Slight center wave rolling method based on Siemens bending-shifting roller model optimization

A technology of Siemens and roll shifting, applied in metal rolling, rolling force/gap control, contour control, etc., can solve problems such as uncontrollable plate shape and roll wear, so as to save costs, increase market share, reduce The effect of leveling process input rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0019] In an embodiment, the present invention adopts the following technical solutions:

[0020] 1. Increase the comparison of the target roll shifting amount A in the Siemens bending and shifting model. If A is less than S, add a random value N on the basis of A to avoid CVC rolls not moving for a long time, or moving to In the same position, the values of S and N are set manually.

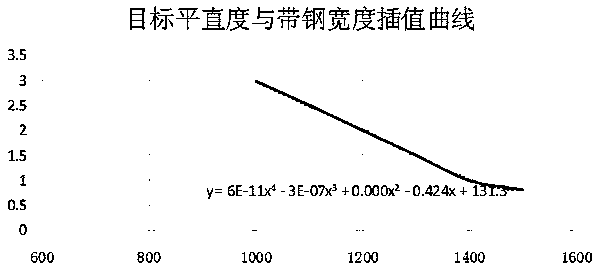

[0021] 2. When setting the basic parameters of the shape calculation, the Siemens roll bending and shifting model will read the alloy composition, width, thickness and other parameters of the current steel strip to set the bending force. The Siemens bending and shifting roll model will store these parameters in the form of txt text in an absolute path on the computer in advance. Modify the Siemens bending and shifting roll model program, and store the alloy co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com