Vehicle automatic fire-extinguishing system by taking vehicle brake system air reservoir as power supply

An automatic fire extinguishing system and vehicle braking technology, which is applied in the field of vehicle fire protection, can solve the problems of environmental pollution, poor fire extinguishing effect, and inability to prevent recombustion, and achieve the effects of good sealing performance, convenient matching installation, and large safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

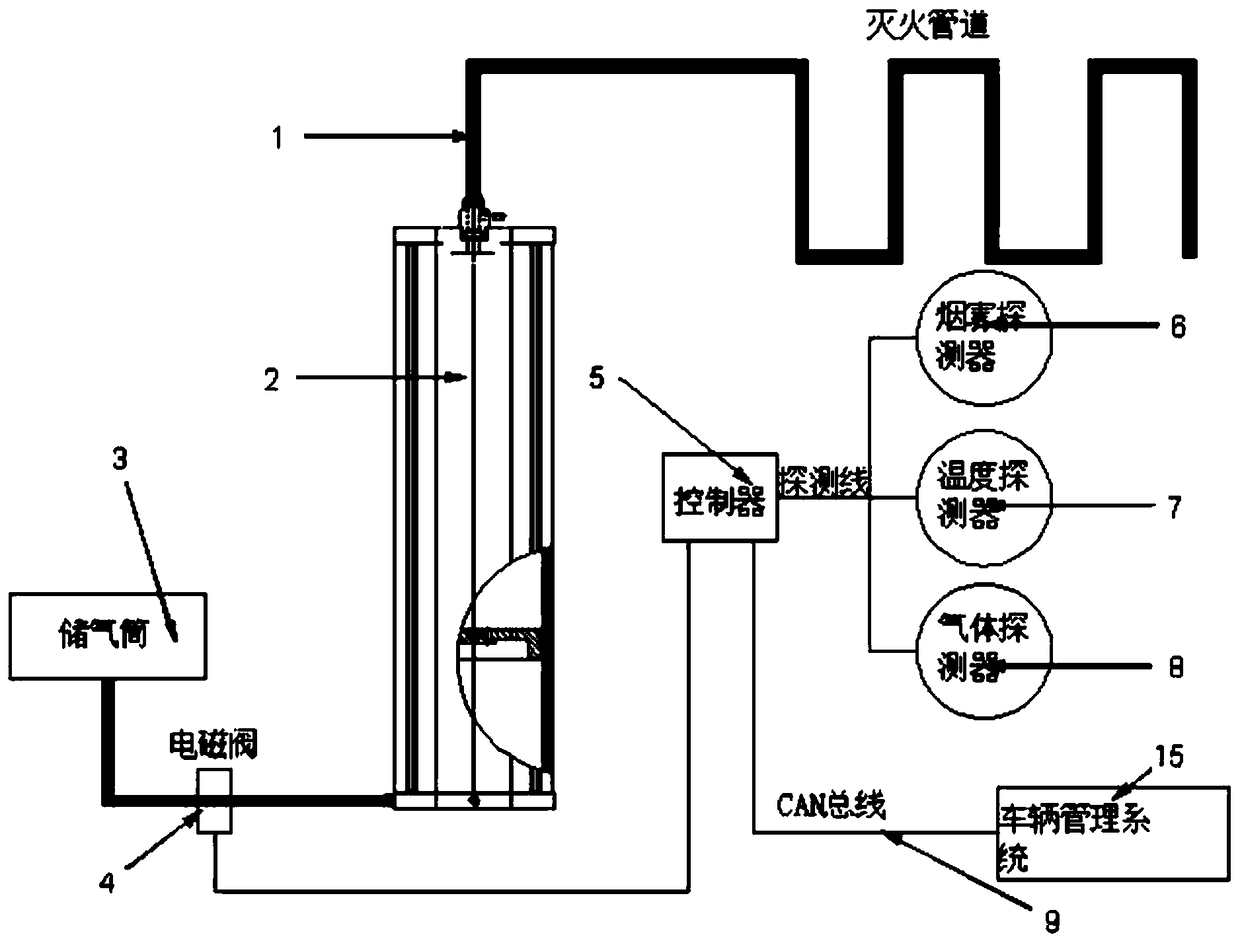

[0020] A vehicle automatic fire extinguishing system with the vehicle braking system air storage tank as the power source, see Figure 1-2 , including fire extinguishing pipeline 1, tank body 2, vehicle brake system air tank 3, solenoid valve 4, controller 5, smoke detector 6, temperature detector 7, gas detector 8, CAN bus 9;

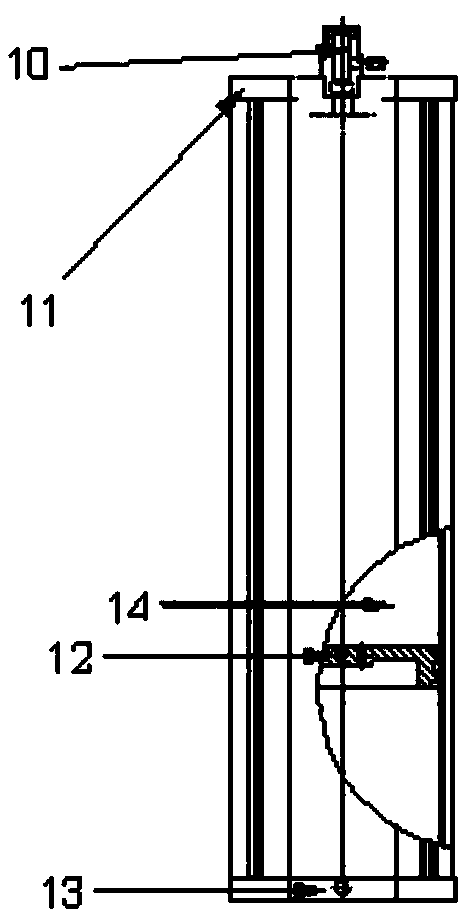

[0021] Specifically, an upper end cover 11 is installed on one end of the tank body 2, and a lower end cover 13 is installed on the other end; a piston 12 is movable inside the tank body 2; 4 connection (specifically: the tank body 2 and the vehicle brake system air storage tank 3 are connected by pipeline, and the pipeline is provided with a solenoid valve 4, which is a normally closed valve); the tank body between the piston 12 and the upper end cover 11 containing the medicament 14;

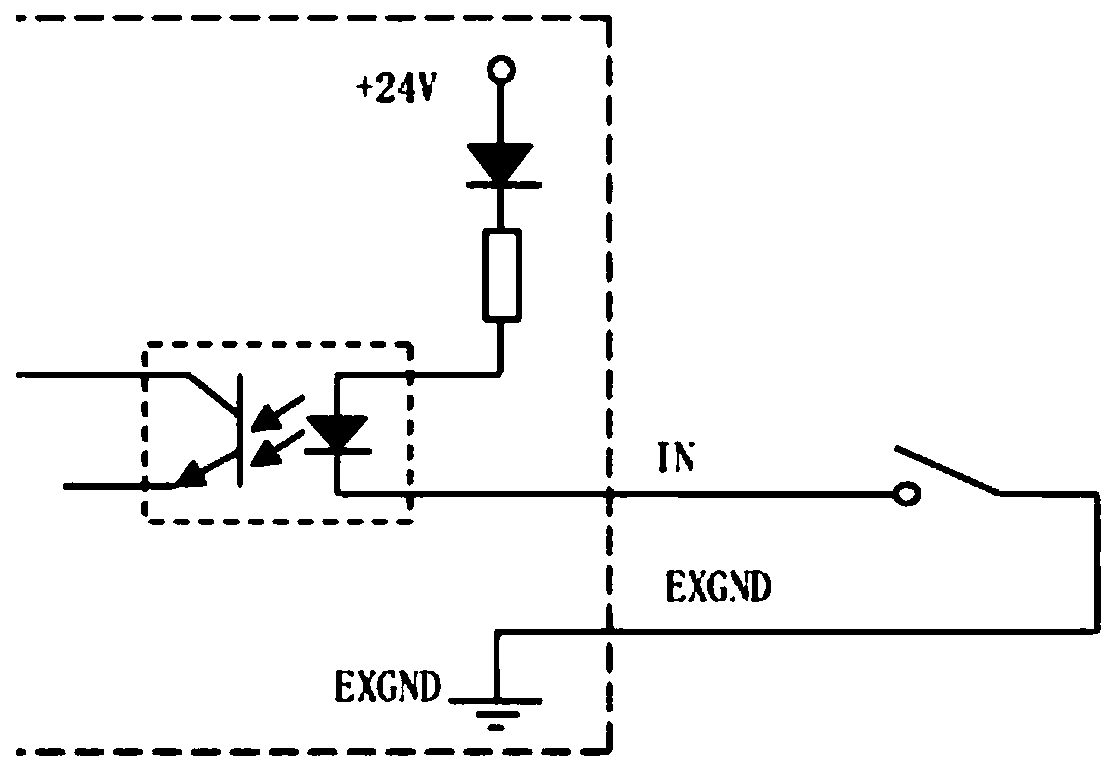

[0022] The control line of the solenoid valve 4 is connected to the controller 5; the controller 5 is respectively connected to the smoke detector 6, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com