Filament cutting head for free trimmer

一种收割头、切割机的技术,应用在切割器、收割机、应用等方向,能够解决切割丝线困难可接近性、切割丝线拆卸困难、不可切割丝线取出等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

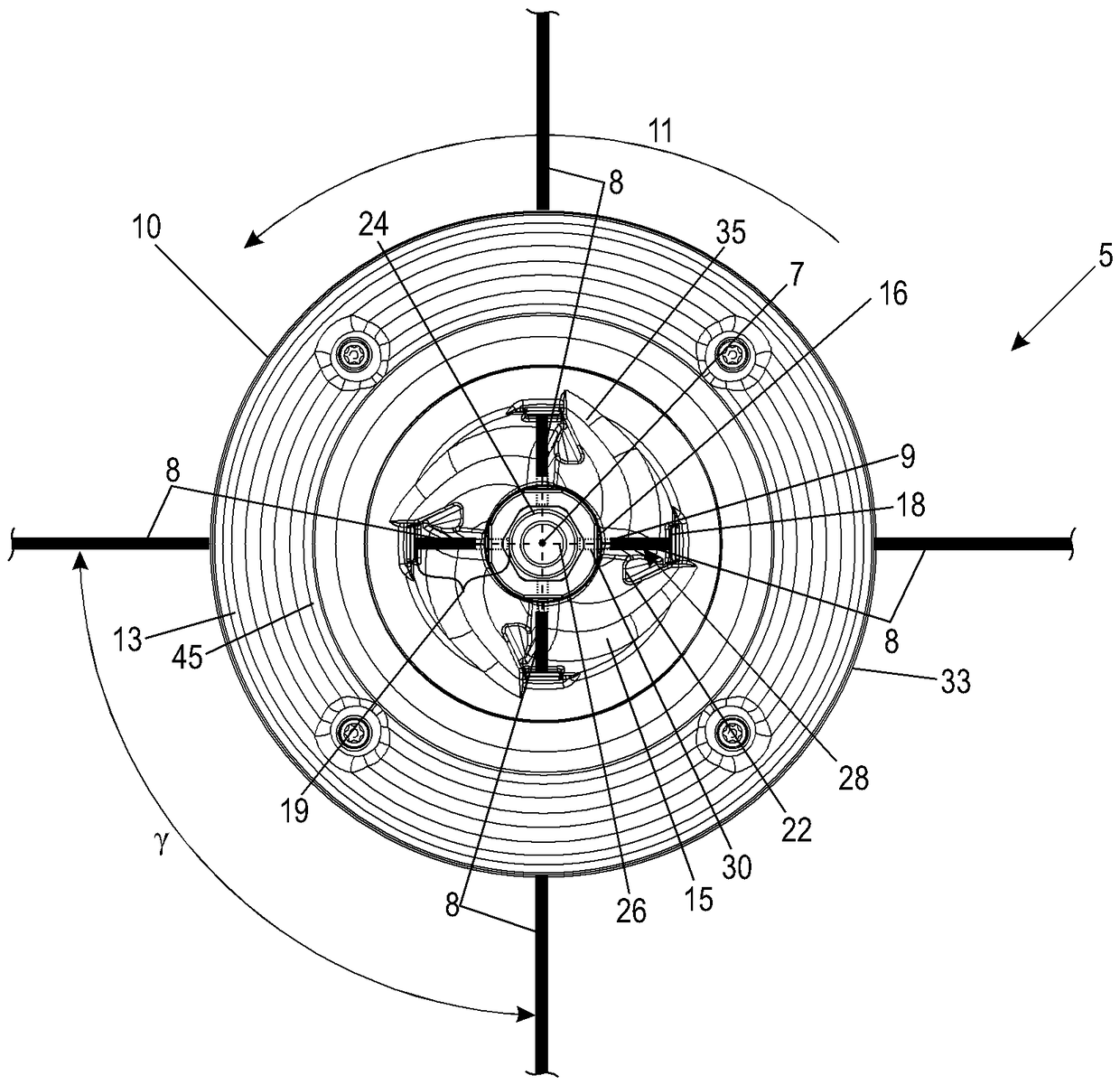

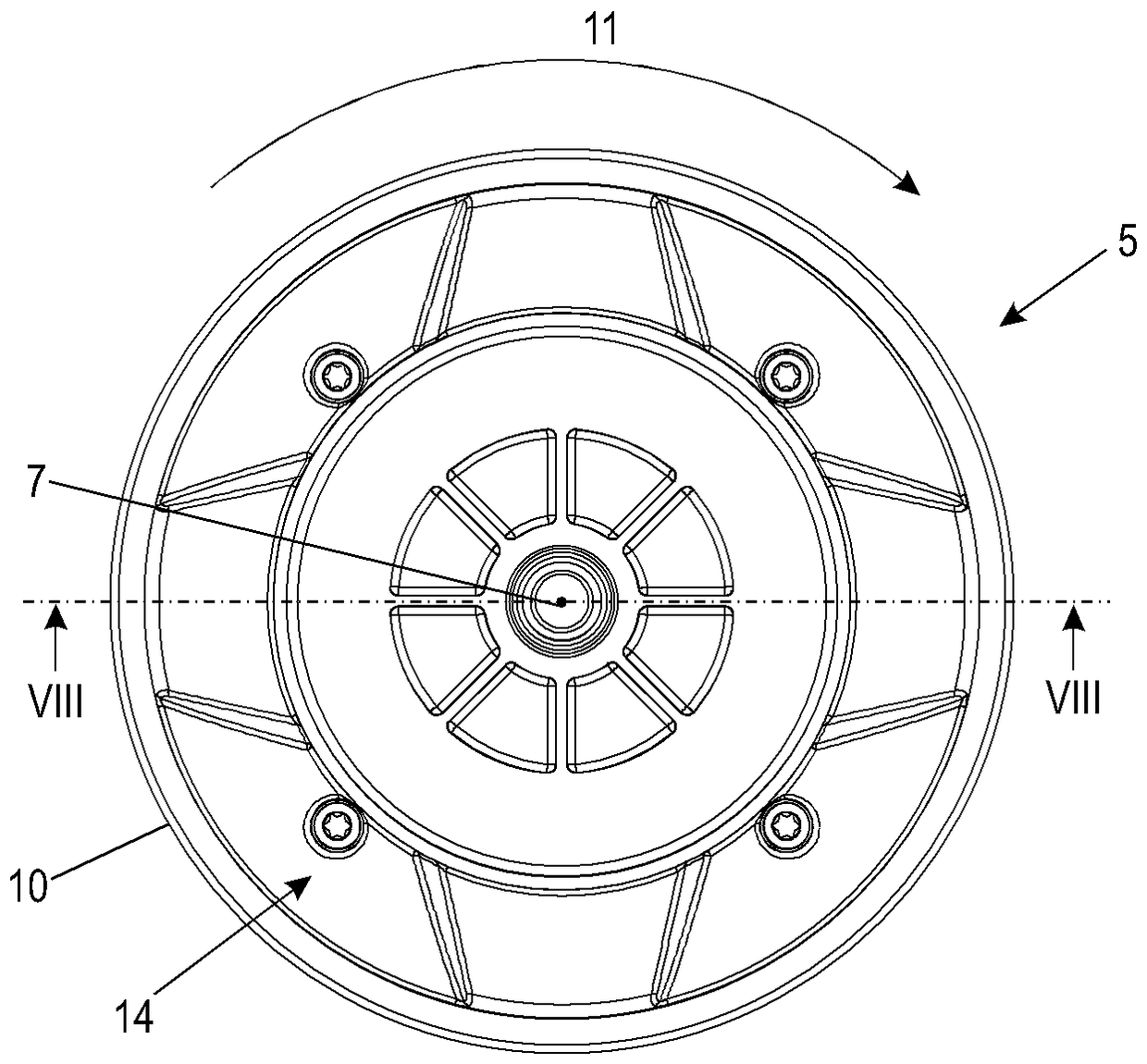

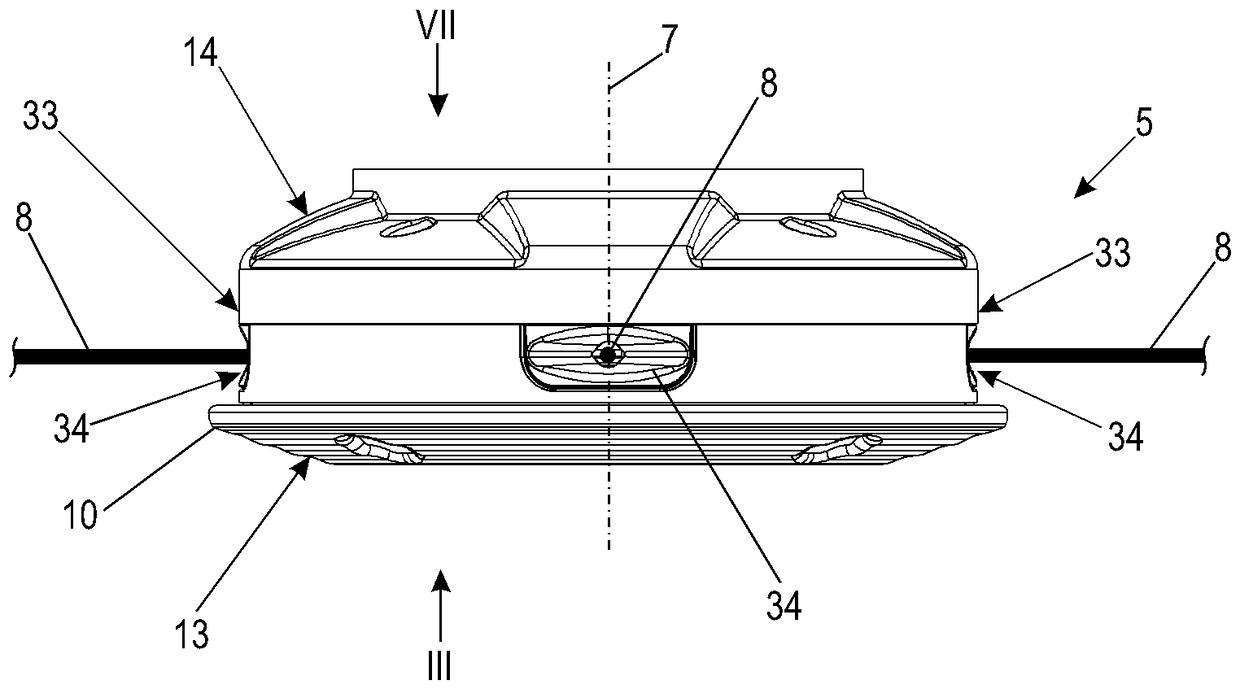

[0030] figure 1 A free cutter 1 is shown schematically, which is held by an operator. Free cutter 1 has a housing 2 in which a drive motor (not shown) is arranged. The free cutter 1 has a shaft 3 which is arranged with one end on the housing 2 and which carries a wire harvesting head 5 with its other end. A drive shaft (not shown) driven by a drive motor arranged in the housing 2 extends through the shaft 3 and drives the silk harvesting head 5 around the axis of rotation 7 . The drive motor can be an internal combustion engine or an electric motor. It can also be provided that the drive motor is arranged at the end of the shaft 3 carrying the wire harvesting head 5 . This is especially advantageous when the drive motor is an electric motor. During operation, the wire harvesting head 5 is covered by a protective cover 6 on the side facing the operator. The wire harvesting head 5 has at least one cutting wire 8 for cutting cuttings such as grass, bushes or the like. The s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap