High-frequency probe card for wafer testing

A high-frequency probe and wafer testing technology, applied in the field of high-frequency probe cards, can solve the problems of high cost, small probe size, easy to wear and even bending, etc., and achieve the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

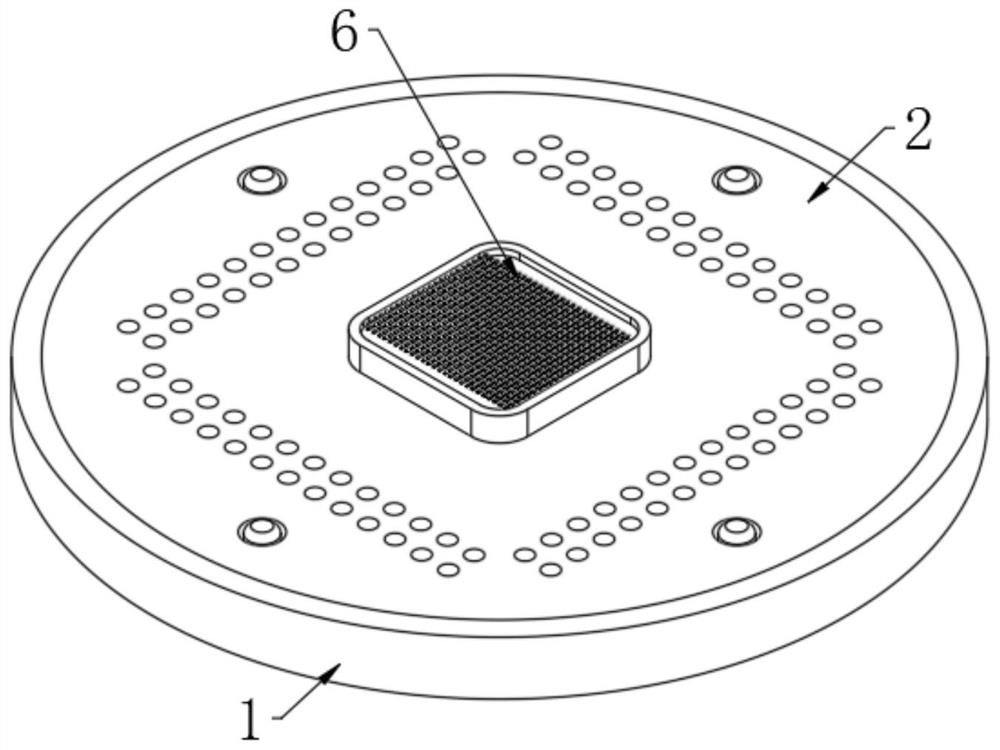

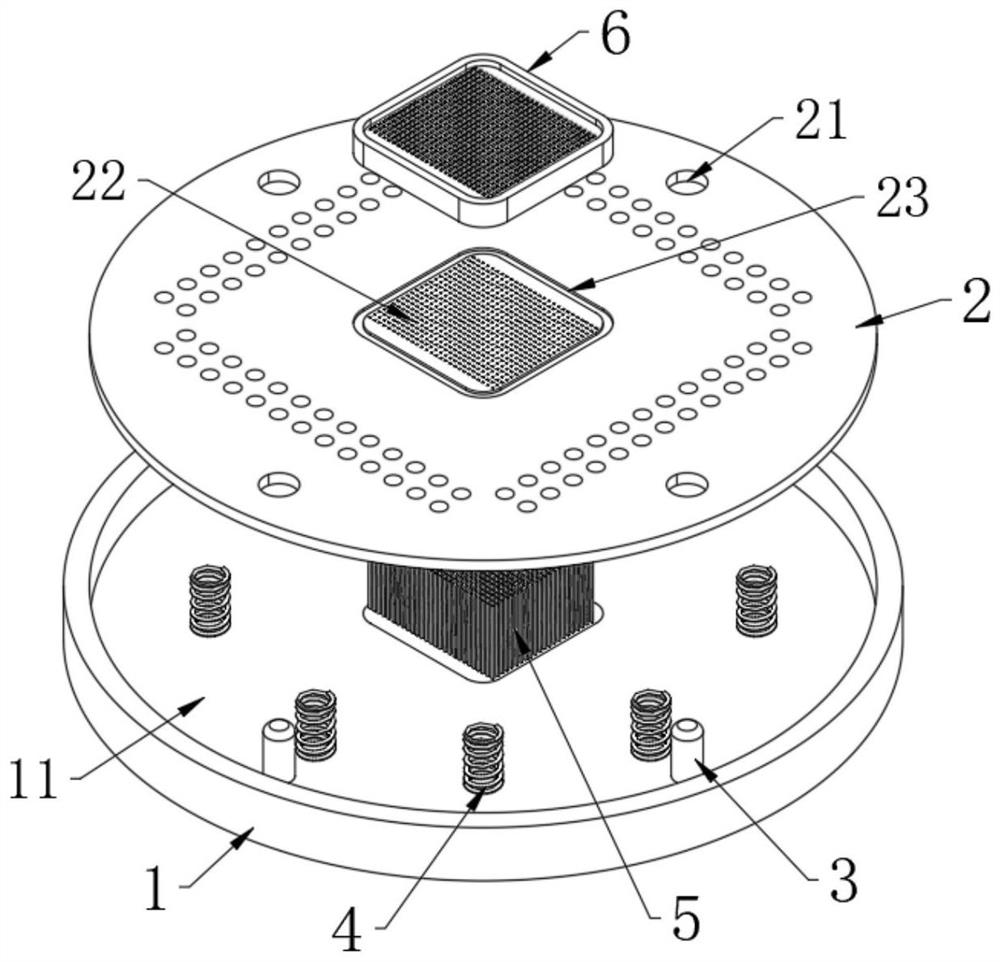

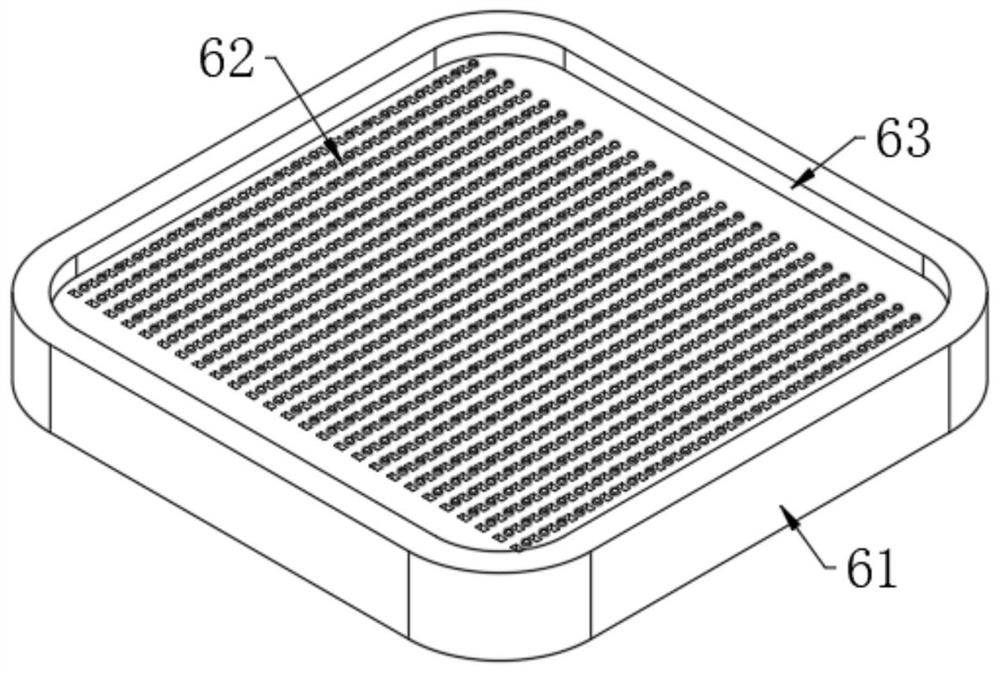

[0032] refer to Figure 1-10 , a high-frequency probe card for wafer testing is proposed in this embodiment, including a connection base 1, a panel 2 is slidably installed on the connection base 1, and a connection tester and an integrated chip signal are fixedly installed on the connection base 1. The probe group 5 of the contact, the probe group 5 runs through the panel 2 and is slidably connected with the panel 2, the panel 2 is detachably installed with a rectification assembly 6, the rectification assembly 6 is located outside the probe group 5, and the rectification assembly 6 is installed on The working state of the probe set 5 is detected at the upper end of the panel 2, and the probe set 5 is straightened and corrected when the correction assembly 6 is disassembled.

[0033] Specifically, when testing the integrated chip, the connecting base 1 and the testing machine are fixedly connected together, and then the testing machine drives the connecting base 1 and the pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com