I-shaped wooden beam quick positioning and mounting device

A technology for positioning installation and wooden beams, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of difficulty in controlling spacing and low efficiency, and achieve reduced construction risk and simple structure , the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

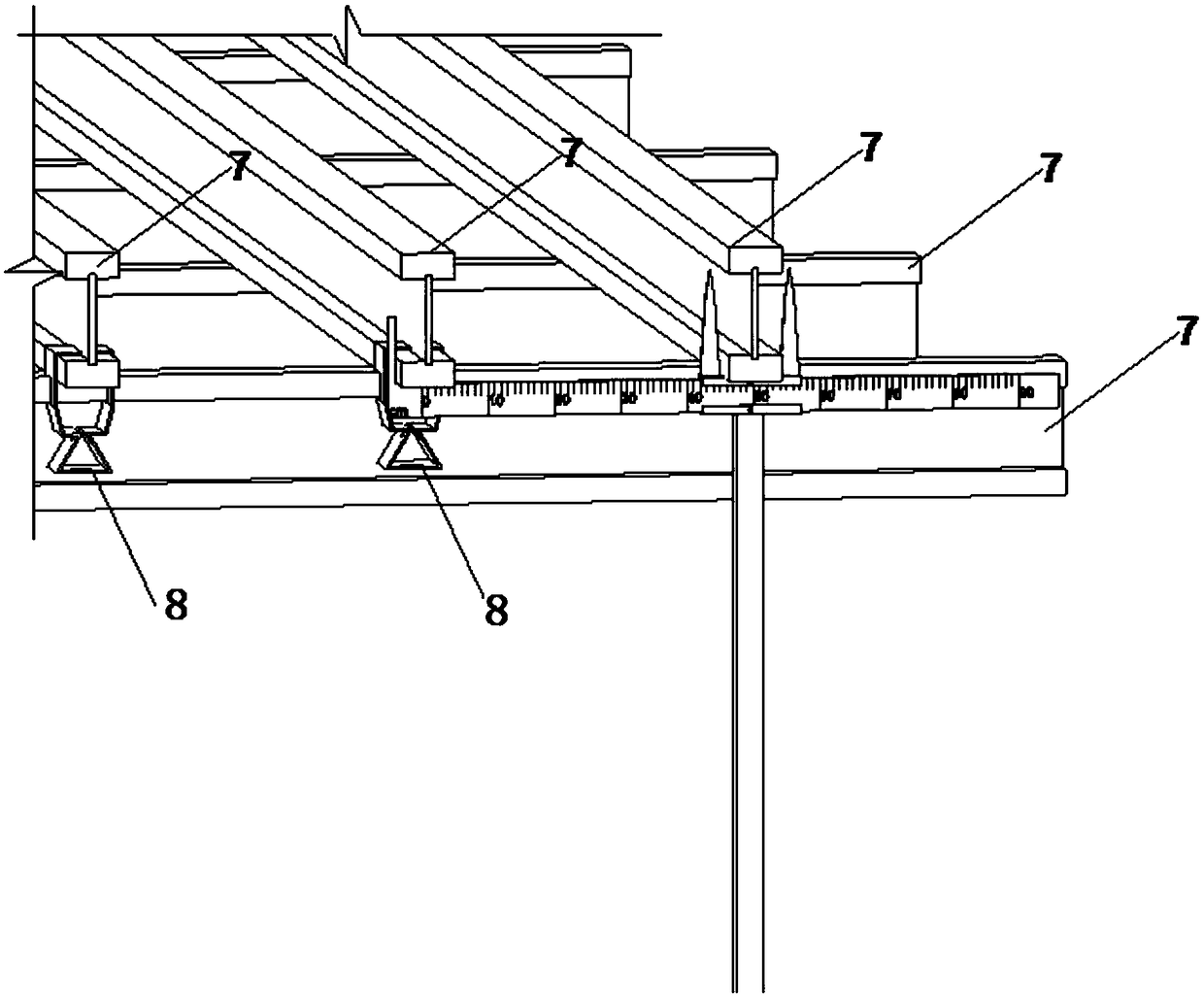

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

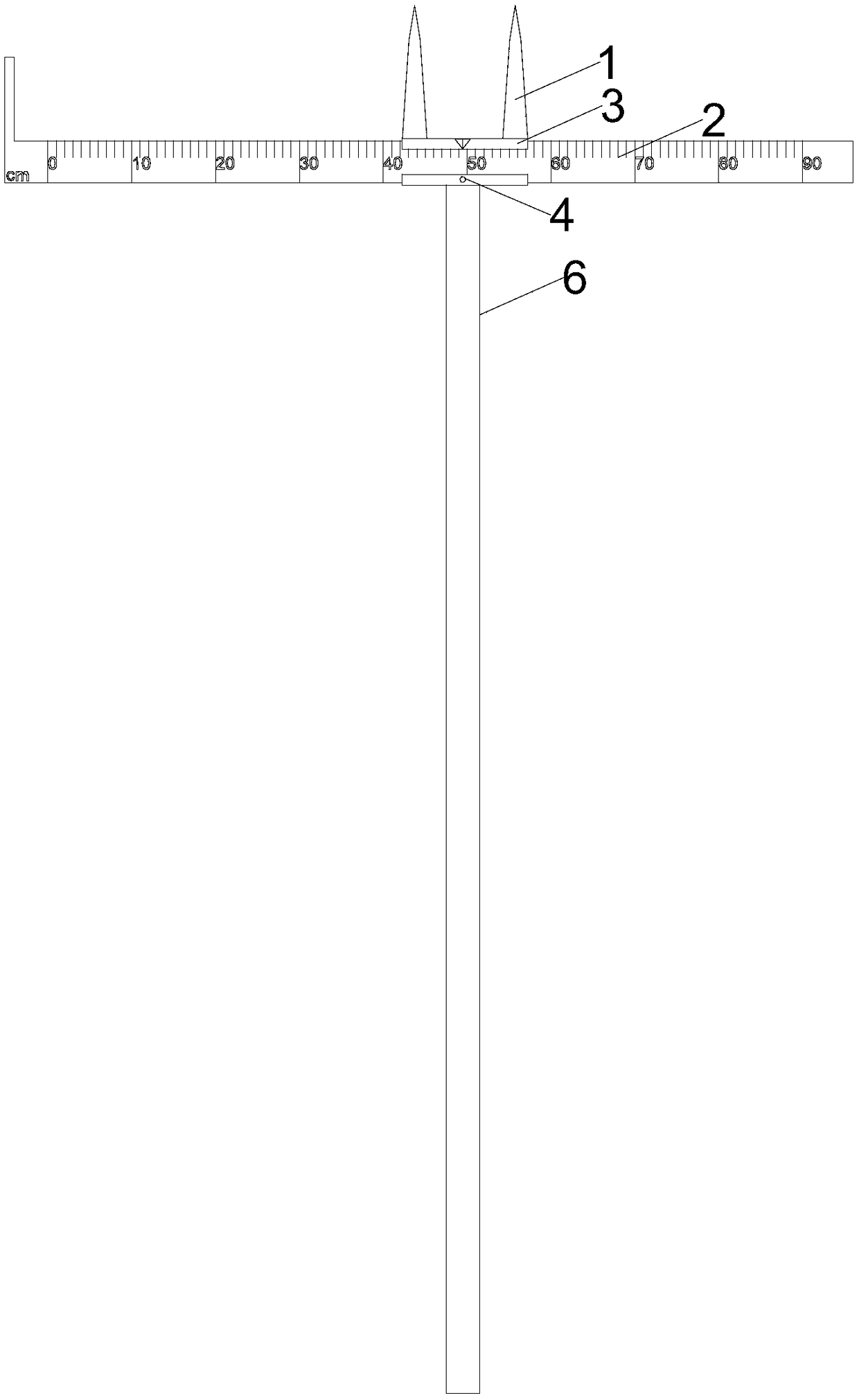

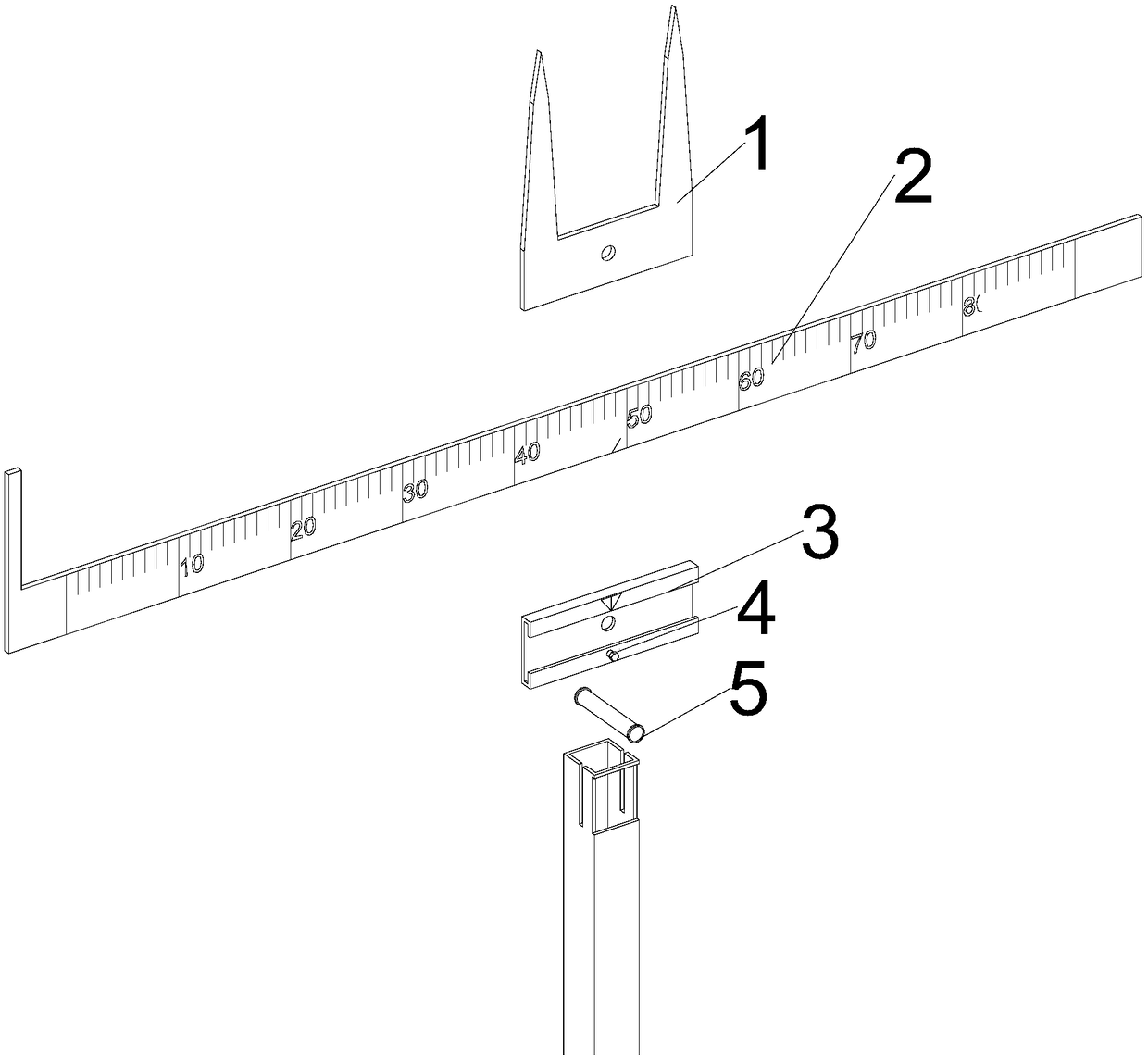

[0024] Such as Figure 1 to Figure 2 As shown, this embodiment provides a fast positioning and installation device for an I-shaped wooden beam, which mainly includes two prong heads 1 , a steel ruler 2 , a C-shaped slot 3 , fastening bolts 4 , rivets 5 , and fork rods 6 . The two prongs 1 are installed in the middle of the top of the fork rod 6, and the C-shaped card slot 3 is installed in the front part of the top of the fork rod 6. The two prongs 1 and the C-shaped card slot 3 are fixed on the fork rod 6 by rivets 5; the steel ruler 2 It is installed in the C-shaped card slot 3 and fixed with the C-shaped card slot 3 by fastening bolts 4 . One end of the steel ruler 2 is provided with a limit clip to locate the steel ruler 2 on the adjacent I-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com