Yarn guiding roller which is connected through rotary insertion and is for textile printing and dyeing machine

A technology of textile printing and dyeing and yarn delivery rollers, which is applied in the field of yarn delivery rollers, which can solve the problems of affecting the normal operation of yarn printing and dyeing, increasing costs, deformation of yarn delivery rollers, etc., so as to facilitate individual replacement, reduce costs and waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

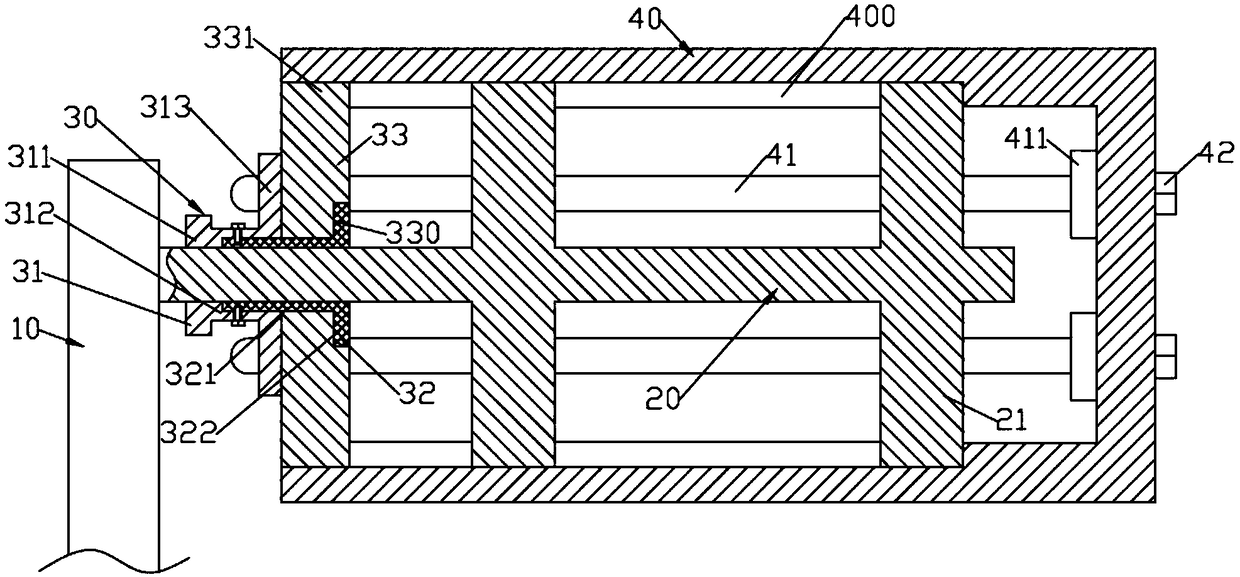

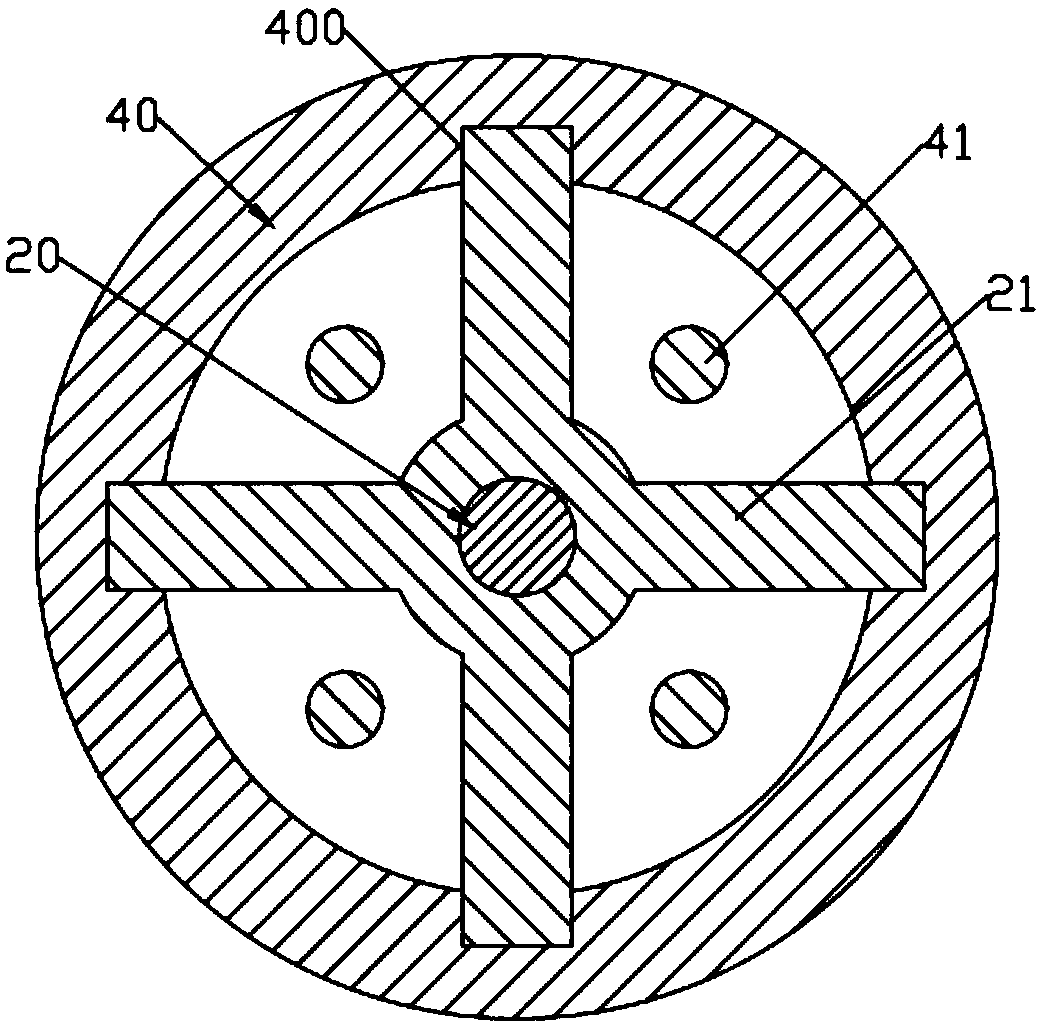

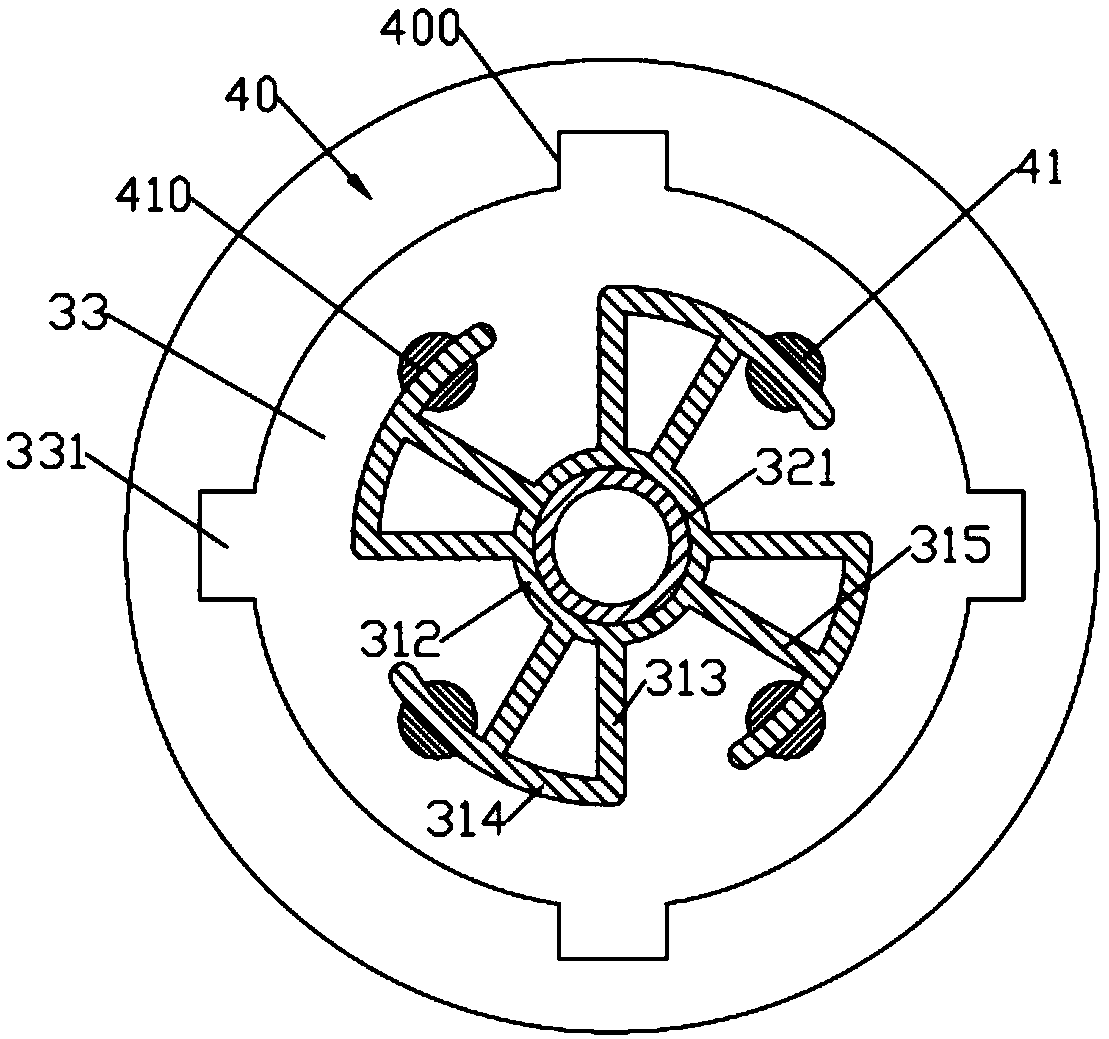

[0016] Such as Figure 1 ~ Figure 3 As shown, a yarn drawing roller for textile printing and dyeing machinery is connected by rotation and insertion, including a support plate 10, a rotation shaft 20, a limit connection device 30 and a roller body 40; the left end of the rotation shaft 20 is pivotally connected to the support plate 10; The left part of the rotating shaft 20 is formed with several cross-shaped guide blocks 21 and all the guide blocks 21 are overlapped left and right; the inside of the roller body 40 is hollow and the left end is not sealed; the inner cavity of the roller body 10 is in the shape of a cylindrical groove; The side wall of the inner chamber is formed with four uniform guide grooves 400 that cooperate with the guide block 21 and the left end of the guide groove 400 is not sealed; The distribution of limit connecting rods 41; the limit connecting rods 41 and the guide groove 400 are staggered; the limit connecting device 30 includes a limit connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com