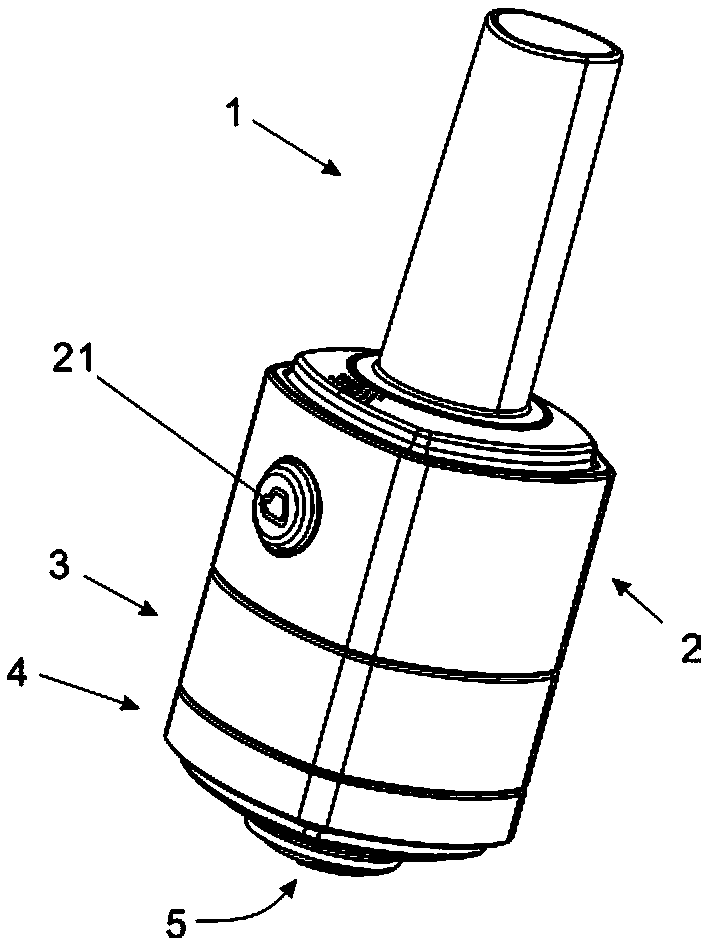

High-power foaming method and device of coffee

A coffee and high-power technology, applied in coffee extraction, beverage preparation devices, household appliances, etc., can solve the problems of poor foaming effect and increased foaming rate, and achieve the effect of small structure occupation and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

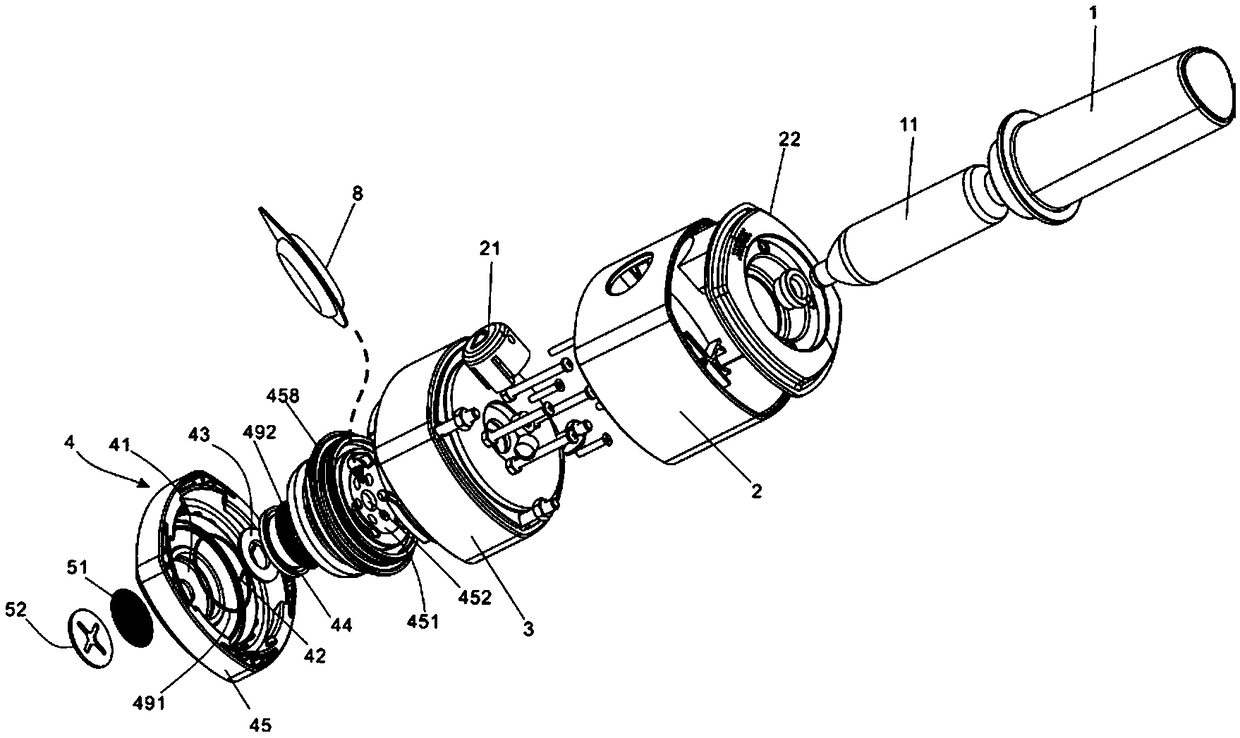

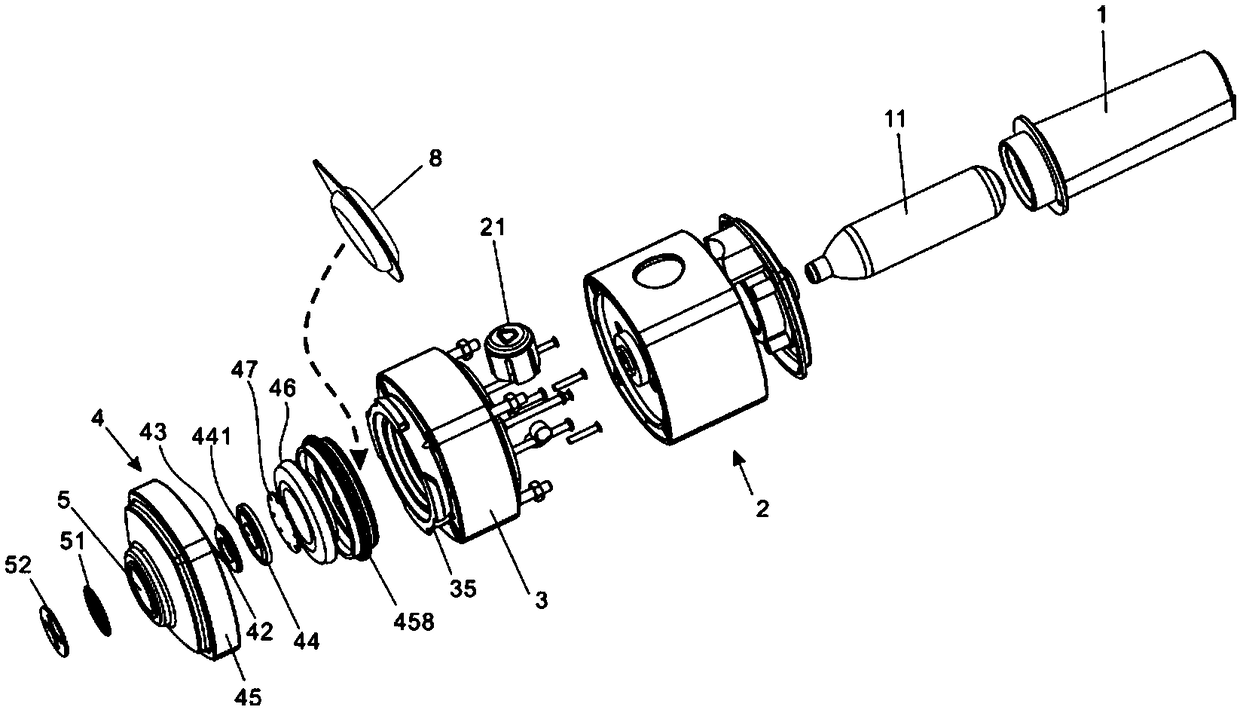

Examples

Embodiment approach

[0062] Yet another embodiment of the present invention: the air pressure source 11 , the pressure control mechanism 2 , and the water storage device 3 are combined to apply pressure with a water pump, and the pumped water enters the coffee storage cavity 451 .

[0063] Pressure sources include carbon dioxide, high pressure steam. If the common drinking water on the market is pressurized by a water pump, it is equivalent to combining the air pressure source, the pressure control mechanism and the water storage device, and this high-power foaming device is also suitable. The structure at this time is: the air pressure source, the pressure control mechanism, and the water storage are combined to apply pressure by the water pump, and the pumped water enters the coffee storage chamber.

[0064] Pocket carbon dioxide gas tanks are the smallest in size, very suitable for portable coffee machines, and they are relatively quiet compared to water pumps.

[0065] In addition, the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com