A disc entrainment self-priming valve

A self-priming valve, disc technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem of shortening the self-priming time, prolong the self-priming start time, reduce the self-priming efficiency, and occupy a small space and volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

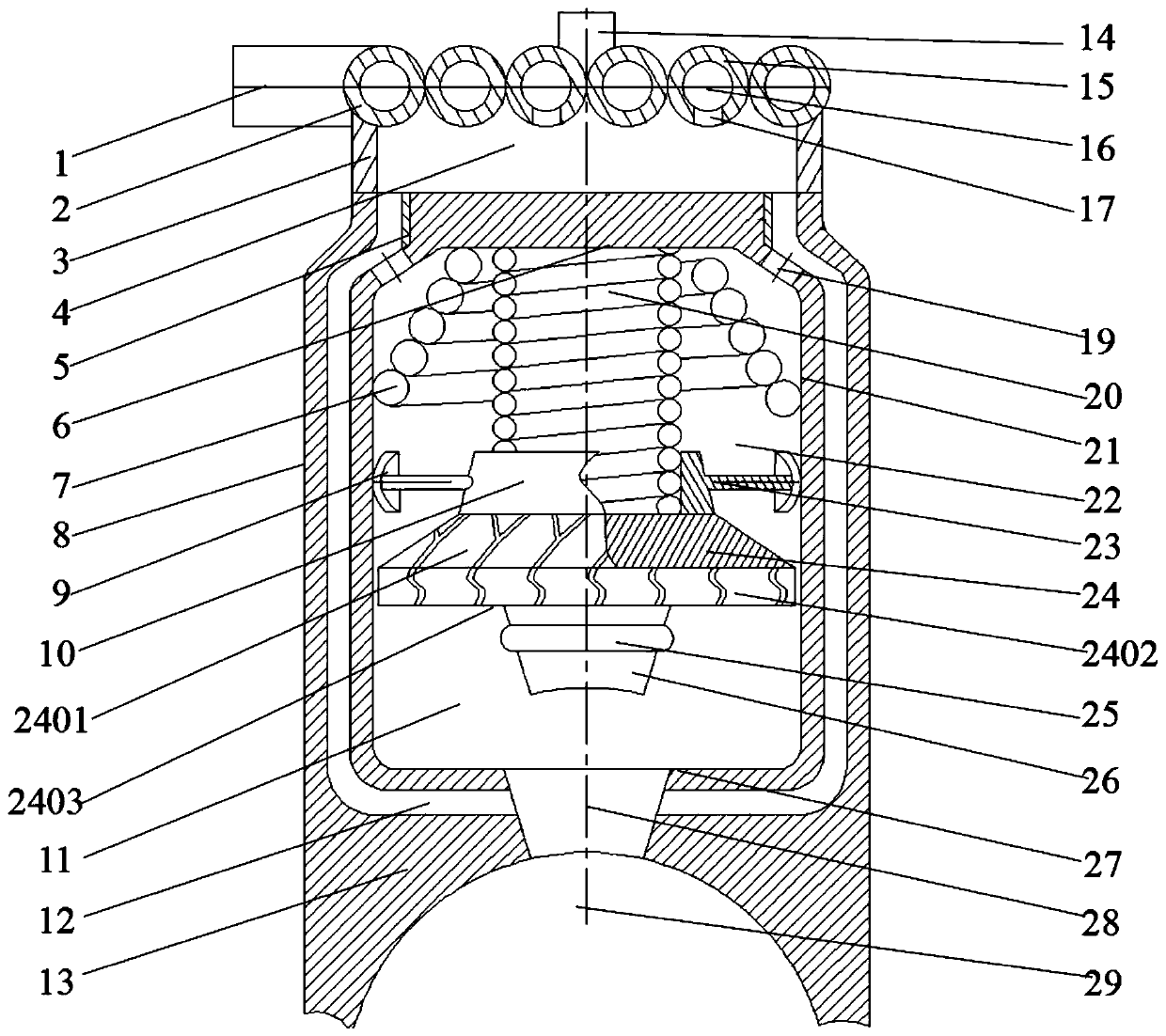

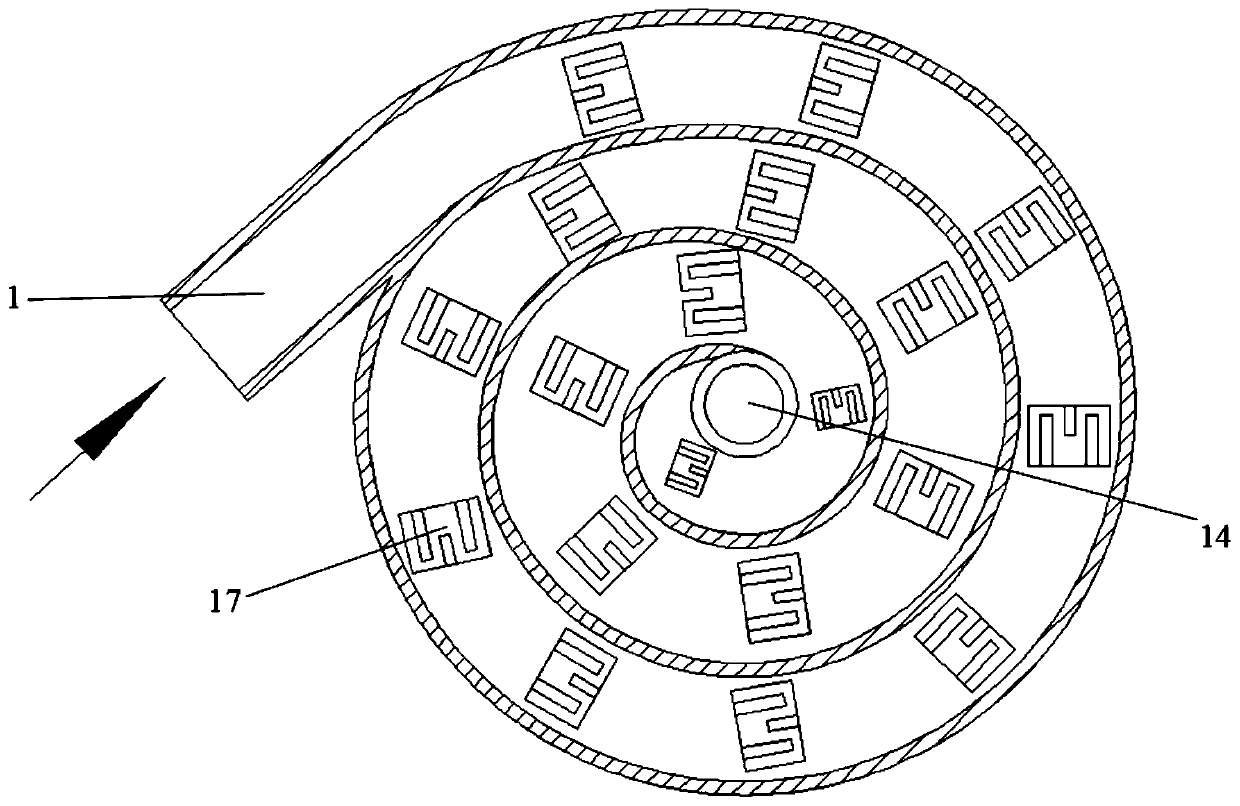

[0034] Such as figure 1As shown, a disc entrainment type self-priming valve according to the present invention comprises a entrainment disc lower cover plate 2, an entrainment disc upper cover plate 15, a first housing 3, a second housing 8, Conical spring 7, connecting spring 20, separating disc 24 and stop plug 26, entrainment disc lower cover plate 2 and entrainment disc upper cover plate 15 fit each other to form a spiral disc entrainment cavity 16, so The disc entrainment chamber 16 is formed by a circular pipeline in a horizontal plane spiraling in a spiral direction, the inlet of the disc entrainment chamber 16 is connected with the air intake pipe 1 in a tangential direction, and the disc entrainment chamber The outlet of 16 is located at the center of disc entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com