Monitoring system for continuous on-line observation of trace gas mercury and monitoring method

A monitoring system, gas mercury technology, applied in the field of mercury gas trace observation, can solve the problem of fast, continuous on-line, long-term observation, detection instruments are easily affected by ambient temperature and humidity, long adsorption equilibrium time, film structure memory, etc. problems, to achieve high sensitivity, fast response, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

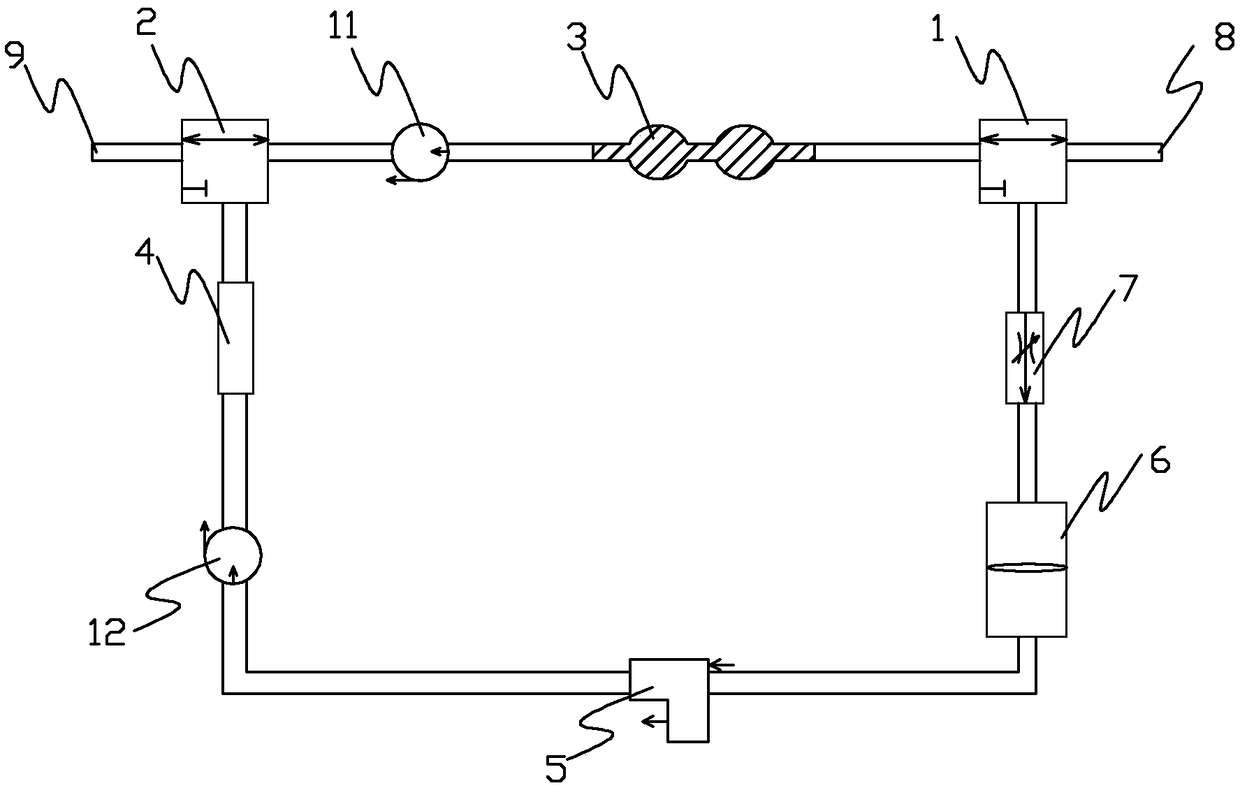

[0023] Embodiment: The monitoring system for continuous on-line observation of trace gas mercury in this embodiment, figure 1 As shown, it includes a first electromagnetic diaphragm pump 1, a mercury trap 3, a first circulating diaphragm air pump 11, a second electromagnetic diaphragm pump 2, a purification pipe 4, a second circulating diaphragm air pump 12, a gas flow meter 5, and a nanocomposite The particle film sensor 6, the flow stabilization device 7 and the main control circuit, the system air inlet 8, the first electromagnetic diaphragm pump, the mercury trap, the first circulating diaphragm air pump, the second electromagnetic diaphragm pump and the system air outlet 9 pass through the pipe successively. One end of the purification pipe is connected with the second electromagnetic diaphragm pump, the purification pipe, the second circulation diaphragm air pump, the gas flow meter, the nanocomposite particle film sensor and the flow stabilization device are connected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com