Special cabinet for transformer substation operation and maintenance safety tools

A technology for operation and maintenance safety and tools, which is applied in the field of power equipment, can solve problems such as affecting insulation performance, dust flying in, and negligence in inspection of safety tools and appliances, so as to avoid the impact of insulation performance and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

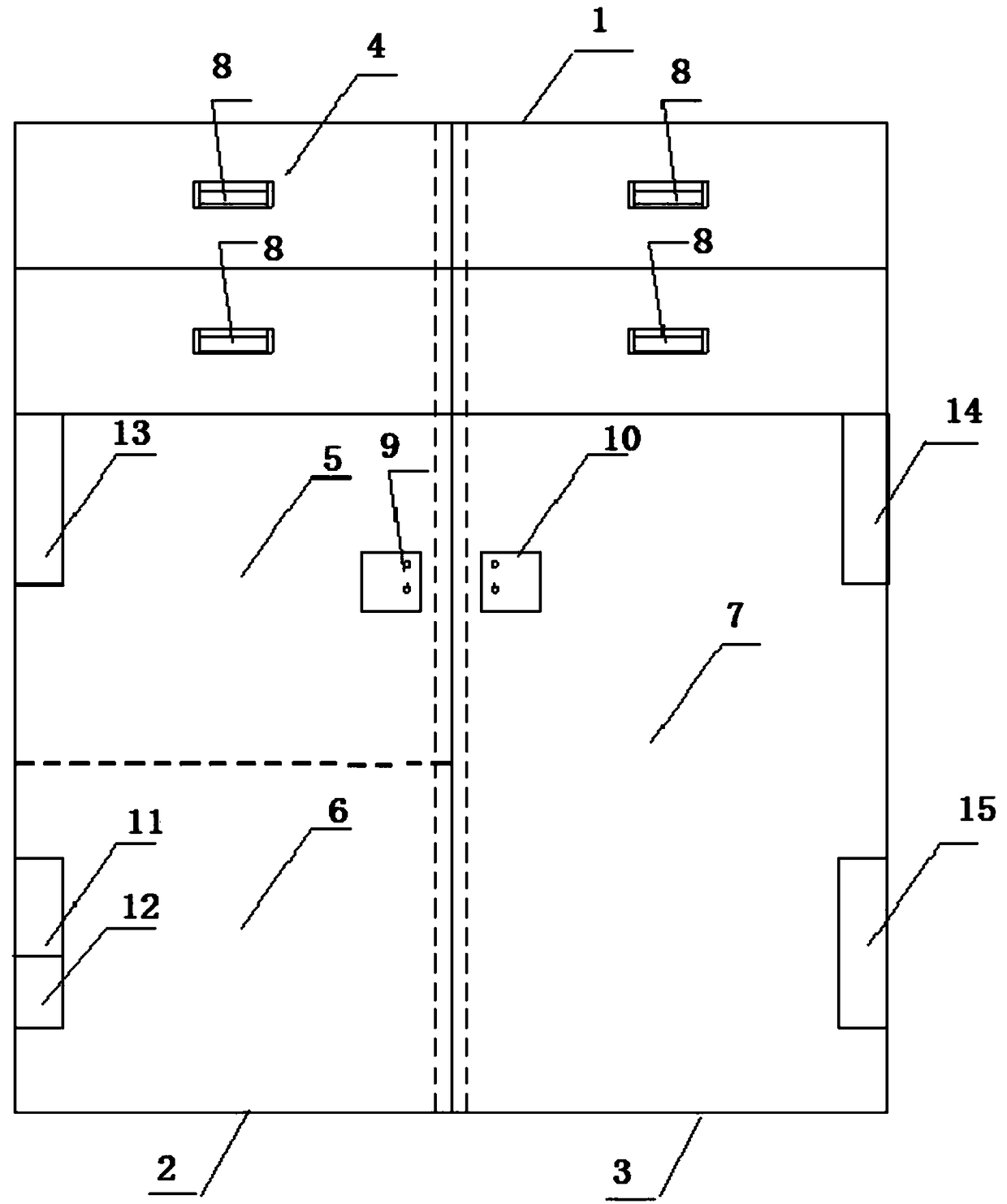

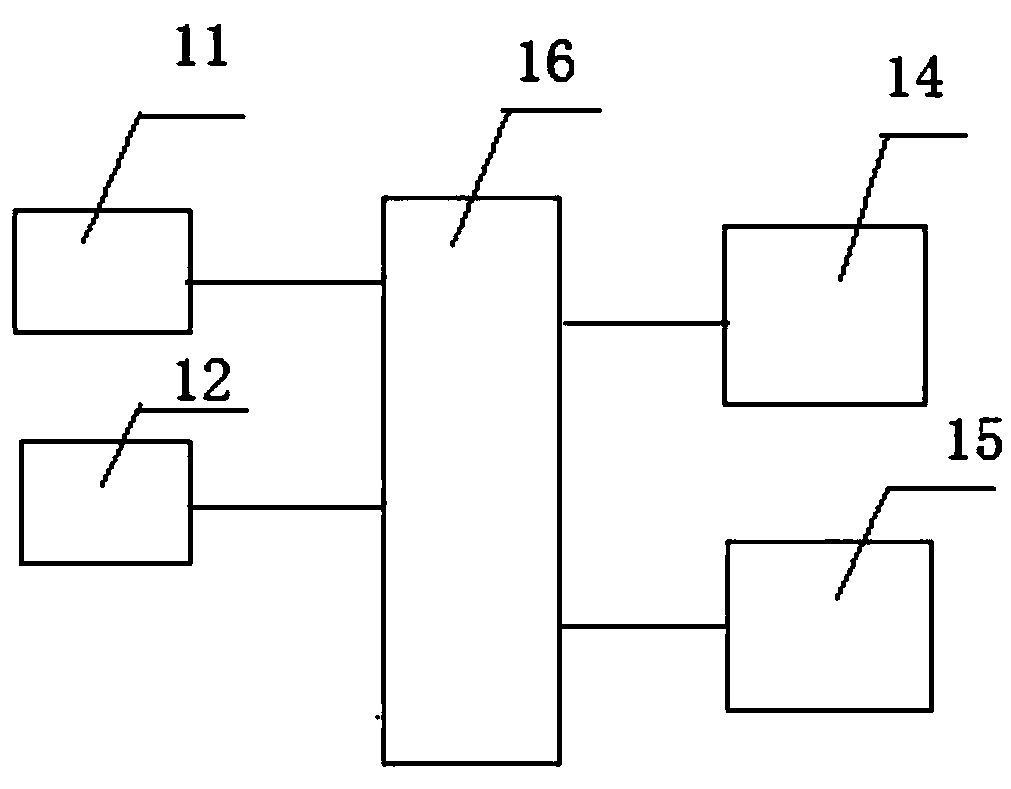

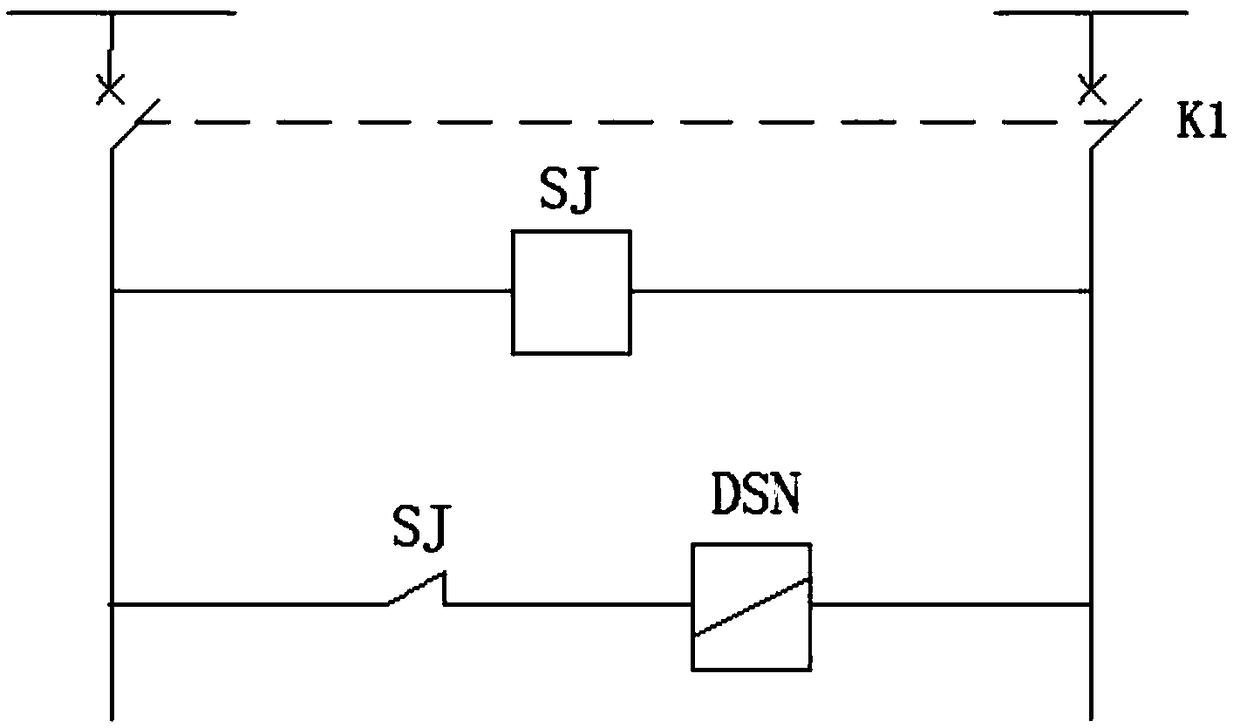

[0027] Such as figure 1 As shown, the special cabinet for power transformation operation and maintenance safety tools of the present invention includes a cabinet body 1, a left cabinet door 2, a right cabinet door 3, and a drawer 4, and the left cabinet door 2 and the right cabinet door 3 are provided with cabinet door sealing strips , the drawer 4 is 4, divided into upper and lower layers, two of each layer are arranged side by side on the upper part of the cabinet body 1, the left side of the lower part of the cabinet body 1 is divided into upper and lower layers, the upper layer is the insulating glove place 5, and the lower layer is The insulating boots are placed 6, the right side of the lower part of the cabinet 1 is the electroscope pen and the insulating rod 7; the drawers 4 are equipped with handles 8, the left cabinet door 2 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com