Girdling device for cable processing and with waste collection function

A waste collection and ring cutting technology, applied in recycling technology, electronic waste recycling, circuits, etc., can solve problems such as low efficiency and labor consumption, and achieve the effect of ensuring efficiency, improving efficiency and quality, and convenient and efficient cutting operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

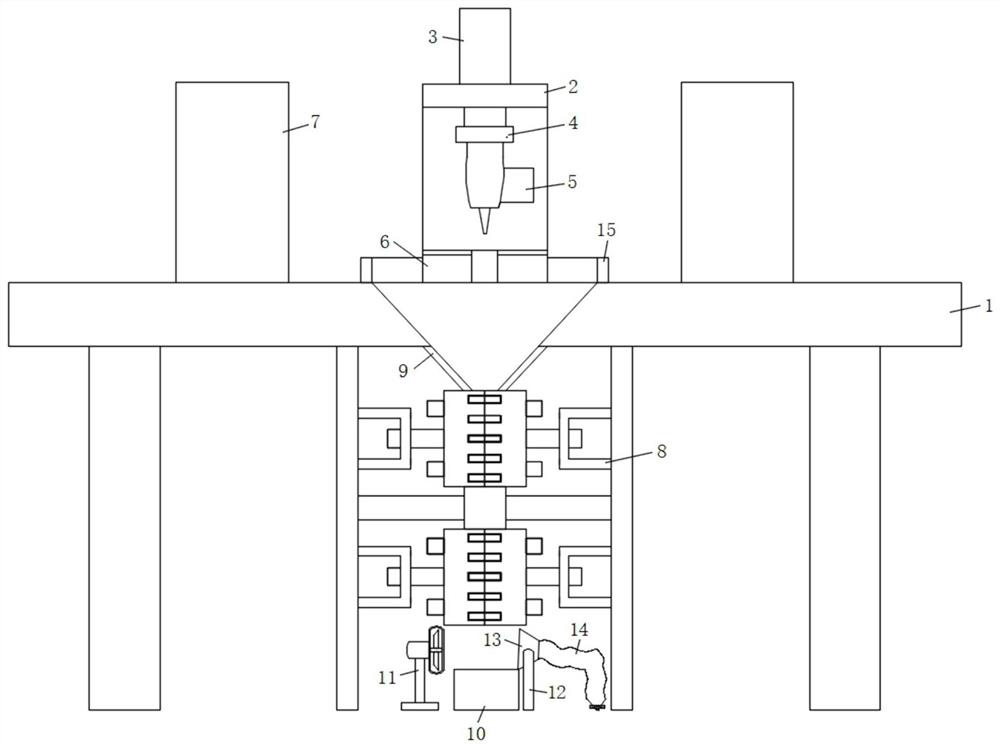

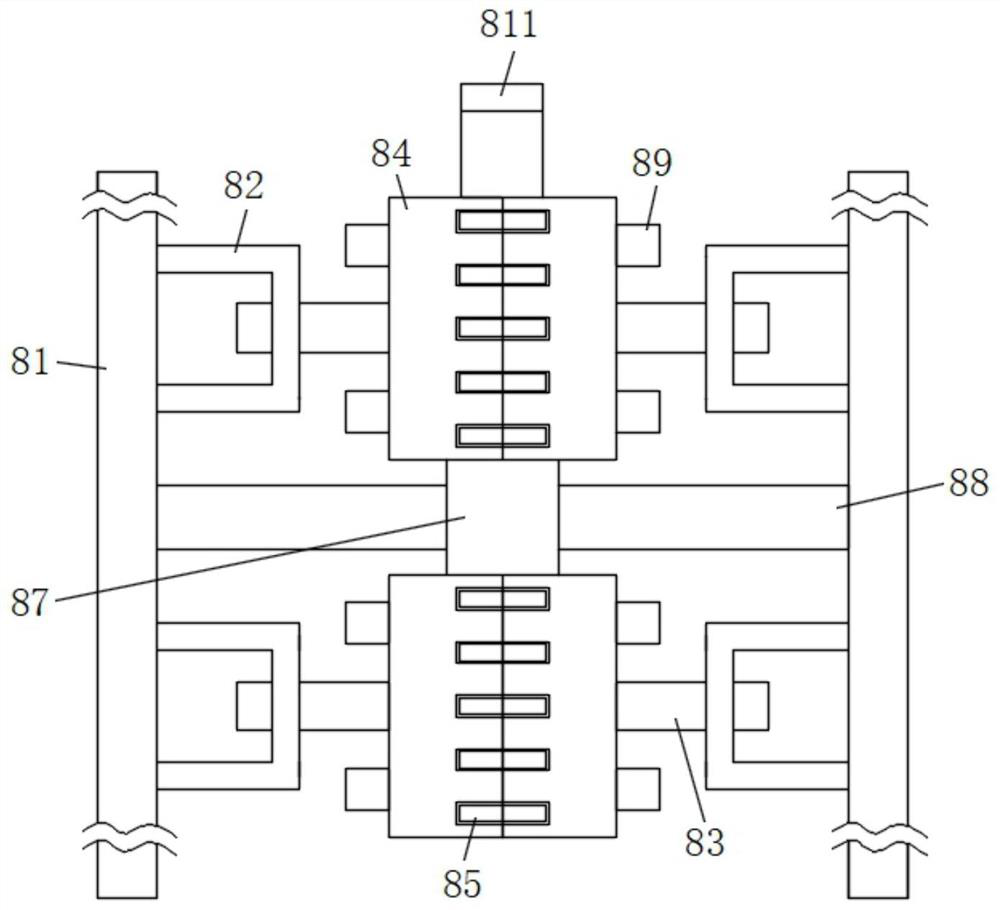

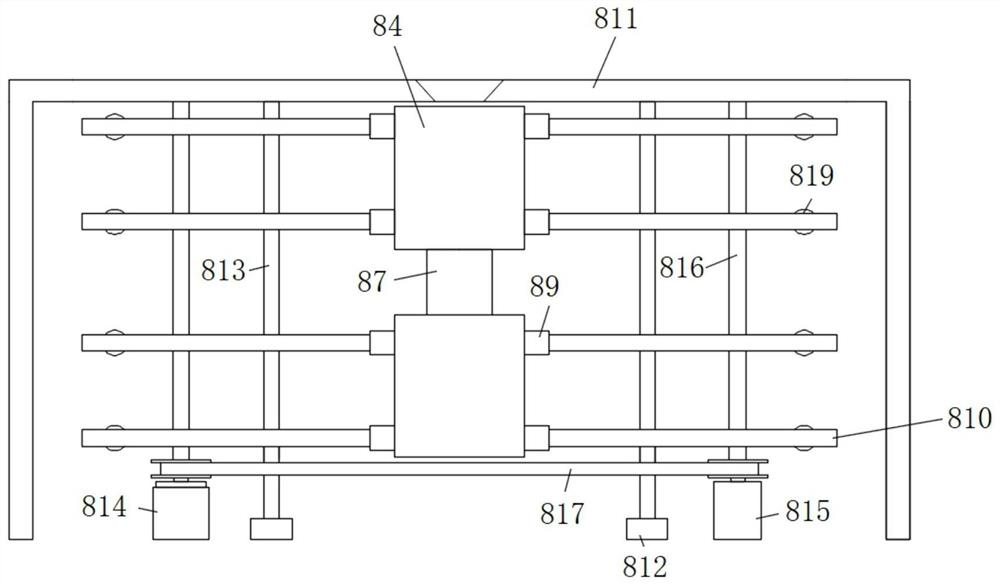

[0030] refer to Figure 1-5A circular cutting device for cable processing with a waste collection function, comprising a workbench 1, a work frame 2 is fixedly connected to the middle part of the top surface of the workbench 1, and a cylinder 3 is fixedly connected to the outer top surface of the work frame 2 through screws, and the cylinder 3 The output end passes through the top surface of the working frame 2 and is fixedly connected with a mounting block 4 at the end by screws. Both sides of the outer top surface are also fixedly connected with fixing mechanisms 7, and the middle part of the top surface of the workbench 1 is also provided with a tapered hole, and the lower side of the tapered hole is also provided with a circumcision mechanism 8. The circumcision mechanism 8 includes a mounting plate 81, two One end of the mounting plate 81 is fixedly connected with a U-shaped frame 82 by screws, and the side of the U-shaped frame 82 is slidably connected with a mounting ro...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a retaining ring 15 is fixedly connected to the inner wall of the top side of the tapered hole, and the retaining ring 15 is placed inside the working frame 2 .

[0034] In this embodiment, the retaining ring 15 is fixedly attached to the inner wall of the top side of the tapered hole, so that the cut cable section can be smoothly introduced into the material guide pan 2 9, thereby realizing the complete cutting operation of the cable section.

Embodiment 3

[0036] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a discharge hole is opened through the middle of the top surface of the cutting table 6, and the lower end of the discharge hole communicates with the tapered hole.

[0037] In this embodiment, a discharge hole is connected between the top surface of the cutting table 6 and the tapered hole, so that the waste cable can smoothly fall into the material guide pan 2 after cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com