Flow gas equilibrating device

A technology of passing air and equalizing holes, which is applied in the direction of steam flow control, electrostatic effect separation, solid separation, etc. It can solve the problems of reduced electrostatic dust removal time, increased flow rate of flue gas 2, and influence on dust removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention goal, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0029] The embodiments of the invention are written in a progressive manner.

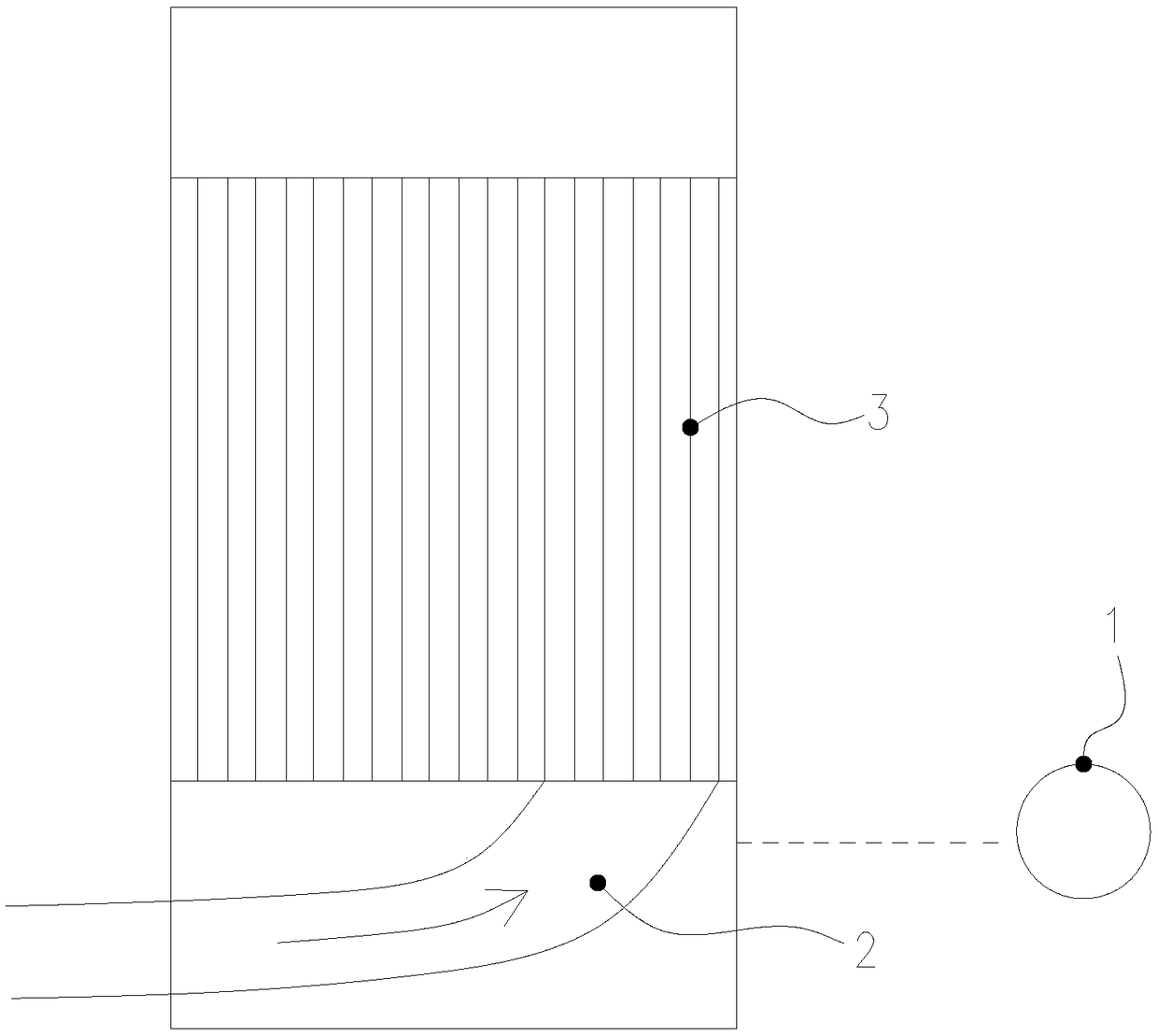

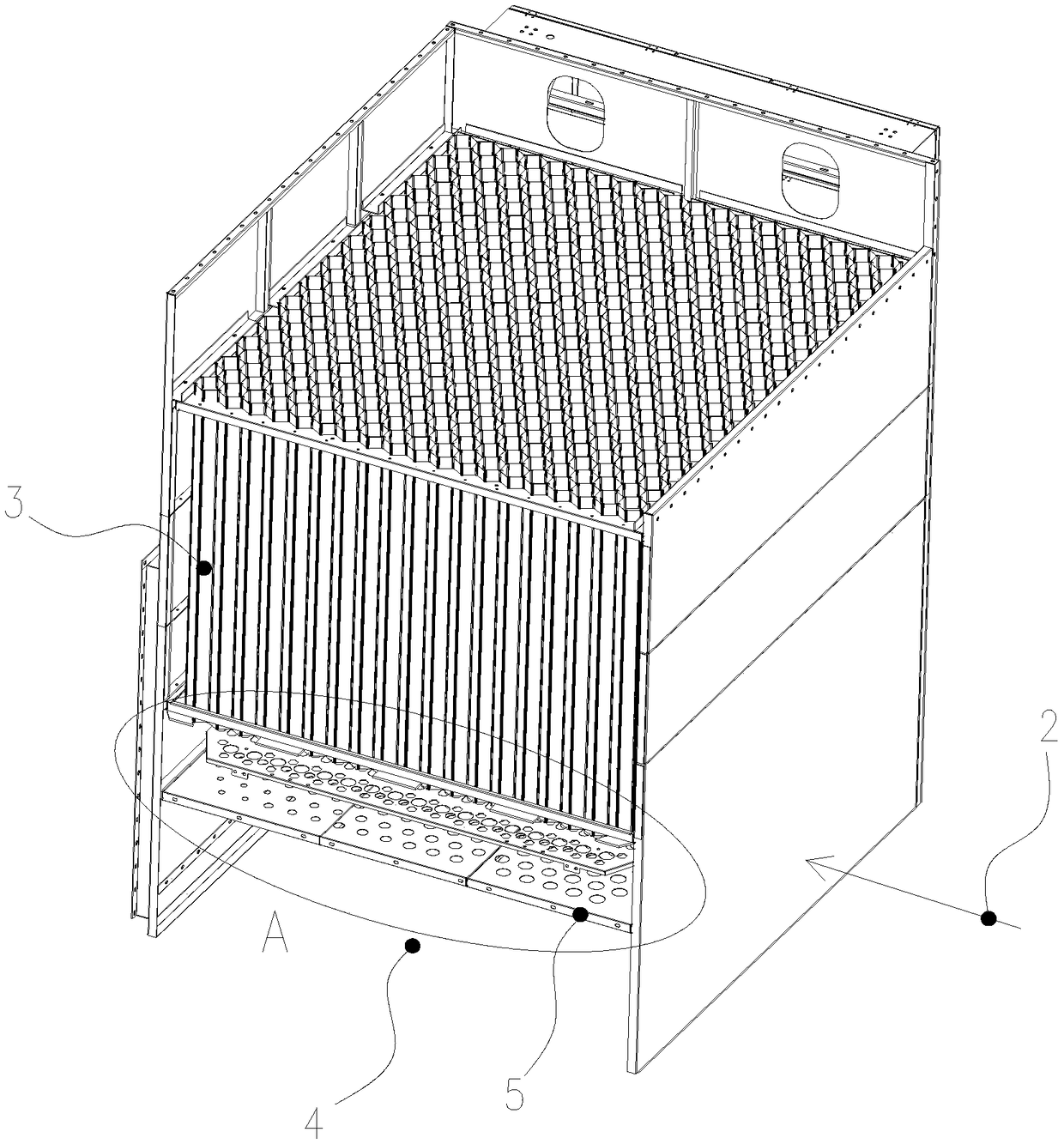

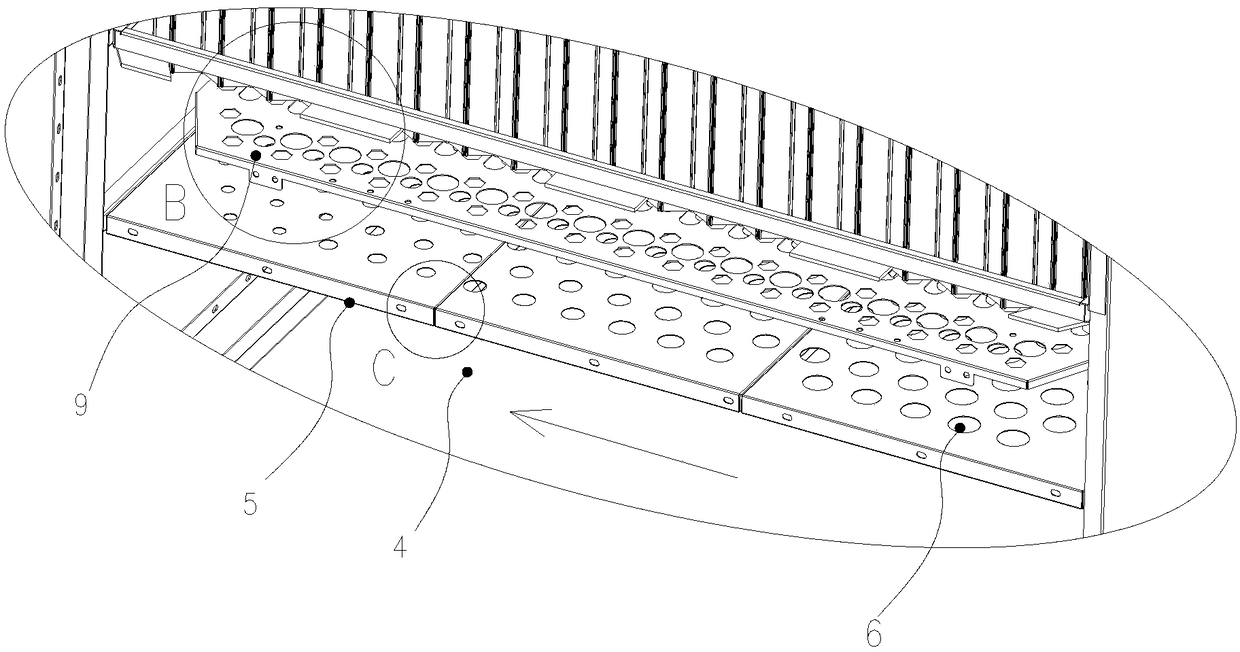

[0030] Such as figure 1 As shown, a wind equalizing device at least includes a cavity 4, and the flue gas 2 enters through the entrance of the cavity 4, and flows from the cavity 4 into the electrostatic field 3; wherein, the flow area of the entrance of the cavity 4 is larger than The smoke circulation area of the electrostatic field 3. In the present invention, through the above-mentioned settings, when the smoke 2 flowing into the cavity 4 intends to enter the electrostatic field 3, due to the reduction of the flow area, there will be short-term storage and collision. The occurrence of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com