Extrusion type conductive adhesive stirring box

A technology of conductive adhesive and stirring box, which is applied in the directions of dissolving, mixer, chemical instrument and method, etc., can solve the problems of affecting the performance of conductive adhesive, inability to achieve up and down convection stirring, uneven distribution of conductive molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

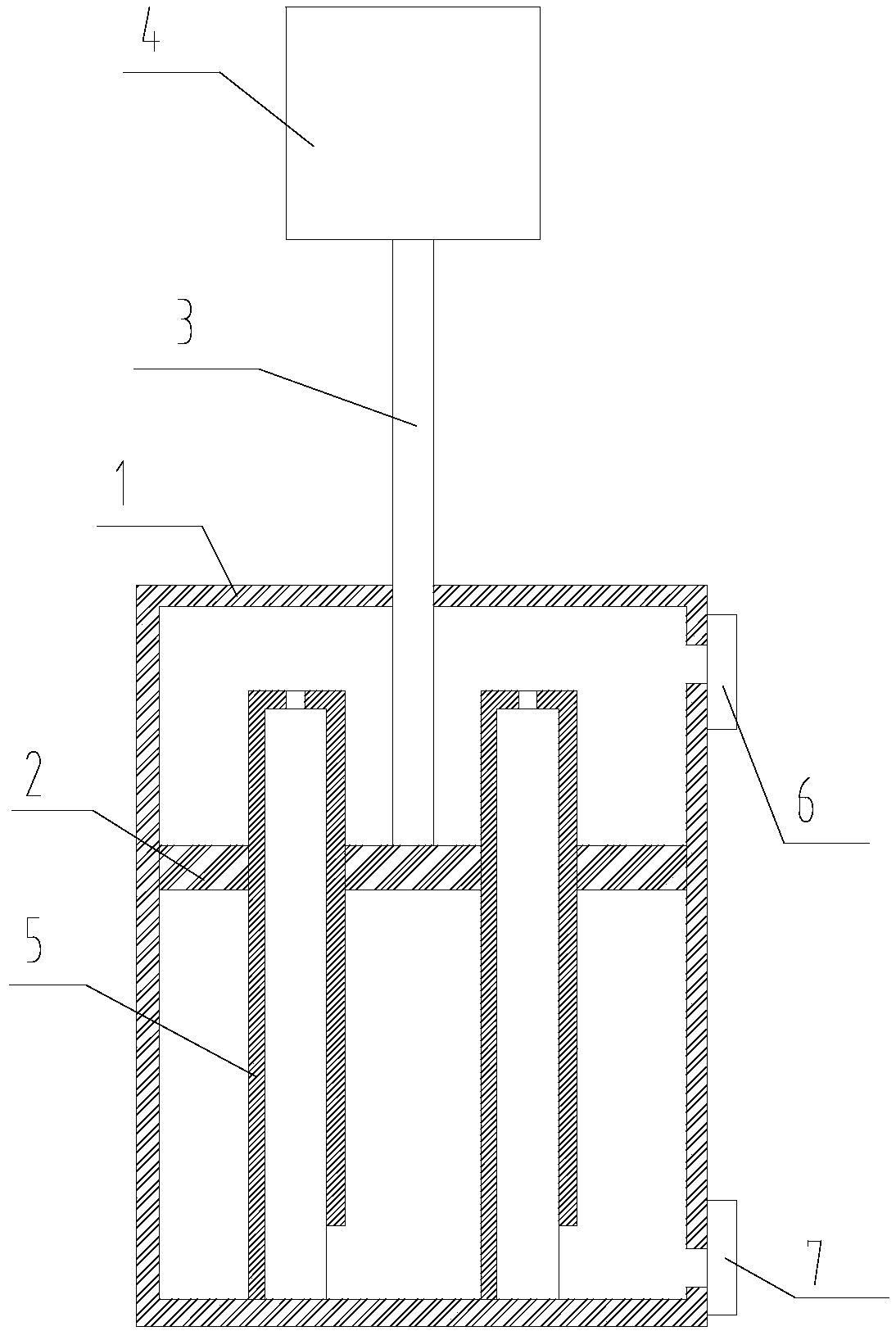

[0013] refer to figure 1 , the present invention proposes an extruded conductive adhesive mixing box, comprising: a box body 1, an extruded plate 2, a connecting shaft 3 and a cylinder 4.

[0014] A plurality of hollow cylinders 5 are installed vertically inside the box 1, and the bottom and top of the cylinders 5 are provided with through-hole structures. The extruding plate 2 is installed horizontally inside the box body 1, and a perforation is provided on the extruding plate 2 corresponding to each cylinder 5, and each cylinder 5 passes through the corresponding perforation. In this way, when the inside of the box body 1 is filled with conductive glue, during the downward movement of the squeeze plate 2, the squeeze plate 2 squeezes the conductive glue below it, rises through the cylinder body 5, and then transfers to the top of the squeeze plate 2; During the upward movement of the extruding plate 2 , the extruding plate extrudes the conductive glue above it and descends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com