Wood board conveying rack

A technology of racks and boards, applied in the field of woodworking equipment, can solve the problems of affecting the conveying effect, no limit device, easy deviation of conveying, etc., and achieve the effect of accurate conveying position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

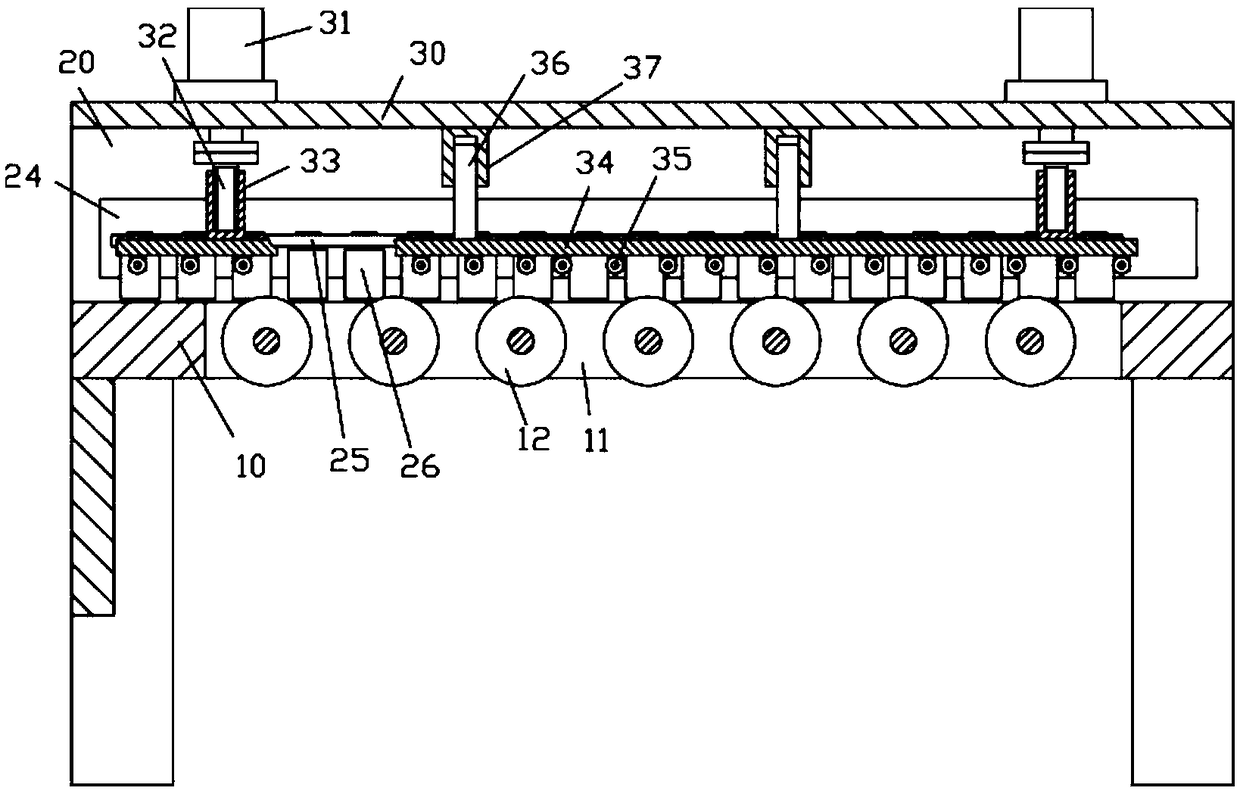

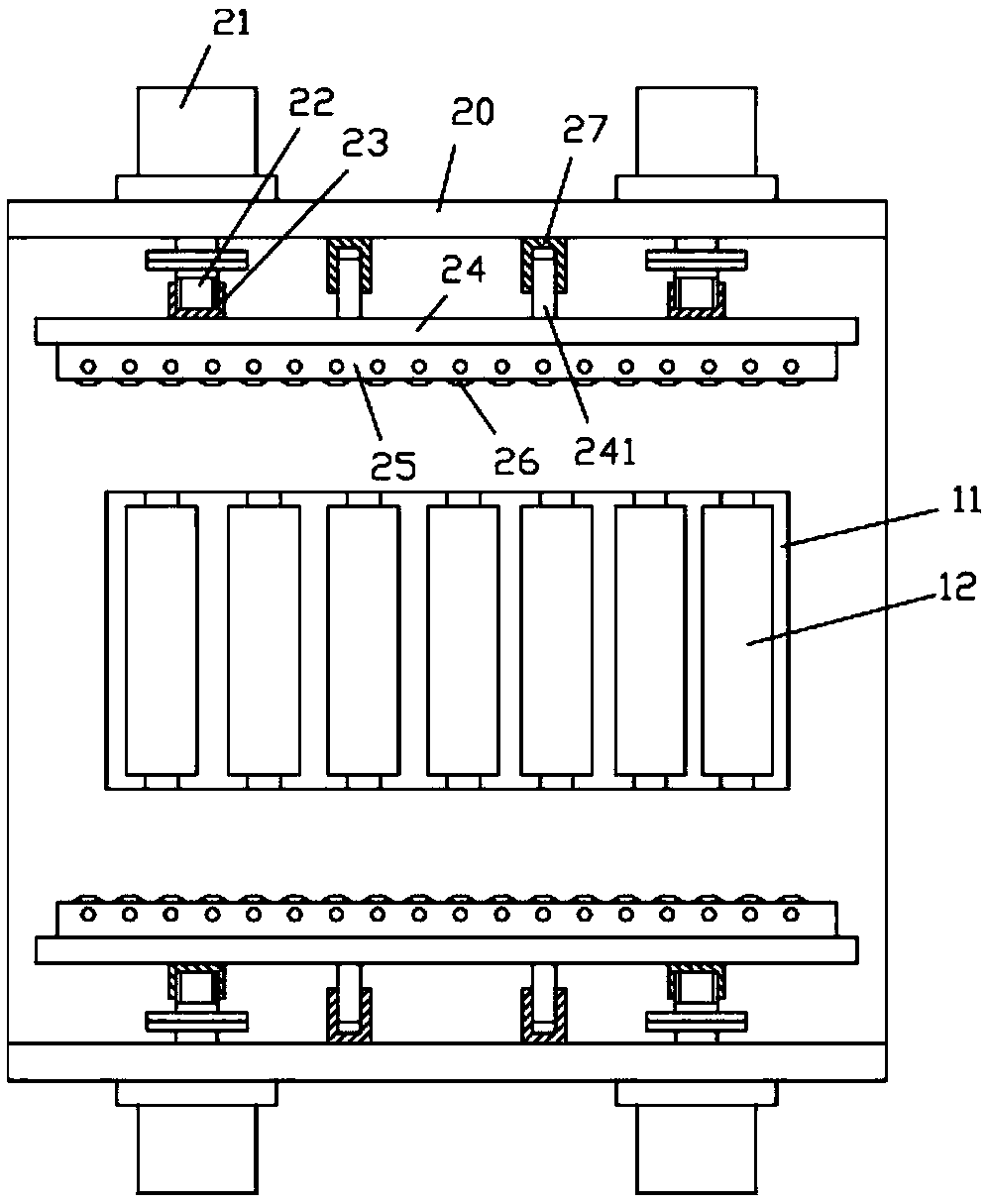

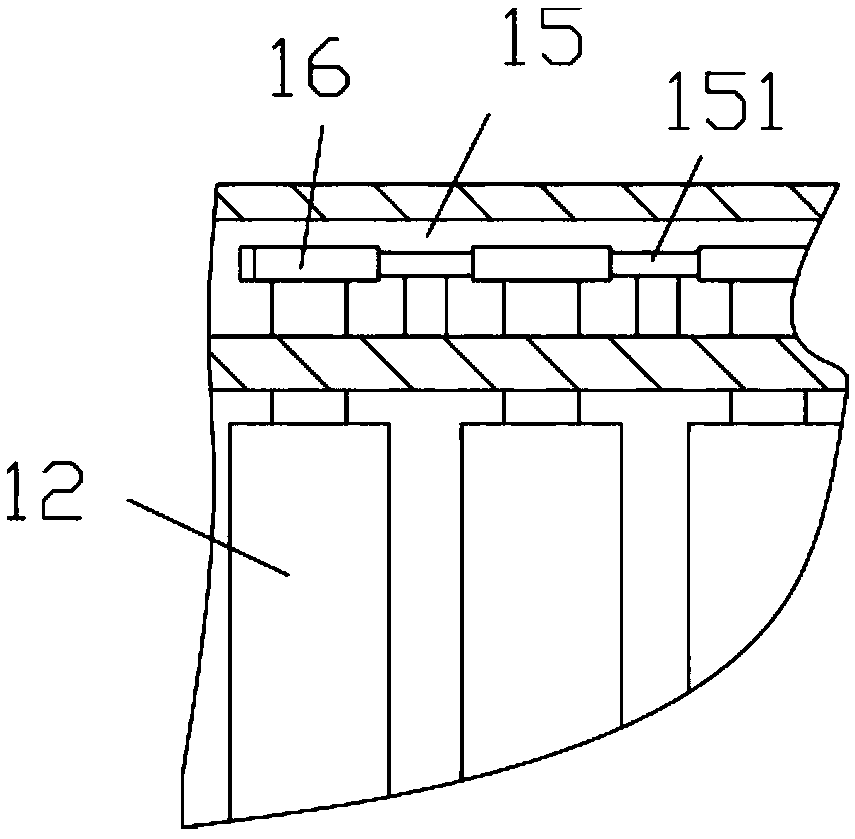

[0016] Examples, see e.g. Figure 1 to Figure 4 Shown, a kind of plank conveying frame comprises frame 10, and the front portion of the top plate of described frame 10 and rear portion top surface all are fixed with side plate body 20, and the left side and the right side of the outer side wall of side plate body 20 All parts are fixed with a telescopic motor 21, the output shaft of the telescopic motor 21 passes through the side plate body 20 and is connected with a telescopic screw rod 22 through a coupling, the telescopic screw sleeve 23 is screwed in the telescopic screw rod 22, and the telescopic screw sleeve 23 on the same side The top of the top is fixed on the same adjustment side plate 24, and the middle part of the opposite wall surface of the two adjustment side plates 24 is fixed with a horizontal plate 25, and the bottom surface of the horizontal plate 25 is hinged with a plurality of guide rollers 26;

[0017] The middle part of the top plate of the frame 10 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com