Cavity-shaped separating structure for strong magnetic separation device

A technology of separation structure and strong magnetic separation, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., to achieve the effect of improving operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The cavity-shaped separation structure for the strong magnetic separation device of the present invention, its preferred embodiment is:

[0020] It includes an outer cylinder, two sorting cavities are arranged in the outer cylinder, a balance cavity is set between the two sorting cavities, a transition cavity is respectively set near the outer ends of the two sorting cavities, and five cavities are arranged in the The outer cylinders are installed by pressing each other, and the ends of the outer cylinders are provided with a material inlet and a material outlet;

[0021] Both ends of the balance chamber are provided with sealing plugs;

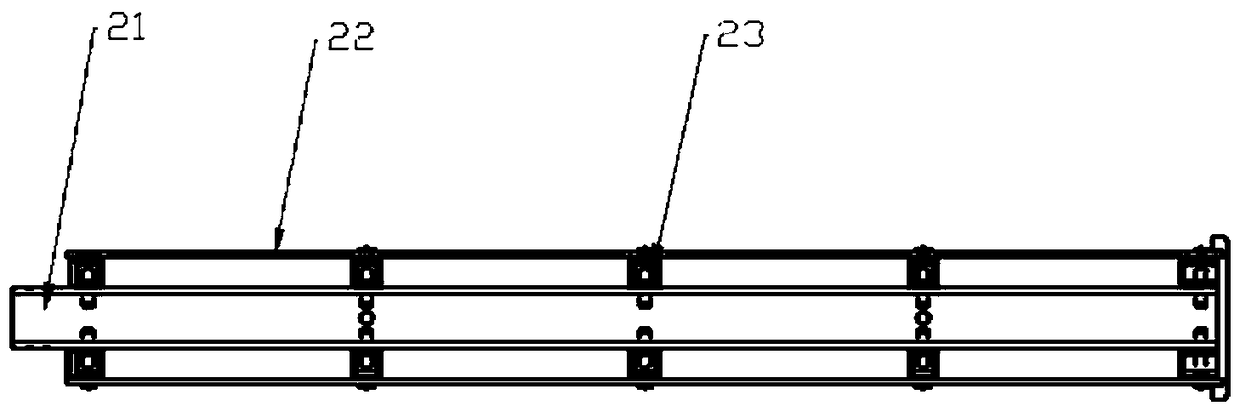

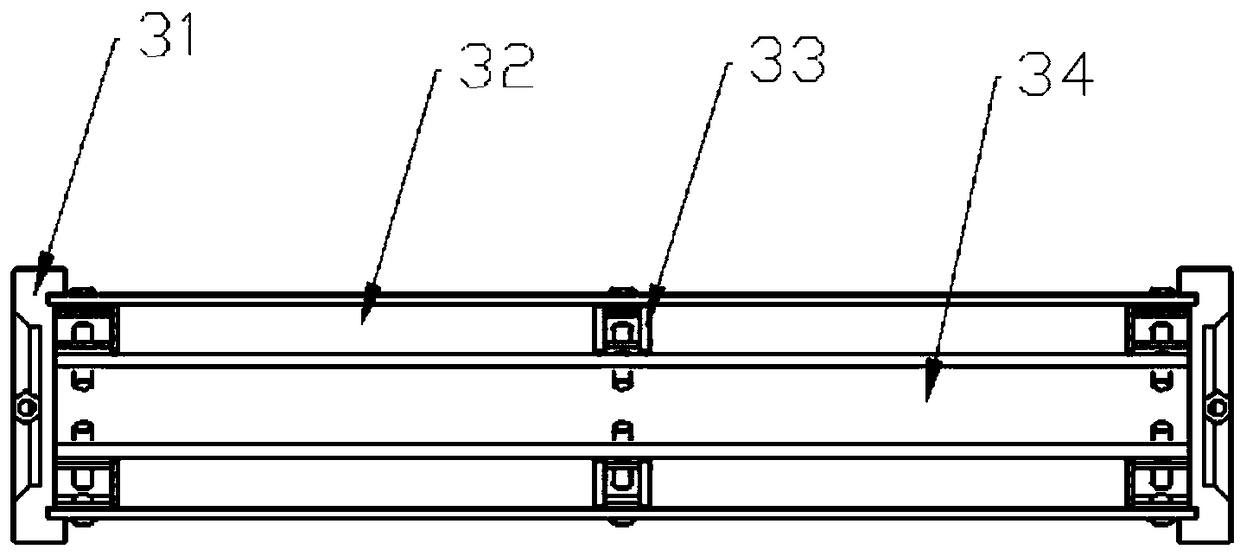

[0022] The transition chamber includes a transition chamber inner chamber and a transition chamber outer chamber, and the sorting chamber includes a sorting chamber inner chamber and a sorting chamber outer chamber, and the sorting chamber outer chamber and the transition chamber outer chamber are connected to the outer cylinder Annul...

specific Embodiment

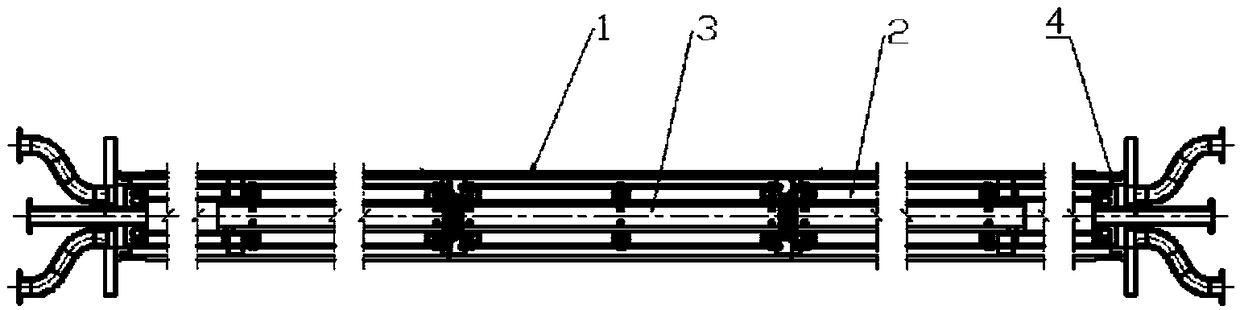

[0030] Such as figure 1 As shown, it is mainly composed of an outer cylinder 1, a separation chamber 2, a balance chamber 3, and a transition chamber 4, wherein the transition chamber 4, the separation chamber 2, and the balance chamber 3 are placed in the outer cylinder 1 in sequence.

[0031] The sorting slurry enters the transition inner cavity 43 through the feed port 42 of the transition cavity 4, and then enters the sorting inner cavity 21 of the sorting cavity 2, and passes through the gap between the sorting inner cavity 21 and the sorting outer cavity 22 under pressure. The non-magnetic material enters the annular passage between the sorting outer chamber 22 and the outer cylinder 1 through the separation basket 23, and then enters the discharge port 41 through the annular passage between the transition chamber outer chamber 44 and the outer cylinder 1 , so as to realize the separation of magnetic materials and non-magnetic materials. In order to increase the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com