A portable glass fillet opening device

A kind of inner fillet and portable technology, which is applied in the field of portable glass inner fillet opening device, can solve the problems of low work efficiency, affecting the safety of operators, and glass debris, etc., and achieves high cutting efficiency, strong safety protection, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

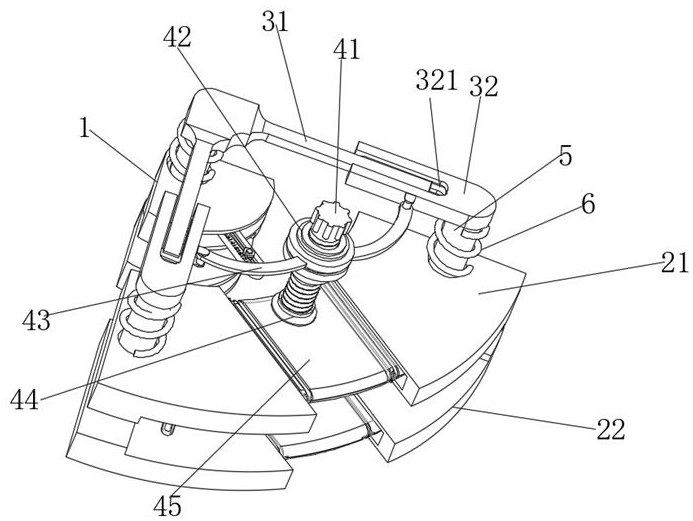

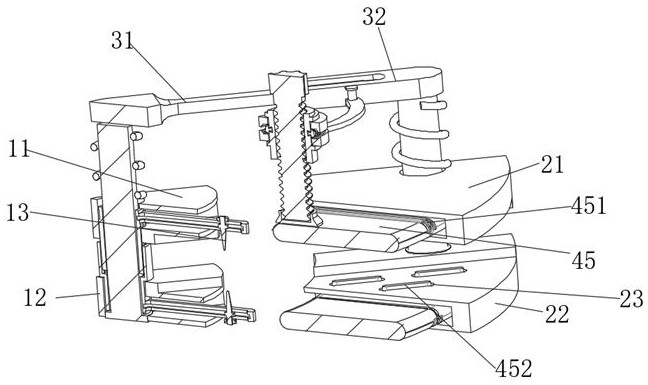

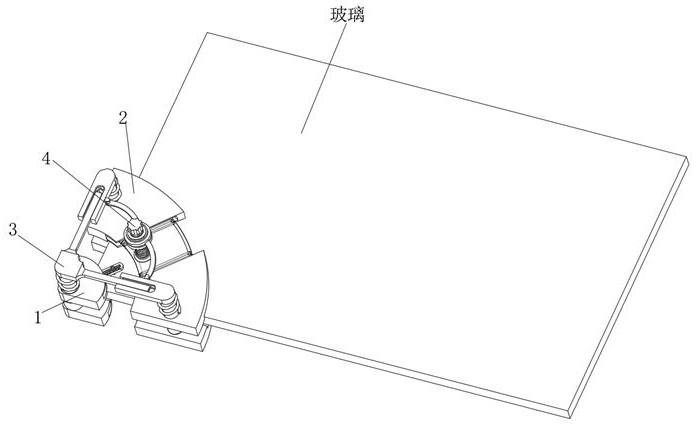

[0041] see Figure 1-10 , a portable glass fillet opening device, including a corner block fixing part 1, a side fixing part 2, a distance adjusting device 3 and a locking device 4, the corner block fixing part 1 includes an upper corner splint 11 and a lower corner splint 12, and the side The side fixing part 2 includes two sets of upper side splints 21 and lower side splints 22, the lower corner splints 12 and the lower side splints 22 are fixed with slide bars 5, the upper corner splints 11 and the upper side splints 21 are all slidably sleeved on the slide bars 5 On, the distance adjusting device 3 comprises a right-angle bar 31 and an adjustment seat 32, the right-angle bar 31 is fixed on the top of the slide bar 5 of the lower angle splint 12, the adjustment seat 32 is fixed on the top of the slide bar 5 of the lower side splint 22, and the adjustment seat 32 is provided with The two ends of the chute 321 and the right-angle rod 31 are provided with guide wheels 311 matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com