Flameproof three-phase asynchronous motor with high energy efficiency

A three-phase asynchronous, flame-proof technology, used in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of low protection level, poor oil drainage, and difficulty in connecting user cables, and achieves a wide range of adaptation and reduced energy consumption. The effect of mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

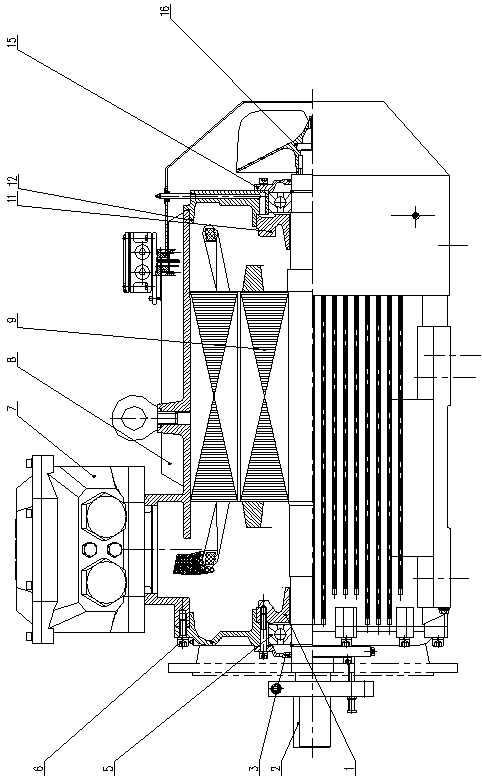

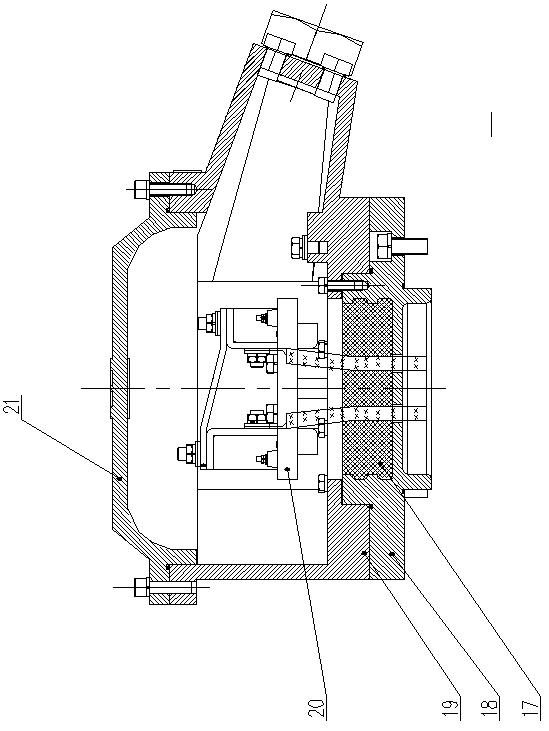

[0036] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0037] Such as figure 1 with figure 2 As shown, an energy-efficient flameproof three-phase asynchronous motor of the present invention includes a frame 8, a stator installed in the frame 8, and a rotor 9 installed in cooperation with the stator. The rotor 9 is fixedly installed on the rotating shaft 2. , The front and rear ends of the base 8 are respectively provided with end covers 6, 12, and bearings 5 are provided between the end covers 6, 12 and the shaft 2, and the inner and outer sides of the bearing 5 are respectively provided with bearing inner covers 1, 11 and Bearing cover 3,15.

[0038] The bearing inner covers 1, 11 closely cooperate with the rotating shaft 2 to form an inner flameproof passage structure; the bearing outer covers 3, 15 and the rotating shaft 2 closely cooperate to form an outer flameproof passage structure; the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com