Cooling cabinets for frequency converters

A frequency converter and cabinet technology, applied in the electrical field, can solve problems such as the lack of competitiveness of frequency converters, and the loss of reactors reduces the efficiency of frequency converters, and achieves the effects of simple structure, improved cooling effect, and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

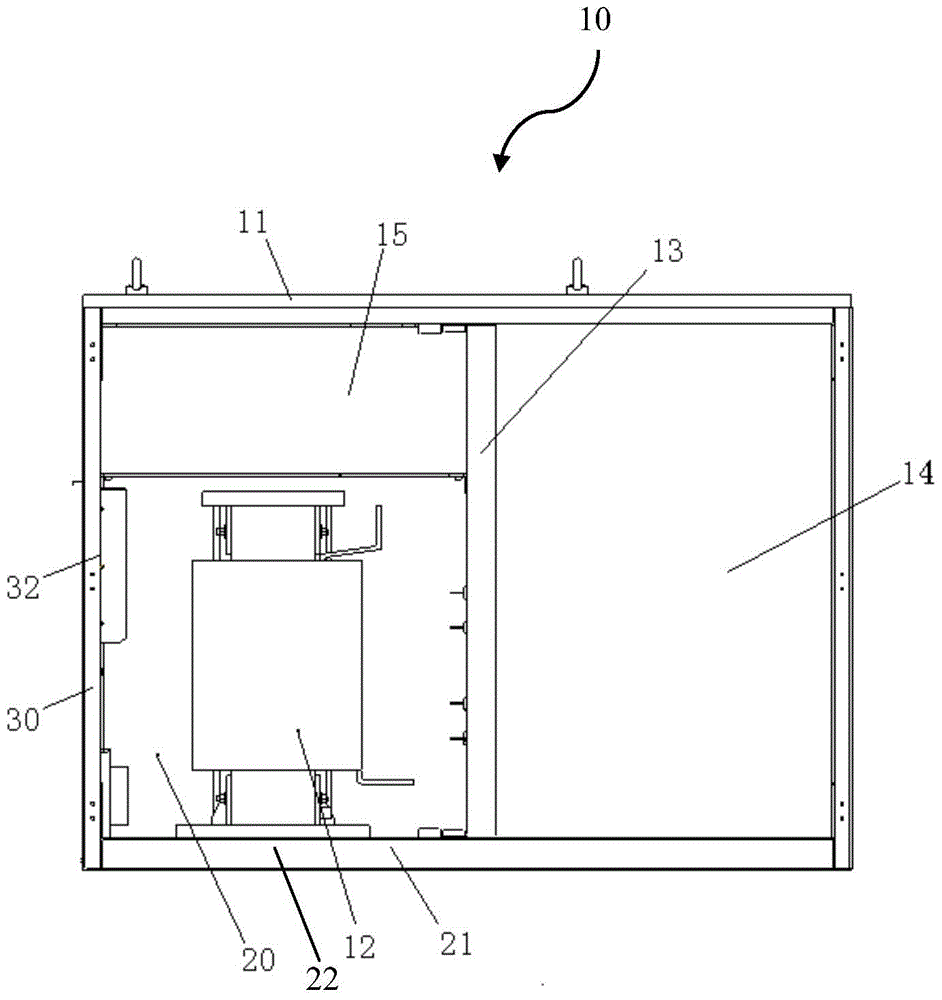

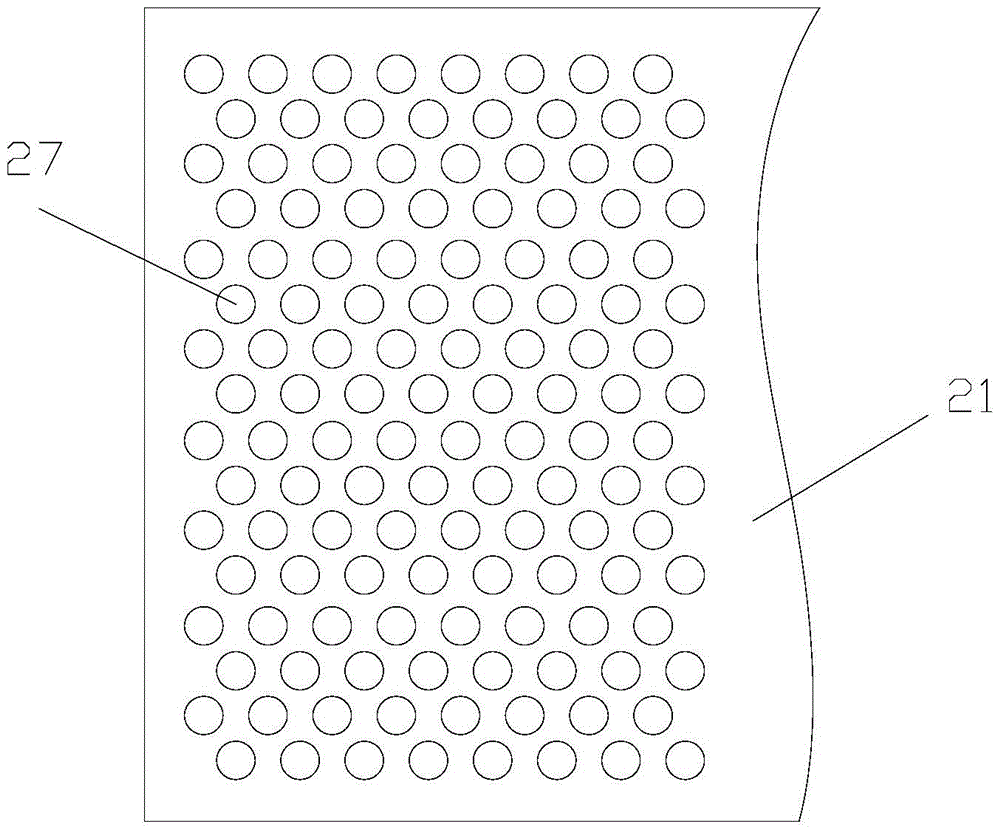

[0026] figure 1 A structural diagram of a cooling cabinet 10 for frequency converters (hereinafter simply referred to as the cabinet 10 ) according to the present invention is schematically shown. Such as figure 1 As shown, the cabinet 10 includes a bottom plate 21 , a side wall 30 and a top plate 11 . Viewed from the outside as a whole, the cabinet 10 is in the shape of a cuboid. A plurality of partitions 13 are arranged inside the cabinet 10 to divide the inside of the cabinet 10 into a plurality of cavities 20 , 14 , 15 . The components of the frequency converter are placed in these cavities, such as figure 1 The device 12 inside the cavity 20. Those skilled in the art will know that other devices are also arranged in the cavities 14 and 15. figure 1 not shown in It should be noted that each of these cavities includes a portion of the side wall 30 of the cabinet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com