Method for preparing microporous ceramic and microporous ceramic heating bar

A technology of microporous ceramics and heating rods, applied in the field of microporous ceramics, can solve the problems of small contact area between the heating wire and the oil guide body, affect the taste of the smoke oil atomization, and provide a good experience, so as to shorten the time of smoking , Improve the smoking experience, improve the reduction and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

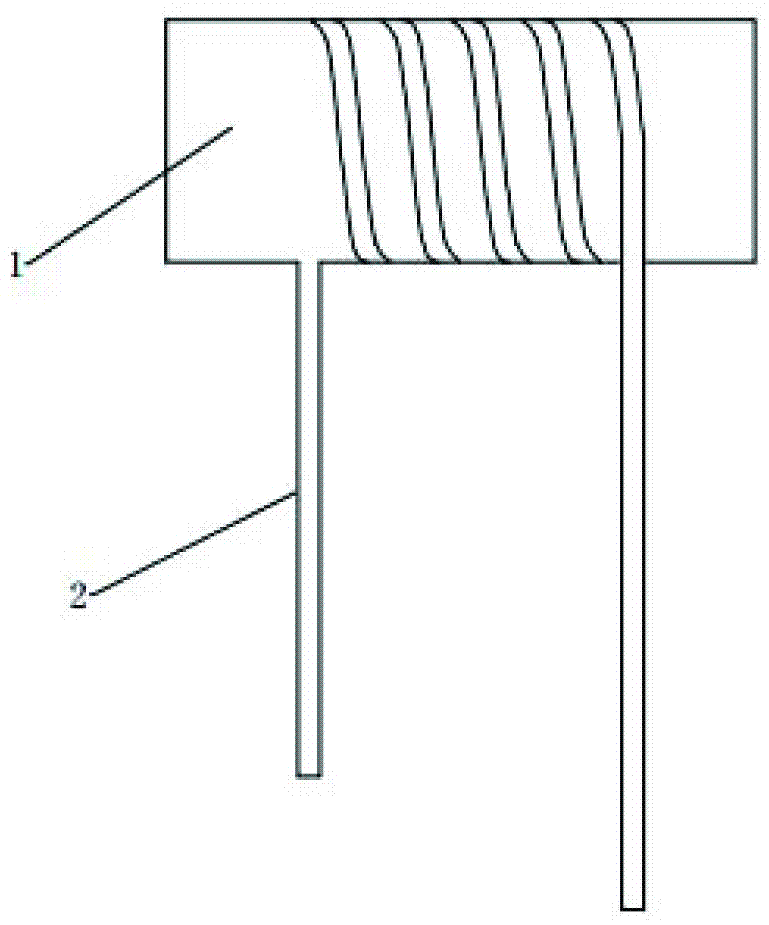

[0024] Example 1, this example is a preparation method for heating and microporous ceramic heating rod in the atomizer in an electronic cigarette, the microporous ceramic heating rod prepared by this method, the heating wire and the microporous ceramic are co-fired Integrate to improve product consistency and facilitate operation. Effectively ensure the stability of electric heating work, avoid local dry burning. Improve the heating efficiency of the heating wire, shorten the time of smoking, and improve the user's smoking experience.

[0025] The preparation method of the microporous ceramic heating rod comprises the following steps:

[0026] 1. Perform batching according to the ingredient list shown in Table 1, and the percentages in the ingredient list in Table 1 are mass percentages.

[0027] Table 1 Ingredients list

[0028] serial number Element Proportion(%) 1 Quartz sand 50-80 2 meerschaum powder 5-15 3 Zeolite powder 1-5 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com