Novel electric crane

A crane and electric technology, which is applied in the field of new electric cranes, can solve the problems of large pulling force of lifting rope, broken lifting rope, and swinging of heavy objects back and forth, so as to avoid damage and ensure the effect of buffering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

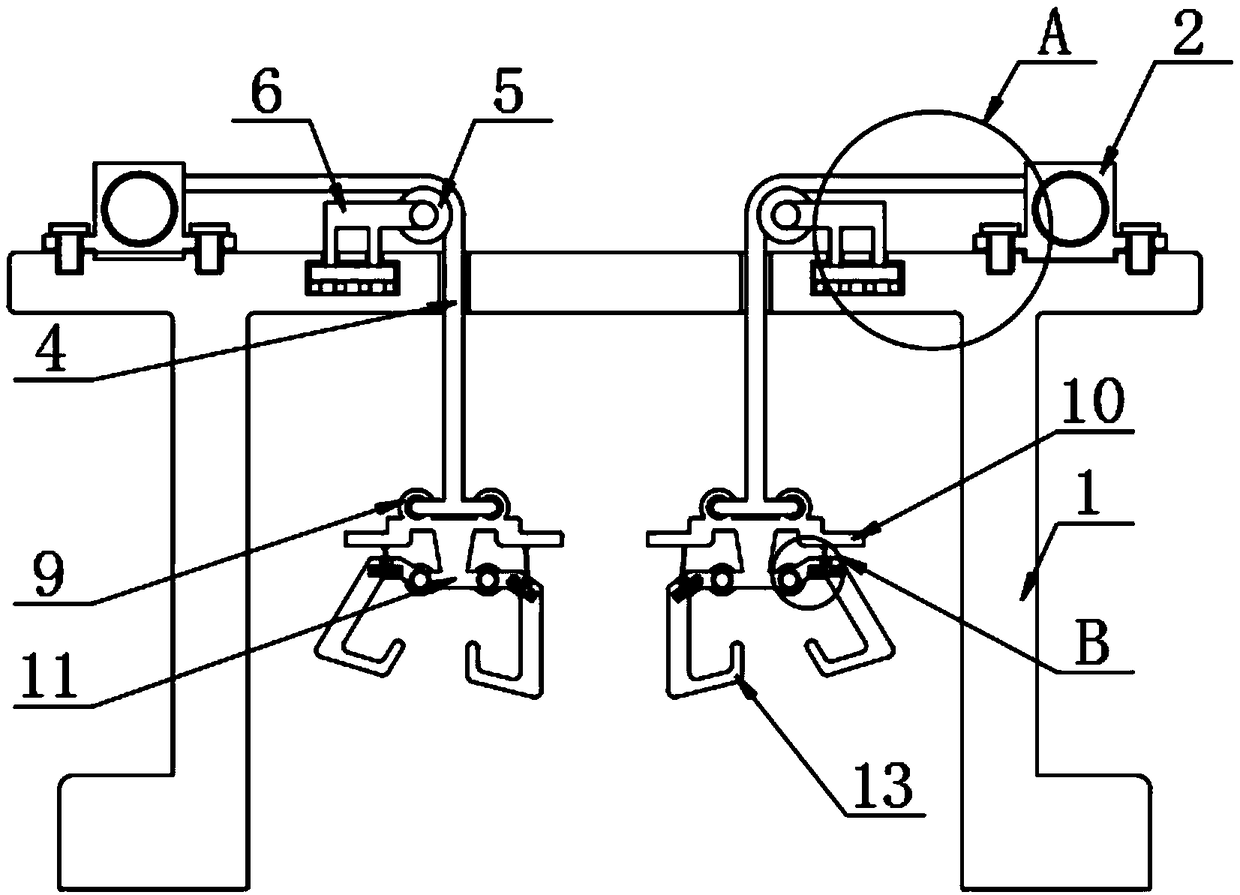

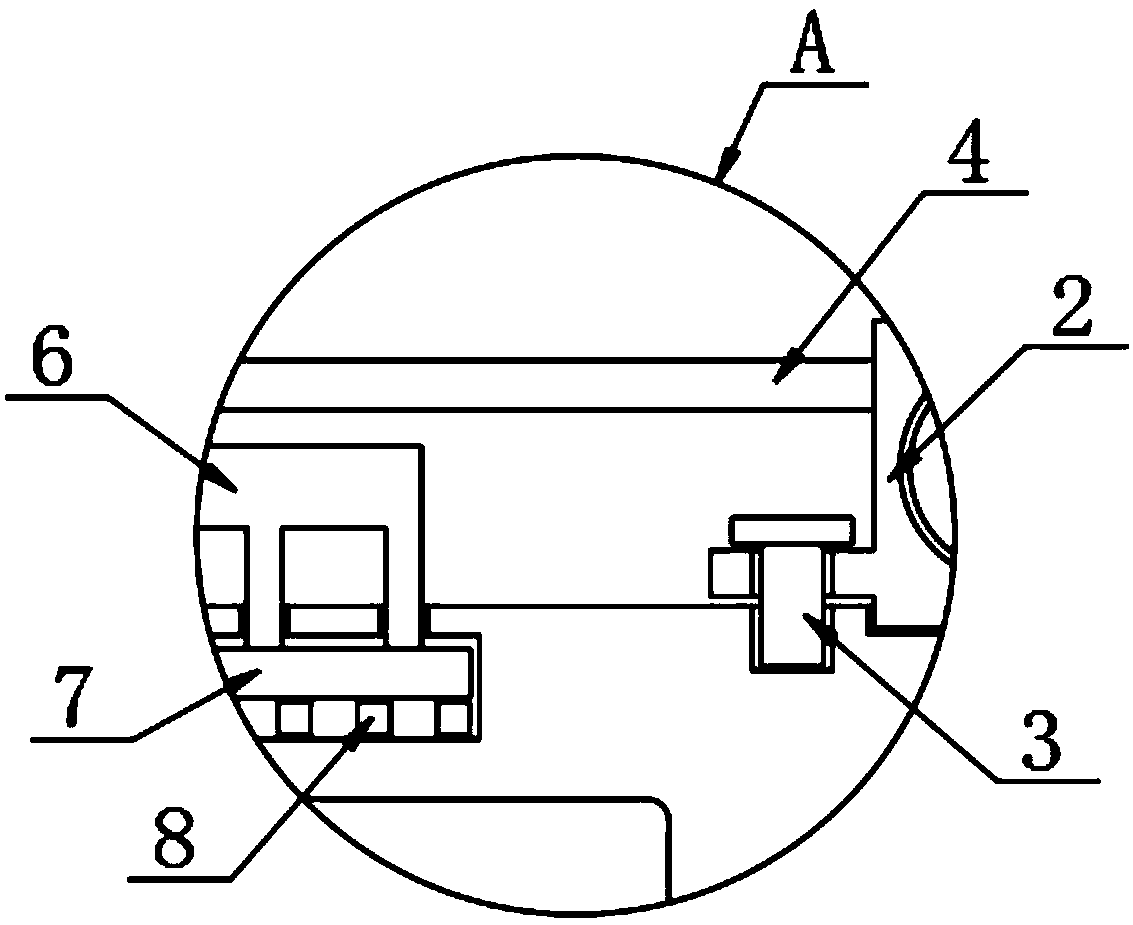

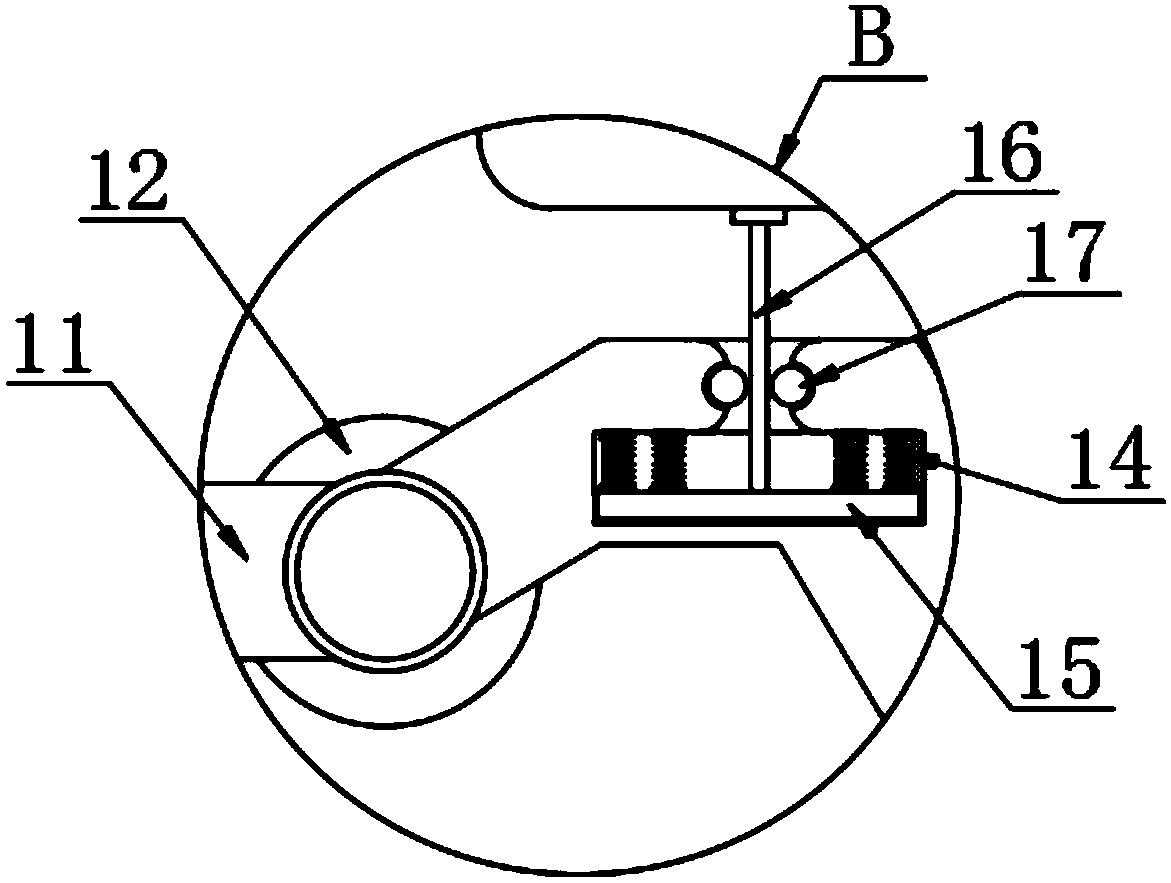

[0022] The present invention provides such Figure 1-3 A new type of electric crane shown includes a bracket 1, the top of the bracket 1 is provided with an electric winding roller 2, and both sides of the electric winding roller 2 are provided with fastening screws 3, and the electric winding roller 2 One side is provided with a hoisting rope 4, and the inside of the hoisting rope 4 is provided with a turning roller 5, and one side of the turning roller 5 is provided with a card frame 6, and the bottom of the card frame 6 is provided with a pressing plate 7, and the bottom of the pressing plate 7 is provided with a There is a rubber block 8, and one end of the lifting rope 4 is provided with a pull ring 9, and the bottom of the pull ring 9 is provided with a pull frame 10, and the bottom of the pull frame 10 is provided with a connecting frame 11, and both sides of the connecting frame 11 are provided with rotating shafts 12. A hook 13 is provided on one side of the rotating ...

Embodiment 2

[0025] The electric winding roller 2 is fixedly connected to the top surface of the support 1 through the fastening screw 3, and after the fastening screw 3 passes through the clamp, the electric winding roller 2 is fastened on the top of the support 1 to prevent the electric winding roller 2 from Shaking occurs during work, and one end of the hoisting rope 4 is connected to the electric winding roller 2, so that the hoisting rope 4 can be wound up or released by the electric winding roller 2.

[0026] The other end of the hoisting rope 4 is fixedly connected to the pull ring 9, which increases the stability of the binding and prevents the hoisting rope 4 from breaking away from the pull ring 9. The hoisting rope 4 is matched with the steering roller 5, which is convenient to change the lifting position through the steering roller 5. The running direction of the rope 4 can smoothly lift the heavy object.

[0027] The pull ring 9, the pull frame 10 and the connecting frame 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com