Segmented sLow descent hinge

A hinge and first flow channel technology, applied in the hinge field, can solve the problems of long closing time, complex hinge structure, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

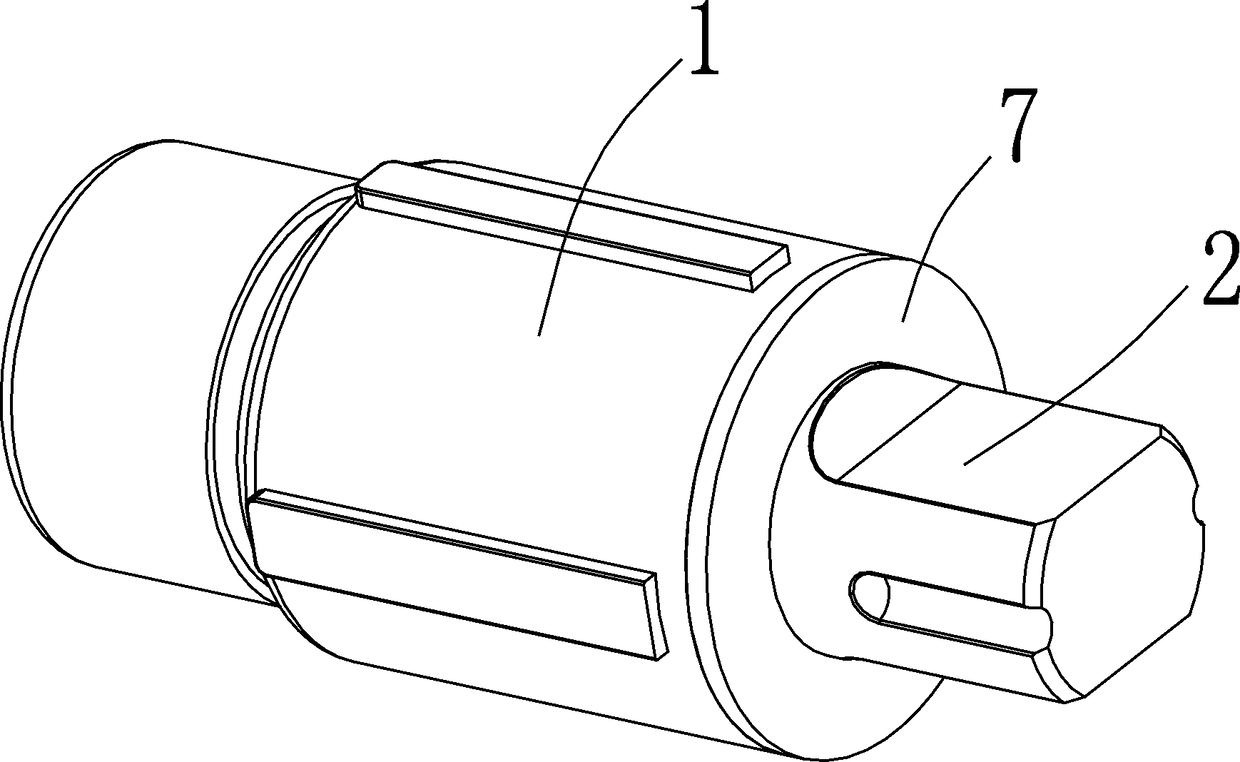

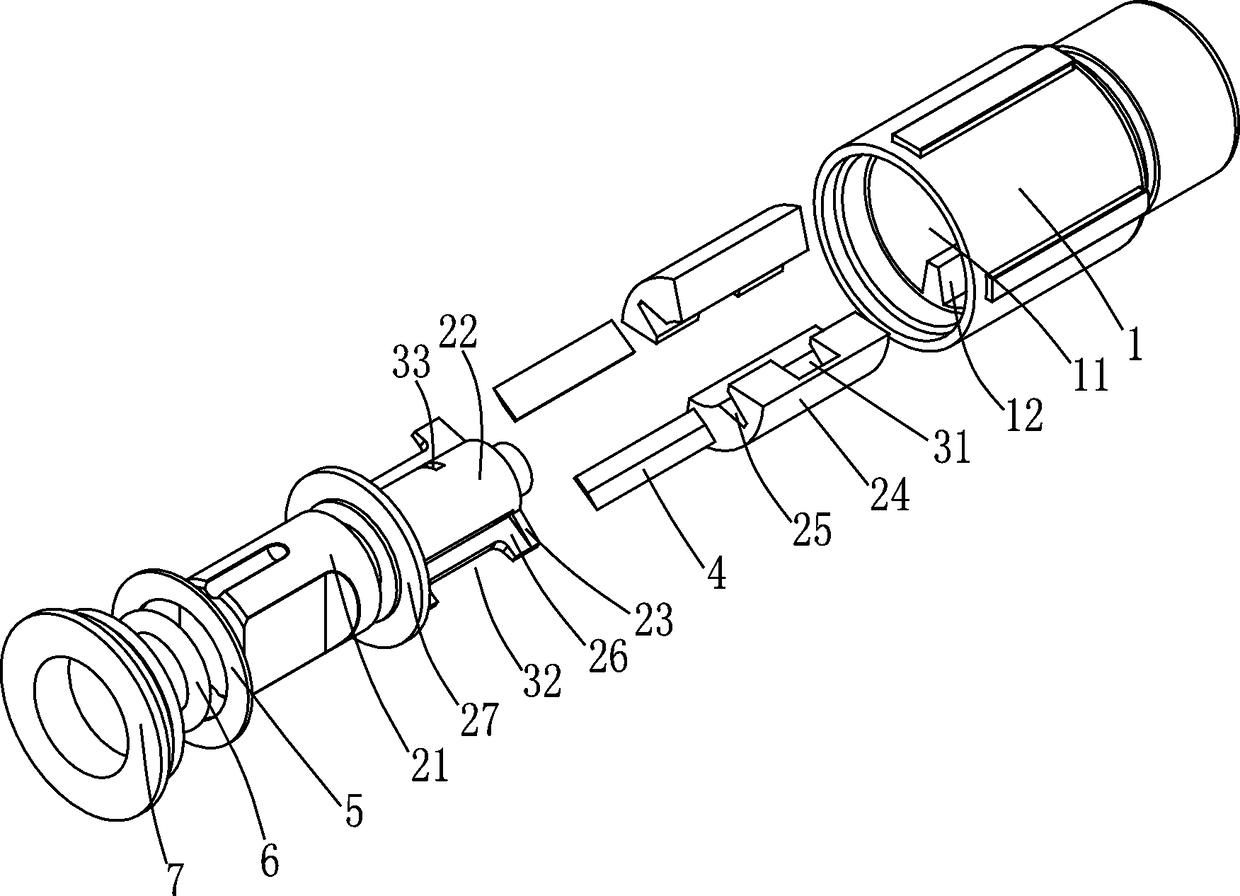

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , a segmented slow-down hinge, including a relatively rotatable housing 1 and a rotating member 2, the housing 1 is provided with a circular hole 11, the rotating member 2 includes a connecting portion 21 and a plug inserted into the housing The rotating shaft 22, the housing 1 and the rotating part 2 cooperate to form a closed space, the housing 1 is provided with a blocking part 12, the rotating shaft 22 is radially provided with an extension part 23, and the extension part 23 is provided with a fan Ring-shaped limiting block 24, the outer peripheral surface of the fan-shaped annular limiting block 24 is attached to the housing 1, and the fan-shaped annular limiting block 24 is axially provided with a groove 25, and the groove 25 One side is provided with a first flow channel 31, the groove 25 is nested with the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com