Method for rolling high-strength hard aluminum alloy

An aluminum alloy and tough technology, applied in the field of rolling high-strength aluminum alloys, can solve the problems of high rolling power consumption, inability to achieve ultra-thin, and prone to cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

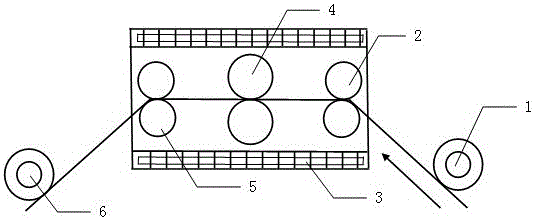

[0023] Example 1: Heat a 230mm thick 7055 aluminum alloy plate to 550°C and enter it into a rolling mill with a magnetic field. Rolling is carried out by rolling roller 4, and the rolling method is shown in Table 1. After obtaining a plate with a predetermined thickness, the aluminum alloy material passes through the rear guide 5, and then is coiled with a reel 6; another group of 7055 aluminum alloy rolling process Turn off the magnetic field and adopt the same rolling method to obtain the product; the equipment voltage is 380V, the frequency is 50Hz, the roll diameter is 0.5m, the lubrication conditions are the same, and all adopt oil cooling; according to the roll diameter, rolling mill power design and rolling temperature, reduction The rolling rate that matches the volume and magnetic induction intensity, the overall rolling method is as follows:

[0024] Table 17055 Aluminum alloy rolling method example

[0025]

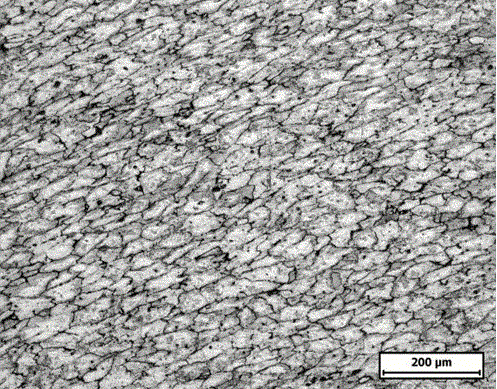

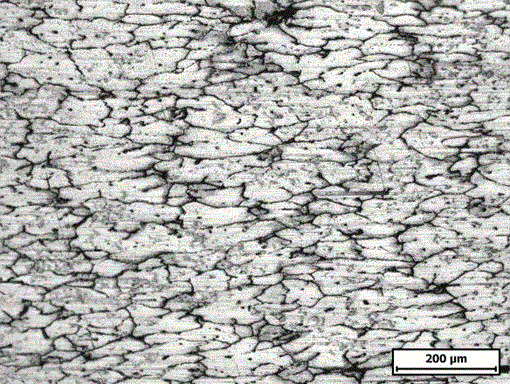

[0026] After applying a magnetic field, the final thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com