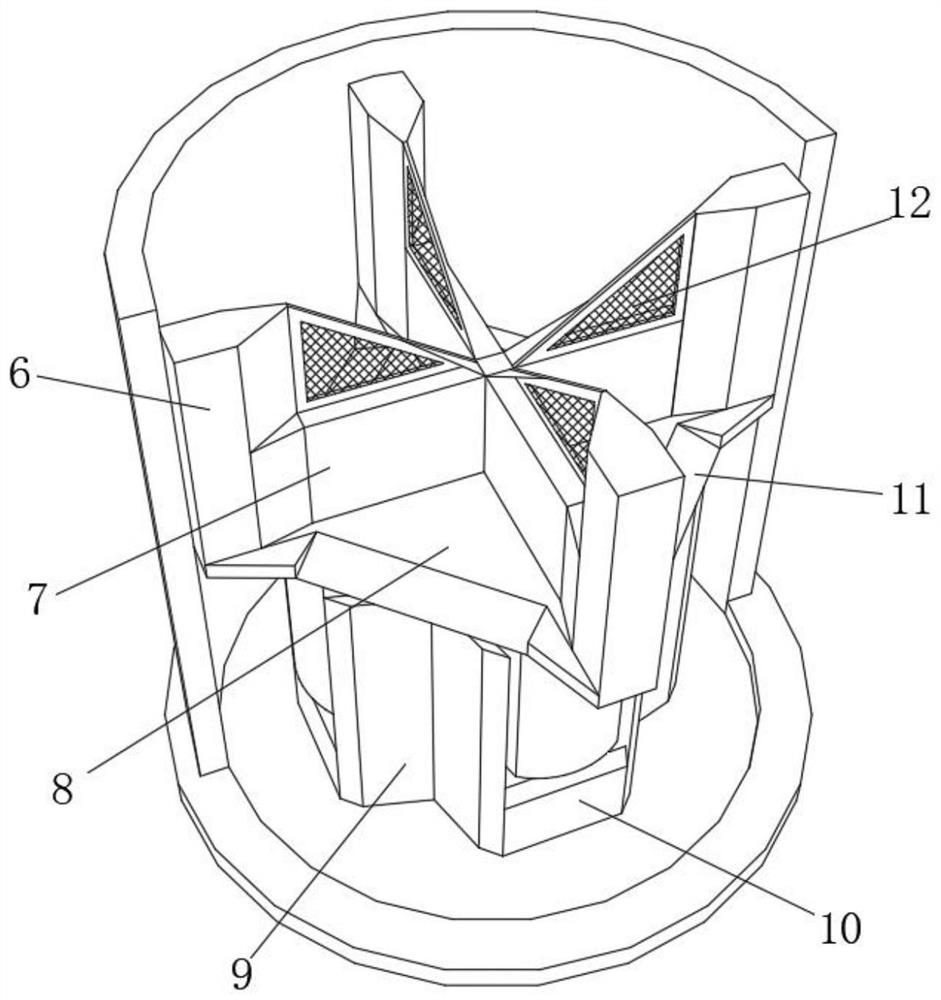

A cement roller press equipped with a new feeding device

The invention aims at providing a cement rolling machine with a novel feeding device and aims at achieving the technical purposes of efficient feeding and good material grinding. The cement rolling machine with the novel feeding device comprises a machine case, a spiral pushing mechanism, a rolling wheel mechanism and a uniform material mixing mechanism. The cement rolling machine with the novel feeding device has the beneficial effects that the sliding-down speed of materials in the upper feeding port can be promoted through the spiral pushing mechanism. Efficient material grinding can be achieved through the rolling wheel mechanism. A side leakage preventing plate mechanism can prevent the materials from laterally leaking from the two ends of a rolling wheel. By means of the uniform material mixing mechanism, the materials descending from the upper portion can be evenly mixed to the rolling wheel, the peripheral face of the rolling wheel evenly grinds the materials, and the situation that the local grinding face of the rolling wheel is excessively used, the using efficiency of other parts of grinding faces is low, and consequently the service life of the grinding wheel is shortened is prevented.

Owner:章丘华明水泥新型建材有限公司

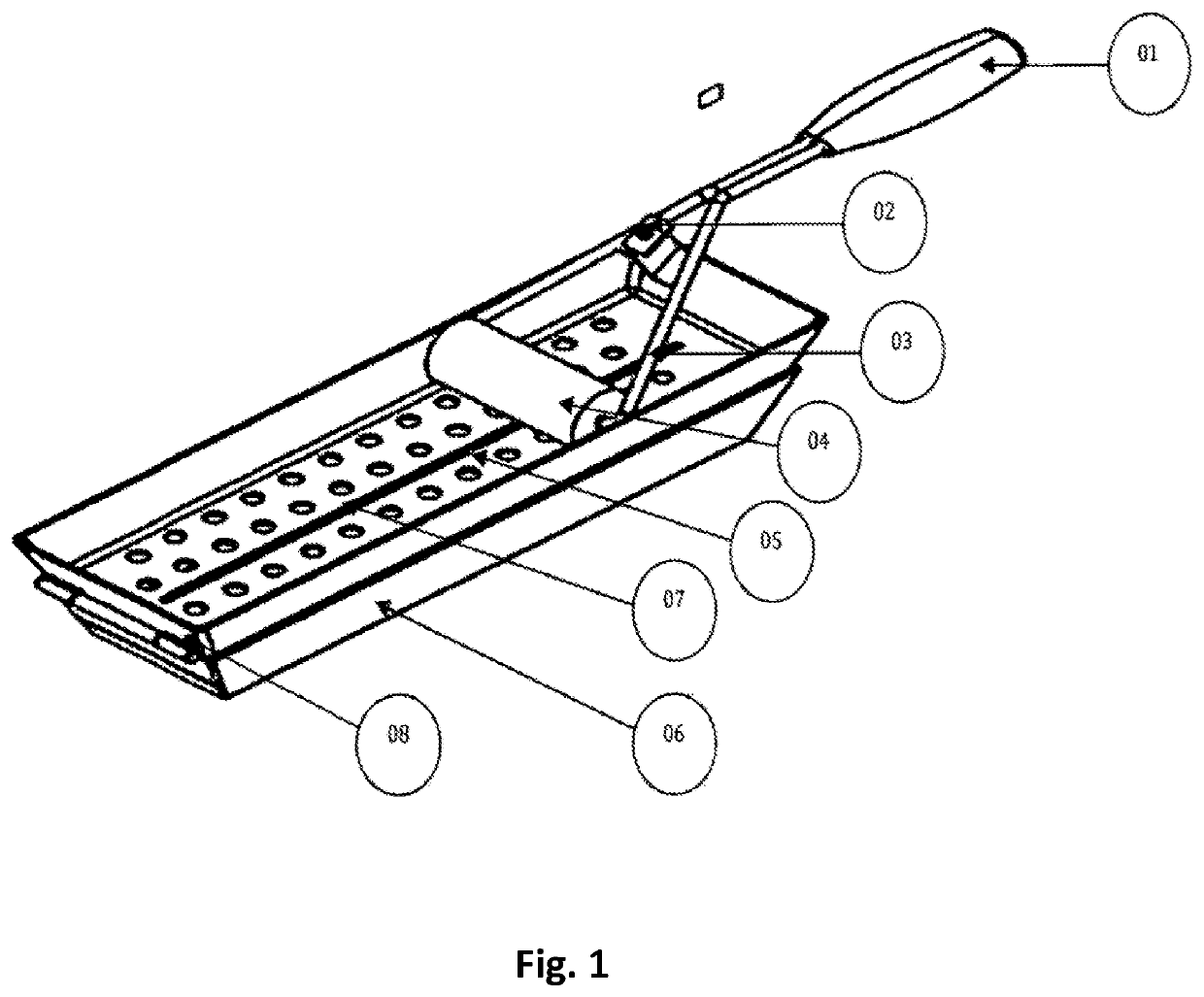

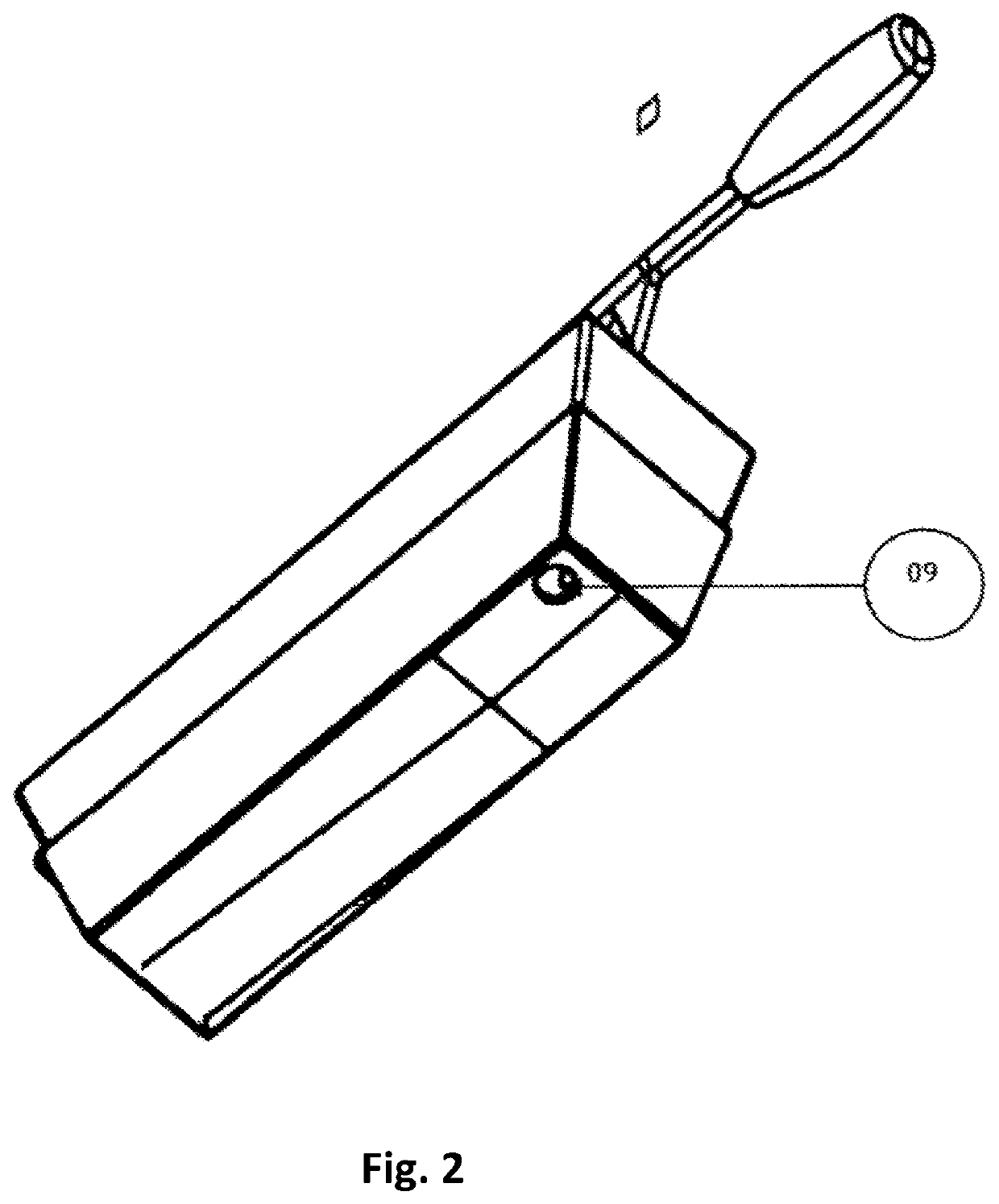

Hand-held apparatus for extracting contents of sachet/pouch

ActiveUS20210292031A1Avoid pollutionQuick extractionBags openingUnpacking by expelling contentsHand heldEngineering

A hand-held apparatus for extracting the contents of a sachet / pouch is disclosed. The hand-held apparatus includes a roller press assembly and a roller glider cum collection bin being disposed below the roller press assembly. The roller press assembly further includes a handle, a detachable frame coupled to a handle and a clamp. The detachable frame is provided with a roller for squeezing the contents of a sachet / pouch. The clamp is provided over the detachable frame and the clamp is coupled to a cutter for cutting the sachet / pouch. The roller glider cum collection bin includes a base for receiving the roller press assembly. The base includes a plurality of holes and a guide rail for providing a channel for the cutter. A collection bin is provided at the bottom of the base for collecting the contents of the sachet / pouch through the plurality of holes.

Owner:SINGH GURDEEP +4

A kind of method of rolling high-strength hard aluminum alloy

ActiveCN105107843BAchieve synergyPlay a synergistic roleMetal rolling arrangementsSingle passRolling speed

The invention relates to a novel method for rolling high-strength hard aluminum alloy. The method is characterized in that a strong magnetic field is applied when aluminum alloy is rolled, resistance to deformation of material can be reduced through the strong magnetic field, and the performance of deformation of material can be raised. Ultrathin and high-performance aluminum alloy can be produced through controlling intensity of magnetic induction of the strong magnetic field, the action time of the strong magnetic field, the rolling temperature, the rolling speed and proper reduction. The method is advantageous in that single pass reduction can be distinctly increased, the rolling efficiency of the high-strength hard aluminum alloy can be raised, the power consumption of a rolling mill is reduced, and the cost is saved. In addition, compared with a common rolling method, resistance to deformation of material is reduced, the grains are refined, the texture is uniformed, a part of the residual stress can be eliminated, defects caused by rolling can be reduced, and the yield during a rolling process can be raised by adopting the method to roll, so a thinner and better product can be achieved.

Owner:常州市凯宏铝业有限公司

Excavator

InactiveUS7048072B2Improve efficiencyDirt can be rolled efficientlyMechanical machines/dredgersSnow cleaningEngineeringExcavator

In an excavator, a blade surface for performing an earth removal operation while a blade is set in contact with the ground satisfies the following conditions: A) upward pushing force components Fu that push dirt upward along the blade surface are generated; B) an upper part of the blade surface has a release surface portion in which a forward-upward release force that rolls the dirt pushed upward by Fu forward is generated; C) when downward pressing force components Fd are generated in response to the generated release force, a total downward pressing force ΣFd> a total upward pushing force ΣFu; and D) if each Fu is given a positive value and if each Fd and a reduced amount of each Fu caused when the dirt hits the release surface portion are given negative values, a value of force at an endmost section of the release surface portion is positive.

Owner:KOBELCO CONSTR MASCH CO LTD

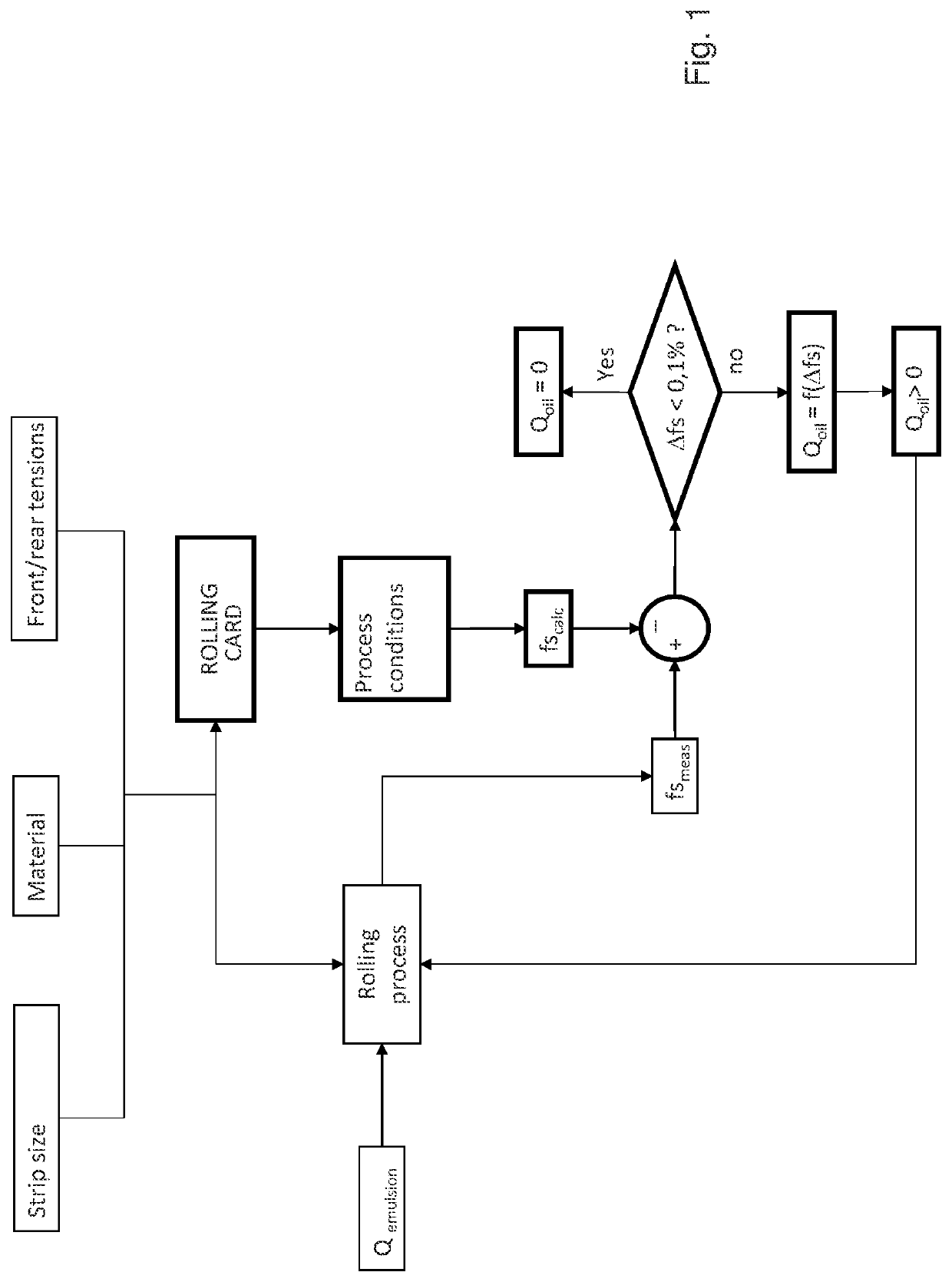

Process for cold rolling an aluminum product and related cold rolling plant

PendingUS20220184680A1Increase work safetyManagement be simplifyRollsMass flow control deviceManufacturing engineeringAluminium preparations

A process of cold rolling an aluminum product, e.g. a strip, which crosses at least one rolling stand, wherein a lubricant is applied to the strip close to said at least one rolling stand by means of a plurality of applying means, said lubricant comprising an emulsion of oil and water. A related rolling plant is also described.

Owner:DANIELI & C OFF MEC SPA

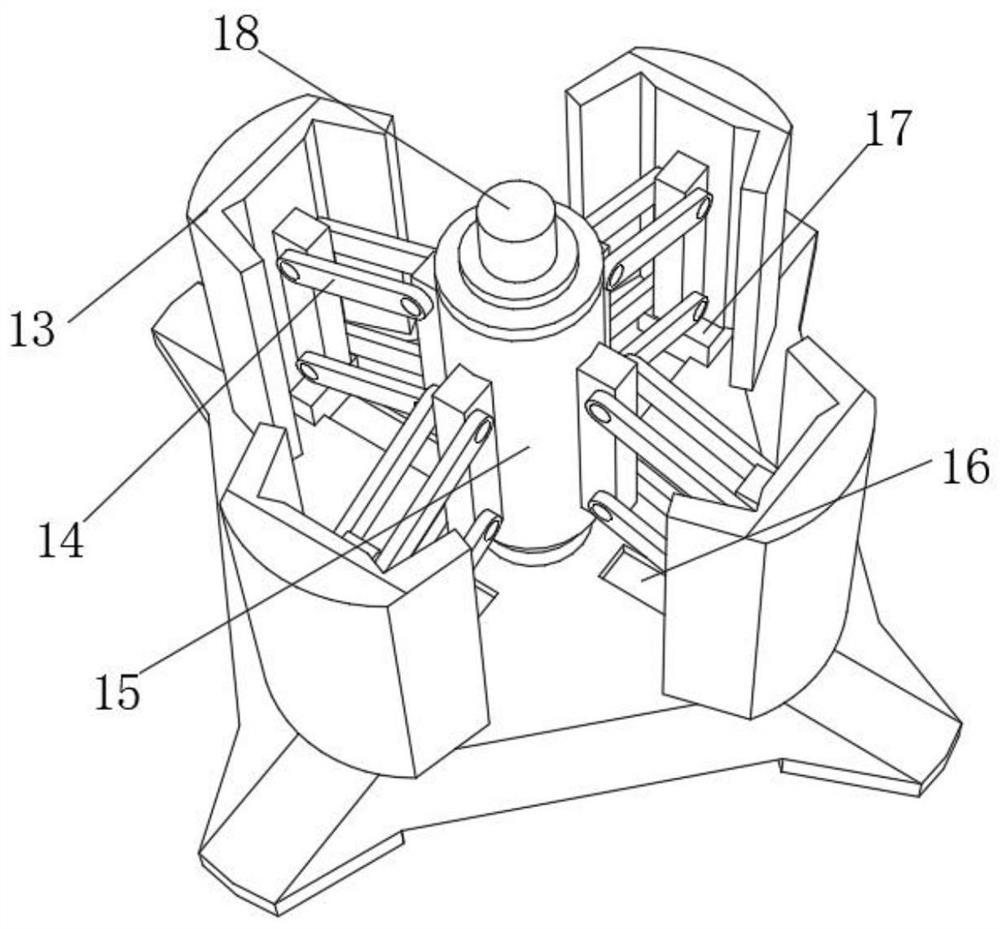

A diatomite treatment device for fireproof coating

The invention relates to a fireproof paint processing device, in particular to a diatomite processing device for fireproof paint. The technical problem to be solved by the present invention is to provide a diatomite treatment device for fireproof coating. A diatomite processing device for fireproof coatings, including a main supporting foot, a diatomite block crushing mechanism, an electromagnetic disk magnetic separation mechanism, a rolling powder mechanism, a paint mixing and filtering mechanism, a right frame and a supporting right bottom plate, etc. ; The top of the supporting main foot is welded to the left connecting frame; a real-time control screen is set at the bottom of the left end of the left connecting frame. The invention realizes the transformation of diatomite block from soil block to soil particle, and separates the iron oxide impurities contained in it through magnetic separation to obtain diatomite particles without heterochromatic impurities, and efficiently rolls diatomite particles , to obtain diatomite powder mixed with liquid paint and filtered to obtain the effect of fine liquid raw materials for fire retardant paint.

Owner:山东常安消防科技有限公司

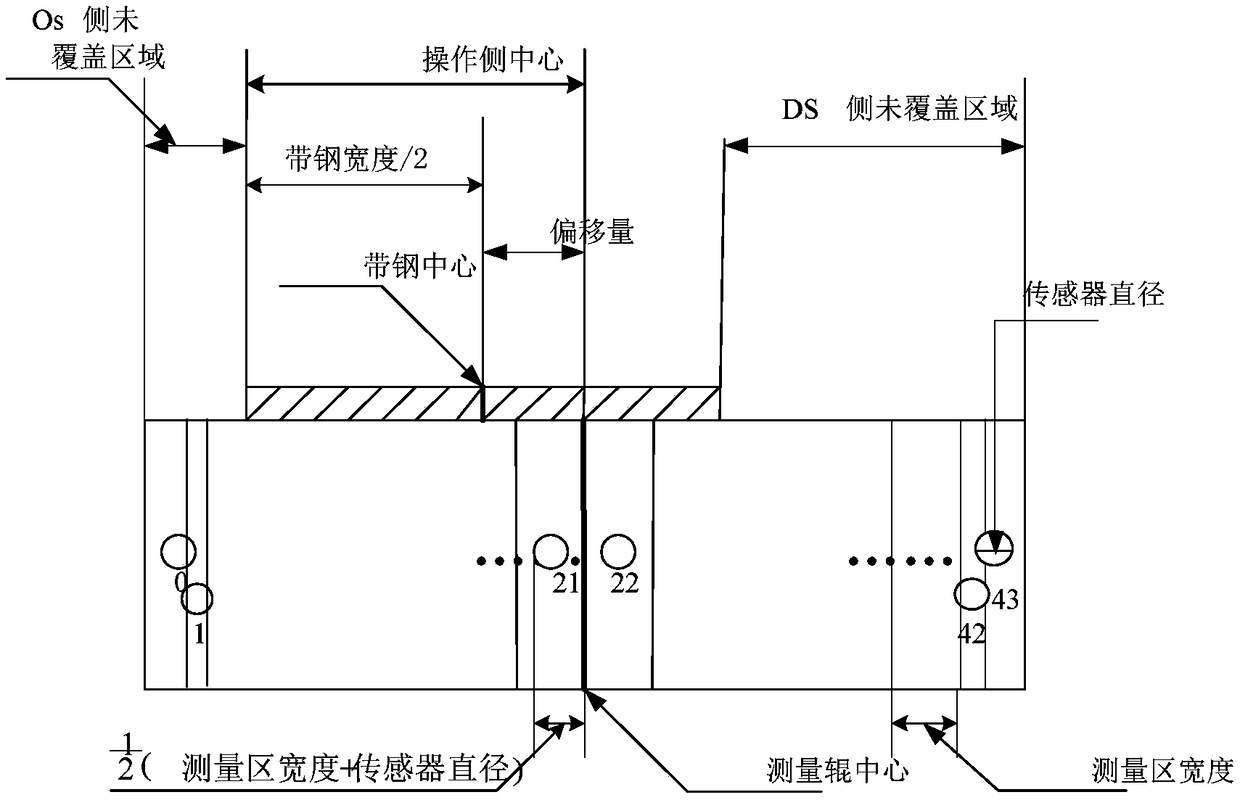

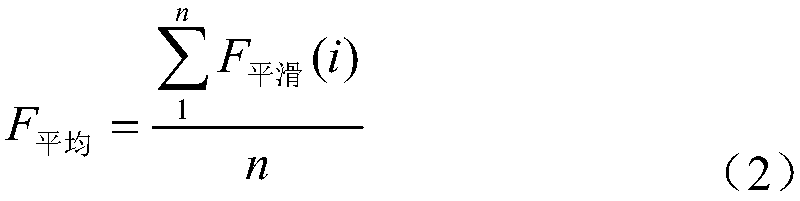

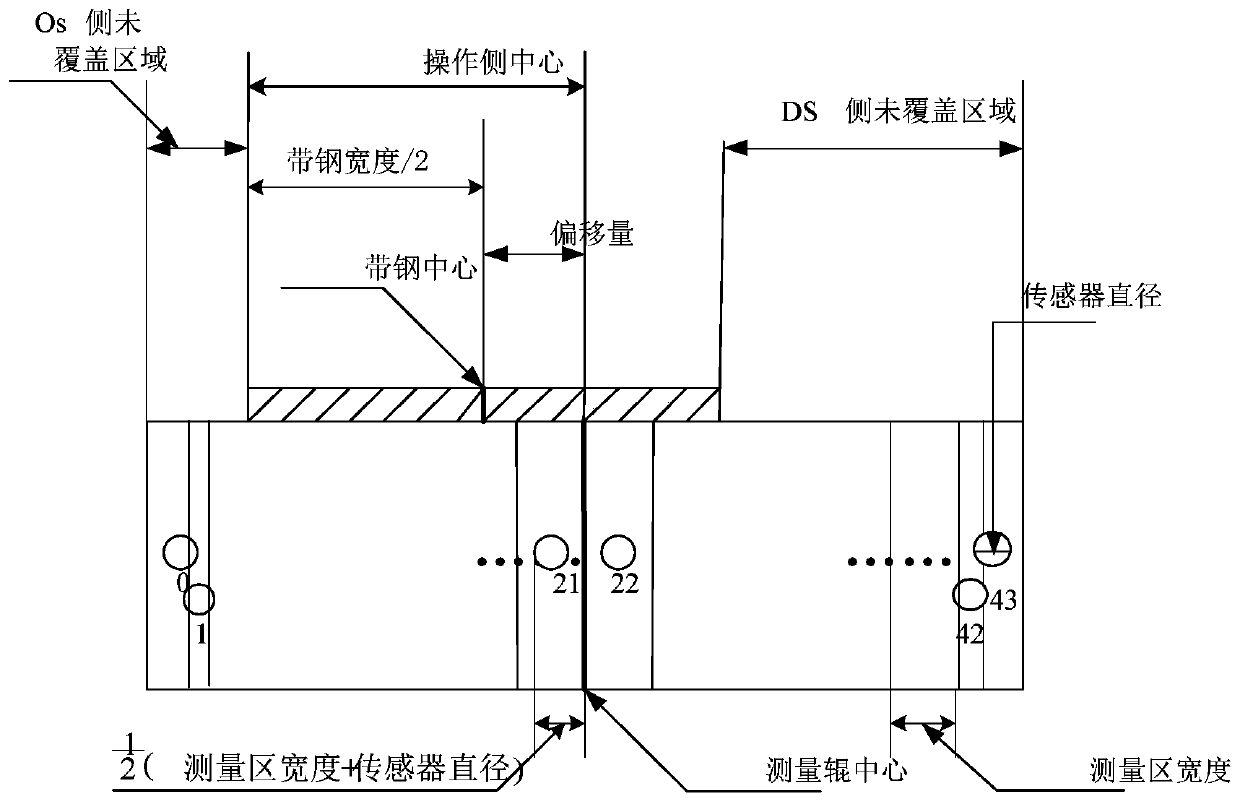

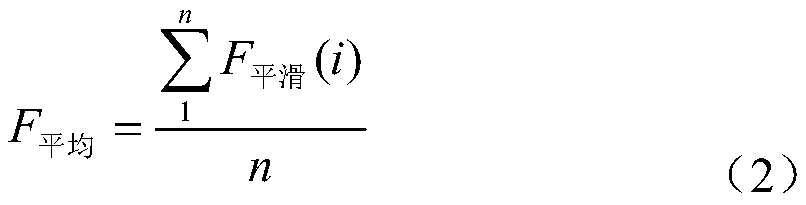

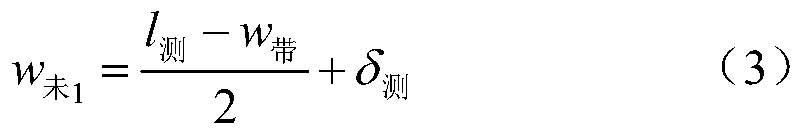

Algorithm for determining offsets of strip steel by utilizing contact type strip-shaped rolls

ActiveCN108804831AQuality improvementEfficient rollingDesign optimisation/simulationSpecial data processing applicationsComputer moduleStrip steel

The invention provides an algorithm for determining offsets of strip steel by utilizing contact type strip-shaped rolls. The algorithm comprises the following steps of: mounting a contact type plate-shaped roll at the outlet of a cold strip rolling mill, comparing radial force detected by the contact type plate-shaped roll with radial force between two adjacent segments F (i), determining a stripsteel edge area and determining sizes of areas not covered by the strip steel on a transmission side and an operation side; and calculating a different between offsets of the strip steel on the transmission side and the operation side through the sizes of the areas not covered by the strip steel on the transmission side and the operation side. According to the algorithm, the offsets of strip steeldetermined through plate-shaped rolls directly enter a plate shape control module so as to control the plate shape quality of products, so that technical requirements of different processing units after cold rolling are adapted, and the plate shape comprehensive technology optimization of the whole cold rolling production process is realized.

Owner:ANGANG STEEL CO LTD

Cloud-based hierarchical system preservation

ActiveUS9953038B2Improve the level ofEfficient and fast constructionDigital data information retrievalSpecial data processing applicationsCloud baseFile system

The efficient backing up of a hierarchical system in cloud blob storage. The hierarchical structure of the system as it existed at a prior instance in time is reconstructed. A change journal that represents changes in the file system that prior instant in time is then used to formulate an updated file system hierarchy as it exists at a second instant in time. An updated injected representation of the file system, and updated file system reversal information is then formulated and provided to cloud blob storage. The injected representation of the file system is a one-to-one function of the content of the file system, in that the reversal information can be used to recover the content of the file system. Injected representations of various nodes in the system hierarchy may also be remotely stored.

Owner:MICROSOFT TECH LICENSING LLC

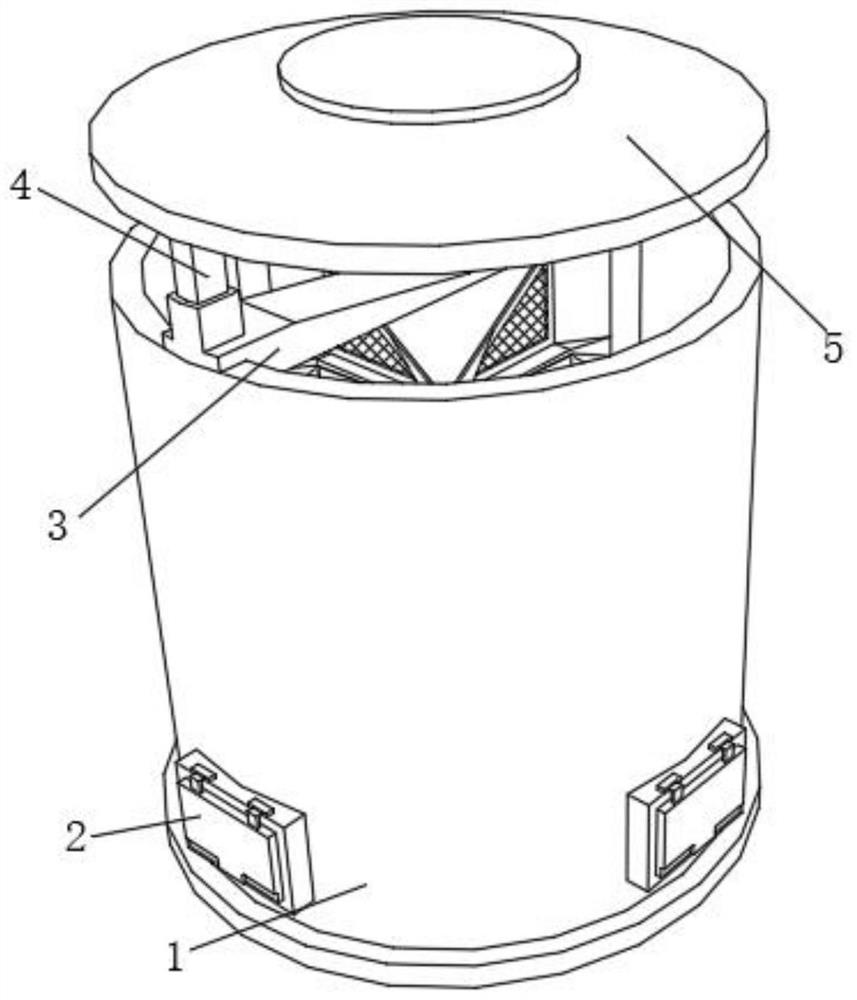

A kind of intelligent trash can convenient for dry and wet separation and using method thereof

ActiveCN113479513BAvoid enteringEffective barrierRefuse receptaclesPressesAgricultural engineeringStructural engineering

Owner:安徽一鸣塑胶股份有限公司

An Algorithm for Determining the Offset of Strip Using Contact Shape Roller

ActiveCN108804831BQuality improvementEfficient rollingDesign optimisation/simulationSpecial data processing applicationsAlgorithmStructural engineering

Owner:ANGANG STEEL CO LTD

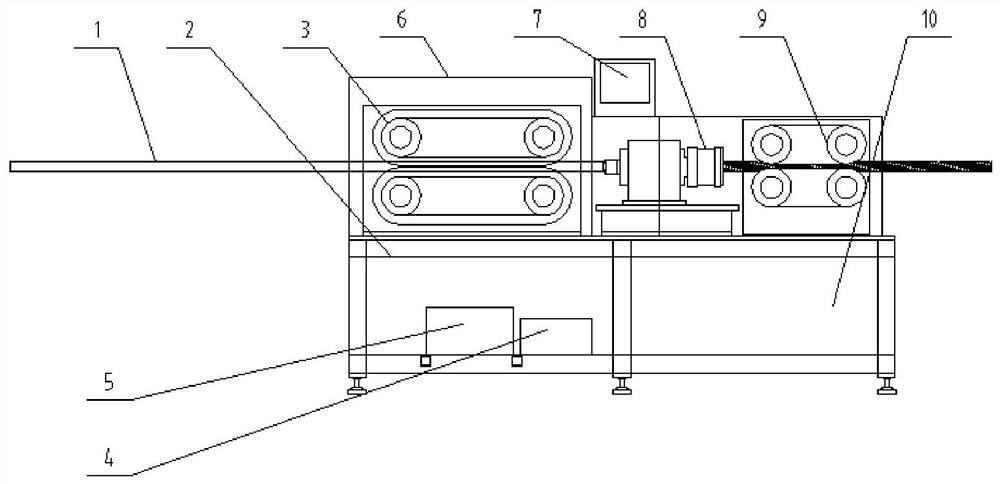

Rolling forming machine for seamless thin-wall corrugated pipe with fixed size and length

ActiveCN112091027AEfficient rollingImprove molding efficiencyShaping toolsControl systemMolding machine

The invention relates to a rolling forming machine for a seamless thin-wall corrugated pipe with fixed size and length. The rolling forming machine for the seamless thin-wall corrugated pipe with fixed size and length comprises a rack, a traction mechanism, a forming mechanism, a discharging mechanism, an oil tank, a lubricating tank and a central control system. According to the rolling forming machine for the seamless thin-wall corrugated pipe with fixed size and length provided by the invention, a plurality of preset matrixes are preset in the central control system, and after a user inputsvarious parameters of a steel pipe to be machined, retrieval, calculation and comparison are conducted according to parameter information, so that the gap and the feeding speed of the traction mechanism, the rolling pressure of the forming mechanism, the oil spraying amount of a lubricating spray head and the gap and the feeding speed of the discharging mechanism are adjusted to corresponding values for the pipe to be machined. Therefore, the forming machine can effectively and efficiently roll pipes with different sizes and different materials, and the forming efficiency of the forming machine is improved.

Owner:AEROSUN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com