Filter paper damage-preventing stable vacuum filtration device

A stable and filter paper technology, applied in the direction of fixed filter element filter, filter separation, gravity filter, etc., can solve the problems of side tilting or tipping of the lower liquid storage bottle, filter paper damage, poor stability, etc., and achieve overall sealing Good, prevent filter paper damage, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

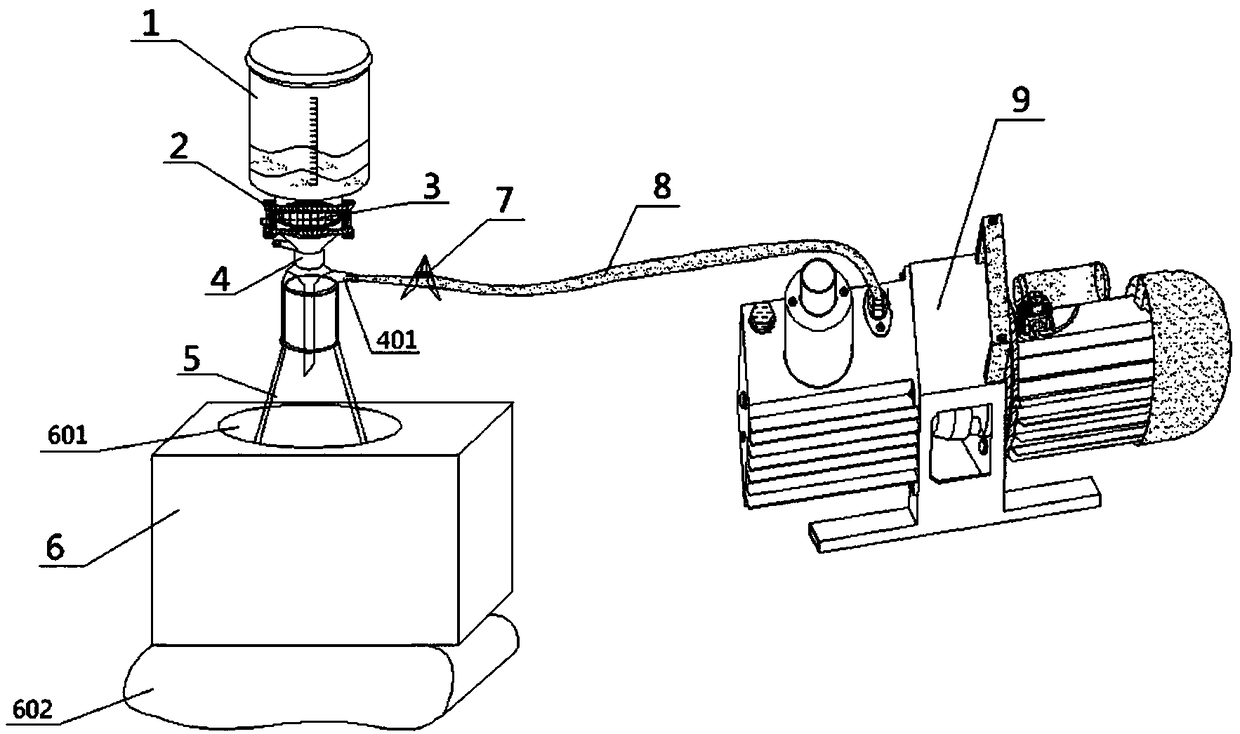

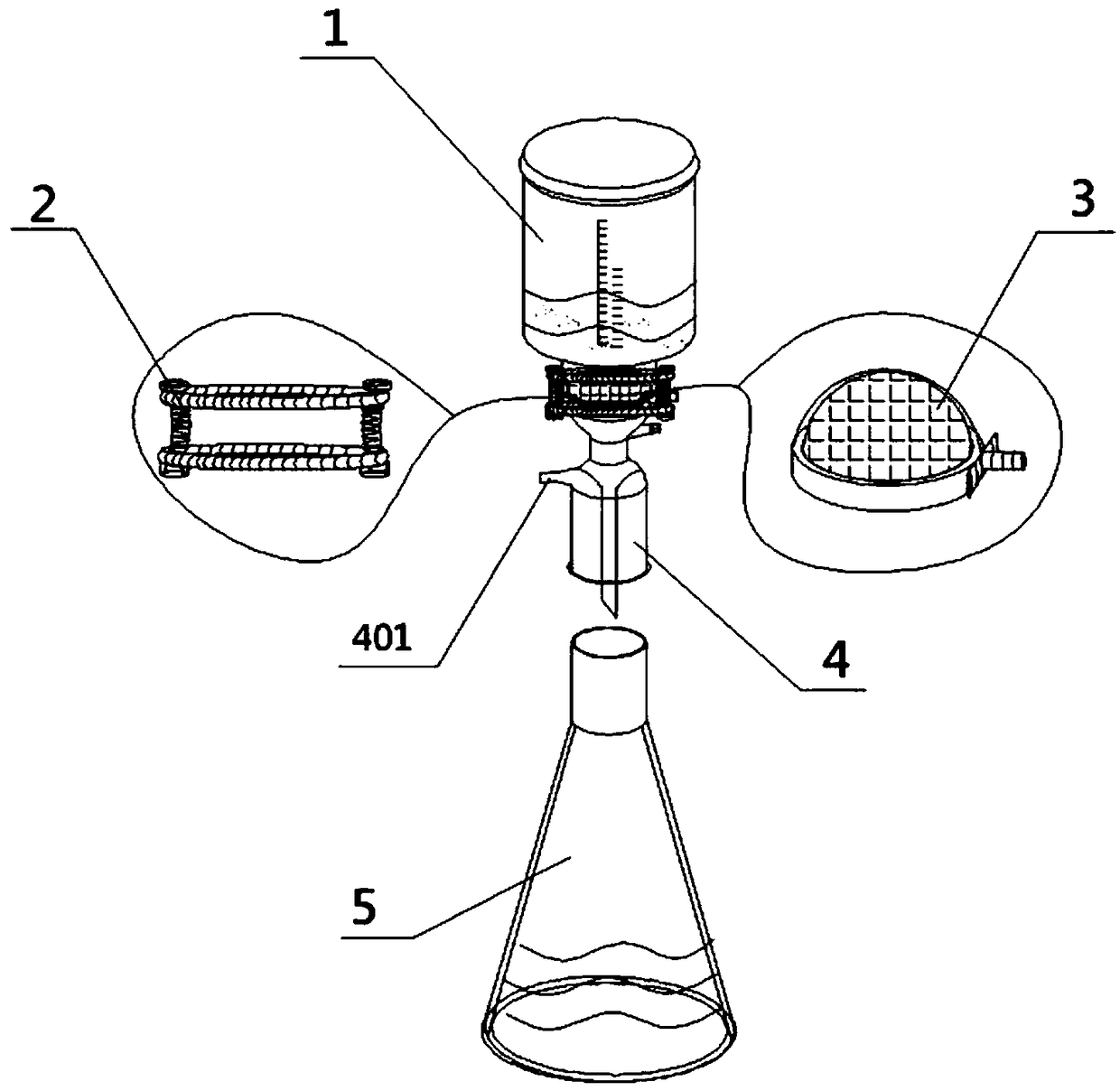

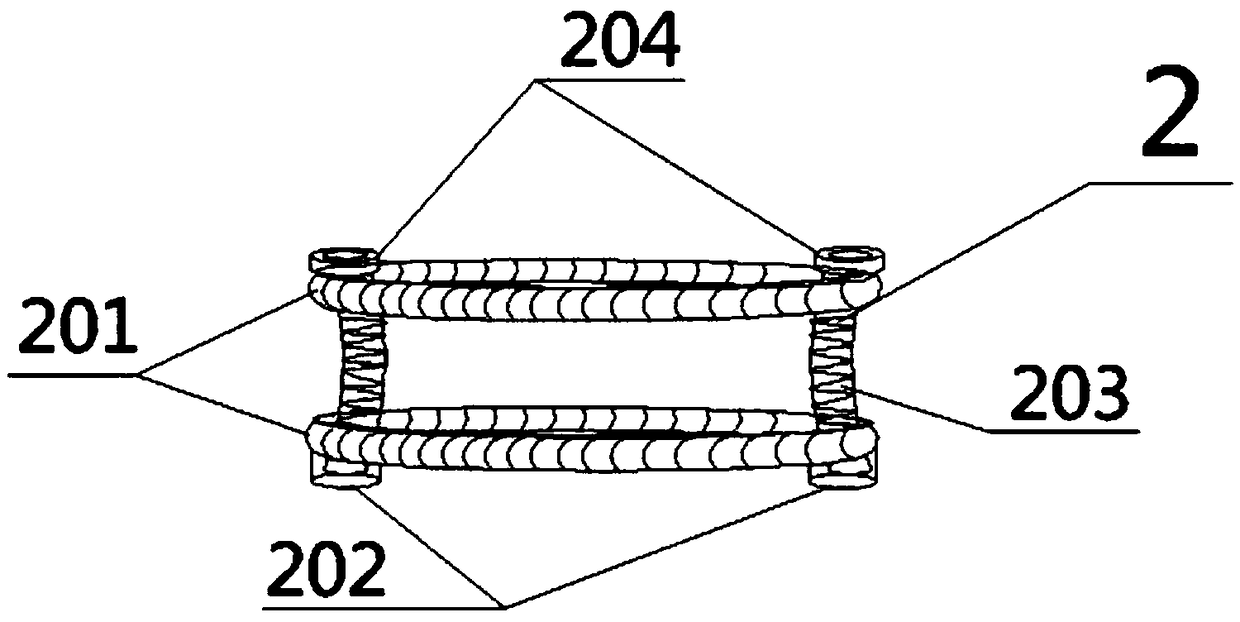

[0012] See the accompanying drawings: a filter paper breaking stable vacuum filtration device, which is characterized in that it includes an upper filter cup (1), a lower liquid storage bottle (5), a filter joint (4), a stable positioning ferrule (2), a filter paper Fixing ring (3), filter paper, rubber tube (8), air stop clip (7), positioning platform (6) and suction filter device (9), filter joint (4) is installed on the lower liquid storage bottle (5), The upper filter cup (1) is installed on the lower liquid storage bottle (5) through the fixed ferrule (2), the filter paper fixing ring (3) is installed at the mouth of the upper filter cup (1), and the filter paper is installed on the filter paper fixing ring ( 3) Inside, the lower liquid storage bottle (5) is installed and fixed on the positioning platform (6), the filter joint (4) has a suction filter port (401), and one end of the rubber tube (8) is installed on the filter joint (4) Above the suction filter port (401), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com