Intelligent hot-bending machine for vehicle-mounted large-size 3D glass

A large-size, 3D technology, applied in the field of large-size 3D glass hot bending machines for intelligent vehicles, to achieve the effect of improving product yield, high stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

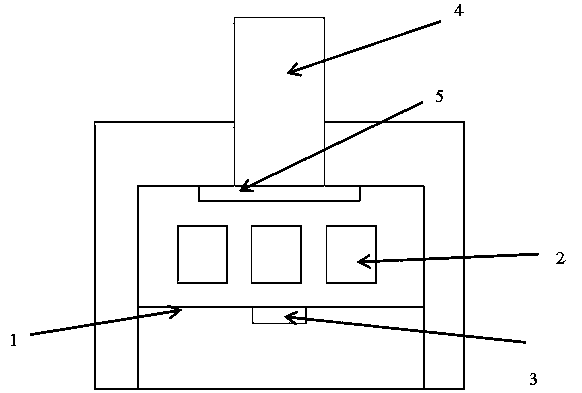

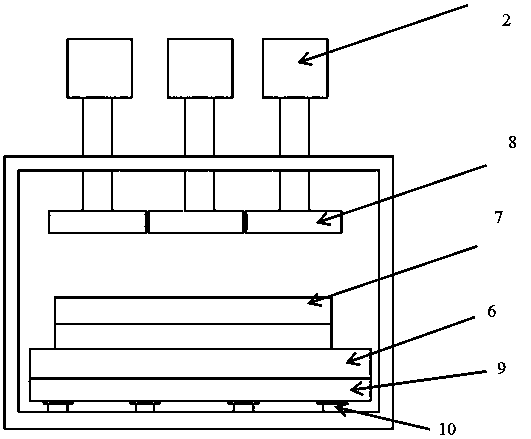

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

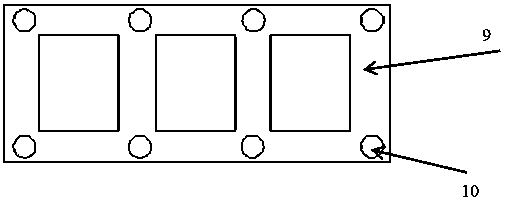

[0021] to combine Figure 1-3 , this embodiment includes a heating furnace chamber, 3 station pressure servo motors and a pusher structure, the front box plate 1 of the furnace chamber is equipped with a front cylinder 3, and the lower heating plate 6 inside the chamber is integrally formed by a steel plate, with a total length of 1 -2m, with 20-40 heating pipe channels, the bottom of the lower heating plate is installed with a bottom support frame 9, the bottom support frame is a back-shaped frame structure, and there are bolt holes at the bottom of the four-sided frame, which are connected to the bottom surface of the box plate through bolts; The upper heating plate 8 is a group of multiple independent heating plates, and is controlled by the servo motor 2 to move up and down. The front box plate of the furnace cavity is controlled by the front cylinder, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com