Brake fixing structure on universal trundle

A technology of universal casters and fixed structures, which is applied in the direction of casters, wheels, vehicle parts, etc., which can solve the problems of easy damage, waste, scrapping of casters and other problems of brake components, and achieve the effect of convenient individual replacement, simple structure and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

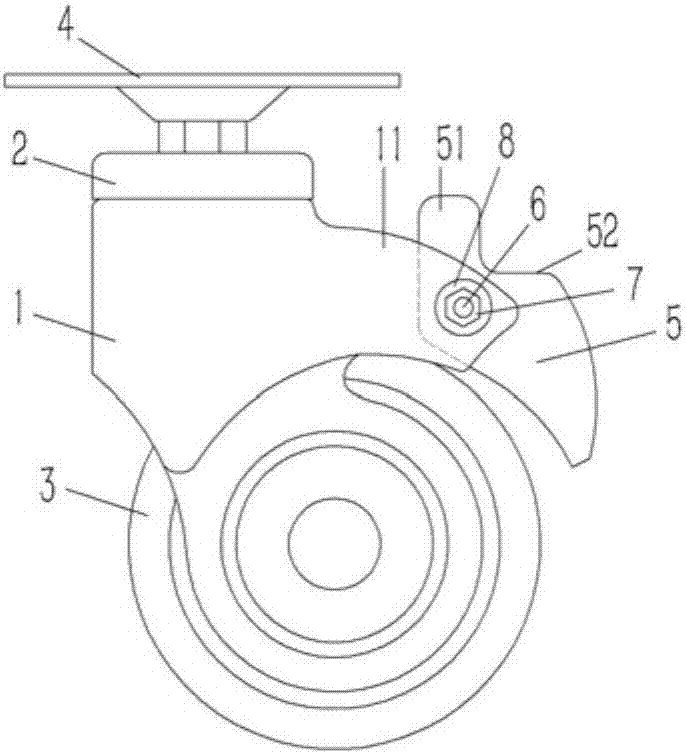

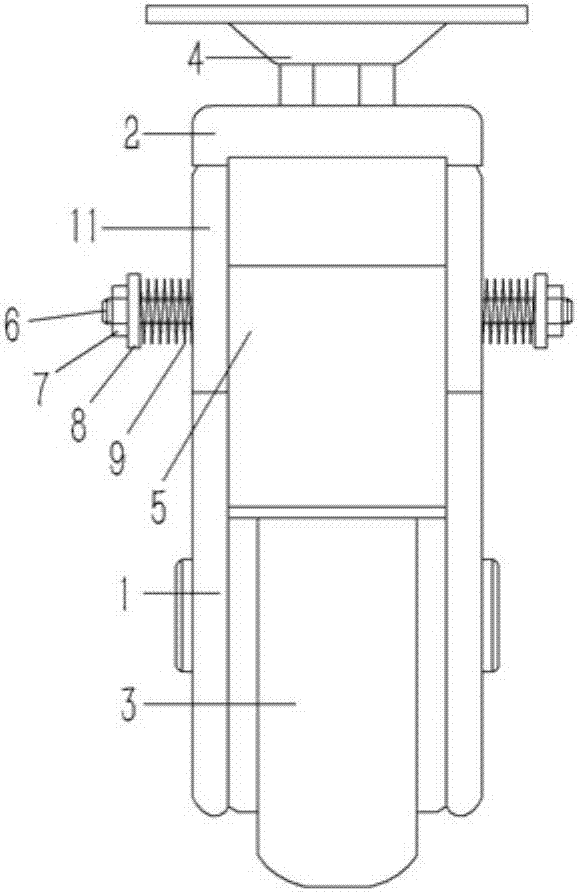

[0015] Example: see figure 1 , 2 As shown, a brake fixing structure on a universal caster includes a caster bracket 1 for a universal caster, a swivel seat 2 is fixed on the upper end of the caster bracket 1, a mounting bracket 4 is hinged on the swivel seat 2, and the caster bracket 1 is provided with Walking wheel 3, the rear side of the two side plates of the caster bracket 1 is formed with an arc-shaped bracket plate 11, and a horizontal screw rod 6 is inserted on the bracket plate 11, and an arc-shaped brake block 5 is inserted on the screw rod 6, and the brake block 5 Clamped between the bracket plates 11; the two ends of the screw rod 6 pass through the bracket plate 11 and are inserted with a compression spring 9, and the two ends of the compression spring 9 are respectively pressed against the gasket 8 and the bracket plate 11, and the gasket 8 Inserted on the screw rod 6, the screw rod 6 is screwed with a nut 7, and the nut 7 is pressed against the washer 8.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com