Dumping mechanism of grinding device for cosmetics production

A technology for grinding devices and cosmetics, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of only one-time dumping, poor discharge control effect, and reduced processing effect, to prevent coagulation, prevent Formed into solid blocks, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

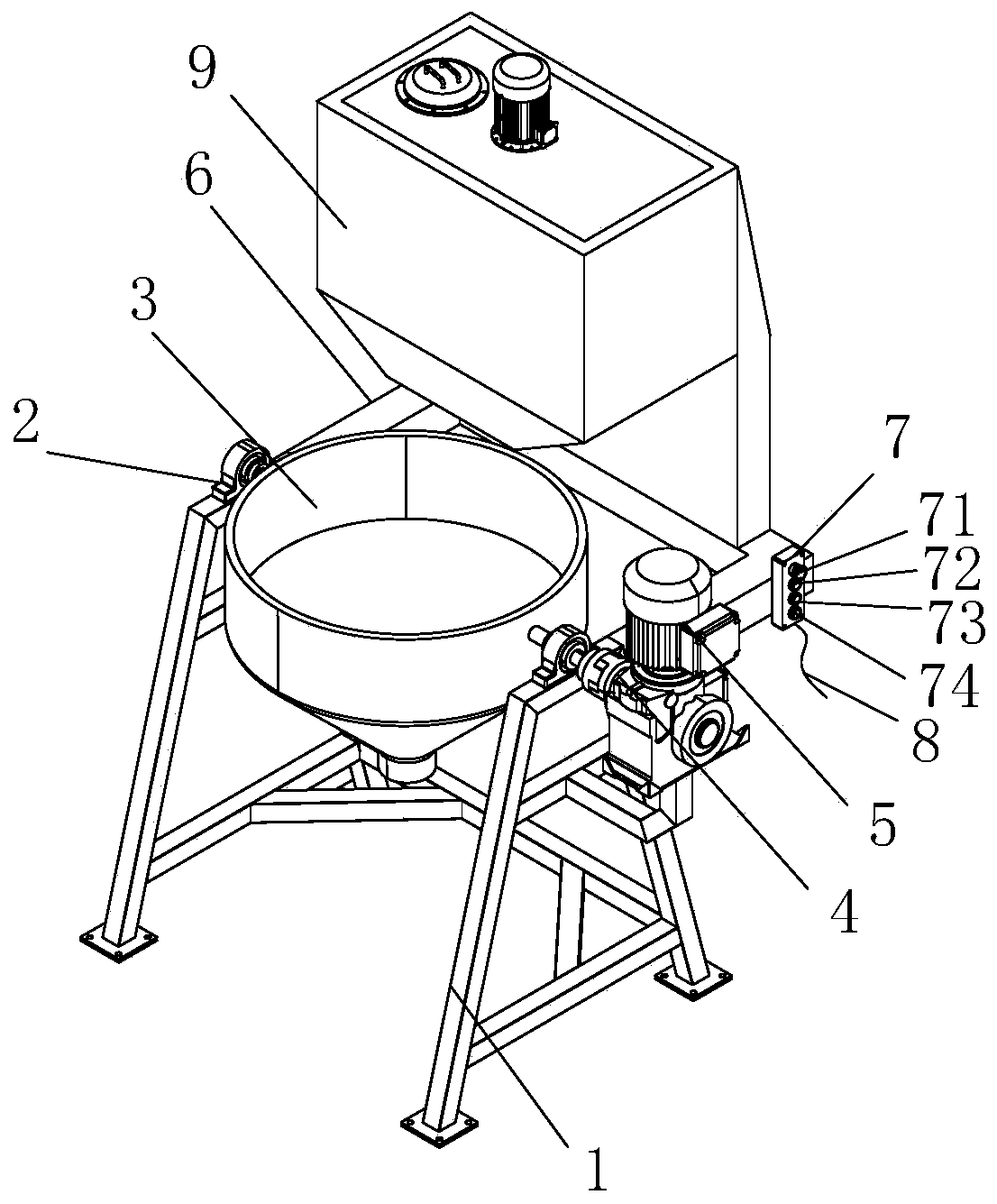

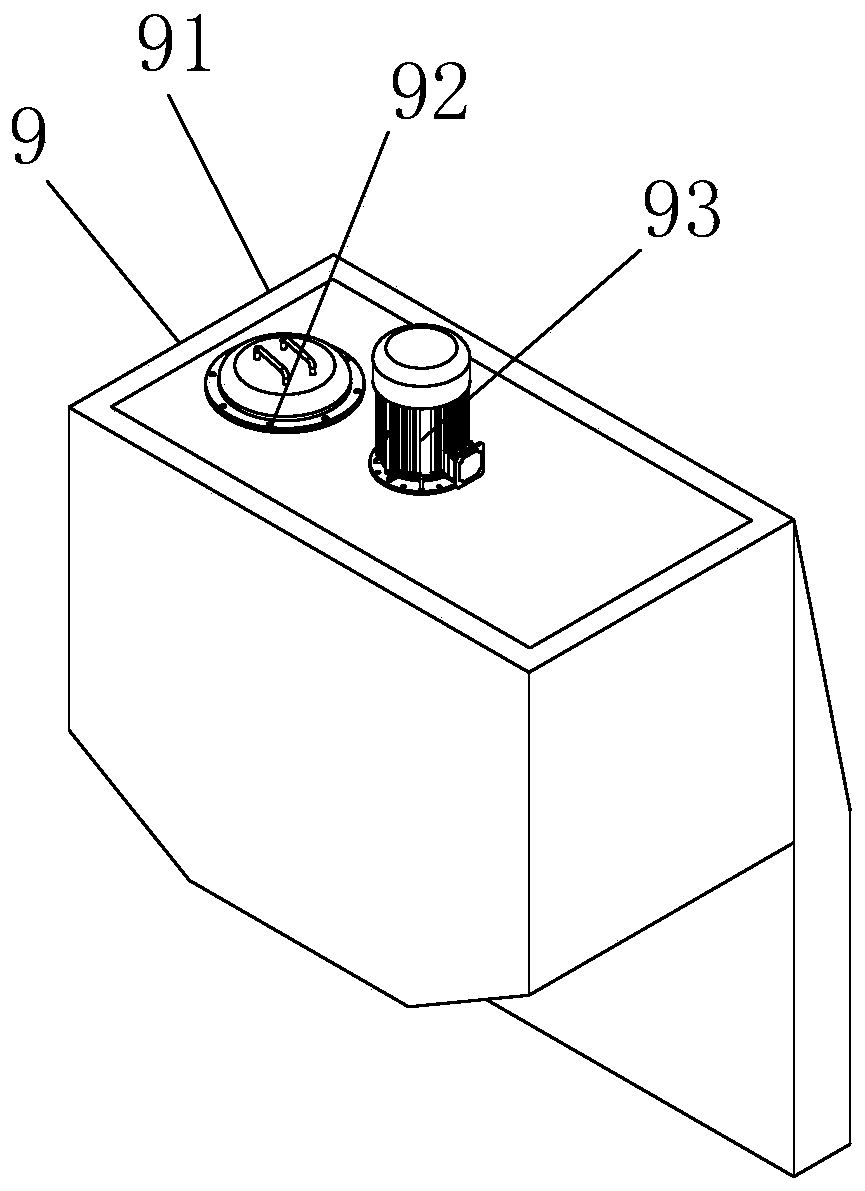

[0031] see figure 1 , the present invention provides a dumping mechanism of a grinding device for cosmetic production through improvement, including a shaft seat 2 fixed at the left and right ends of the top of the bracket 1, the inner side of the shaft seat 2 is rotatably connected with the dumping barrel 3, and the right side of the shaft seat 2 is decelerated The output shaft at the left end of the machine 4 runs through, the right side of the reducer 4 is connected with the first motor 5, the upper end of the back of the support 1 is welded and fixed with the back frame 6, and a controller 7 is installed at the rear end of the right side of the back frame 6, and the bottom of the controller 7 is provided with The power cord 8, the back end of the back frame 6 is provided with a pretreatment device 9, and the controller 7 includes an emergency stop button 71, a first switch 72, a second switch 73 and a third switch 74 which are sequentially installed on the front surface fro...

Embodiment 2

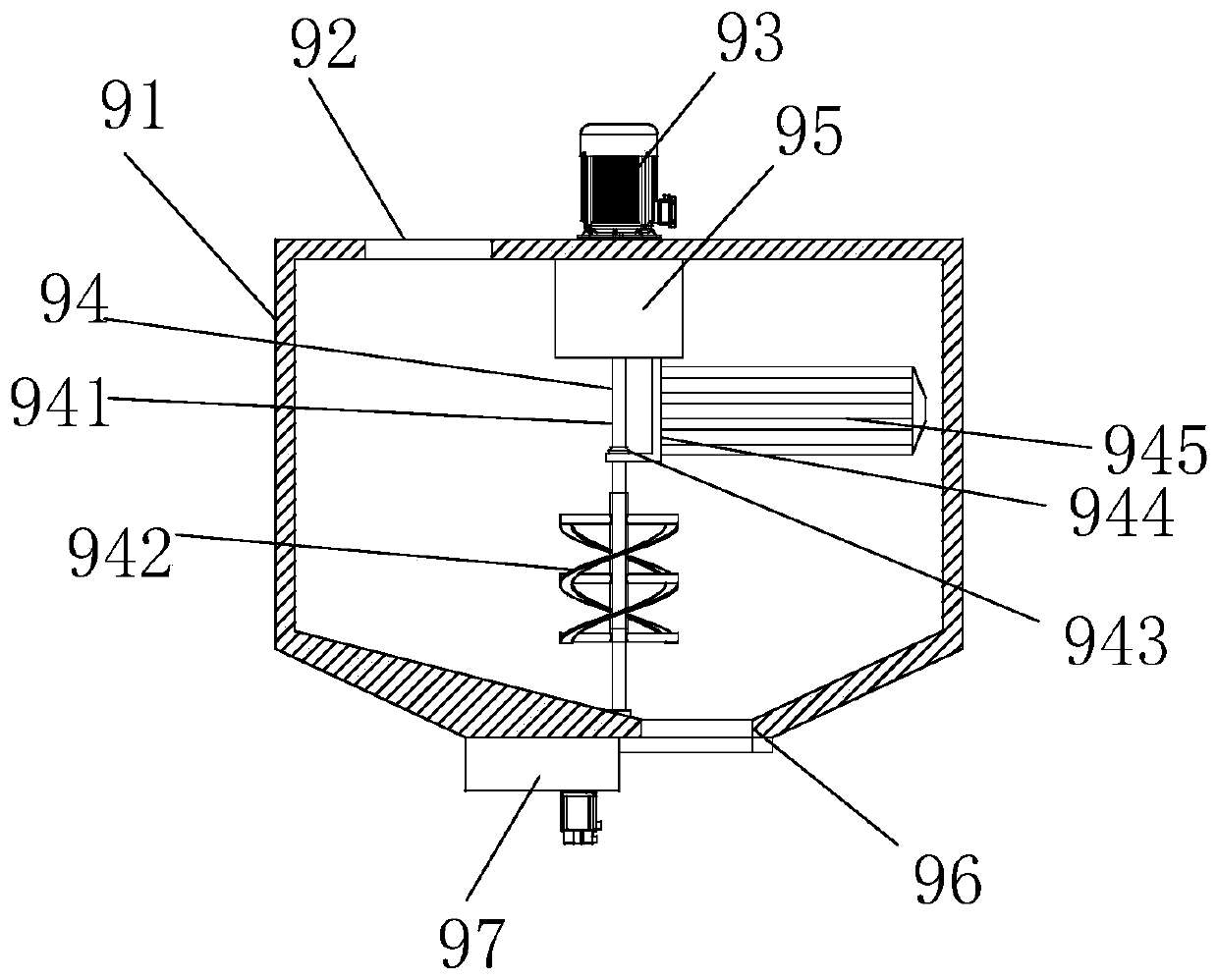

[0038] The present invention provides a dumping mechanism of a grinding device for cosmetics production through improvement. The left and right lower ends of the box body 91 are both inclined to the position of the discharge port 96, and the surface is smooth, which is convenient for discharging materials, with good effect and high efficiency. The right end of the bottom of the discharge port 96 is fixed with a carrier, and the left end of the carrier is provided with an arc-shaped chute, and the right side of the blocking plate 972 is movably embedded in the arc-shaped chute, so as to provide stability for the movement of the blocking plate 972; the second gear 955 is not driven by the upper connecting shaft 952, and the second gear 955 will not act on the connecting shaft 952 when the first gear 954 rotates, and only realizes autorotation.

[0039] The present invention provides a dumping mechanism of a grinding device for cosmetics production through improvement, and its wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com