Flammable and burning-resistant carbonaceous heat source and preparation method and application thereof

A carbonaceous heat source and burn-resistant technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of not considering the human health hazards of the binder, difficult to ignite quickly, and fast burning rate, so as to reduce health risks, The effect of shortening the time of smoke emission and strong fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

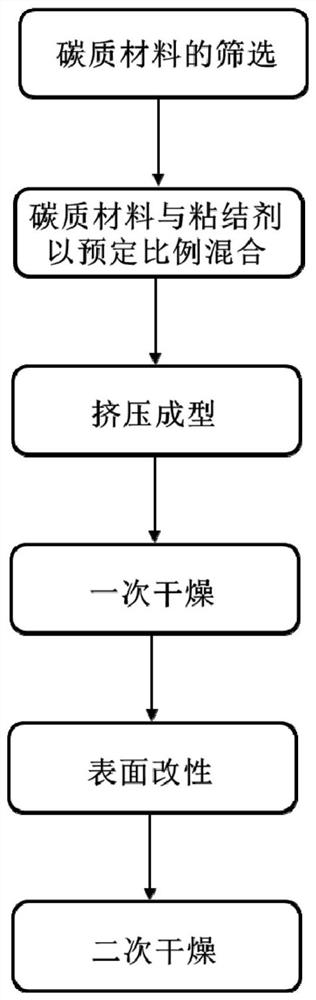

Method used

Image

Examples

Embodiment 1

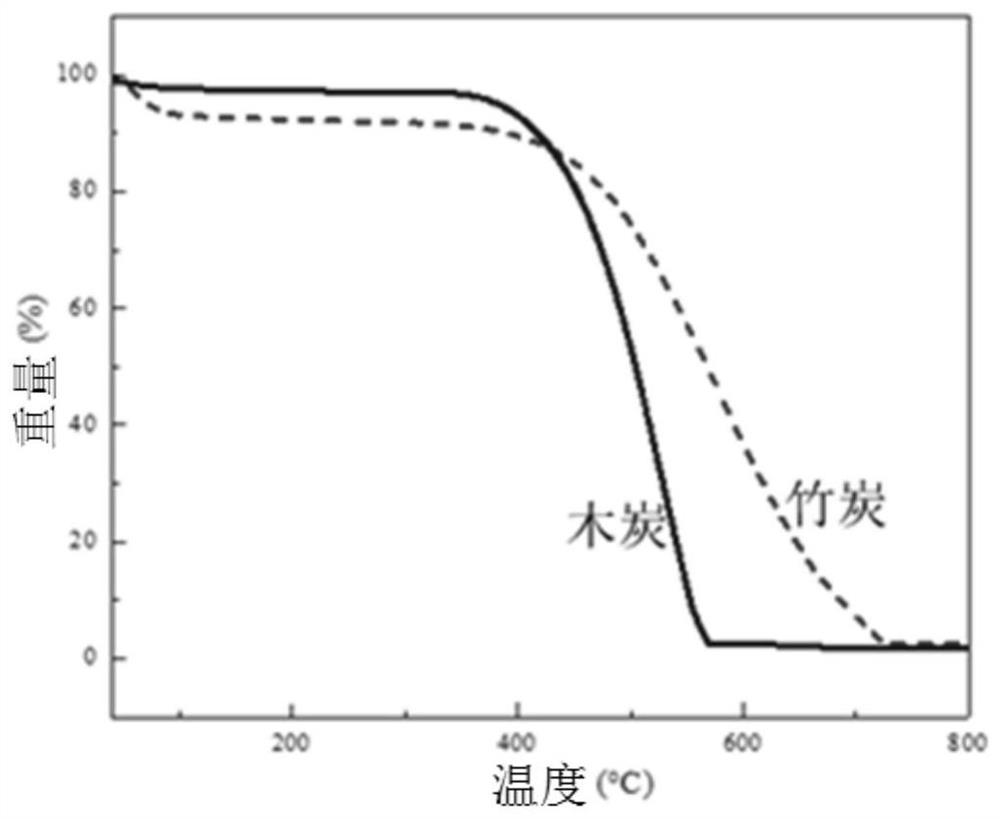

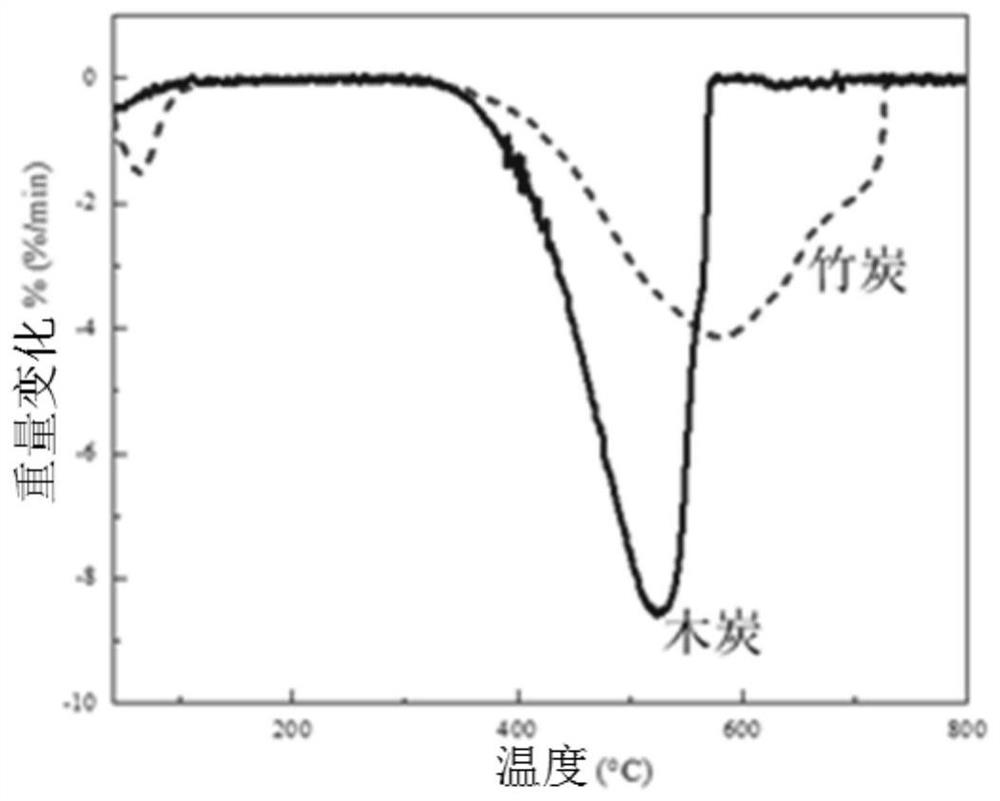

[0036] Select a kind of charcoal and bamboo charcoal, crush and grind it, then pass through a 100-mesh sieve, and use an industrial analyzer to analyze its moisture, volatile matter, fixed carbon and ash content (Table 1), the results show that the ash content of fruit charcoal is 3.3 %, the ash content of bamboo charcoal is 2.8%; the elemental analyzer is used to determine that the content of carbon element is higher than 85%, and the content of sulfur and nitrogen is lower than 0.4%; the ash content of the charcoal and bamboo charcoal after combustion is tested by XRF Show that main oxide composition is silicon dioxide, calcium oxide, magnesia, ferric oxide and aluminum oxide (table 2); Adopt automatic calorimeter analysis calorific value to be 28-30MJ / kg; Produced thermal comprehensive analyzer, get its TG ( figure 2 ), DTG curve ( image 3 ), it was found that the burn-out temperatures of the charcoal and bamboo charcoal were 559°C and 724°C, respectively, and the maximu...

Embodiment 2

[0043] Select cotton stalk carbon and semi-coke obtained by pyrolysis at 700°C after washing a kind of coal with high volatile content and low ash content in western my country, crush and grind it finely, and then pass through a 600-mesh sieve, using the carbonaceous charcoal described in Example 1 Material screening methods are tested and judged. According to the test results, both cotton stalk carbon and the semi-coke were selected as flammable carbon.

[0044] The cotton stalk charcoal of 40 parts by weight of 600 orders, the semi-coke of 20 parts by weight of 600 orders, the graphite powder of 15 parts by weight of 600 orders, the water-free glutinous rice glue of 5 parts by weight of 600 orders, and the water of 20 parts by weight in a mixer Mixed and stirred evenly, and aged for 20 minutes, the carbon rod was extruded by a screw extrusion molding machine, the extrusion molding pressure was 8MPa and the temperature was 85°C, and the extruded carbon rod was dried in the air...

Embodiment 3

[0046] Select coconut shell activated carbon and tobacco carbon obtained by pyrolysis of waste from a certain tobacco industry at 600°C, pulverize and grind them finely, then pass through a 400-mesh sieve, and use the carbonaceous material screening method described in Example 1 to test and judge. According to the test results, coconut shell activated carbon was selected as the auxiliary carbon source of the flammable carbon, and tobacco carbon was selected as the flammable carbon.

[0047] Tobacco charcoal of 40 parts by weight of 400 orders, activated carbon of 6 parts by weight of 400 orders, graphite powder of 14 parts by weight of 800 orders, non-water glutinous rice glue of 9.5 parts by weight of 400 orders, kaolin of 0.5 parts by weight of 200 orders, 30 parts by weight of The water was mixed and stirred evenly in the mixer, and aged for 60 minutes. The carbon rod was extruded by a screw extrusion molding machine. The extrusion molding pressure was 3MPa and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com