Electronic cigarette power control method and electronic cigarette

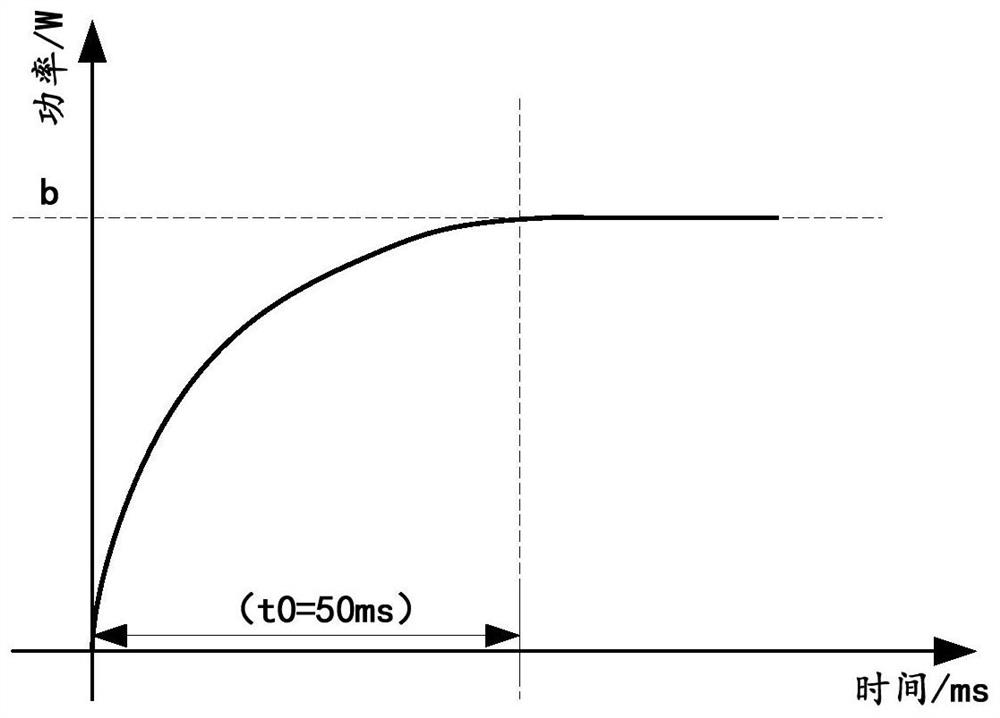

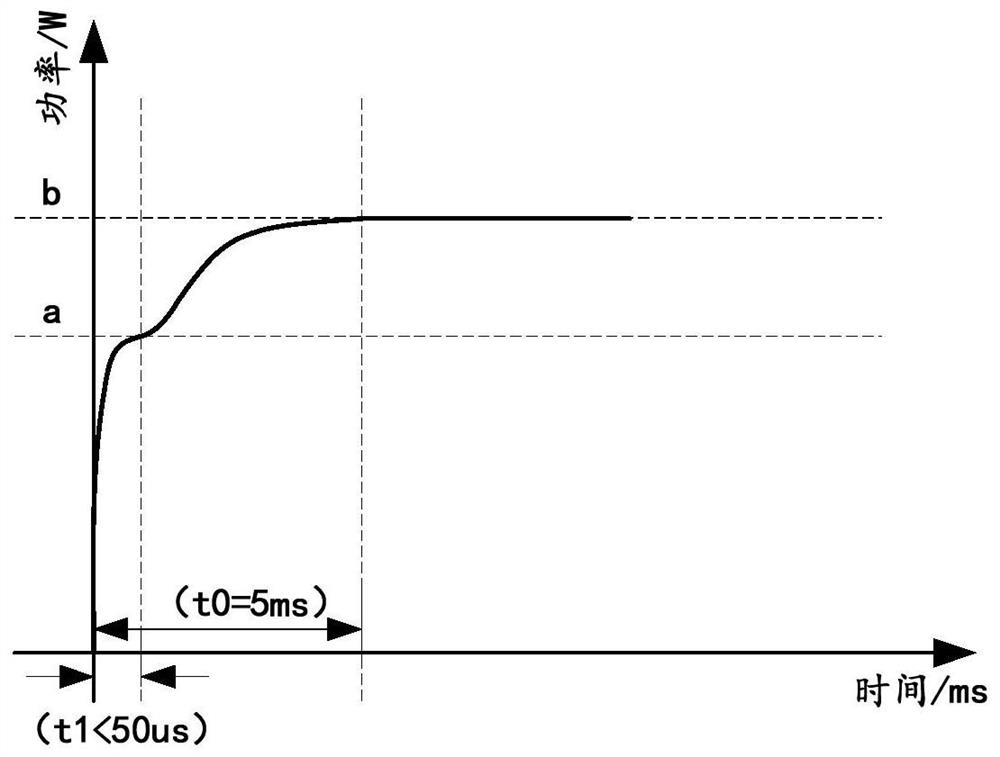

A power control and e-cigarette technology, applied in the field of e-cigarettes, can solve the problems of e-cigarettes such as long smoke out time, long power rise time, affecting user experience, etc., to shorten the smoke out time, shorten the power rise time, and reduce the ratio adjustment the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] see figure 2, is a schematic structural diagram of an electronic cigarette provided in an embodiment of the present invention, the electronic cigarette includes: a controller 10, a power supply device 20 and a heating element 30, the controller 10 is connected to the power supply device 20, and the power supply device 20 is connected to the heating element 30 , wherein the controller 10 is used to control the power supply device 20, the power supply device 20 is used to output power to supply power to the heating element 30, and the heating element 30 is used to heat the atomized substrate to generate an aerosol, that is, in the embodiment of the present invention, The controller 10 can control the power supply device 20 to output power to the heating element 30, so that the heating element 30 can heat the atomized substrate according to the power output by the power supply device 20 to generate aerosol, and realize the ignition of the electronic cigarette.

[0057] Wh...

Embodiment 2

[0091] see image 3 , is a schematic flow chart of an electronic cigarette power control method provided in an embodiment of the present invention, which is applied to an electronic cigarette, and the electronic cigarette is the electronic cigarette described in the above-mentioned embodiment. Execution is used to control the output power of the power supply device to the heating element, and the electronic cigarette power control method includes:

[0092] S120: Determine the target power.

[0093] The target power is the final and constant output power that the output power of the power supply device will eventually reach during the rising process.

[0094] Before determining the procedure for target power, refer to Figure 4 , the electronic cigarette power control method also includes:

[0095] S110: Receive a startup instruction, where the startup instruction includes a user-set power.

[0096] The above-mentioned "activation instruction" is an instruction generated by...

Embodiment 3

[0172] see Figure 9 , is a schematic structural diagram of an electronic cigarette power control device provided in an embodiment of the present invention, which is applied to an electronic cigarette. The electronic cigarette is the electronic cigarette described in the above embodiment. The functions of each module of the device provided in the embodiment of the present invention are as The above-mentioned controller 10 is executed to control the power supply device to output power to the heating element. The electronic cigarette power control device includes:

[0173] A determination module 100, the determination module 100 is used to determine the target power.

[0174] A setting module 200, the setting module 200 is configured to set an intermediate power according to the target power, and the intermediate power is smaller than the target power.

[0175] The first control module 300, the first control module 300 is used to control the power supply device to output power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com