Industrial power-assisted suspender

An industrial and spreader technology, applied in the direction of cranes, etc., can solve the problems of inconvenient installation and disassembly, insufficient smooth operation of the spreader, and inaccurate control, etc. Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

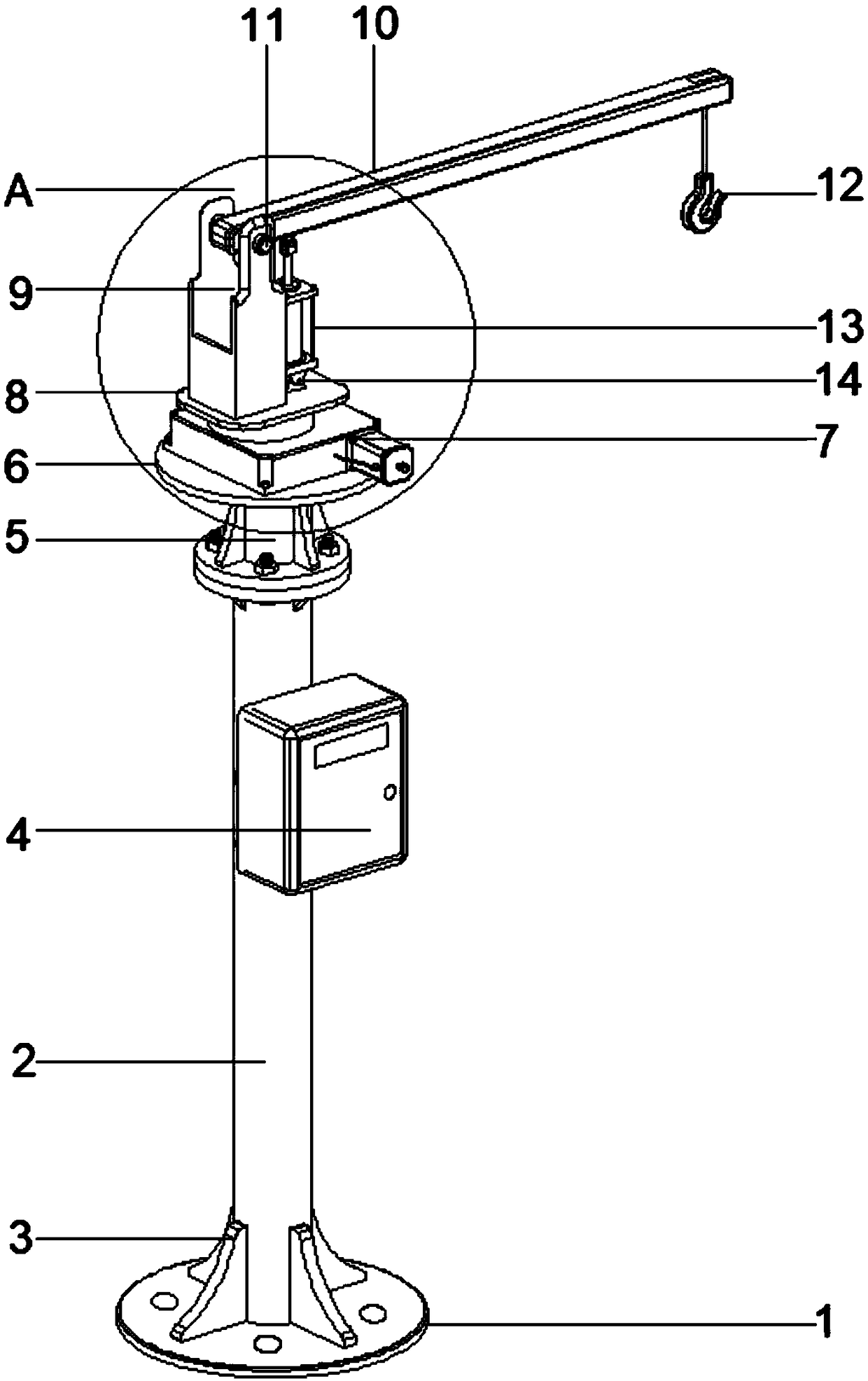

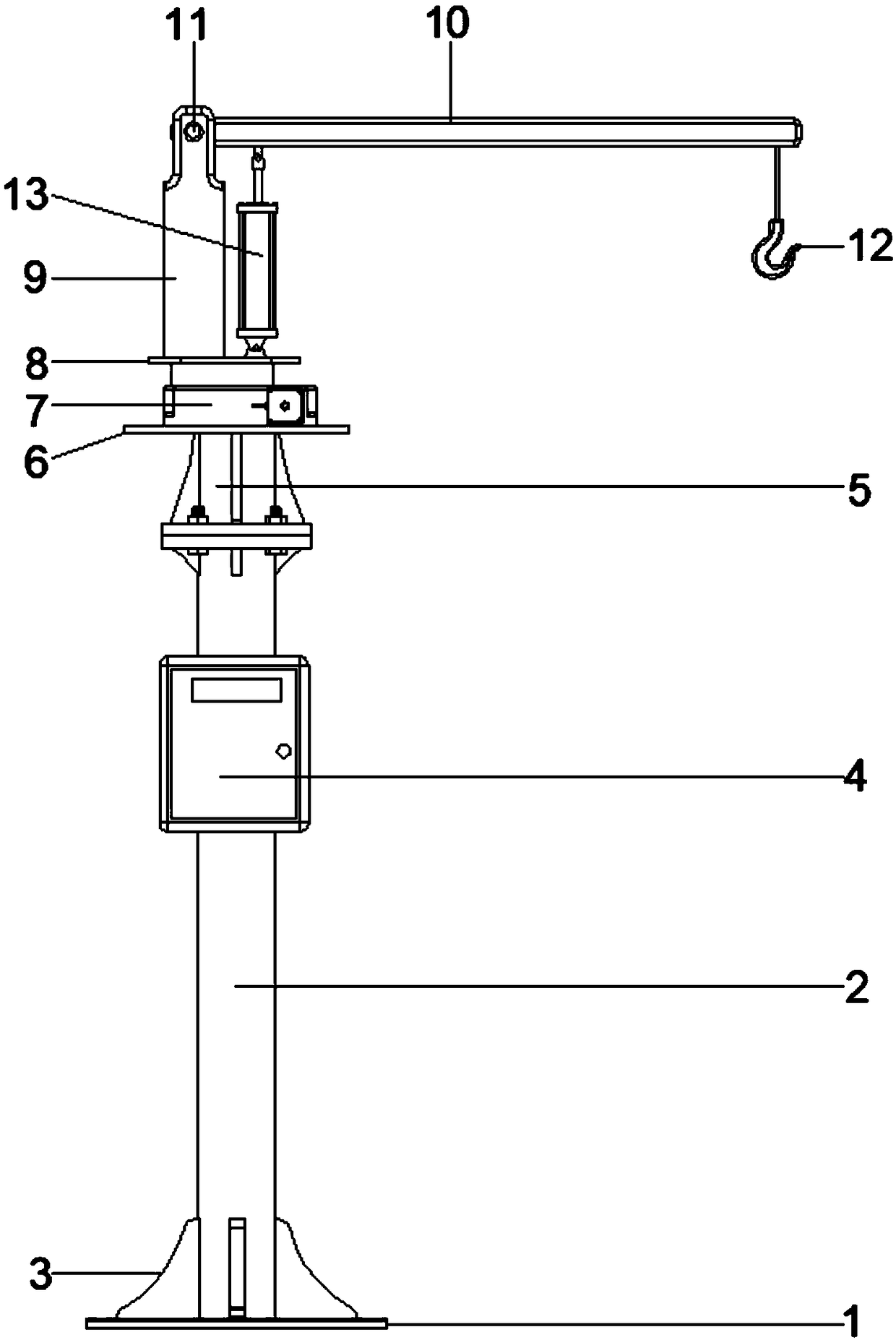

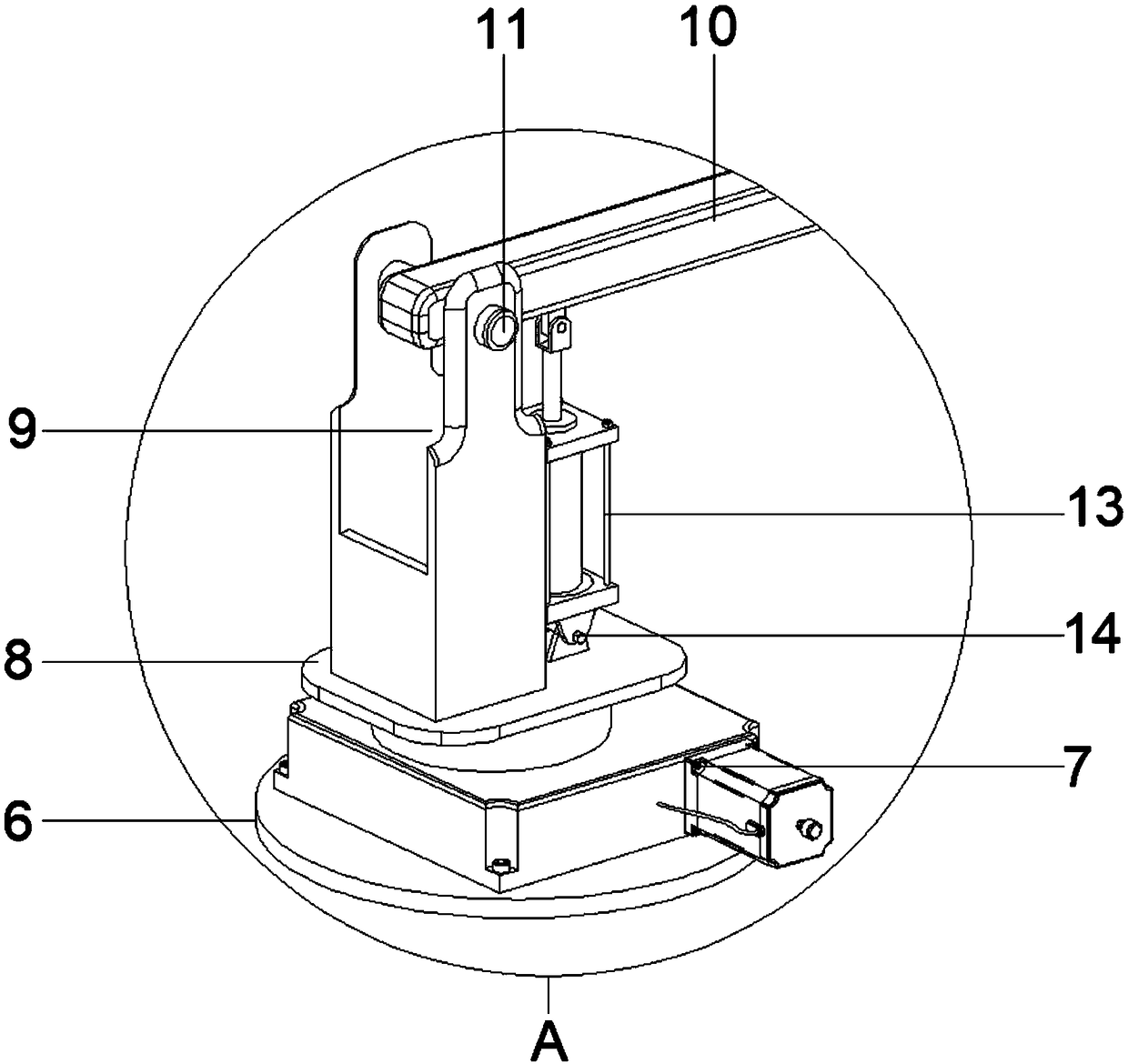

[0028] An industrial booster spreader, comprising: a base 1, a supporting column 2, a reinforcing plate 3, a control box 4, a connecting column 5, a mounting plate 6, a rotating platform 7, a bottom plate 8, a bracket 9, a boom 10, and a pin shaft 11 , hook 12, hydraulic cylinder 13, rotary support 14; base 1 is a circular plate-shaped structure; support column 2 is arranged on the upper side of base 1, and support column 2 and base 1 are connected by welding of reinforcement plate 3; control box 4 is arranged on the side of the supporting column 2, and the control box 4 is connected to the supporting column 2 through a clamp; the connecting column 5 is arranged on the upper side of the supporting column 2, and the connecting column 5 is connected to the supporting column 2 through a flange; The mounting plate 6 is arranged on the upper side of the connecting column 5, and the mounting plate 6 is connected with the connecting column 5 by welding; the rotating platform 7 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com