Secondary side heat supply automatic balance adjustment method based on return water temperature and intelligent energy consumption monitoring system thereof

A technology with return water temperature and automatic balance, applied in heating system, space heating and ventilation details, household heating, etc. The effect of eliminating the hydraulic imbalance of the second network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

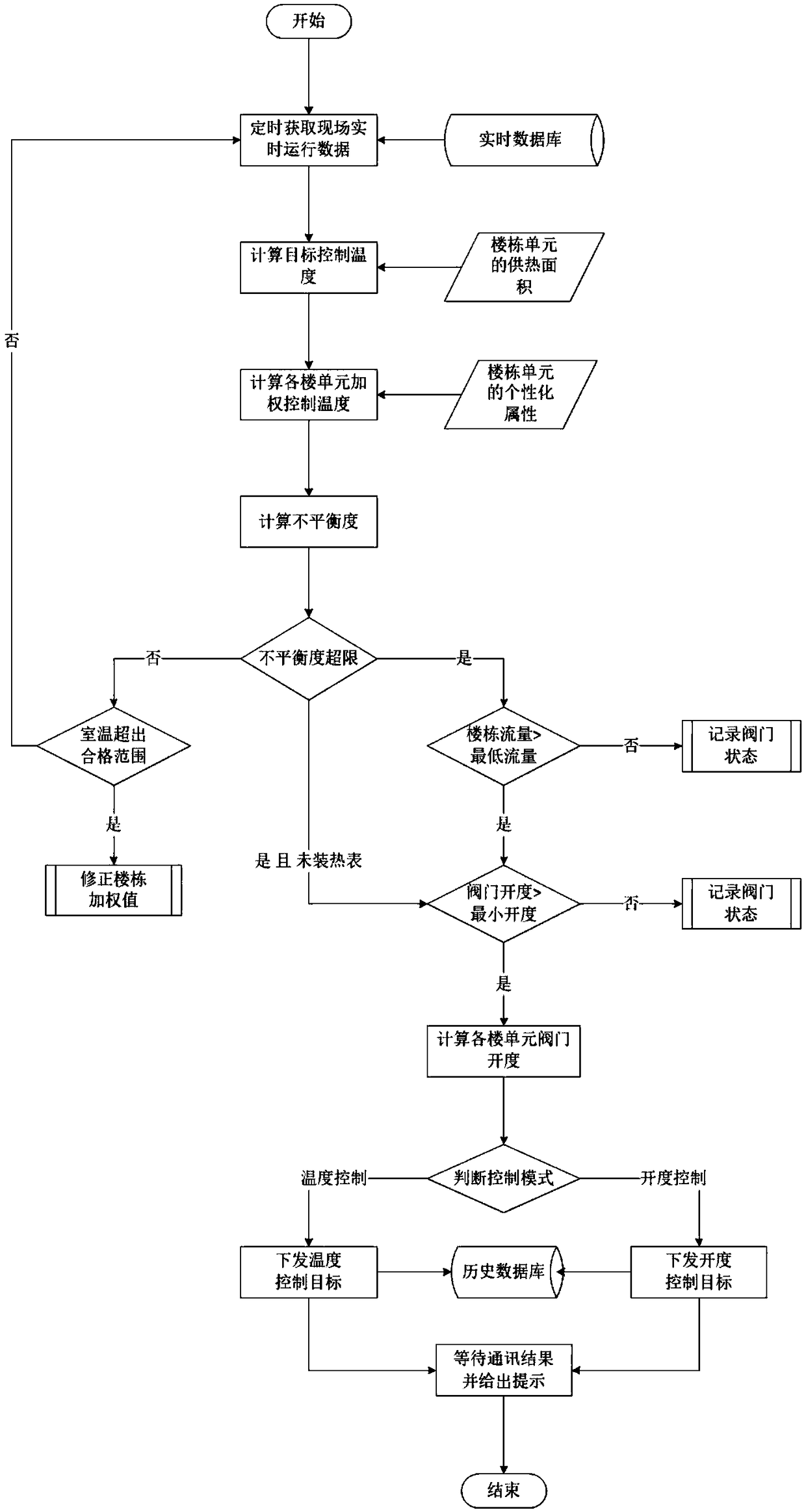

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 (no electricity, no network, no building heat meter)

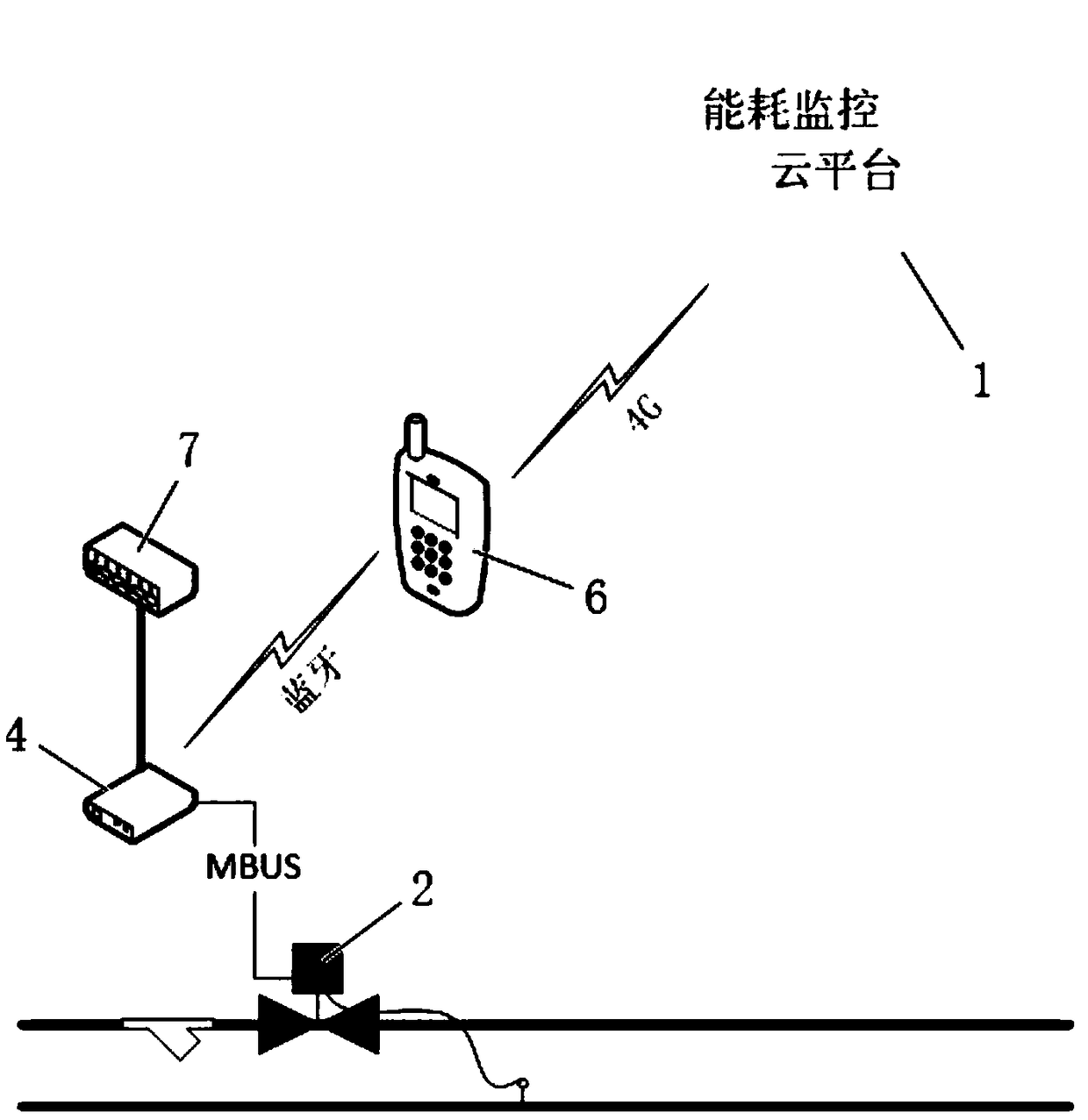

[0088] Such as figure 2 As shown, the intelligent energy consumption monitoring system includes an energy consumption monitoring cloud platform 1, an intelligent control device 4 and a mobile power supply 7 corresponding to each building unit, and an electric valve 2 arranged at each building unit, wherein the electric valve Connected with the intelligent control device signal, the mobile power supply supplies power to the intelligent control device, and the electric valve can collect the actual water supply temperature, return water temperature and flow rate of the thermal inlet of the building unit;

[0089] The intelligent control device 4 can be connected to the smart phone 6 via Bluetooth, and the smart phone is used to read the on-site operation data and send it to the energy consumption monitoring cloud platform through the network, and the energy consumption monitoring cloud platform summarizes...

Embodiment 2

[0090] Embodiment 2 (no network, no building heat meter)

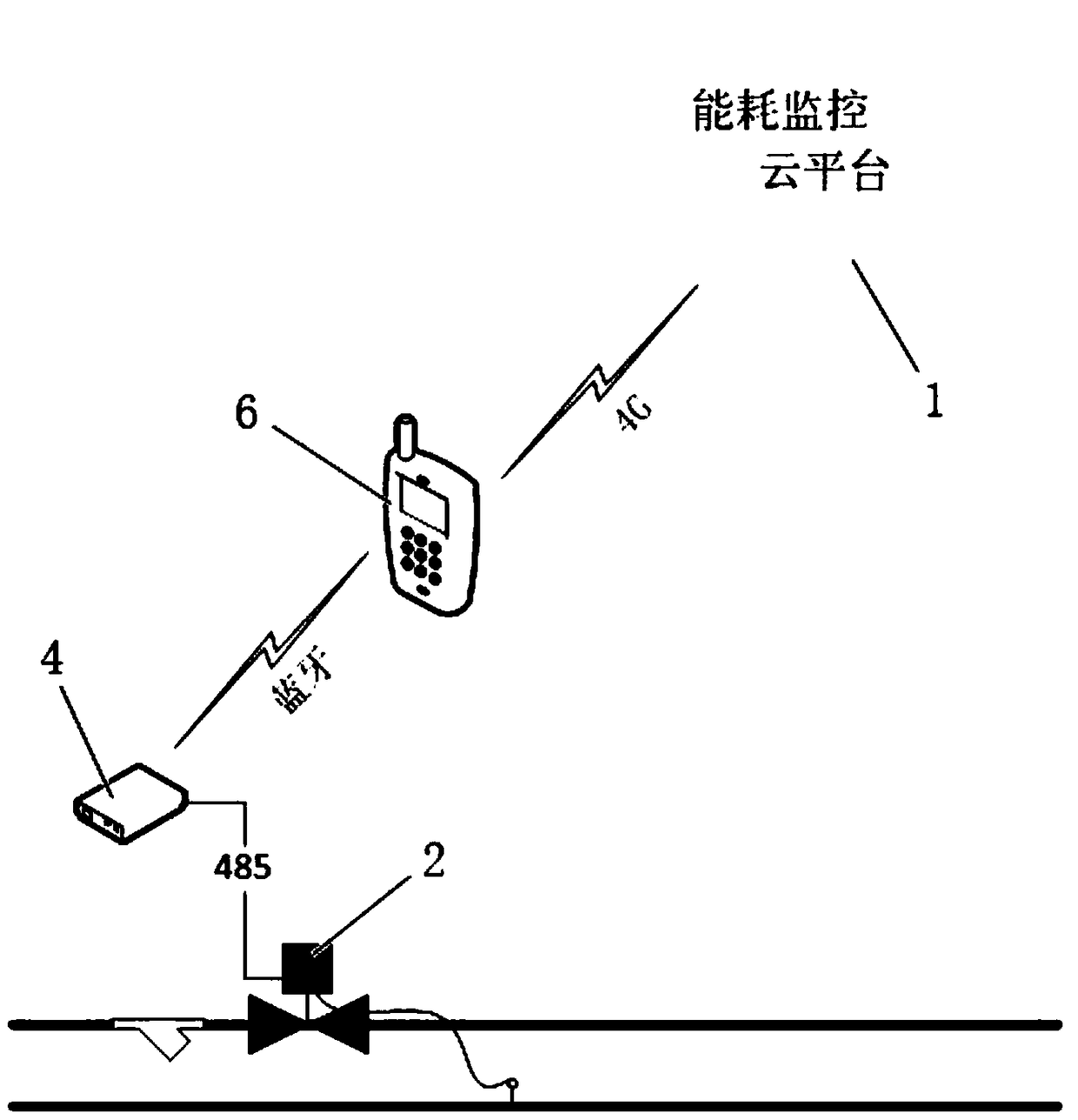

[0091] Such as image 3 As shown, the intelligent energy consumption monitoring system includes an energy consumption monitoring cloud platform 1, an intelligent control device 4 corresponding to each building unit, and an electric valve 2 arranged at each building unit, wherein the electric valve and the intelligent control device Signal connection, the electric valve can collect the actual water supply temperature, return water temperature and flow of the thermal inlet of the building unit;

[0092] The intelligent control device 4 can be connected to the smart phone 6 via Bluetooth, and the smart phone is used to read the on-site operation data and send it to the energy consumption monitoring cloud platform through the network, and the energy consumption monitoring cloud platform summarizes the operation data uploaded by each building unit , Calculate the target control temperature and the set opening of each elect...

Embodiment 3

[0093] Embodiment 3 (with network, without building heat meter)

[0094] Such as Figure 4 As shown, the intelligent energy consumption monitoring system includes an energy consumption monitoring cloud platform 1, an intelligent control device 4 corresponding to each building unit, and an electric valve 2 arranged at each building unit, wherein the electric valve and the intelligent control device Signal connection, the intelligent control device is connected to the energy consumption monitoring cloud platform network, and the electric valve can collect the actual water supply temperature, return water temperature and flow rate of the thermal inlet of the building unit;

[0095] The intelligent control device 4 can send the on-site operation data to the energy consumption monitoring cloud platform through the network. The control command is sent to the intelligent control device, and the intelligent control device controls the opening of the electric valve to the set opening....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com