AMOLED display panel and preparation method thereof

A technology for display panels and substrates, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of screen brightness uniformity deterioration and brightness decline, achieve high transmittance, and ensure light output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] method one:

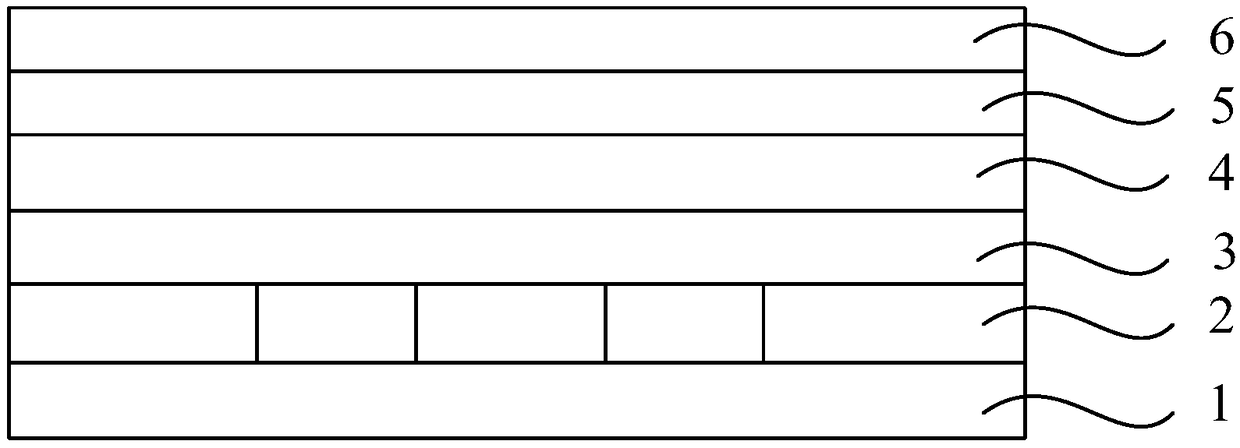

[0034] Such as figure 1 As shown, a luminescent layer 2, a cathode layer 3, a transparent conductive film layer 4, a polarizer 5 and a protective layer 6 are sequentially arranged on the base substrate 1, wherein the transparent conductive film layer 4 is directly formed on the cathode layer 3 and the cathode layer 3 Electrically connected to achieve the effect of reducing the resistance of the cathode layer 3.

[0035] Method 2:

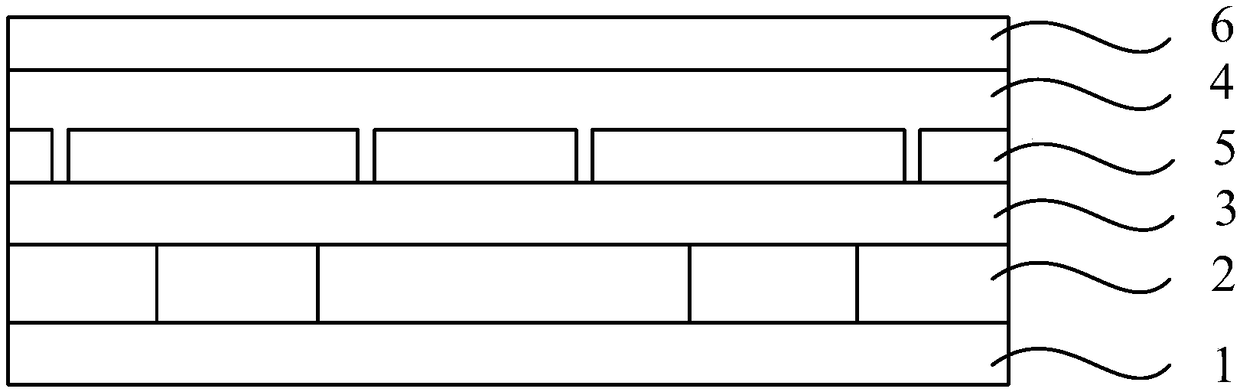

[0036] Such as figure 2 As shown, a light-emitting layer 2, a cathode layer 3, a polarizer 5, a transparent conductive film layer 4, and a protective film layer are sequentially arranged on the substrate 1, and a plurality of via holes are formed on the polarizer 5, and the transparent cathode layer 3 passes through the via holes. It is electrically connected to the cathode layer 3 , and the projection of the via hole on the base substrate 1 is located within the projection of the pixel definition layer on the base substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com