Centering-type anti-looseness bone nail for orthopedics surgery

An orthopaedic surgery and anti-loosening technology, applied in the field of bone nails, can solve problems such as alignment errors and unstable steel plate fixation, and achieve the effects of being beneficial to recovery, stable fixation, and not easy to loosen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

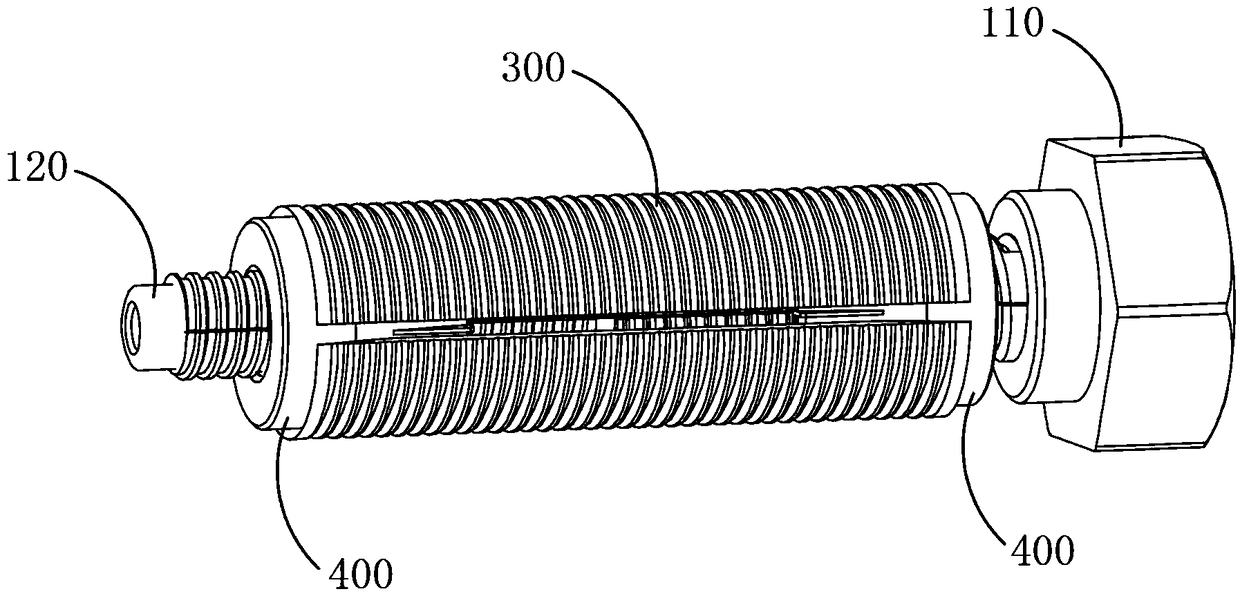

[0042] Such as Figure 7 As shown, the above-mentioned fixed section 200 includes a screw rod 240, and the screw rod 240 is a cylindrical structure arranged coaxially with the threaded rod 120. Distributed locking protrusions and the extension direction of the locking protrusions are parallel to the axial direction of the nail rod 240. A movable link is provided between the nail rod 240 and the smooth section of the threaded rod 120, and the nail rod 240 is connected through a flexible The piece is mounted on the smooth section of the threaded rod 120.

[0043] The center of the end face of the nail rod 240 away from the threaded rod 120 is provided with a mounting groove a, and the center of the end face of the nail rod 240 close to the threaded rod 120 is provided with a mounting groove b, the groove bottom of the mounting groove a, The center of the area between the groove bottoms of the installation groove b is provided with an installation hole a connected to the install...

no. 2 approach )

[0051] The difference between this embodiment and the first embodiment mainly lies in the structure of the fixing section 200 .

[0052] Such as Figure 8 As shown, the above-mentioned fixing section 200 includes a screw 210 and a nut 220 matched with the screw 210. The screw 210 is a cylindrical structure arranged coaxially with the threaded rod 120. The nut 220 is sleeved on the screw 210. Externally, a movable joint is provided between the screw rod 210 and the smooth section of the threaded rod 120 and the screw rod 210 is installed on the smooth section of the threaded rod 120 through the movable joint.

[0053] The center of the end face of the screw rod 210 away from the threaded rod 120 is provided with a mounting groove c, the center of the end face of the screw rod 210 close to the threaded rod 120 is provided with a mounting groove d, the bottom of the mounting groove a, the mounting groove The center of the area between the groove bottoms of b is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com