Multi-row precise ball speed reducer

A reducer, precision technology, applied in the direction of portable lifting devices, transmission parts, gear transmissions, etc., can solve the problems of poor transmission performance, poor practicability, and reduced vibration stability of the transmission mechanism, and achieve the elimination of backlash, The effect of good stress and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

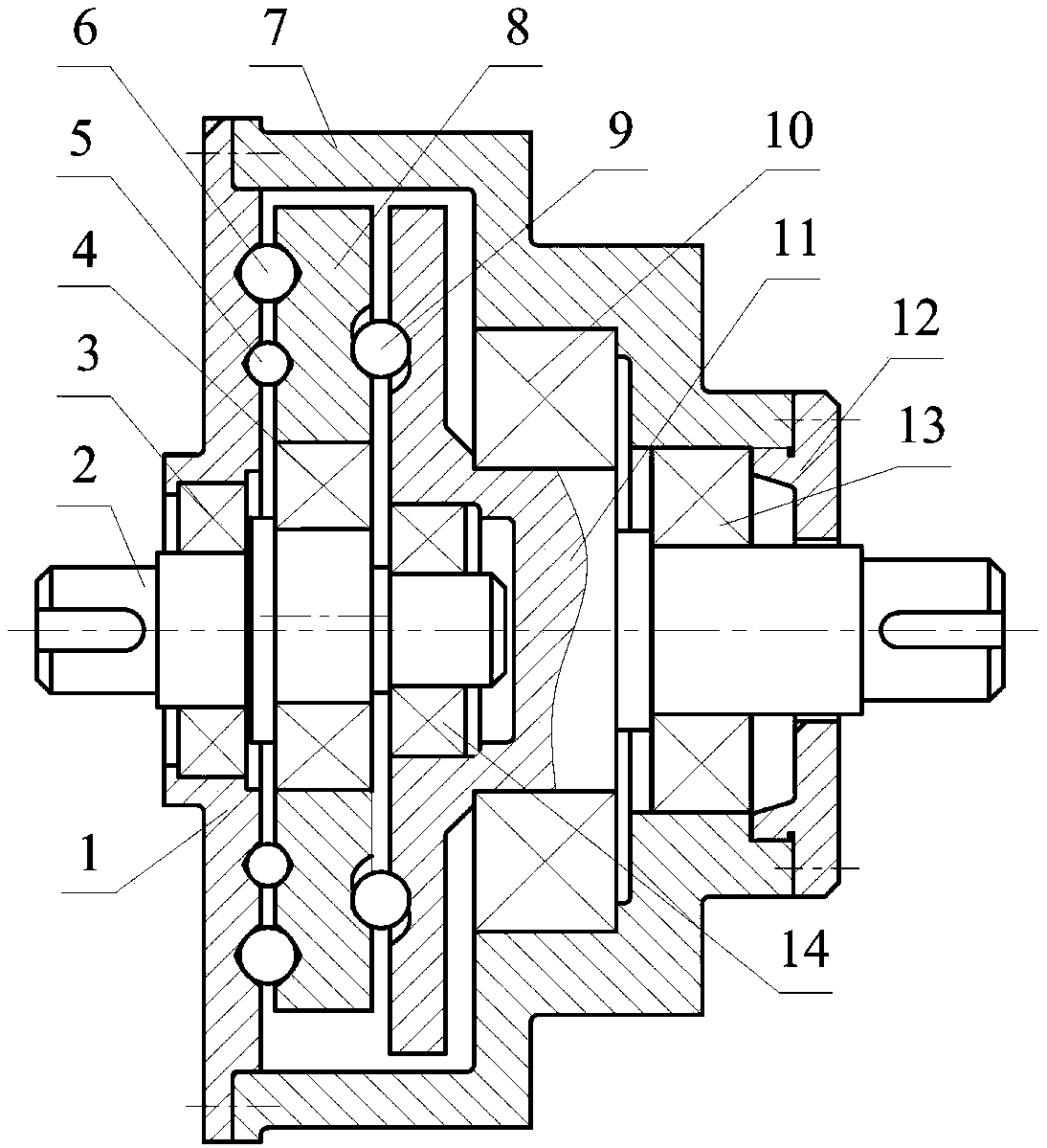

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] 1. Double-row precision ball reducer behind the annular groove constant velocity mechanism

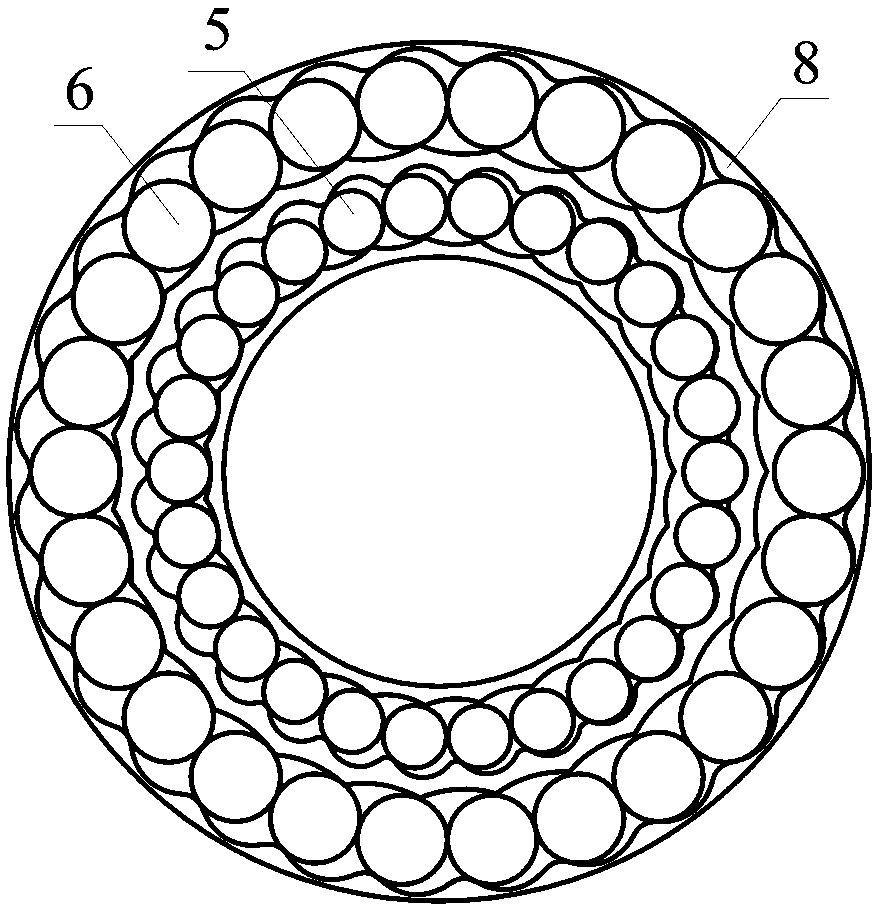

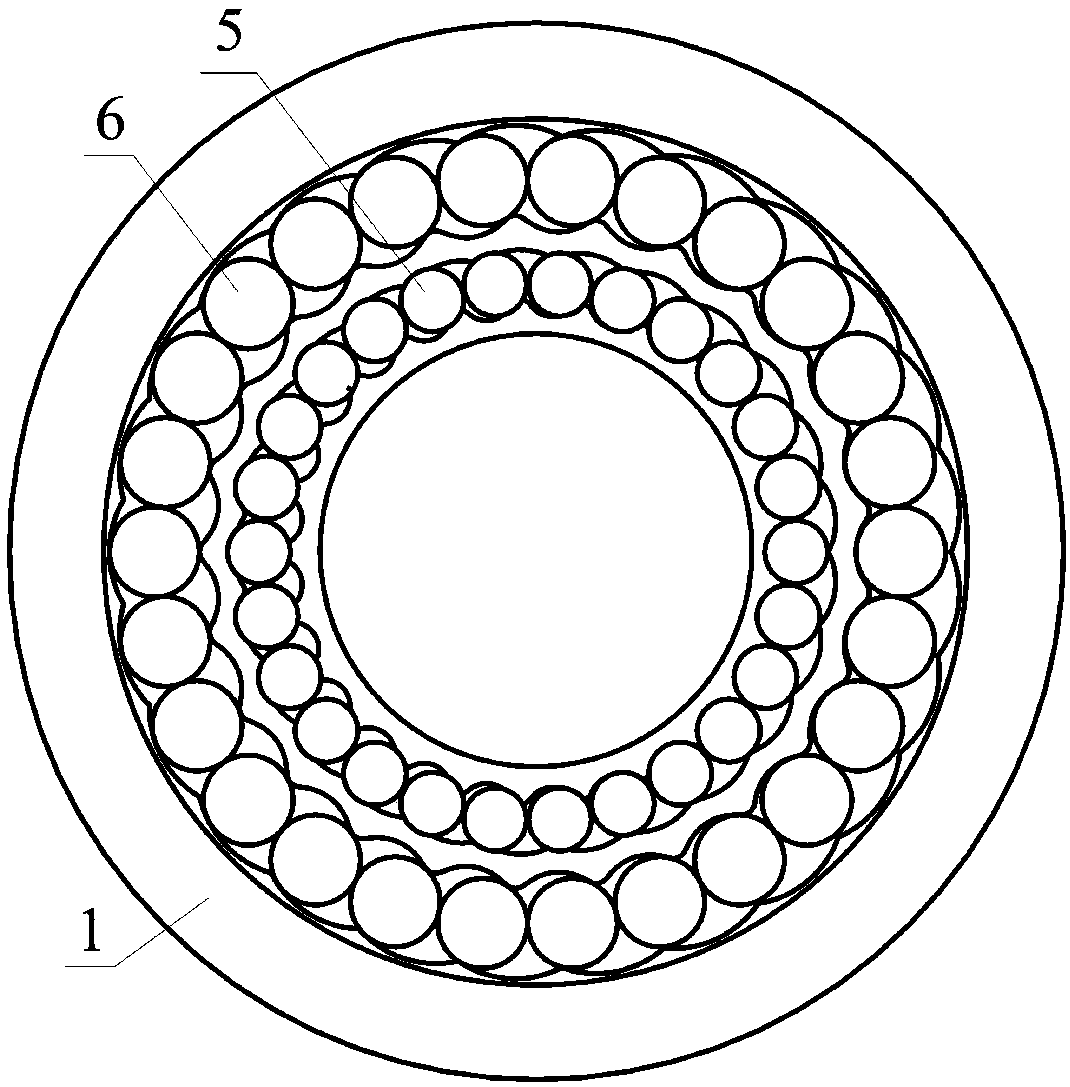

[0035] figure 1 It is a specific embodiment of the double-row precision ball reducer with the annular groove constant velocity mechanism behind the disclosed by the present invention, such as Figure 1~4 As shown, the double-row precision ball reducer is composed of center disc I1, input shaft I2, bearing aI3, bearing aII4, inner deceleration ball I5, outer deceleration ball I6, outer shell I7, planetary disc I8, constant velocity ball I9, bearing aIII10 , Output shaft Ⅰ11, gap adjustment disc Ⅰ12, bearing aⅣ13, bearing aⅣ14. The eccentric section of the input shaft I2 is installed with bearing aII4, and the planetary disk I8 is installed on the bearing aII4, and two rows of teeth are processed on the planetary disk I8, both of which are Z 3 A ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap