Analog-simulation filling and compacting forming experiment method for mine coal-rock layers

A technology of similar simulation and experimental methods, which is applied in the field of filling and compacting of similar materials in similar simulation experiments in mines, can solve problems such as inconsistent operation methods, uneven loading, complex and changeable experimental processes, etc., and achieve improved accuracy and reliability. Reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0023] The invention provides an experimental method for filling and compacting a similar simulated coal rock layer in a mine.

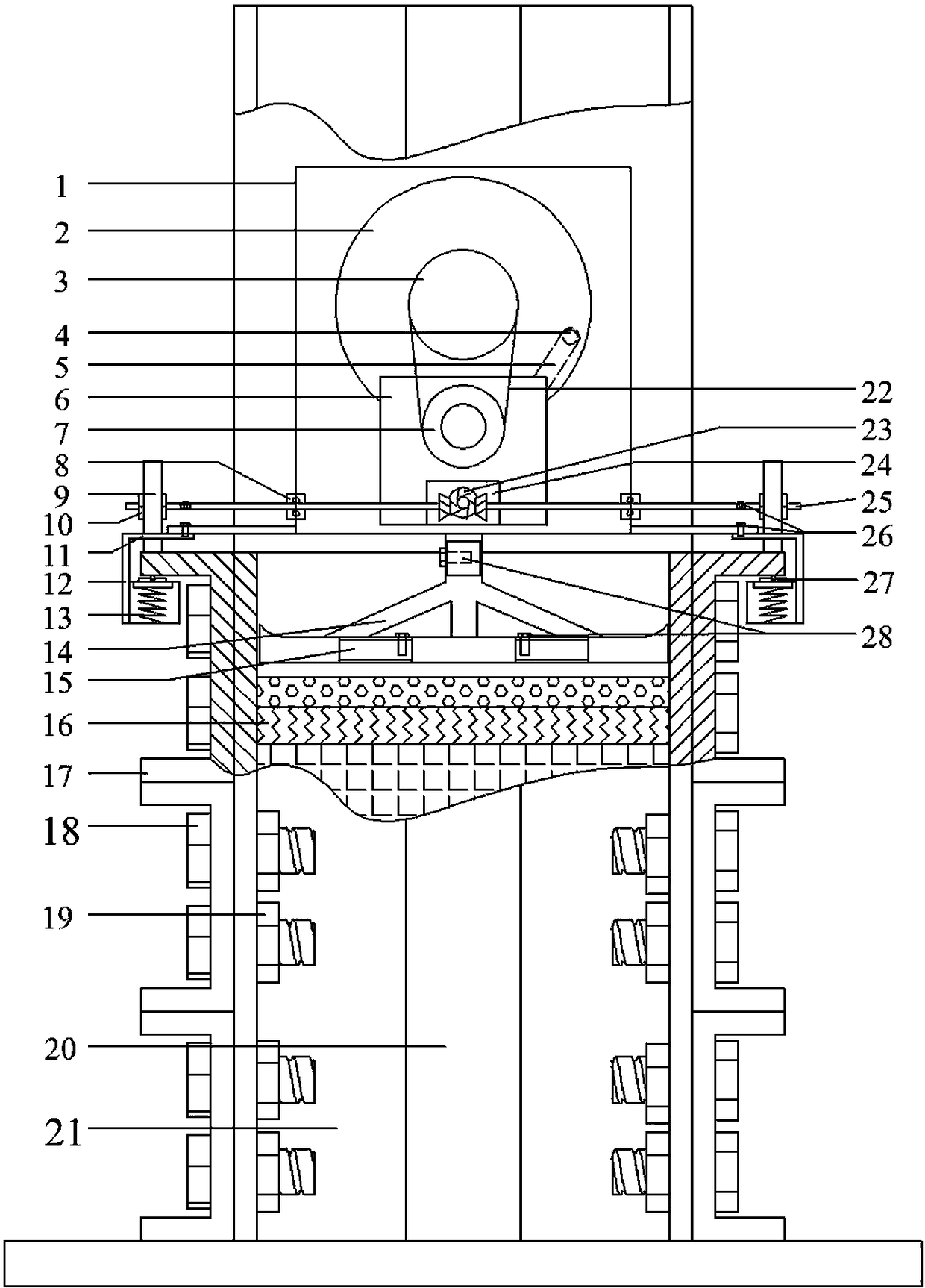

[0024] Such as figure 1 Shown, a kind of mine similar simulated coal rock formation filling compaction forming experimental method, comprises the following steps:

[0025] Step 1. Calculate the geometric similarity ratio, bulk density similarity ratio, stress similarity ratio and strength similarity ratio of similar simulation according to the actual engineering conditions on site, and determine the parameters such as the model frame type, the bulk density of the coal rock layer, and the excavation speed;

[0026] Step 2, install and debug the power mechanism, tamping mechanism, walking mechanism and restraining mechanism of the similar simulated coal rock bed filling sliding type automatic tamping device;

[0027] Step 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap