Spin riveting buckling device used for meter assembly

A technology of riveting buckle and instrument, applied in the field of riveting buckle edge device, can solve the problems of small installation space of aluminum case and watch case, difficult to control processing quality, increased difficulty of riveting, etc., achieves compact structure, is conducive to quality control Control and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

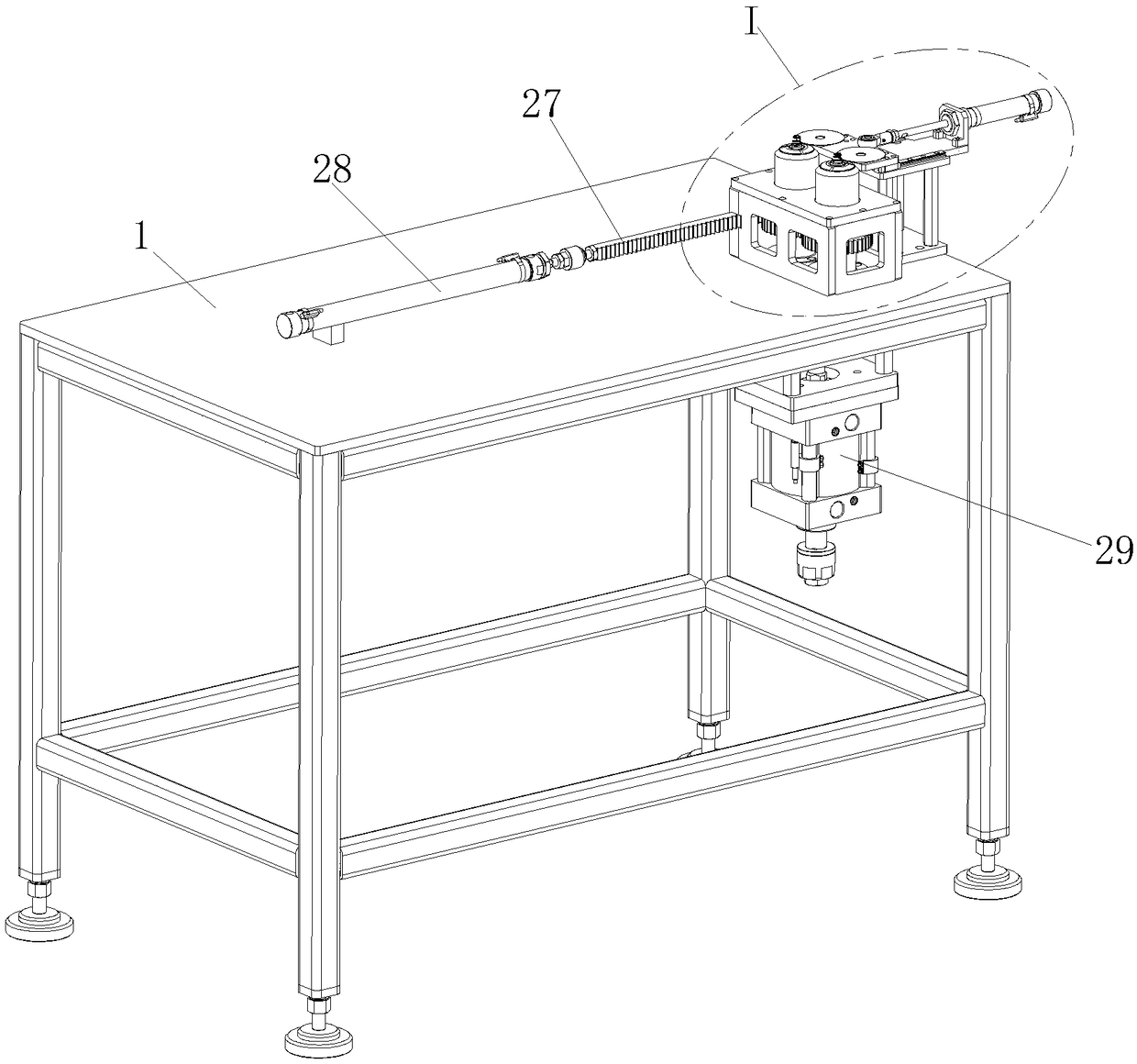

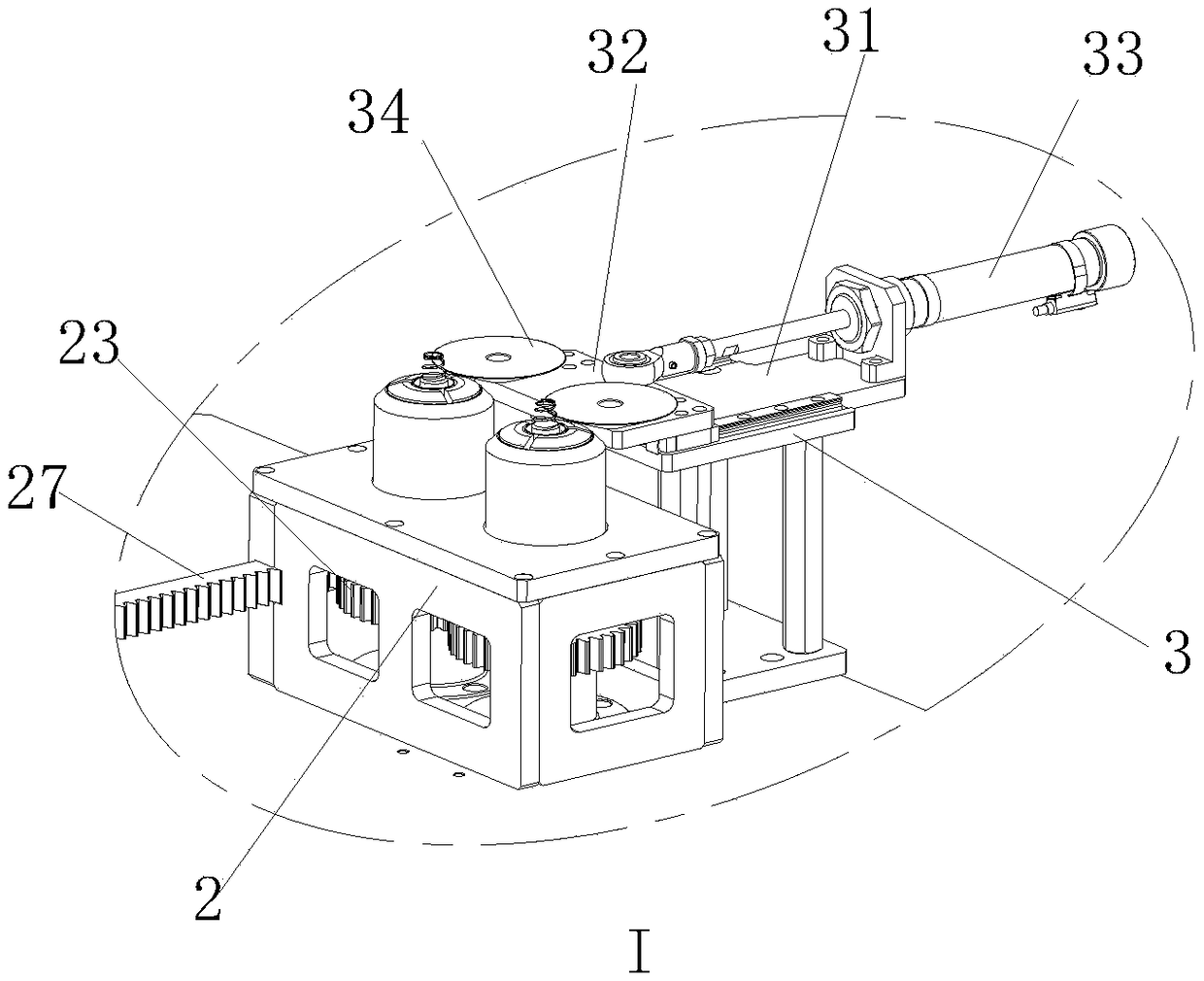

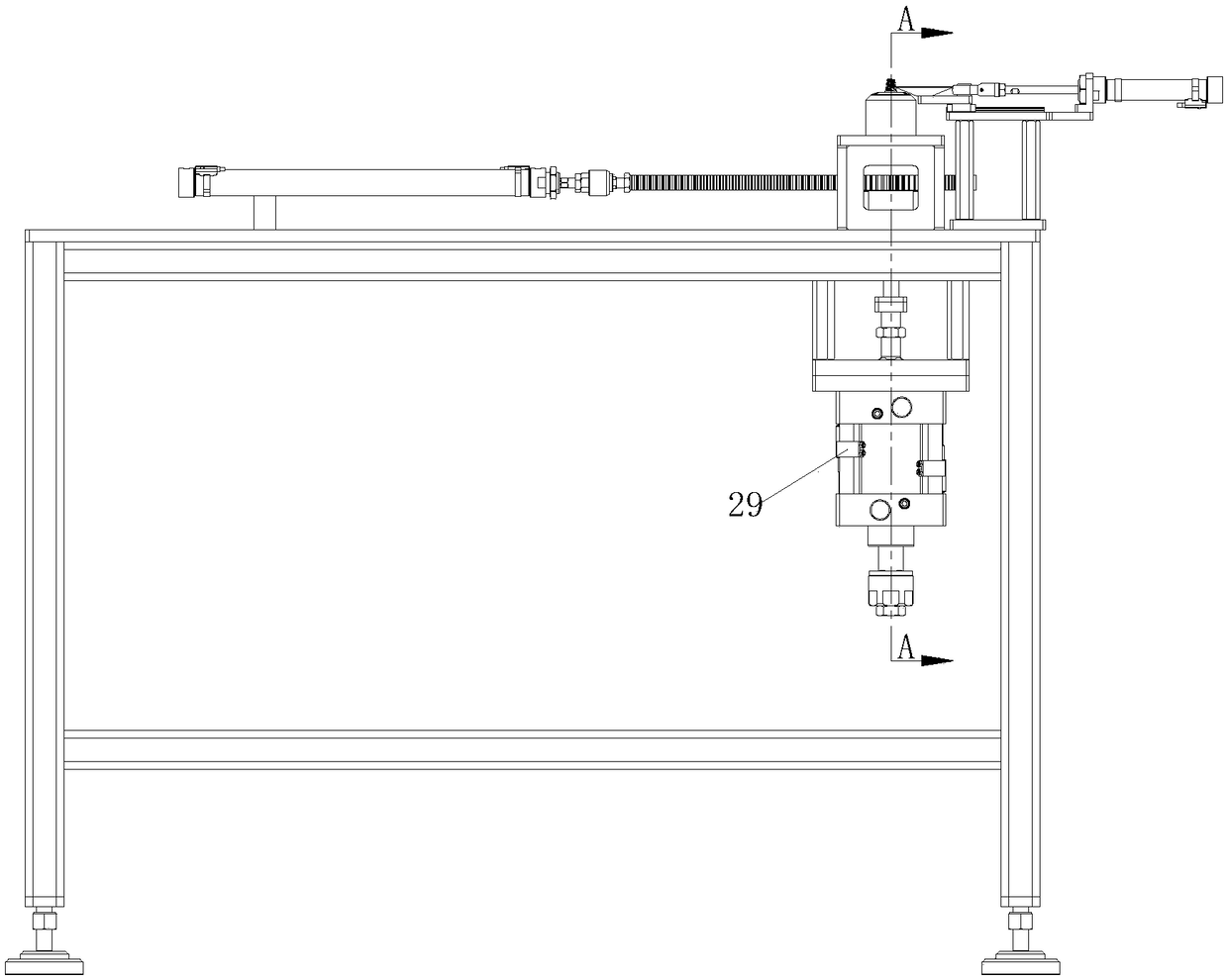

[0023] Such as Figure 1 to Figure 6 As shown, a spin riveting buckling device for instrument assembly includes a frame 1 with a rotating mechanism 2 and a buckling mechanism 3 arranged close to the rotating mechanism 2 on the frame 1.

[0024] In the rotating mechanism 2, an aluminum case 4, a spring 5, and a watch case 6 are sequentially placed from bottom to top, and the aluminum case 4 is clamped to rotate.

[0025] The clinch riveting mechanism 3 turns the edge of the aluminum case 4 inward so that it is pressed tightly on the shoulder of the watch case 6.

[0026] The rotating mechanism 2 includes two mounting seats arranged in a row for clamping the aluminum shell 4.

[0027] The mounting seat includes a fixed seat 21, a bearing 22 coaxially connected to the fixed seat 21, a fastening rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com