Side discharging horizontal type packer

A side-discharge, horizontal technology, applied in the field of balers, can solve the problems of difficult to accurately control the pressure and density of bale blocks, high requirements on material properties, and difficult to separate the baled materials, so as to reduce the settings of transmission parts and power mechanisms, The effect of high degree of automation and effective work area optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

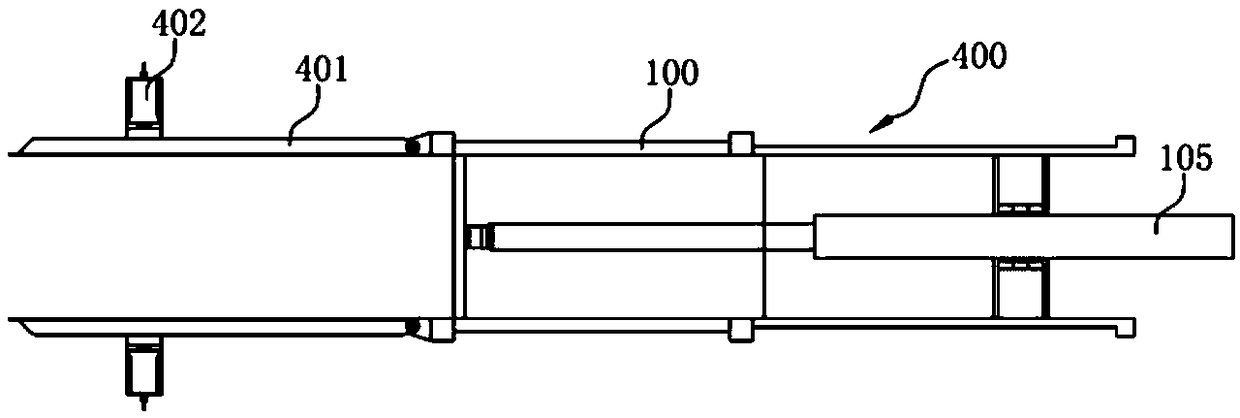

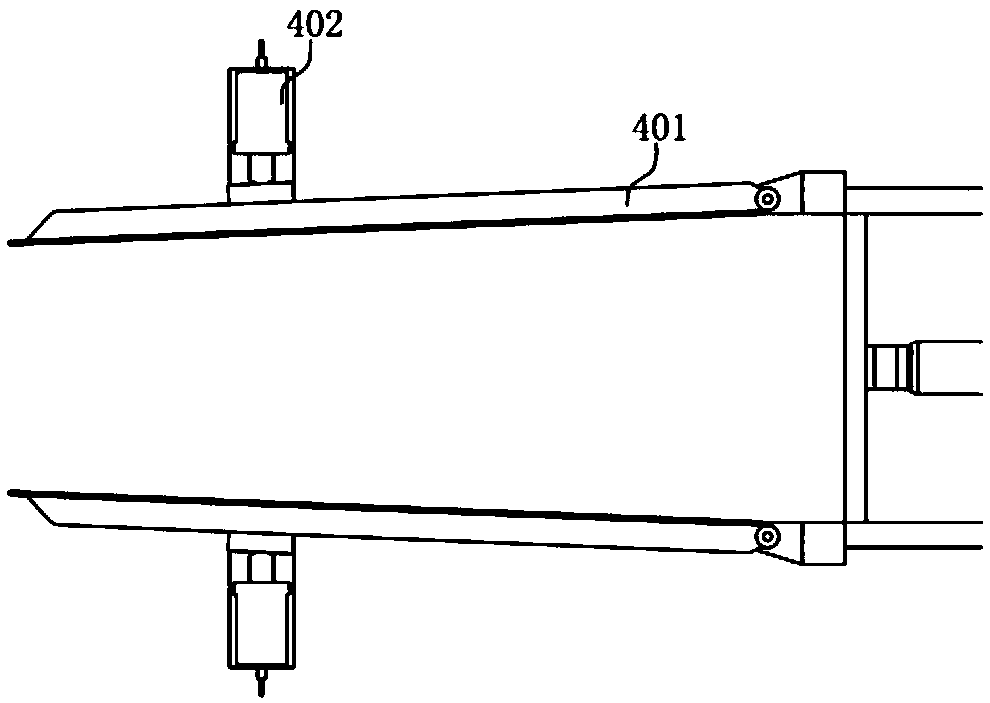

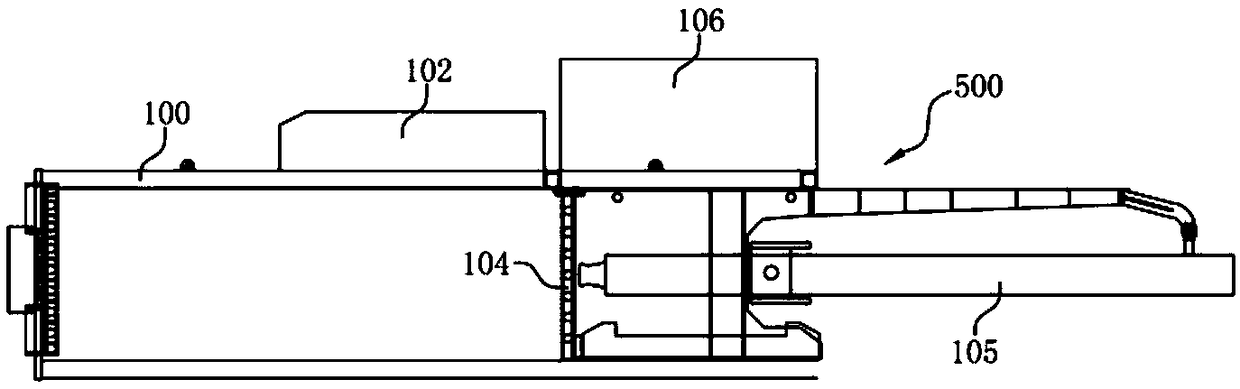

[0060] Example 1: see Image 6 with Figure 7 This embodiment discloses a side-discharge horizontal baler, including a frame 100, a bag outlet 103, a door 200, and a rear baffle 300. The frame 100 is provided with a packing cavity 101 in the packing cavity 101 The front end of the package is provided with a feed port 102 and a push plate assembly, where the push plate assembly includes a push plate 104, a push plate cylinder 105 and a pump station group 106; the package outlet 103 is set on the side of the rear end of the packing chamber 101; the hatch 200 and The package outlet 103 is correspondingly provided; the back baffle 300 is provided at the rear of the packing cavity 101 and corresponds to the push plate 104, and a package outlet device corresponding to the package outlet 103 is provided on the back baffle 300.

[0061] Specifically, the cabin door 200 in this embodiment includes a slide 201, a door body 202, a push-pull assembly, and a locking assembly. Four sets of guid...

Embodiment 2

[0073] Embodiment 2: Combining the specific positional relationship and connection relationship, the specific structure and movement mode are further detailed as follows:

[0074] The side-discharge horizontal baler is composed of a frame 100, a push plate 104, a push plate cylinder 105, a pump station group 106, a hatch 200, a bag discharge device, a material inlet 102 and other parts. An oil cylinder bracket 107 is installed in the frame near the tail, and the push plate cylinder is fixed on the cylinder support 107. The push plate cylinder drives the push plate to move horizontally back and forth for packing operations. The upper part of the frame is located at the pump station group 106, which includes motors, oil pumps, valve blocks, hydraulic valves, oil tanks, oil pipes and other accessories, which are the power and control units of the baler.

[0075] The frame is the frame of the side-discharge horizontal baler, which is divided into the top surface of the rack, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com