Sectional heating type heating body and low-temperature smoking set

A technology of segmented heating and heating body, which is applied in the fields of tobacco, smoker's products, applications, etc., can solve the problem of long waiting time for smoking, and achieve the effect of shortening the smoking time, improving heating efficiency and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

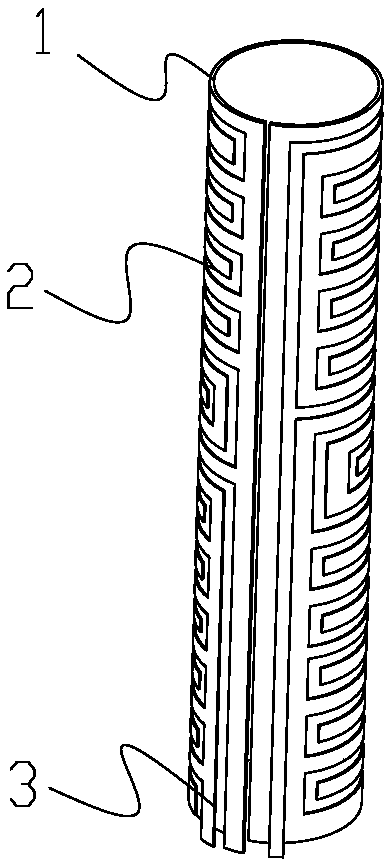

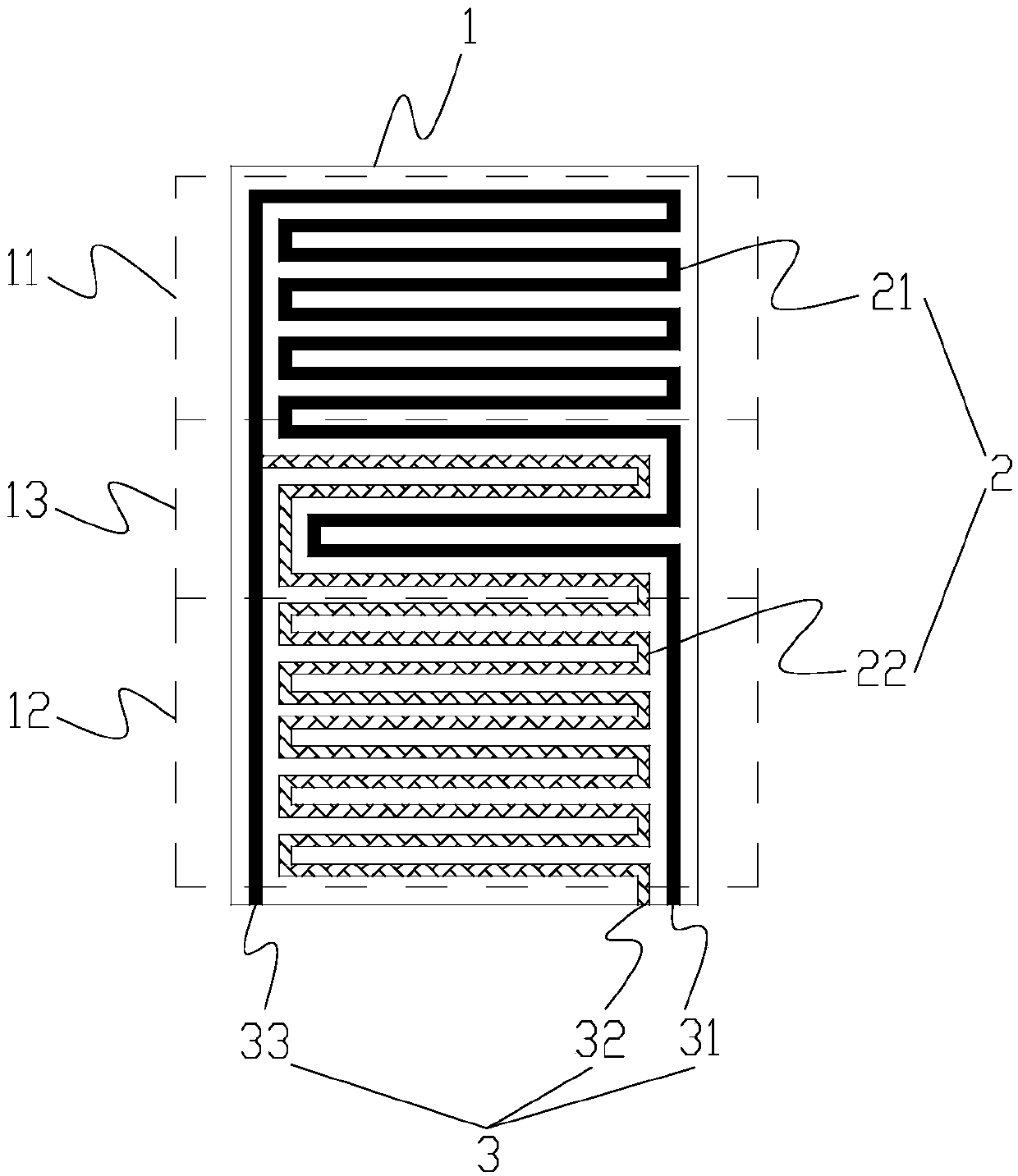

[0038] see figure 1 and figure 2 , the segmental heating type heating element in the illustration is a preferred solution of the present invention, which uses a heating tube 1 as a heating carrier, and the heating tube 1 is a cylindrical tube, and the inner cavity is used for inserting cigarettes. The heating sheet 2 is attached and fixed on the surface. After the heating sheet 2 is energized, the internal cigarettes are surrounded and heated by the heating tube 1. A number of electrodes 3 are fixed at one end of the heating tube 1. The electrodes 3 are in contact with the two ends of the heating sheet 2. Connect the heating sheet 2 to an external power source to form a closed heating circuit.

[0039] Specific as figure 2 As shown, the cylindrical outer surface of the heating pipe 1 of this embodiment is divided into three sections in the axial direction, and the first independent heating area 11, the second independent heating area 12, and the first independent heating a...

Embodiment 2

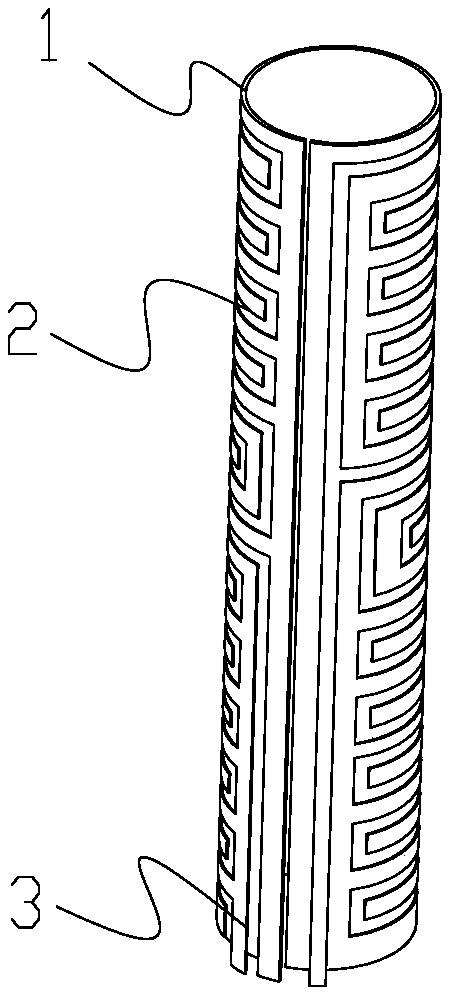

[0054] see in conjunction image 3 and Figure 4 , the segmented heating heating element of this embodiment is another preferred solution of the present invention, the overall structure of the heating element is the same as that of Embodiment 1, the difference is that on the mixed heating area 13 of the heating pipe 1 of this embodiment The first heating sheet 21 and the second heating sheet 22 inside the mixed heating area 13 adopt the same serpentine continuous bending arrangement in the corresponding independent heating area, and the first heating sheet 21 and the second heating sheet 22 are in half Evenly distributed, that is, the first heating sheet 21 and the second heating sheet 22 respectively cover the heating pipes of half the circumference of the mixed heating area, and the two groups of heating sheets are symmetrically distributed in the circumferential direction, so that in the first independent heating area 11 and the second independent heating area When 12 gene...

Embodiment 3

[0056] see in conjunction Figure 5 , the segmented heating heating element in this embodiment is another preferred solution of the present invention. The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the heating carrier in this embodiment adopts a heating core 1', the The heating core 1' is a solid ceramic rod, a ceramic sheet, or an insulated metal rod or metal sheet. The heating core 1' is inserted into the cigarette, and the heating sheet 2 is attached to the outer surface of the heating core 1'. The heating sheet After the power is turned on, the cigarette is centrally heated. The arrangement of the heating sheet 2 on the outer surface of the heating core 1' is the same as that of the first and second embodiments.

[0057] The specific working process of the segmented heating heating element in the above embodiments is as follows: when in use, the first electrode 31, the second electrode 32 and the common electrode 33 are all connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com