Patents

Literature

31results about How to "Achieve continuous mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting rubusoside from sweet tea leaves

ActiveCN108516997ALow desalination and decolorization costGood removal effectSugar derivativesSugar derivatives preparationUltrafiltrationFiltration

The invention relates to a method for extracting rubusoside from sweet tea leaves. The method comprises the following steps of (1) smashing and sieving the sweet tea leaves, adding water and conducting continuous countercurrent extraction and filtration; (2) adding an enzyme preparation for enzymolysis, conducting inactivation, cooling, flocculation and filtration and washing filtered residues with water; (3) conducting ultrafiltration and nanofiltration; (4) conducting adsorption through a macroporous adsorption resin chromatographic column, conducting washing with water, discarding water washing liquid and conducting gradient elution with an organic solvent and concentration under reduced pressure; (5) conducting adsorption through an aluminum oxide chromatographic column and conductingwashing with water concentration under reduced pressure; (6) adding activated carbon and conducting stirring, filtration, concentration under reduced pressure and spray drying; (7) dissolving the organic solvent and conducting filtration, crystallization, suction filtration, vacuum drying and pulverization to obtain a rubusoside product. The rubusoside product extracted by the method has pure white color, the purity is greater than or equal to 99%, and the yield is greater than or equal to 90.5%. The method has a simple operation process, short extraction time, low energy consumption and a lowcost and can achieve continuous large-scale production.

Owner:HUNAN HUACHENG BIOTECH

Method for extracting rubusoside from sweet tea leaves

InactiveCN109180755ALow desalination and decolorization costGood removal effectSugar derivativesSugar derivatives preparationFiltrationUltrafiltration

The invention relates to a method for extracting rubusoside from sweet tea leaves. The method comprises the following steps: (1) crushing sweet tea leaves, sieving the material, adding water, continuously performing countercurrent extraction, and filtering the material; (2) adding an enzyme preparation for enzymatic hydrolysis, and performing steps of inactivation, cooling, flocculation, filtration, and filter residue washing with water; (3) performing ultrafiltration and nanofiltration; (4) performing adsorption on macroporous adsorption resin chromatography column, washing the material withwater, discarding a washing solution, performing gradient elution with an organic solvent, and performing vacuum concentration; (5) performing adsorption on an alumina column, washing the material with water, and performing vacuum concentration; (6) adding activated carbon, stirring the material, filtering the material, and performing vacuum concentration and spray drying; and 7) dissolving the material with the organic solvent, and performing steps of filtering, crystallization, pumping filtration, vacuum drying, and crushing to obtain the rubusoside product. The extracted rubusoside productpresents pure white color, the purity is greater than or equal to 99%, and the yield is greater than or equal to 90.5%. The method of the invention has the advantages of simple operation process, short extraction time, low energy consumption and low cost, and can realize continuous large-scale production.

Owner:湖北志林农业科技开发有限公司

Method for recycling strigose hydrangea leaf polyphenol from strigose hydrangea leaf flocculated slag after rubusoside extraction

The invention discloses a method for recycling strigose hydrangea leaf polyphenol from strigose hydrangea leaf flocculated slag after rubusoside extraction. The method comprises the following steps: (1) carrying out acid dissolution, namely putting an acid solution into strigose hydrangea leaf flocculated slag after rubusoside extraction, stirring till the flocculated slag is dissolved, centrifuging, and filtering so as to obtain filtrate; (2) enriching with a macroporous adsorption resin, namely feeding the filtrate into a macroporous adsorption resin column to carry out enrichment, washing with water, eluting with an organic solvent, carrying out vacuum concentration on an elution liquid, recycling an eluant, and carrying out low-temperature vacuum drying, thereby obtaining a strigose hydrangea leaf polyphenol product. The strigose hydrangea leaf polyphenol product prepared by using the method has a product purity greater than or equal to 96% and a yield greater than or equal to 90%,wastes can be recycled and reused, the cost can be reduced, and in addition, environment pollution can be reduced; the method disclosed by the invention is short in extraction time, simple in operation process, low in energy consumption and cost, and continuous large-scale production can be achieved.

Owner:HUNAN HUACHENG BIOTECH

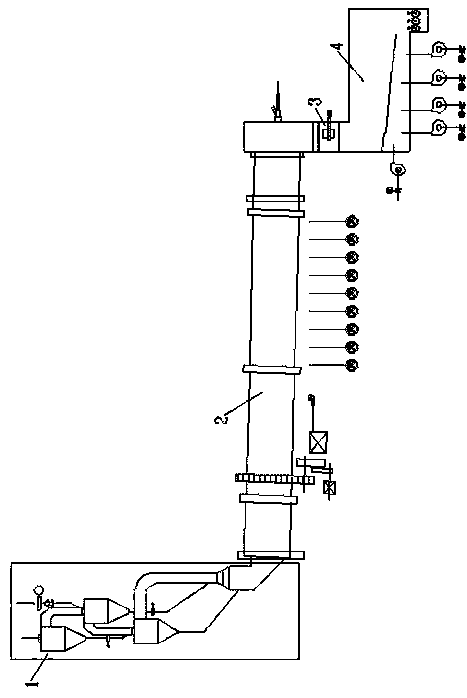

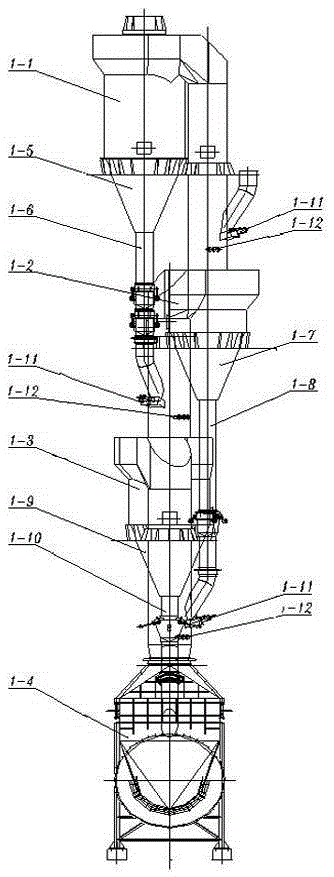

Device for producing spodumene and preparation process

ActiveCN103922355AMeet heat transfer needsReduce energy consumptionAluminium silicatesCooling effectProcess engineering

The invention discloses a device for producing spodumene and a preparation process. The device comprises a coarse particle suspension preheater, a rotary kiln, a separating valve and a leakage-free grate type cooling machine which are sequentially connected. The preparation process comprises the steps of preheating by adopting the coarse particle suspension preheater, roasting and transforming by adopting the rotary kin, separating by adopting the separating valve, and cooling by adopting the leakage-free grate type cooling machine. According to the device, by designing the coarse particle suspension preheater, tail gas of the rotary kiln is fully utilized for preheating, thus the energy consumption is reduced; by adopting the separating valve, the spodumene discharged out from the kiln can be effectively separated, and the safe and smooth operation of the whole system is ensured; by adopting the leakage-free grate type cooling machine, an optimal cooling effect can be achieved, and heat carried away by the spodumene discharged out from the kiln is fully utilized, thus the energy consumption of the system is reduced. The device realizes large-scale production and central automatic operation control of the spodumene, thereby greatly increasing the labor productivity and being better in economic benefit and environment protection benefit.

Owner:SICHUAN CALCINER TECH

Method for continuously producing graphene aerogel microspheres

The invention discloses a method for continuously producing graphene aerogel microspheres. The method comprises the following steps: mixing graphene oxide and water to form a graphene oxide dispersion liquid with a concentration of 3-20 mg / ml, mixing an alkali metal hydroxide and the graphene oxide dispersion liquid, and performing ultrasonic dispersion to obtain a graphene oxide liquid crystal solution; placing the graphene oxide liquid crystal solution into a slurry supply device, applying pressure by adopting a pressure supply device, supplying the graphene oxide liquid crystal solution to a calcium chloride coagulation bath through a flow divider, and allowing the obtained coagulation bath to stand for 5-30 min to obtain graphene oxide microspheres; placing the graphene oxide microspheres into a sodium ascorbate solution, and performing a reaction at 60-90 DEG C for 5-25 h to obtain graphene wet gel microspheres; and performing post-treatment on the graphene wet gel microspheres to obtain the graphene aerogel microspheres. The method provided by the invention can continuously produce the graphene aerogel microspheres.

Owner:ZHONGSU NEW TECH CO LTD

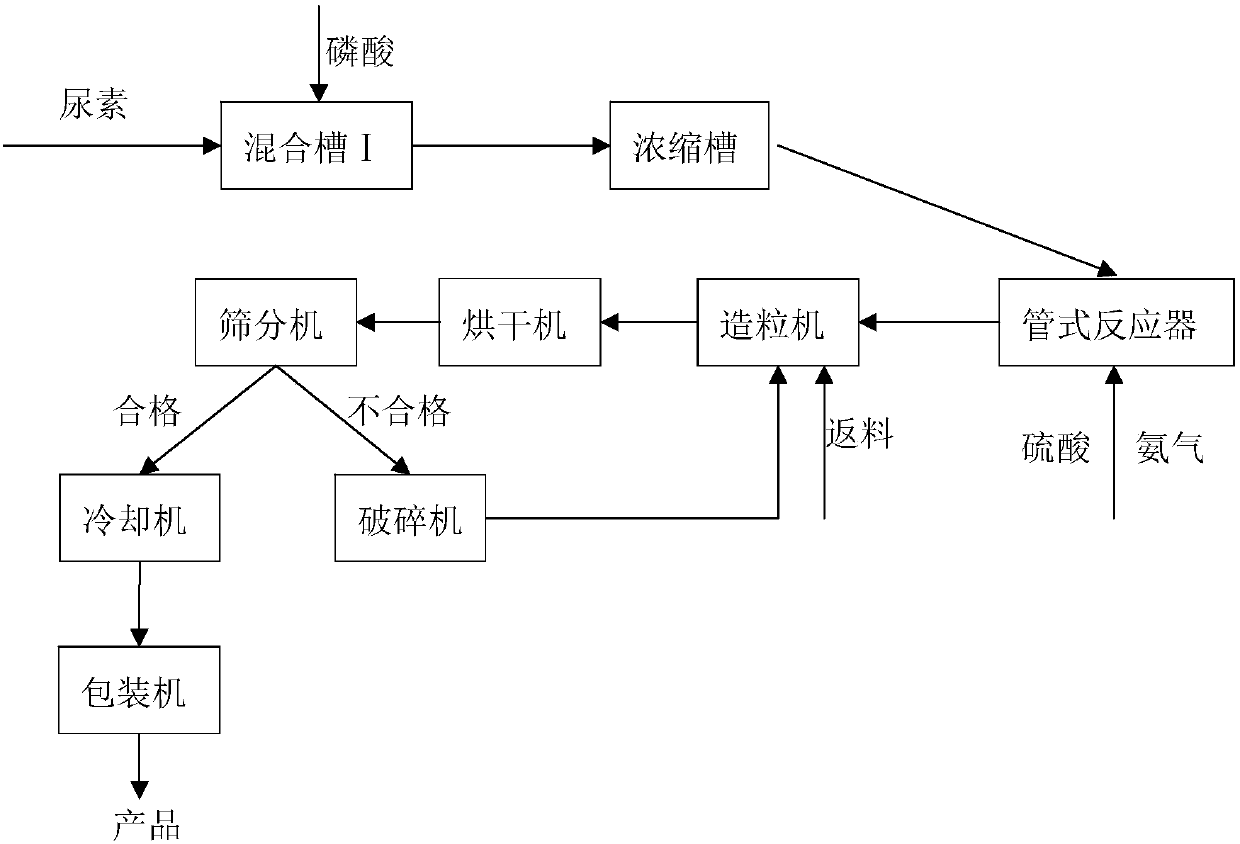

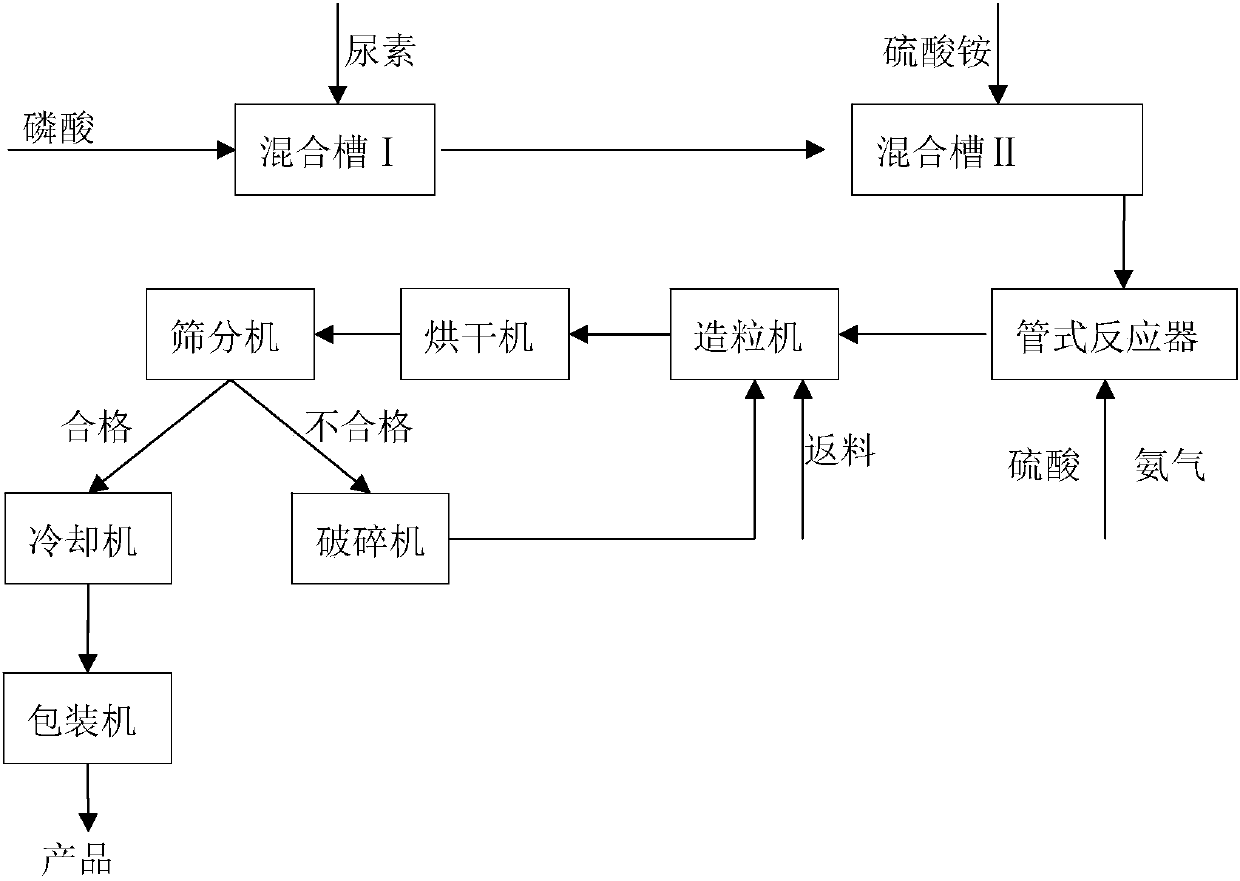

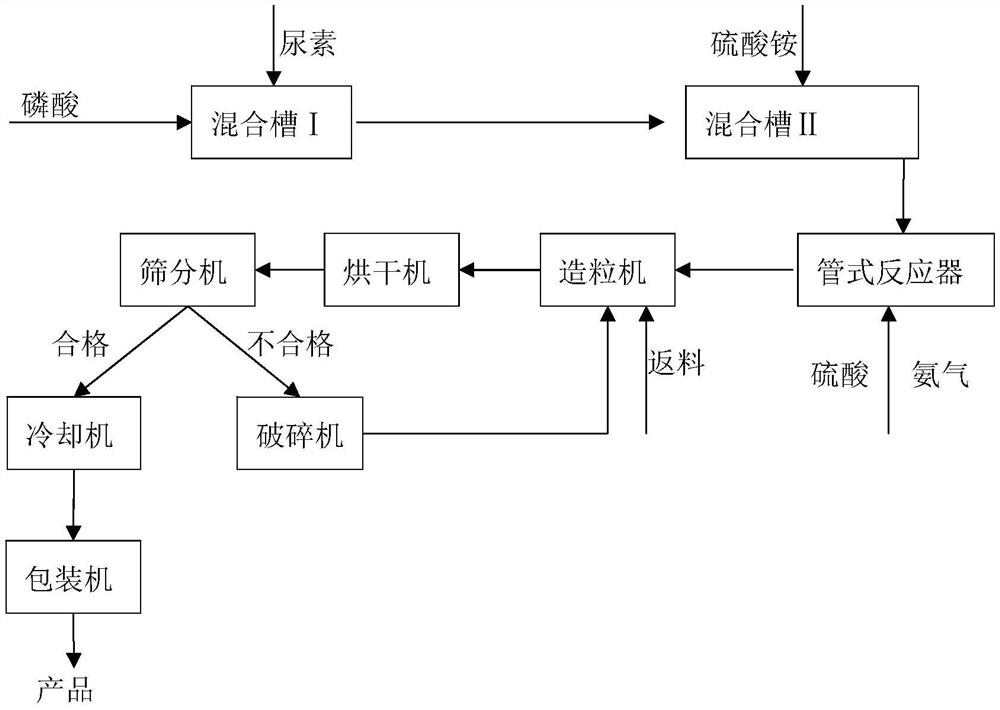

Preparation method for acidic fertilizer

InactiveCN107721730AContinuous productionAvoid fixationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidBiological activation

The invention relates to a preparation method for an acidic fertilizer. The preparation method comprises the following steps: mixing of phosphoric acid with urea; reaction after completion of mixing;and granulating and drying. The acidic fertilizer provided by the invention comprises urea phosphate and ammonium bisulfate and has a pH value of 2.5 to 3.5, so the pH value of alkaline soil can be reduced, and the volatilization loss of ammonium nitrogen in the alkaline soil is reduced; in addition, the stability of amide nitrogen can be increased, and activation effects can be exerted on phosphorus and medium-trace elements; meanwhile, the phosphorus can be avoided from fixation by elements like calcium and magnesium, and the moving ability of the phosphorus is improved; when the pH value ofthe acidic fertilizer is lower than 2.5, the acidic fertilizer has too great viscosity and is easy to absorb moisture; and when the pH value of the acidic fertilizer is excessively high, the pH valueof soil can not be effectively reduced, and the purpose of activating the phosphorus and the medium-trace elements can not be achieved.

Owner:菏泽金正大生态工程有限公司 +2

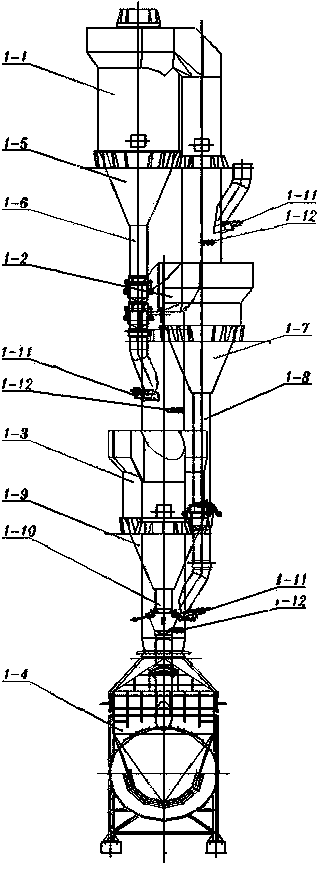

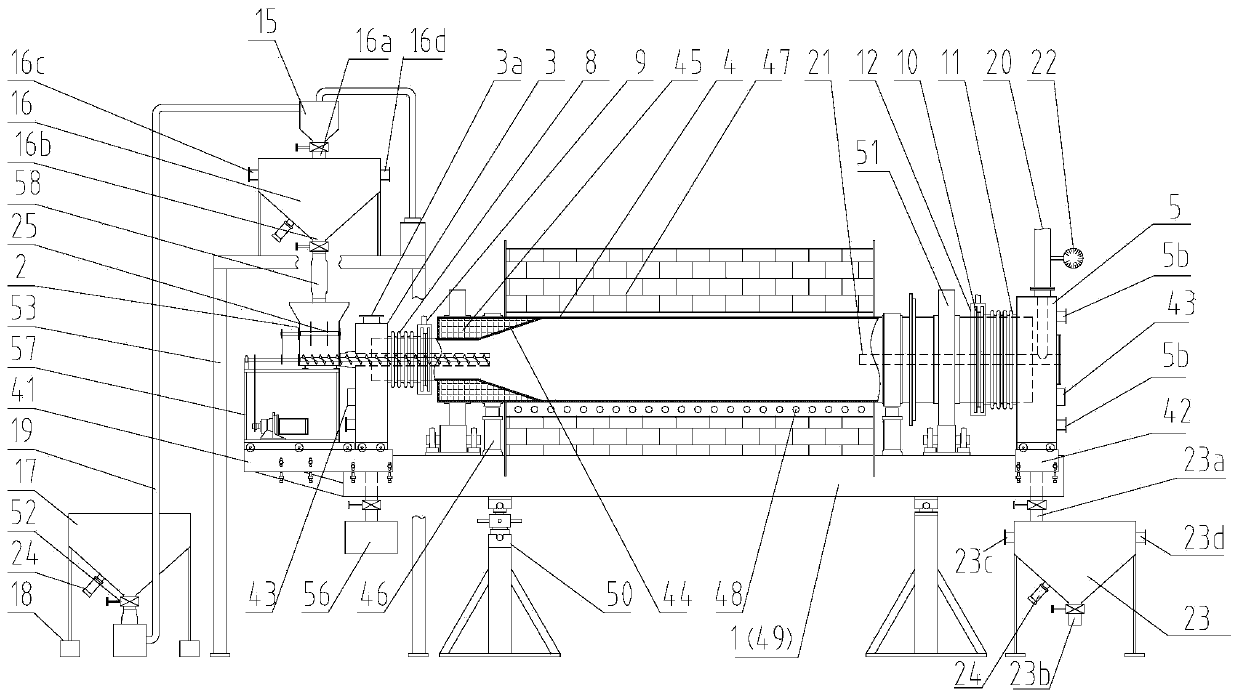

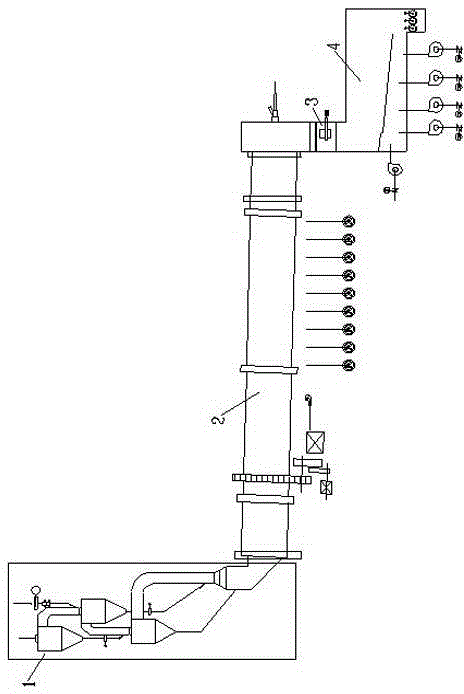

Continuous silicon carbon negative dynamic CVD sintering furnace

ActiveCN110500879AGood overall sealingAchieve continuous mass productionCharge composition/stateRotary drum furnacesFlangeSilicon

The invention discloses a continuous silicon carbon negative dynamic CVD sintering furnace, which comprises an installation platform, a spiral feeder, a furnace head cover, a furnace pipe and a furnace tail cover, wherein the head end of the furnace pipe is positioned in the furnace head cover and the tail end of the furnace pipe is positioned in the furnace tail cover, the spiral feeder is joinedwith the furnace head cover, and a discharging port is formed in the furnace tail cover; the part, outside the furnace head cover, of the head end of the furnace pipe is provided with a first sealingflange, a first corrugated pipe is arranged between the first sealing flange and the furnace head cover, the first sealing flange is in sealing connection with the first corrugated pipe, and a firstexhaust hood is sleeved on the outer periphery of the connection between the first sealing flange and the first corrugated pipe; the part, outside the furnace tail cover, of the tail end of the furnace pipe is provided with a second sealing flange, a second corrugated pipe is arranged between the second sealing flange and the furnace tail cover, the second sealing flange is in sealing connection with the second corrugated pipe, and a second exhaust hood is sleeved on the outer periphery of the second sealing flange and the second corrugated pipe. The sintering furnace adopts the exhaust hood to timely exhaust the gas capable of leaking so as to prevent the danger of explosion caused by the leakage of dangerous gas, and the sintering furnace has good overall sealing property, is safe and reliable.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

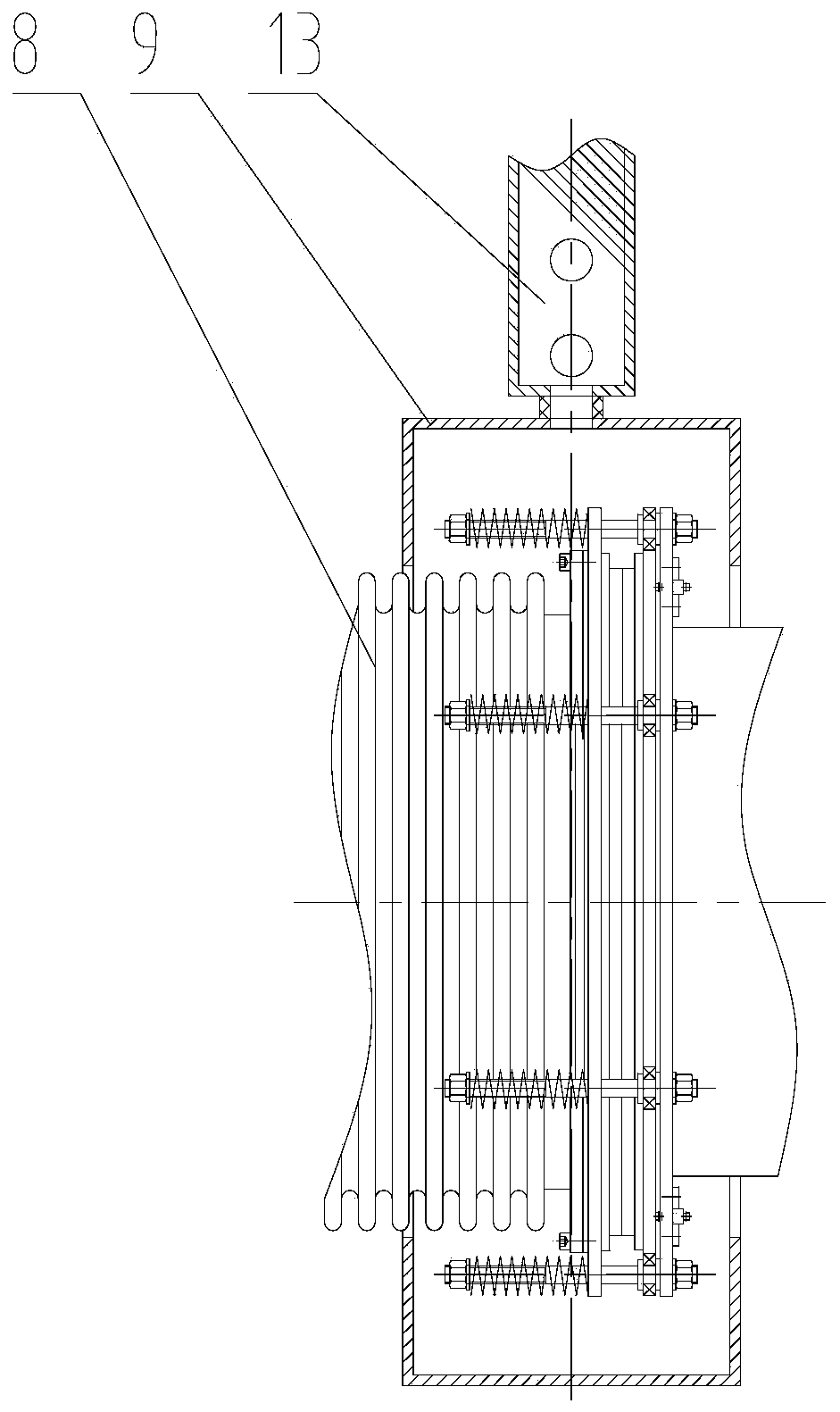

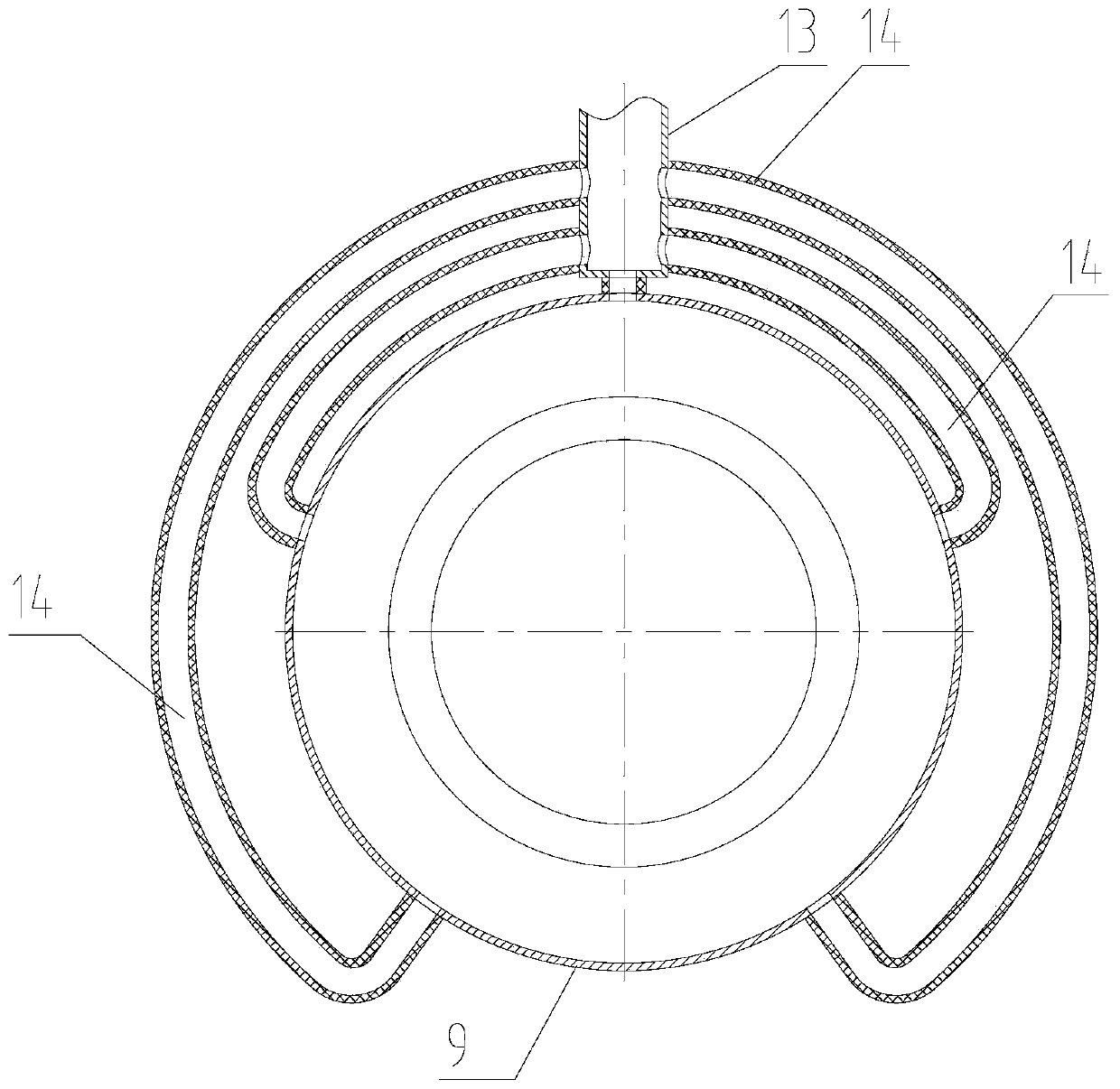

Method for preparing multi-channel hollow fiber nano-filtration membranes

The invention relates to a method for preparing multi-channel hollow fiber nano-filtration membranes. The method includes steps of (1), adding polymers, organic solvents and additives into a reaction kettle according to certain proportions, stirring the polymers, the organic solvents and the additives to form uniform and stable membrane casting solution, defoaming the membrane casting solution under a vacuum condition, ejecting the membrane casting solution via multi-channel hollow fiber molds under the driving effects of air pressures, feeding the membrane casting solution into external coagulating bath under certain core solution flow rate and air spacing conditions, carrying out phase transformation to form multi-channel hollow fiber basement membranes, sufficiently soaking the multi-channel hollow fiber basement membranes, then taking out the multi-channel hollow fiber basement membranes, airing the multi-channel hollow fiber basement membranes at certain temperatures, packaging the multi-channel hollow fiber basement membranes in stainless steel assemblies, plugging two ends of each stainless steel assembly by the aid of cotton and sealing the stainless steel assemblies by glue; (2), preparing aqueous-phase solution with certain concentration and oil-phase solution with certain concentration, injecting the aqueous-phase solution in multi-channel inner holes, reserving the aqueous-phase solution in the multi-channel inner holes for a certain period of time, purging the aqueous-phase solution by the aid of strong airflow, injecting the oil-phase solution into the multi-channel inner holes, reserving the oil-phase solution in the multi-channel inner holes for a certain period of time, purging the oil-phase solution by little airflow, arranging the multi-channel inner holes in an oven, carrying out reaction and taking the multi-channel inner holes out of the oven to obtain the multi-channel hollow fiber nano-filtration membranes. The method for preparing the multi-channel hollow fiber nano-filtration membranes has the advantages of high toughness and strength.

Owner:江苏向阳科技有限公司

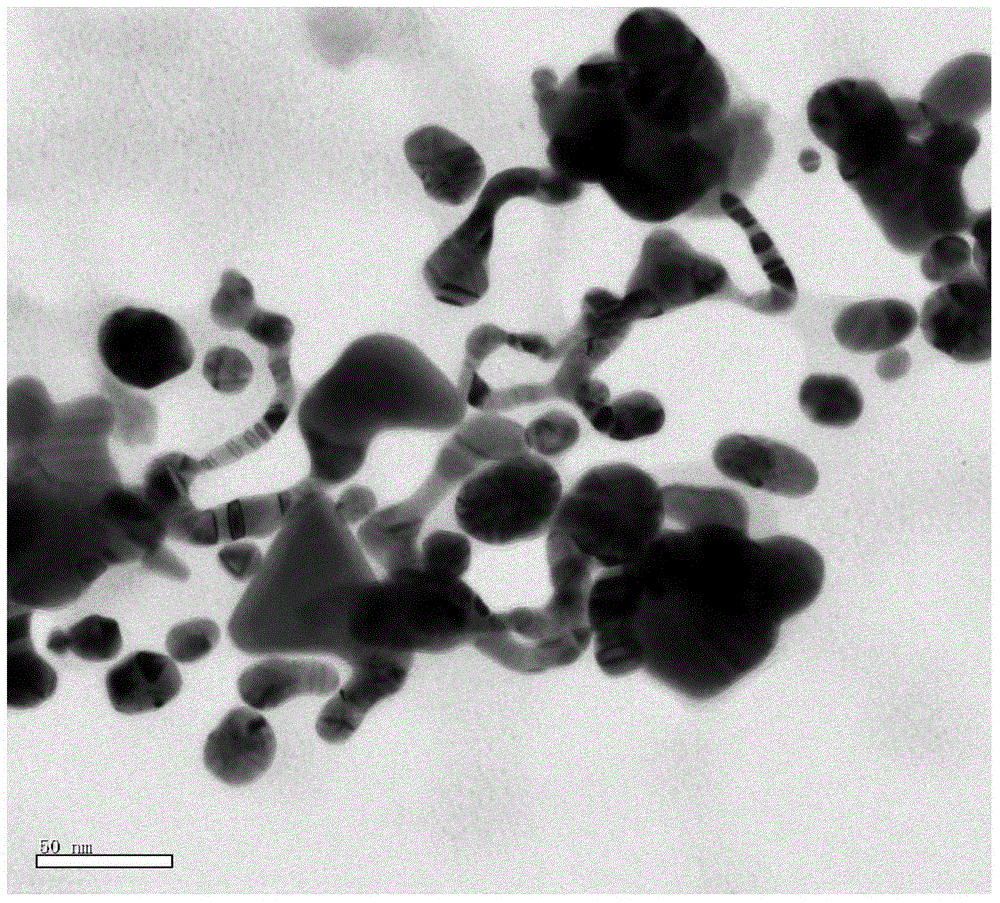

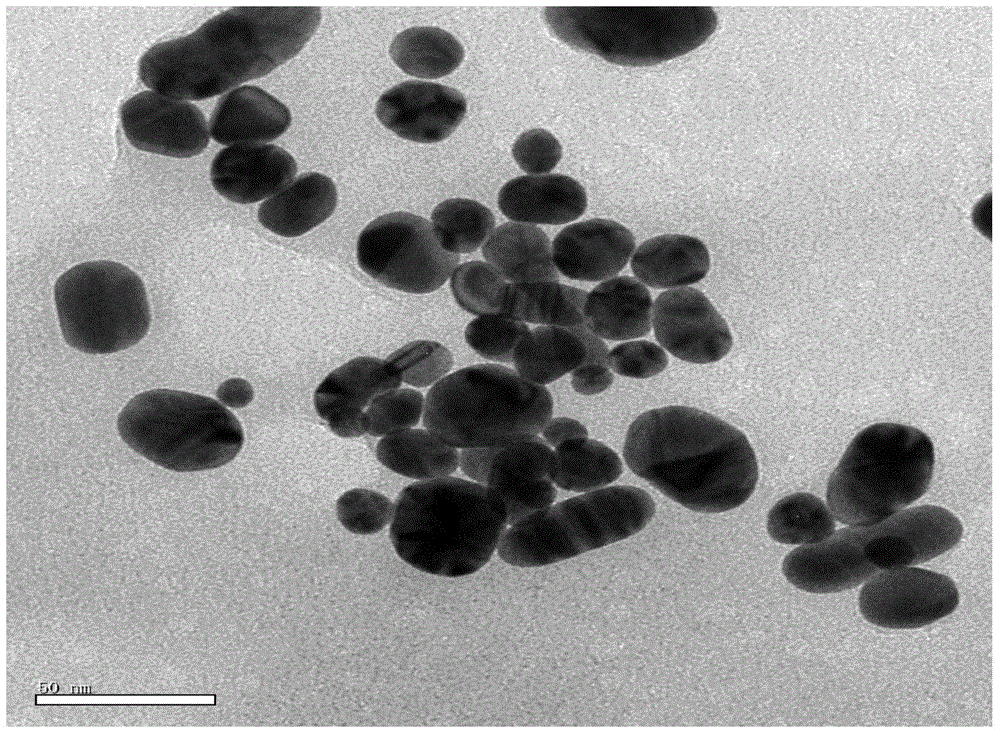

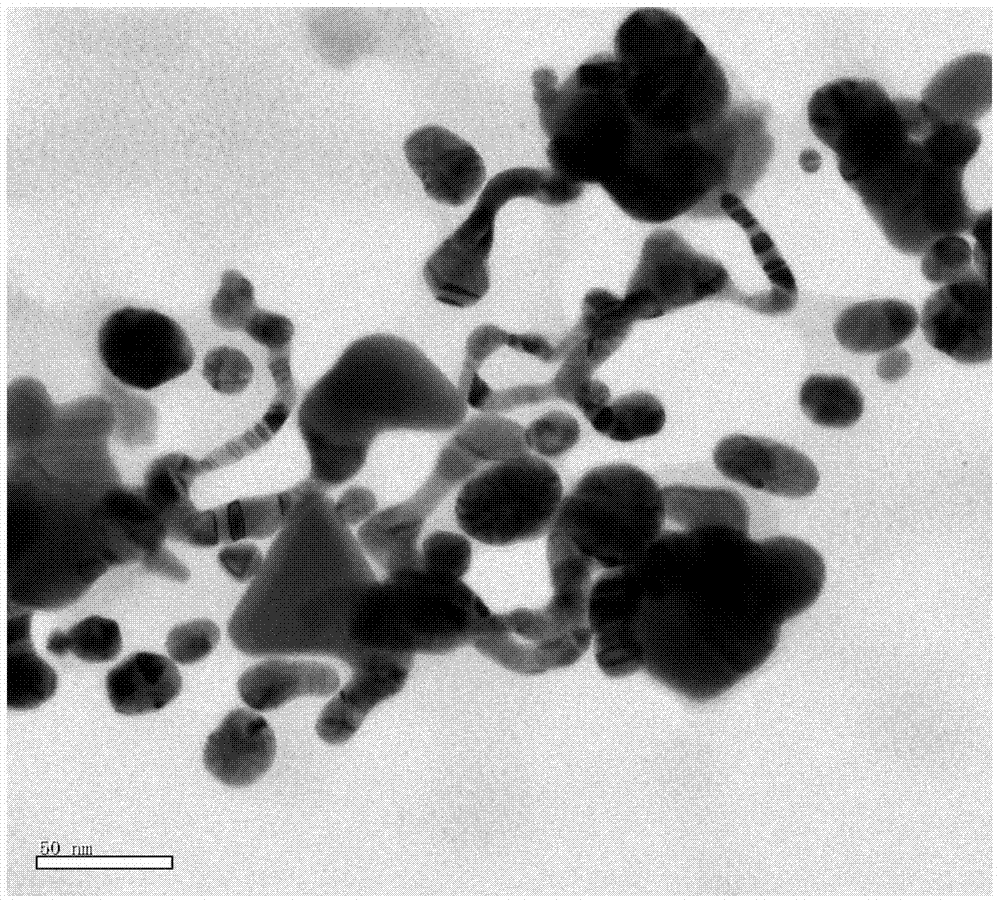

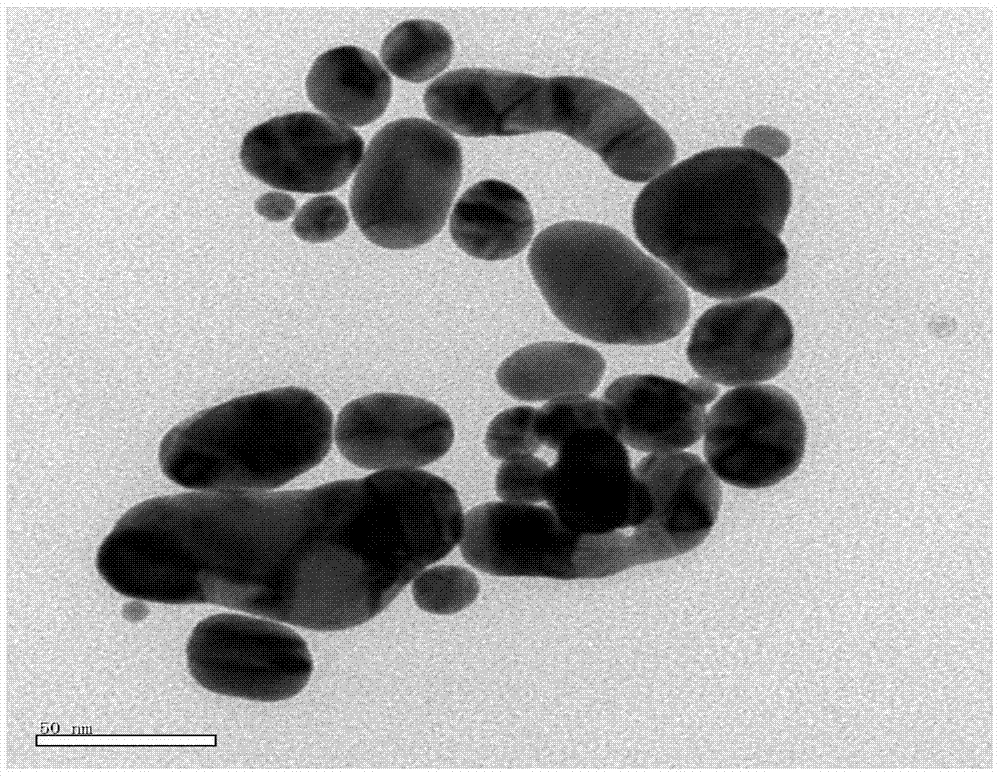

Controllable preparation method for gold nanoparticles induced by polysaccharide derivative

ActiveCN104907579AGood water solubilityGood biocompatibilityMaterial nanotechnologySodium chlorateNanoparticle

The invention discloses a controllable preparation method for gold nanoparticles induced by a polysaccharide derivative, and belongs to the technical field of green preparation of nano materials. The controllable preparation method includes the steps that under the acidity condition (pH4.8), an oxidized curdlan polysaccharide derivative is prepared through 4-accetamide-2, 2, 6, 6-tetramethyl piperidine-1-oxyl, sodium chlorate and sodium hypochlorite; the pH of the oxidized curdlan polysaccharide solution is adjusted, the solution is mixed with a chloroauric acid solution at the same volume, reaction is performed for 1.5 h at the temperature of 100 DEG C, a mixed solution is cooled to a room temperature, then filtered, centrifuged, dispersed, dialyzed, frozen and dried to obtain the gold nanoparticles, and through control over the pH value of the oxidized curdlan polysaccharide solution, gold nanoparticles of different shapes and grain sizes can be obtained. In this way, the preparation method is environmentally friendly, simple, easy to implement and good in stability, the shape and grain size of the gold nanoparticles are controllable, continuous large-scale production can be achieved, and the method has good application prospects.

Owner:东台海滨科技创业园管理有限公司

Preparation method of fresh fig fruit concentrated juice

The preparation method of a fresh fig fruit concentrated juice comprises the following steps: (1) homogenization and extraction: taking figs, adding hot water, and conducting homogenization, standing,filtering, enzyme deactivation and cooling; (2) flocculation and clarification: adjusting pH value to weakly alkaline, adding a flocculating clarifying agent, and conducting stirring, standing, centrifugation, ultrafiltration, and water washing to obtain an ultrafiltrate; (3) decolorization and deastringency: loading the ultrafiltrate onto a macroporous adsorption resin column, collecting effluent, conducting washing, collecting washing liquid, loading the effluent and the effluent on a polyamide resin column, collecting effluent, conducting washing with water, and collecting washing liquid to obtain a liquid after decolorization and deastringency; (4) neutralization and desalting: loading the liquid after decolorization and deastringency onto a cation exchange resin column, collecting effluent, conducting washing with water, and collecting washing liquid and concentration to obtain a concentrate; and (5) composite debittering: adding activated carbon to the concentrate, and conducting stirring, pressure filtration, resin debittering, ultrafiltration, sterilization, and cooling. The concentrated juice obtained by the method of the invention has the advantages of clear and translucent appearance, high total sugar content, high total amino acid content, high yield, no bitter and astringent taste and high solid content; the method of the invention has the advantages of simpleness, short extraction time, low energy consumption and low cost, and can realize continuous large-scale production.

Owner:HUNAN HUACHENG BIOTECH

A method for recovering sweet tea polyphenols from sweet tea flocculation slag after extracting rubusoside

A method for recovering sweet tea polyphenols from sweet tea flocculation slag after rubusoside extraction, comprising the following steps: (1) acid dissolution: adding an acid solution to the sweet tea flocculation slag after extraction of rubusoside, stirring until the flocculation slag dissolves, Centrifuge and filter to obtain filtrate; (2) Macroporous adsorption resin enrichment: enrich the filtrate on a macroporous adsorption resin column, wash with water, elute with organic solvent, concentrate the eluate under reduced pressure and recover the solvent to obtain a concentrated solution; (3) Alumina refining: put the concentrated solution on the alumina chromatography column, wash with water, gradient elution, concentrate the eluate under reduced pressure and recover the eluent, dry in vacuum at low temperature to obtain sweet tea polyphenol products. The purity of the sweet tea polyphenol product obtained by the method of the present invention is ≥96%, and the yield is ≥90%. Not only wastes are reused, cost is saved, but also environmental pollution is reduced; the method of the present invention has short extraction time, simple operation process, energy consumption, The cost is low, and continuous mass production can be realized.

Owner:HUNAN HUACHENG BIOTECH

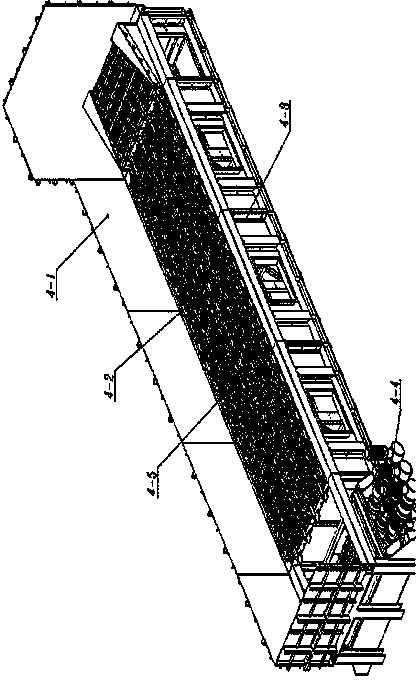

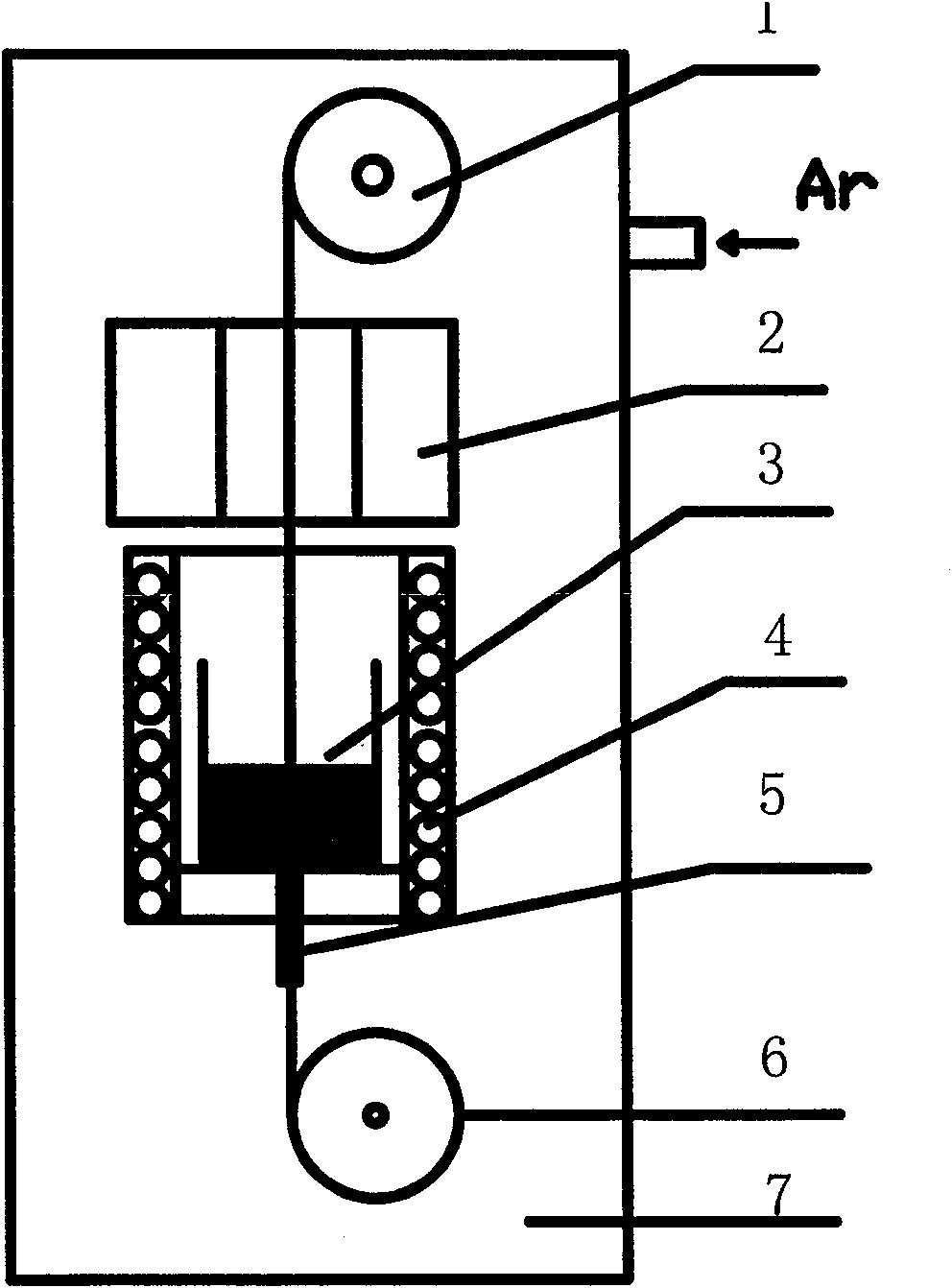

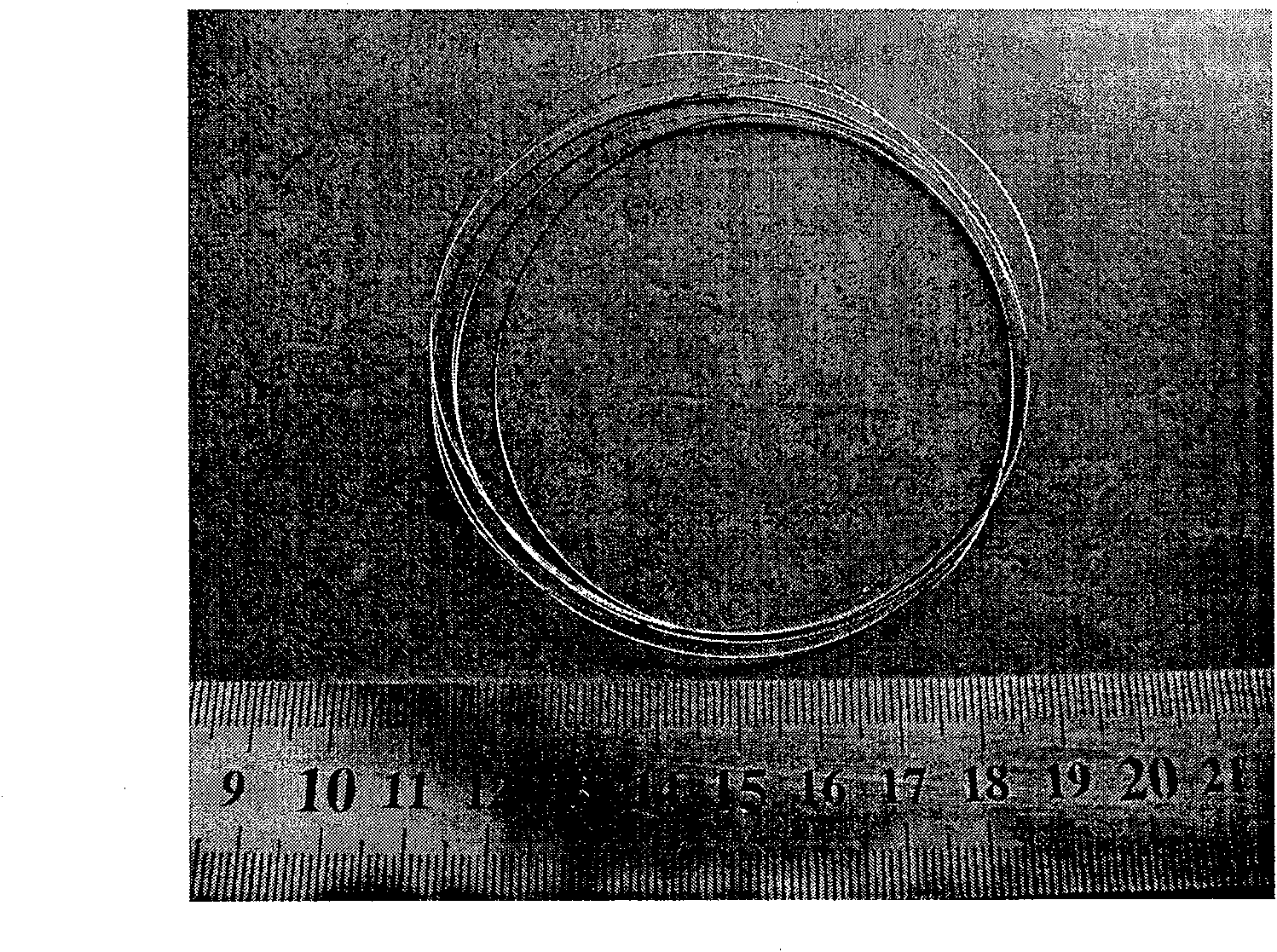

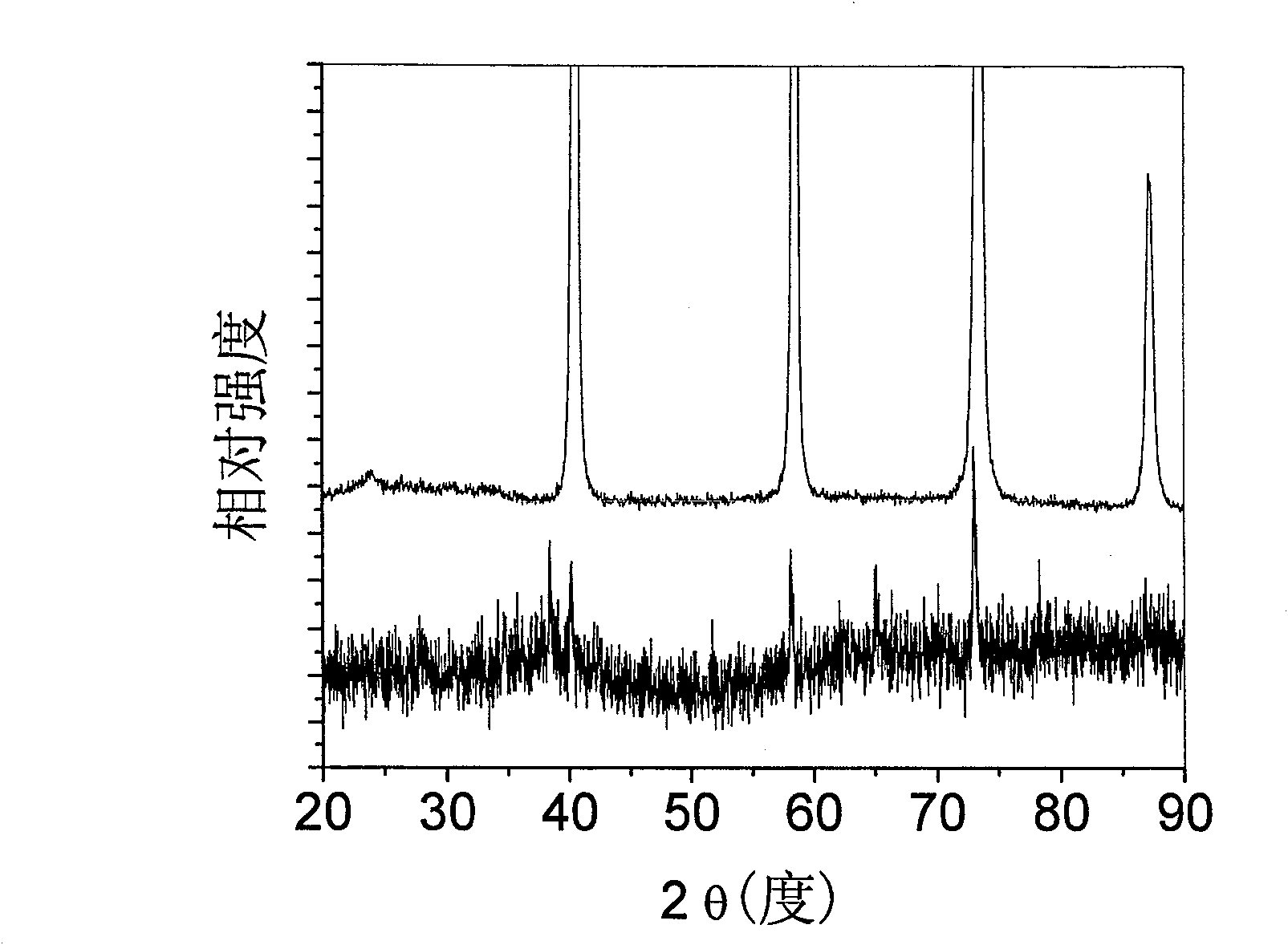

Continuous preparation equipment and process for metal glass cladded metal wire composite material

InactiveCN100554488CAchieve continuous mass productionShort processHot-dipping/immersion processesElectric arc furnaceCrucible

The invention discloses an equipment and process for continuously preparing metallic glass-coated metal wire composite materials by means of a melt impregnation method, belonging to the field of amorphous alloys (metallic glass). The invention is composed of a vacuum system, a heating system, a cooling device and a traction mechanism. Its technological features are as follows: the alloy prepared according to the nominal composition is smelted into a uniform master alloy in an electric arc furnace, and then the master alloy and metal wire are installed at the bottom In the crucible with a small hole, one end of the wire passes through the small hole of the crucible from the inside to the outside, remelts the master alloy in the heating furnace and keeps it warm, and then pulls down the metal wire immersed in the melt through the traction mechanism driven by the motor, so that Its surface is evenly impregnated with a layer of alloy liquid, and after passing through the heating zone, it is rapidly cooled by the cooling medium to form metallic glass, and finally obtain a metallic glass-coated wire composite material with high strength and elongation, which is suitable for use as body armor. Anti-collision helmets and other uses.

Owner:UNIV OF SCI & TECH BEIJING

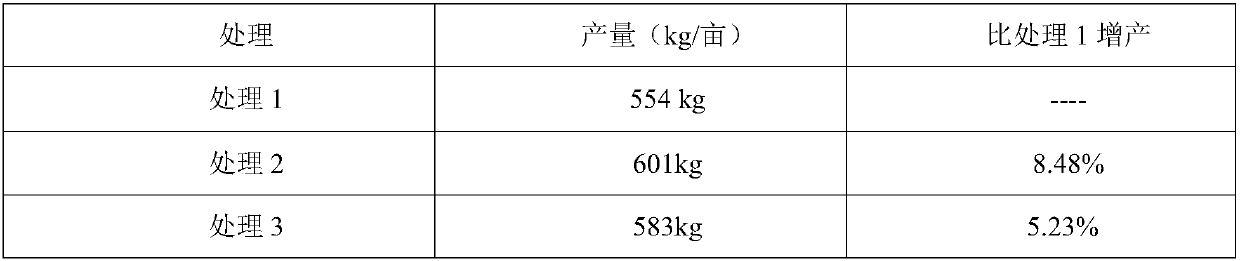

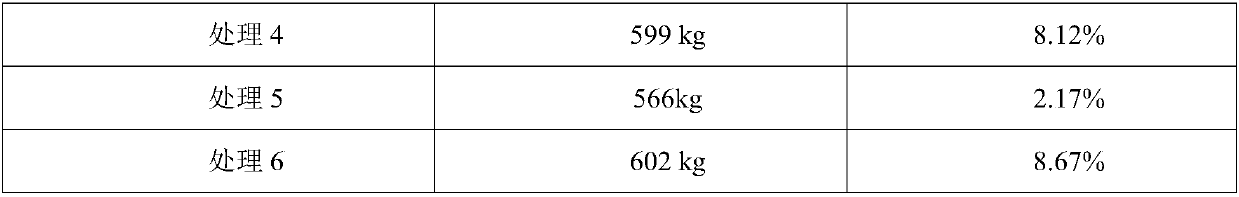

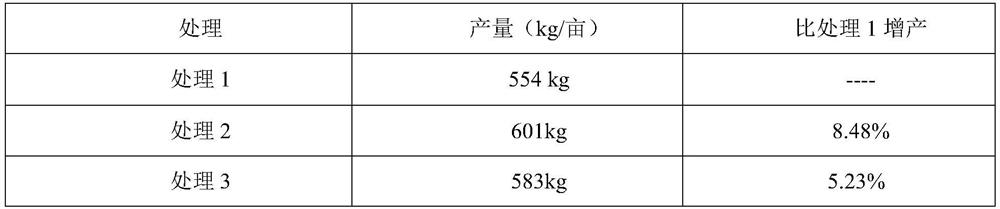

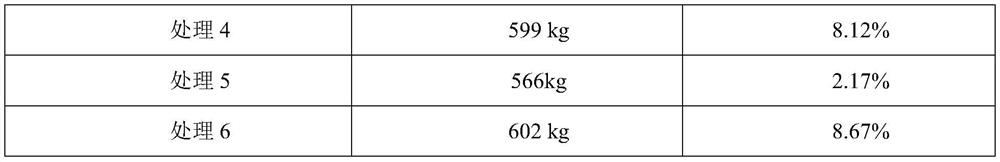

Urea sulfate and urea phosphate fertilizer and preparation method and application thereof

ActiveCN107892597AImprove fertilizer efficiencyHas the effect of reducing weightOrganic phosphatic fertilisersAmmonium salt fertilisersDiammonium phosphatePhosphoric acid

The invention relates to a urea sulfate and urea phosphate fertilizer and a preparation method and application thereof. The fertilizer is prepared from, by mass, 20% or above of P2O5, 1% or above of amidonitrogen, 10% or above ammonium nitrogen, 12% or above of total N and 5% or above of S, and the pH of the fertilizer is 2.5-4. The preparation method comprises the steps that phosphoric acid, urea, ammonium sulfate or / and ammonium bisulfate are mixed; reaction is performed after mixing, and granulation and drying are performed. The urea sulfate and urea phosphate fertilizer is a soil conditioning fertilizer universal for alkaline soil and has the advantage of high in fertilizer efficiency, and a wheat test shows that the yield can be increased by about 8% compared with the yield obtained by applying diammonium phosphate.

Owner:菏泽金正大生态工程有限公司 +1

Ultra-high performance ultra-large sized tyre and preparation process thereof

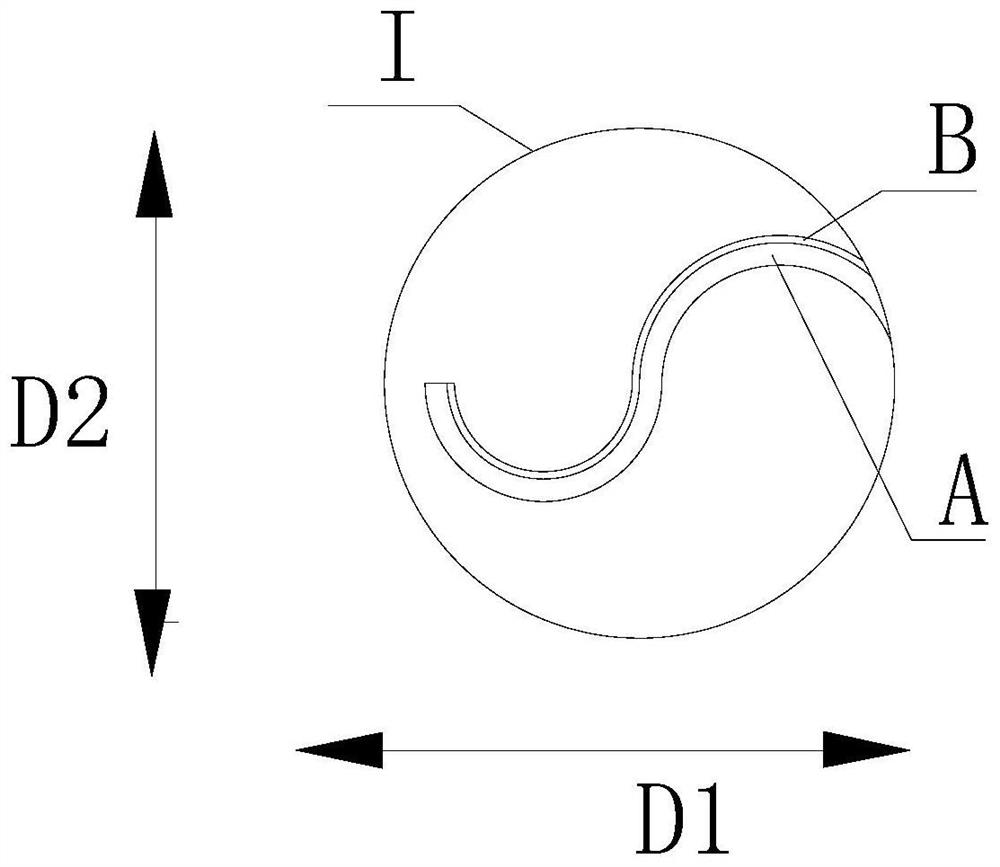

ActiveCN102935788AEnsure performance meets requirementsSimple internal structureTyresPneumatic tyre reinforcementsFinite elemente analyseMechanical engineering

The invention discloses an ultra-high performance ultra-large sized tyre and a preparation process thereof. The specification of the ultra-high performance ultra-large sized tyre is 305 / 25R32108W, the rim diameter is 32 inches, the rim width is 11J, the outer diameter is 965mm, the section width is 313mm, and the load is 1000kg. The tyre contour designed by high-performance tyre contour design software and subjected to finite element analysis is adopted, and the advanced structural design means and the stable process control can be adopted, the volume production of the tyre with the specification is realized, simultaneously all aspects of performances of the tyre can meet the requirements, product development risks are effectively reduced and the product development period is reduced.

Owner:QINGDAO SENTURY TIRE CO LTD

Continuous preparation process of zanthoxylum bungeanum seed protein

PendingCN111363001AIncrease reaction rateHigh separation purityPeptide preparation methodsZanthoxylum bungeanumFreeze-drying

The invention provides a continuous preparation process of zanthoxylum bungeanum seed protein, which comprises the following steps: pretreating zanthoxylum bungeanum seeds, extracting grease by adopting a subcritical process, and collecting degreased zanthoxylum bungeanum seed meal; carrying out superfine grinding on zanthoxylum bungeanum seed meal, sieving, carrying out ultrasonic hedging countercurrent reaction together with alkali liquor, wherein when the ultrasonic hedging countercurrent reaction is performed, the system is alkalescent; obtaining protein slurry after the ultrasonic hedgingcountercurrent reaction; enabling the protein slurry to pass through an ultrasonic vibrating screen and then a centrifugal machine to screen out insoluble substances twice, so as to obtain protein clear liquid; and adding an acid solution into the protein clear liquid to regulate the system to be weakly acidic, separating by using a centrifuge, and carrying out freeze drying by using a freeze dryer to obtain the zanthoxylum bungeanum seed protein. The continuous preparation process combining subcritical degreasing, ultrasonic oscillation continuous extraction, weak acid settling separation and high-speed freezing separation is adopted, the finished zanthoxylum bungeanum seed protein product with good quality and high yield is obtained, the reaction time is short, and the production efficiency is high.

Owner:上海辰钿实业有限公司

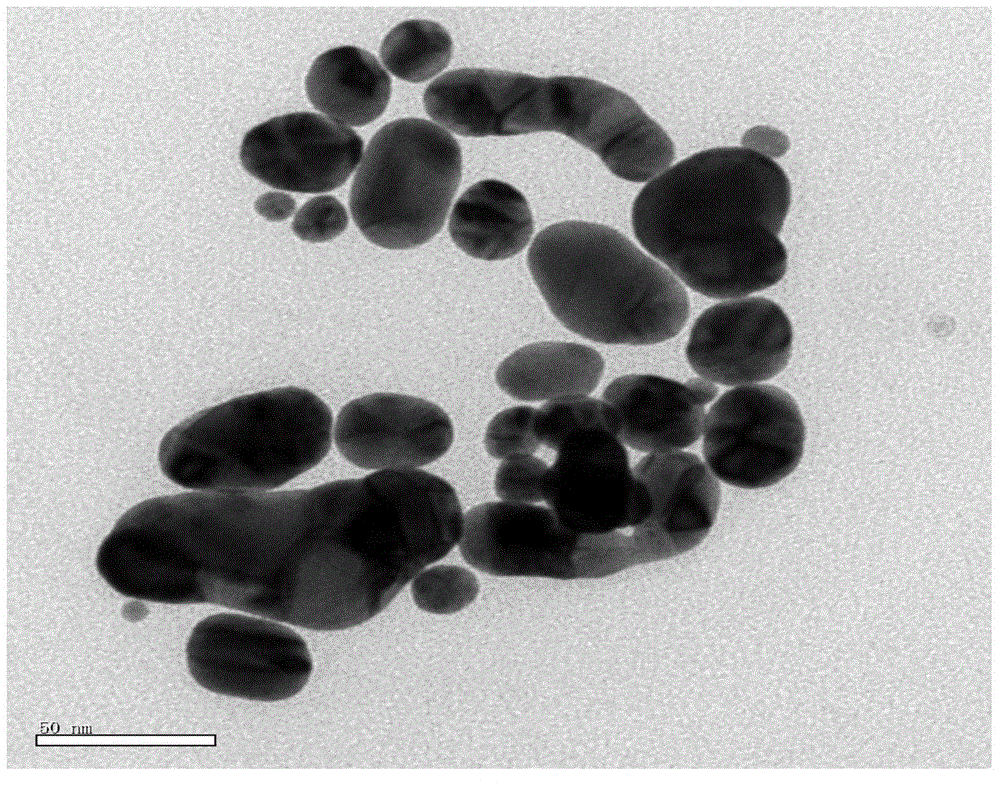

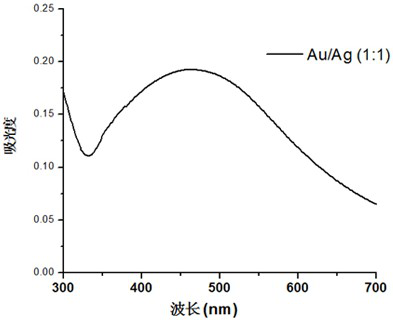

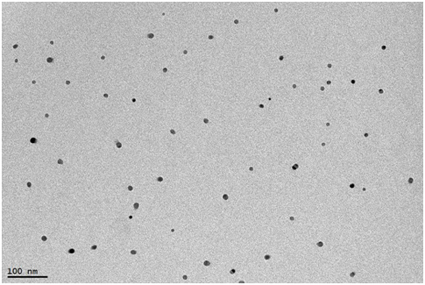

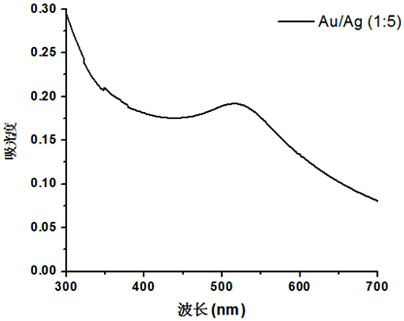

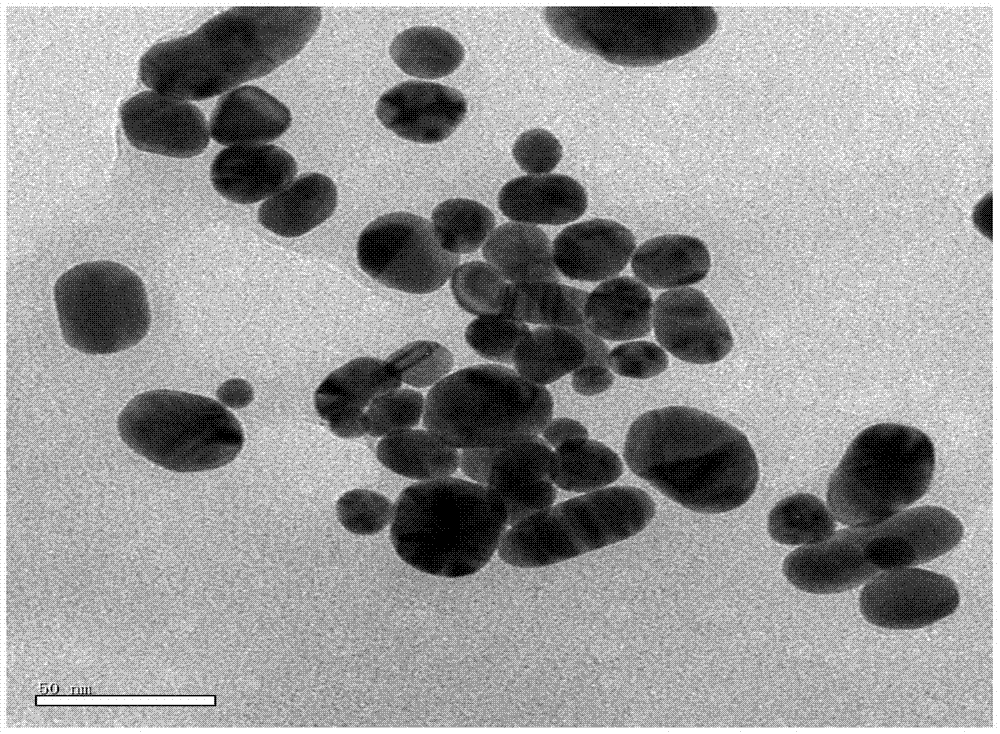

A kind of preparation method of dextran/nano gold-silver alloy composite

ActiveCN108213459BUniform particle sizeImprove antibacterial propertiesMaterial nanotechnologyMetallurgyReaction temperature

The invention relates to a preparation method of a glucan / nanogold-silver alloy compound. Gold nanoseed / glucan is adopted as seeds to prepare into the glucan / nanogold-silver alloy compound throughsynthesis. According to the preparation method of the glucan / nanogold-silver alloy compound provided by the invention, the gold nano particles are adopted as the seeds and can provide attachment points for the growth of silver nano particles, so that the required reaction temperature is greatly reduced, and the reaction time is reduced; and the synthesized gold-silver alloy compound is uniform inparticle size, so that the antimicrobial activity of nano silver is greatly improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A kind of method extracting starch from Luo Han Guo tuber root

Owner:HUNAN HUACHENG BIOTECH

Ultra-high performance ultra-large sized tyre and preparation process thereof

ActiveCN102935788BEnsure performance meets requirementsSimple internal structureTyresPneumatic tyre reinforcementsElement analysisSoftware design

The invention discloses an ultra-high performance ultra-large sized tyre and a preparation process thereof. The specification of the ultra-high performance ultra-large sized tyre is 305 / 25R32108W, the rim diameter is 32 inches, the rim width is 11J, the outer diameter is 965mm, the section width is 313mm, and the load is 1000kg. The tyre contour designed by high-performance tyre contour design software and subjected to finite element analysis is adopted, and the advanced structural design means and the stable process control can be adopted, the volume production of the tyre with the specification is realized, simultaneously all aspects of performances of the tyre can meet the requirements, product development risks are effectively reduced and the product development period is reduced.

Owner:QINGDAO SENTURY TIRE CO LTD

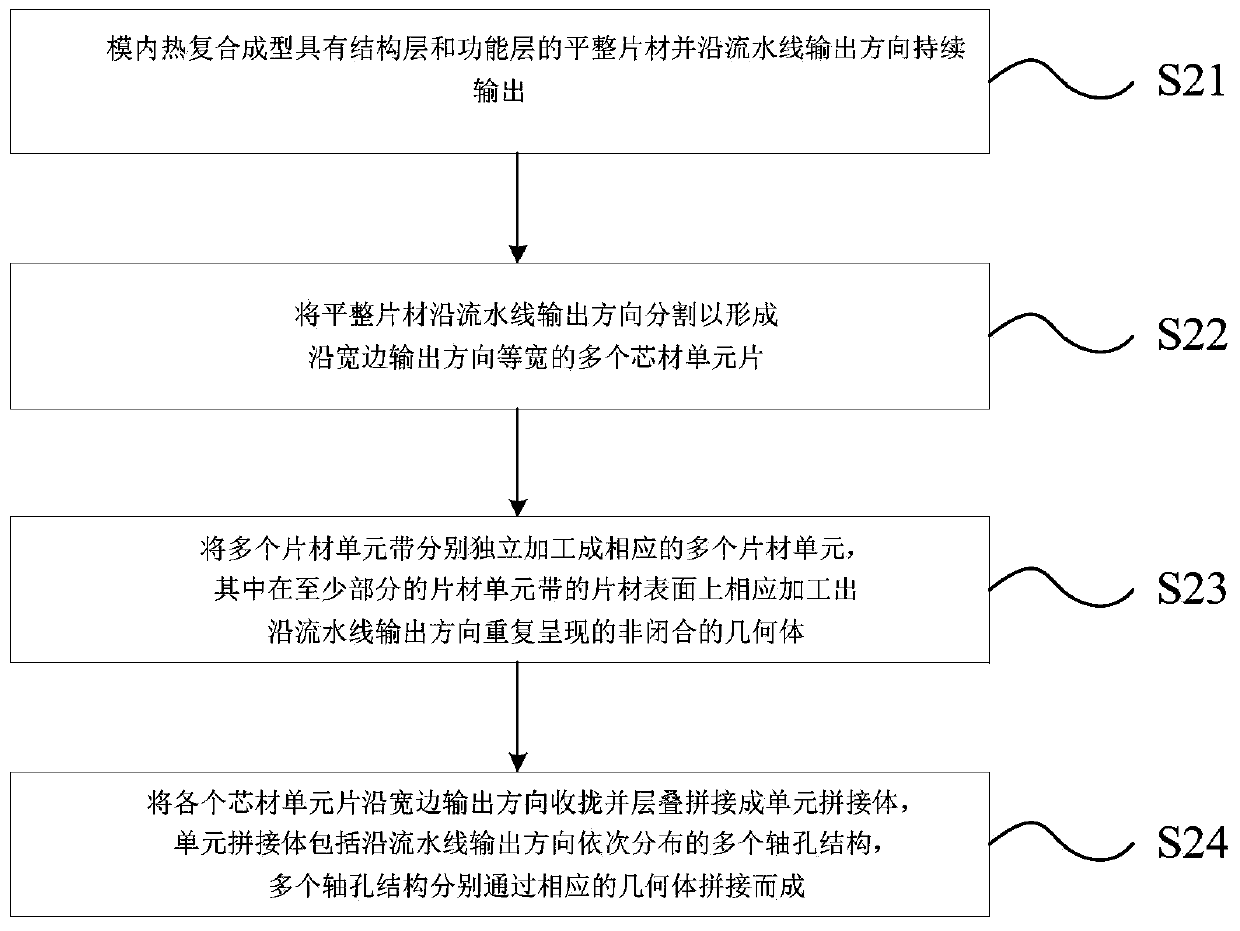

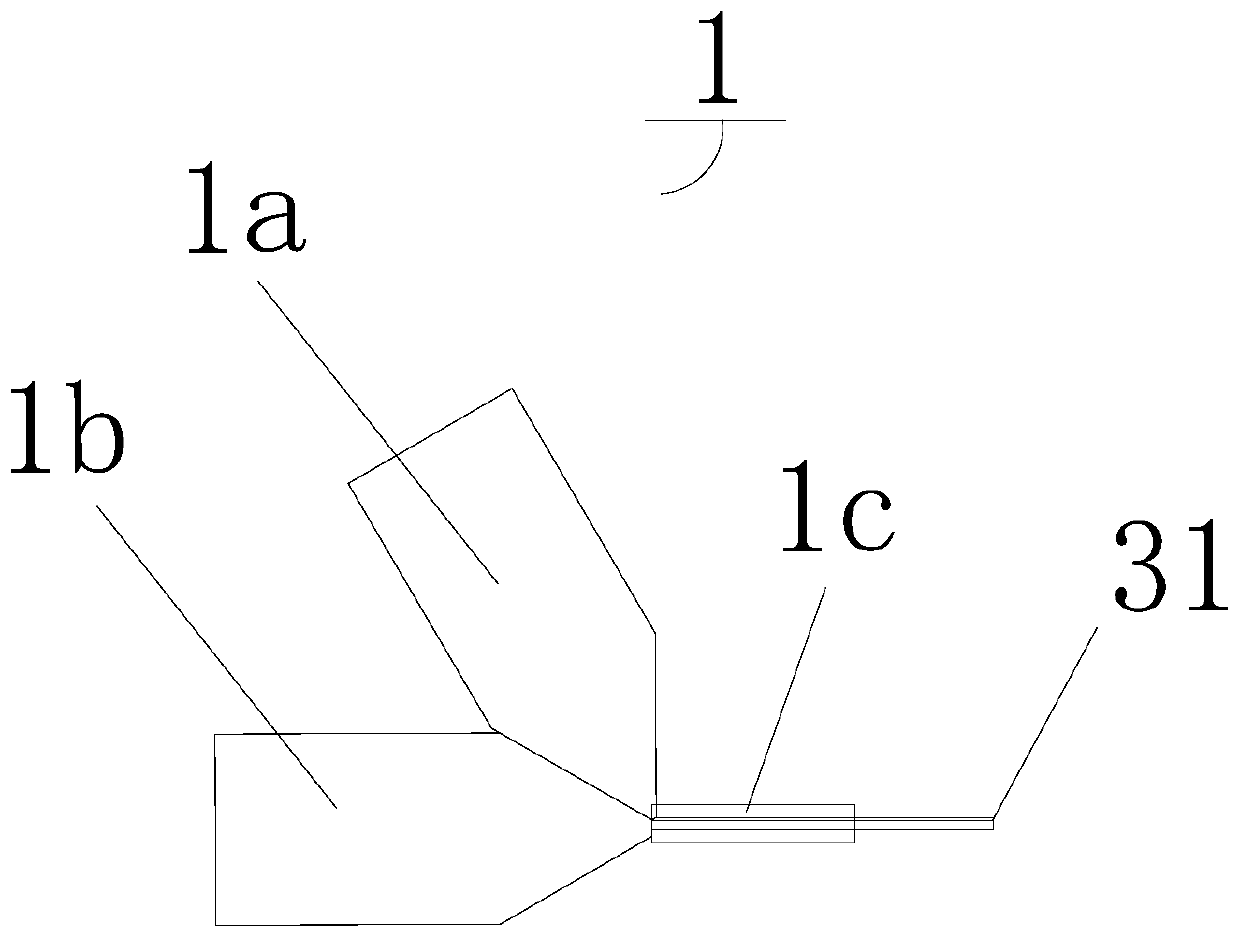

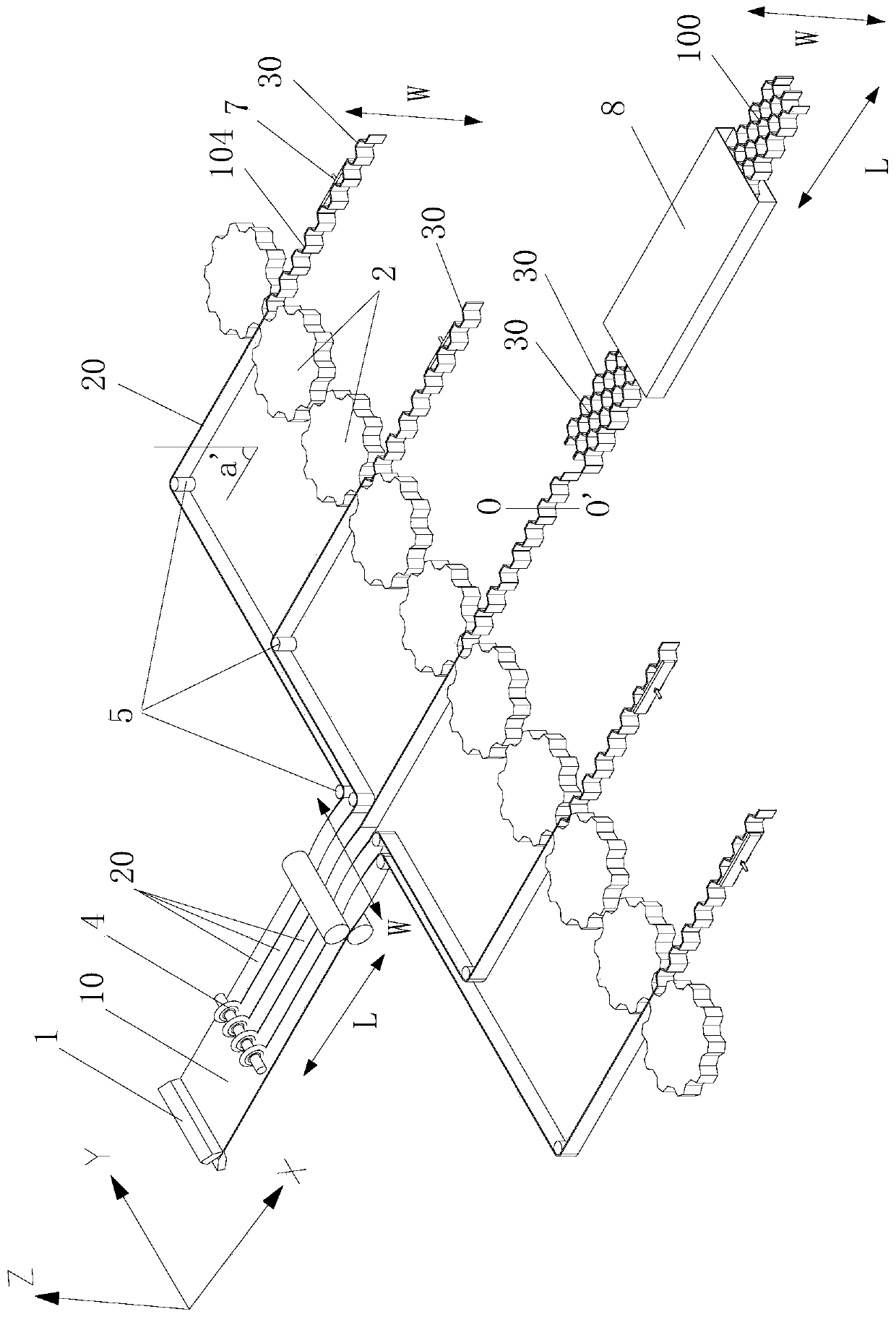

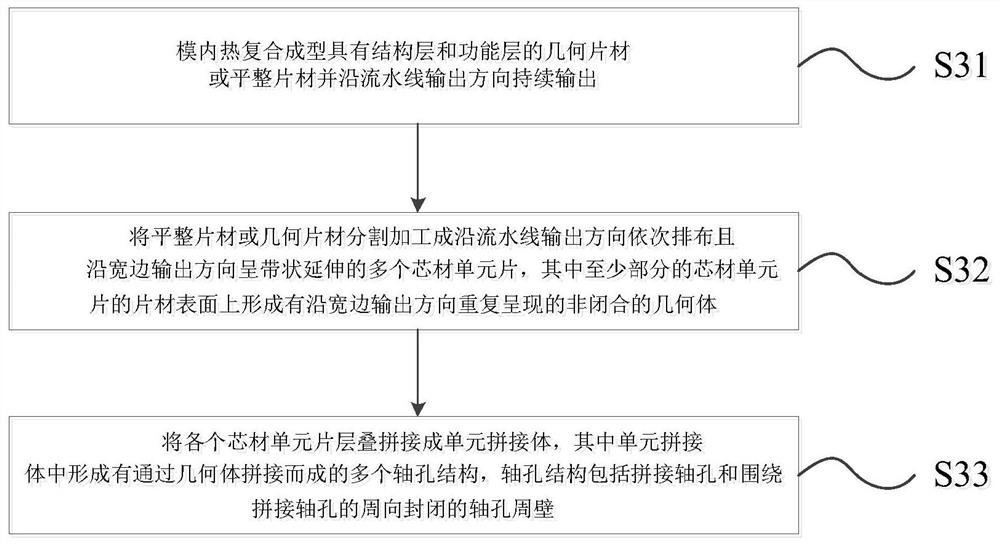

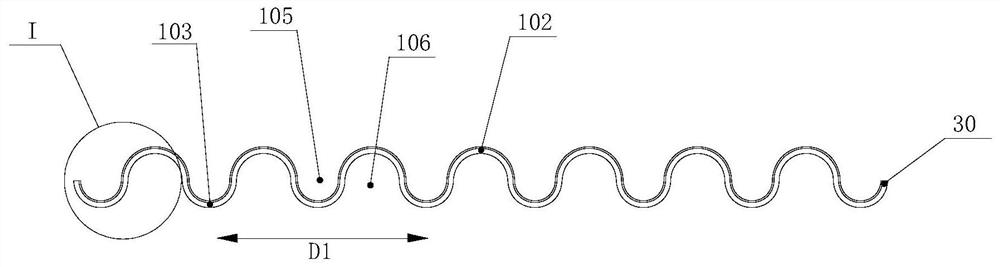

Production method and production device for thermoplastic composite core material

PendingCN110181844AKeep heavy loads lightImprove production continuityDomestic articlesAssembly lineEngineering

The invention discloses a production method and a production device for a thermoplastic composite core material. The production method comprises the steps of thermally compounding and forming a flat sheet with a structure layer and a function layer in a mold, and continuously outputting along an assembly line output direction; dividing the flat sheet along the assembly line output direction so asto form multiple core material unit sheets with equal widths along a broadside output direction; and independently processing the multiple core material unit sheets into multiple corresponding core material unit sheets, drawing the core material unit sheets along the broadside output direction, and splicing to form a unit splicing body. The production device comprises a thermal compounding extrusion mold, a geometry forming assembly, a cutting assembly, a guiding and positioning assembly, a hot melting and connecting assembly, and the like. The production method and the production device for the thermoplastic composite core material provided by the invention can be used for continuously producing the double-layer structure thermoplastic composite core material with high structural strengthand diversified functions in a low-cost way.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for extracting polysaccharide and d-mannitol from mogroside extraction waste liquid

ActiveCN110105458BImprove qualityHigh yieldOrganic chemistry methodsHydroxy compound separation/purificationAlcoholMannitol

The method for extracting polysaccharides and D-mannitol from the mogroside extraction waste liquid comprises the following steps: (1) boiling the mogroside extraction waste liquid, keeping warm, sterilizing, cooling, ultrafiltration, washing with water, passing through Put the anion exchange resin column on the liquid, collect the effluent, wash with water, collect the washing liquid, and concentrate; (2) put on the gel resin column, elute isocraticly, collect the target eluate in sections, and concentrate; Add alcohol solution to the concentrated solution, stir, stand still, filter, and dry to obtain the Luo Han Guo polysaccharide product; concentrate the filtrate and mix it with the crude D-mannitol concentrate, crystallize, filter, wash with alcohol, and dry to obtain the D-mannitol product . The mass content of Luo Han Guo polysaccharide obtained by the method of the present invention is more than or equal to 95%, and the yield is more than or equal to 92%; the mass content of the obtained D-mannitol is more than or equal to 98%, and the yield is more than or equal to 92%, and the quality is stable; Low, less waste liquid discharge, large-scale production can be realized.

Owner:HUNAN HUACHENG BIOTECH

A method for extracting rubusoside from sweet tea leaves

ActiveCN108516997BLow desalination and decolorization costGood removal effectSugar derivativesSugar derivatives preparationActivated carbonGlycoside

The invention relates to a method for extracting rubusoside from sweet tea leaves. The method comprises the following steps of (1) smashing and sieving the sweet tea leaves, adding water and conducting continuous countercurrent extraction and filtration; (2) adding an enzyme preparation for enzymolysis, conducting inactivation, cooling, flocculation and filtration and washing filtered residues with water; (3) conducting ultrafiltration and nanofiltration; (4) conducting adsorption through a macroporous adsorption resin chromatographic column, conducting washing with water, discarding water washing liquid and conducting gradient elution with an organic solvent and concentration under reduced pressure; (5) conducting adsorption through an aluminum oxide chromatographic column and conductingwashing with water concentration under reduced pressure; (6) adding activated carbon and conducting stirring, filtration, concentration under reduced pressure and spray drying; (7) dissolving the organic solvent and conducting filtration, crystallization, suction filtration, vacuum drying and pulverization to obtain a rubusoside product. The rubusoside product extracted by the method has pure white color, the purity is greater than or equal to 99%, and the yield is greater than or equal to 90.5%. The method has a simple operation process, short extraction time, low energy consumption and a lowcost and can achieve continuous large-scale production.

Owner:HUNAN HUACHENG BIOTECH

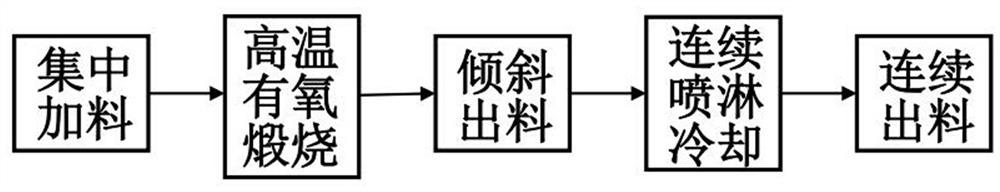

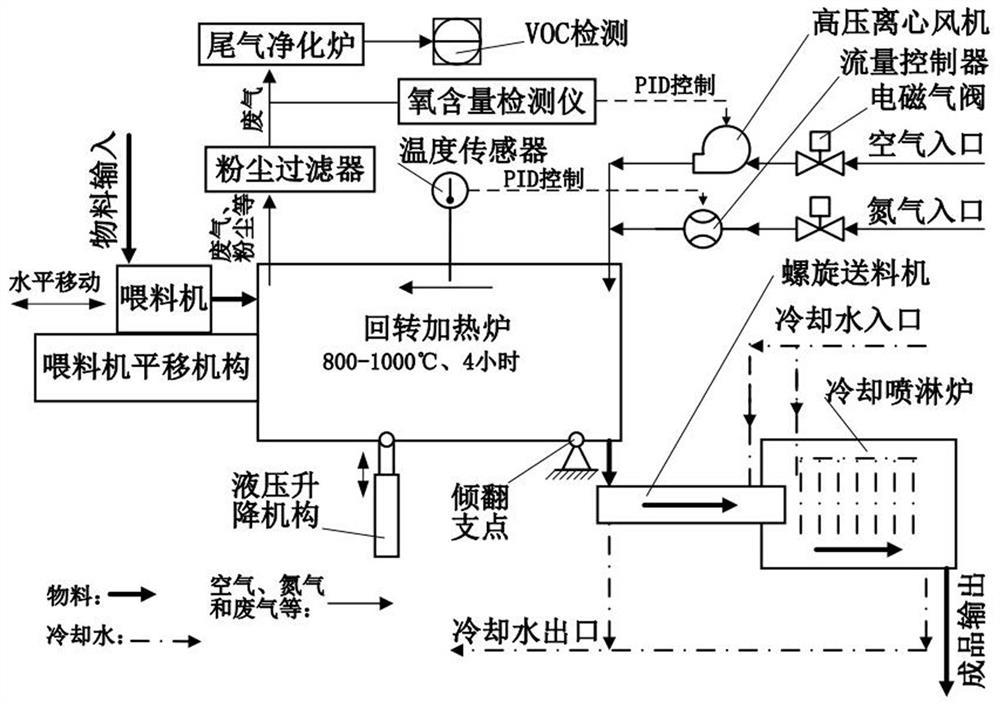

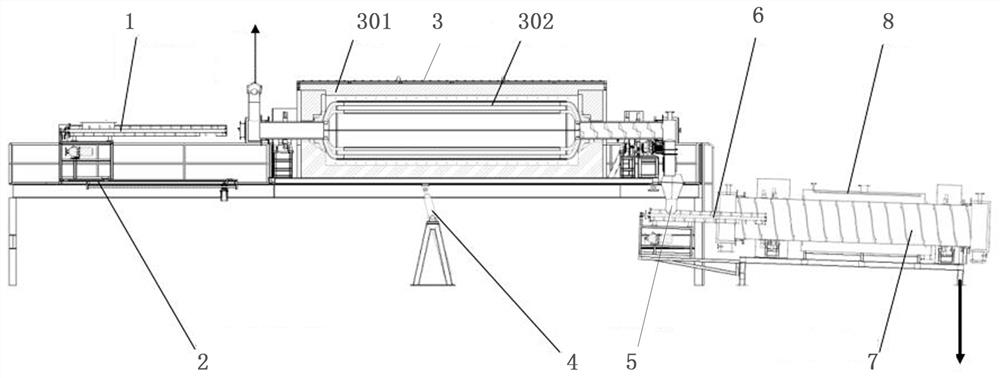

Filler recovery device for thermosetting plastic waste and recovery method

PendingCN112642844AAchieve recyclingReduce pollutionHuman health protectionDispersed particle filtrationPlastic wasteNitrogen gas

The invention provides a filler recovery device for thermosetting plastic waste and a recovery method. The filler recovery device mainly comprises a feeder, a feeder translation device, a rotary heating furnace, a spiral feeder, a cooling spray furnace, a dust filter, a tail gas purification furnace, a VOC detection device, a hydraulic lifting mechanism, a water cooling system, an air input system, a nitrogen input system, an electrical control system and the like. Organic matter in the thermosetting plastic waste is removed through a long-time high-temperature aerobic combustion method, filler in waste is recycled and can be reused for production of thermosetting plastic, cyclic utilization of the waste is achieved, and therefore the production cost is reduced, environmental pollution is reduced, and economic benefits are improved; and moreover, the production process of centralized feeding, high-temperature aerobic calcining, inclined discharging, continuous spraying cooling and continuous discharging is adopted, the device is compact in structure and high in production efficiency, and continuous batch production can be achieved.

Owner:洛阳炬星窑炉有限公司

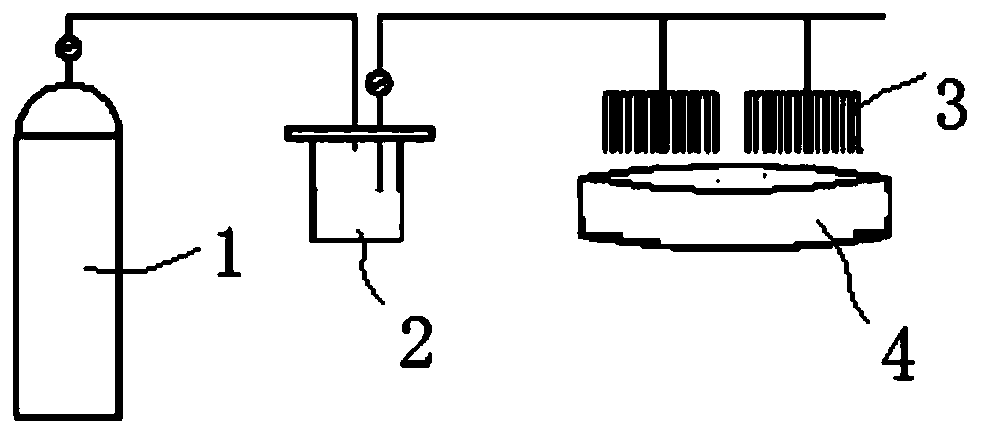

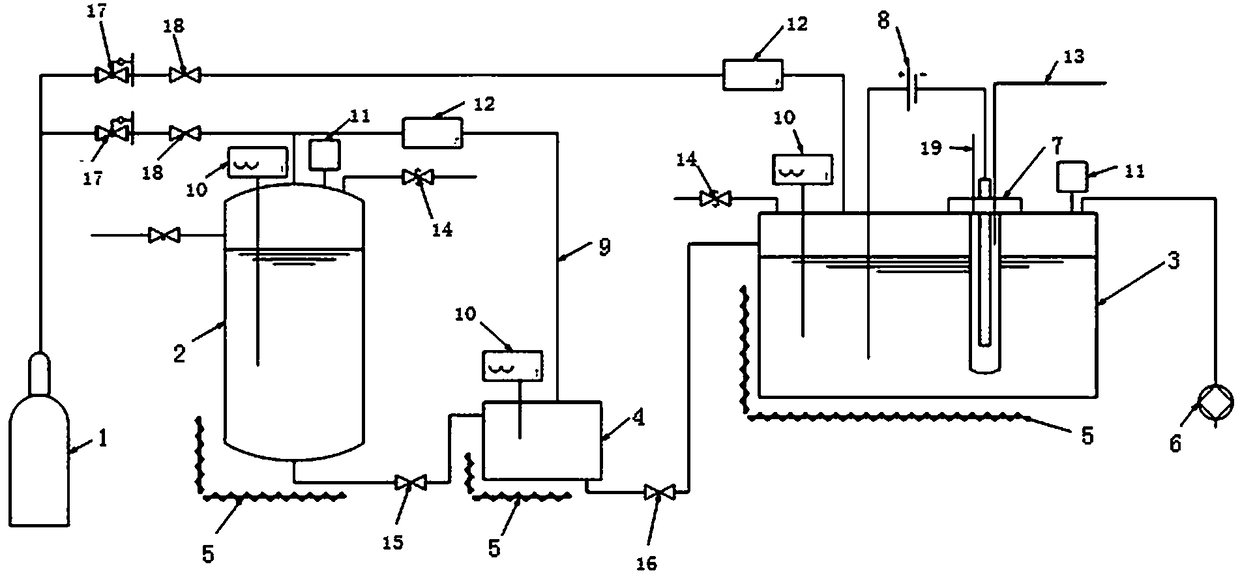

Electrolysis device for preparing high-purity metallic sodium

The invention discloses an electrolysis device for preparing high-purity metallic sodium. The electrolysis device for preparing the high-purity metallic sodium comprises a shielding gas source, a crude sodium tank, an electrolytic bath and a filtering tank. The filtering tank is arranged between the crude sodium tank and the electrolytic bath. The bottom of the crude sodium tank is connected withthe filtering tank through a pipeline. The pipeline enabling the crude sodium tank to be connected with the filtering tank is provided with a first stop valve. The bottom of the filtering tank is connected with the electrolytic bath through a pipeline. A second stop valve is arranged on the pipeline enabling the filtering tank and the electrolytic bath to be connected. The filtering tank is provided with a sodium solution flow guide pipe. One end of the sodium solution flow guide pipe communicates with the filtering tank. The other end of the sodium solution flow guide pipe communicates with the crude sodium tank. According to the electrolysis device for preparing the high-purity metallic sodium, the amount of crude sodium added to the electrolytic bath every time is controlled through a transition container and valves, the situation that a large amount of crude sodium swarms into the electrolytic bath and cause accidents can be avoided, and the safety coefficient of the electrolysis device is high.

Owner:中国东方电气集团有限公司

A controllable preparation method of polysaccharide derivative-induced gold nanoparticles

ActiveCN104907579BGood water solubilityGood biocompatibilityMaterial nanotechnologyEnvironmental resistanceGold particles

The invention discloses a controllable preparation method for gold nanoparticles induced by a polysaccharide derivative, and belongs to the technical field of green preparation of nano materials. The controllable preparation method includes the steps that under the acidity condition (pH4.8), an oxidized curdlan polysaccharide derivative is prepared through 4-accetamide-2, 2, 6, 6-tetramethyl piperidine-1-oxyl, sodium chlorate and sodium hypochlorite; the pH of the oxidized curdlan polysaccharide solution is adjusted, the solution is mixed with a chloroauric acid solution at the same volume, reaction is performed for 1.5 h at the temperature of 100 DEG C, a mixed solution is cooled to a room temperature, then filtered, centrifuged, dispersed, dialyzed, frozen and dried to obtain the gold nanoparticles, and through control over the pH value of the oxidized curdlan polysaccharide solution, gold nanoparticles of different shapes and grain sizes can be obtained. In this way, the preparation method is environmentally friendly, simple, easy to implement and good in stability, the shape and grain size of the gold nanoparticles are controllable, continuous large-scale production can be achieved, and the method has good application prospects.

Owner:东台海滨科技创业园管理有限公司

Production method and production equipment of thermoplastic composite core material

ActiveCN110185915BKeep heavy loads lightImprove production continuitySheets/panelsPlastic materialsAssembly line

The invention discloses a production method and production equipment for a thermoplastic composite core material. The production method comprises the following steps: compound molding geometrical sheets or flat sheets with structural layers and functional layers in a mold and continuously outputting the geometrical sheets or the flat sheets along the output direction of an assembly line; and cutting and processing the flat sheets or geometrical sheets into a plurality of core material unit sheets which are successively arranged along the output direction of the assembly line and stretch alongthe output direction of the wide side in a stripe-type direction, and stacking and splicing the core material unit sheets to a unit splicing body. The production equipment comprises a thermal compoundextruding mold, plastic material surface processing equipment, a cutting assembly, a guiding and positioning assembly, a rubber gun and the like. The invention provides the production method and theproduction equipment for the thermoplastic composite core material. The thermoplastic composite core material of a double-layered structure with high structural strength and functional diversity can be continuously produced with a low cost.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of urea thiophosphate fertilizer and its preparation method and application

ActiveCN107892597BImprove fertilizer efficiencyHas the effect of reducing weightOrganic phosphatic fertilisersAmmonium salt fertilisersO-Phosphoric AcidHydrogen Sulfate

The invention relates to a urea thiophosphate fertilizer and its preparation method and application. The fertilizer contains the following nutrient content in mass percentage: P 2 o 5 ≥20%, amide nitrogen ≥1%, ammonium nitrogen ≥10%, total N ≥ 12%, S ≥ 5%, and the pH of the fertilizer is 2.5‑4. The preparation method comprises: a step of mixing phosphoric acid, urea, and ammonium sulfate or / and ammonium bisulfate; a reaction step after mixing; a granulation and drying step. The invention is a general-purpose soil improvement fertilizer for alkaline soil, and has the characteristics of high fertilizer efficiency. Experiments on wheat show that the yield can be increased by about 8% compared with the application of diammonium phosphate.

Owner:菏泽金正大生态工程有限公司 +1

A kind of preparation method of polysaccharide-based silver nanoparticles

The invention discloses a polysaccharide-based silver nano-particle preparing method and relates to the technical field of preparation of silver nano-particles. Prepared oxidized curdlan with the carboxyl group content 2.07-4.87mmol / g and a silver nitrate solution are mixed in an isopyknic mode to form a mixed solution, the mixed solution reacts under the magnetic stirring at the constant temperature of 70-100 DEG C for 0.5-2h and then is cooled to be at the room temperature, filtered, centrifuged, dispersed, dialyzed and freeze-dried to prepare polysaccharide-based silver nano-particles, and spherical silver nano-particles controllable in particle diameter can be obtained by controlling the concentration of the oxidized curdlan, the carboxyl group content and the silver nitrate concentration. Therefore, the polysaccharide-based silver nano-particle preparing method is environment-friendly, simple and easy to operate and enables the silver nano-particles to be controllable in particle diameter, evenly dispersed and good in stability, and continuous large-scale production can be achieved.

Owner:东台海滨科技创业园管理有限公司

A device and preparation process for producing spodumene

ActiveCN103922355BWind speed adjustmentMeet heat transfer needsAluminium silicatesCooling effectProcess engineering

The invention discloses a device for producing spodumene and a preparation process. The device comprises a coarse particle suspension preheater, a rotary kiln, a separating valve and a leakage-free grate type cooling machine which are sequentially connected. The preparation process comprises the steps of preheating by adopting the coarse particle suspension preheater, roasting and transforming by adopting the rotary kin, separating by adopting the separating valve, and cooling by adopting the leakage-free grate type cooling machine. According to the device, by designing the coarse particle suspension preheater, tail gas of the rotary kiln is fully utilized for preheating, thus the energy consumption is reduced; by adopting the separating valve, the spodumene discharged out from the kiln can be effectively separated, and the safe and smooth operation of the whole system is ensured; by adopting the leakage-free grate type cooling machine, an optimal cooling effect can be achieved, and heat carried away by the spodumene discharged out from the kiln is fully utilized, thus the energy consumption of the system is reduced. The device realizes large-scale production and central automatic operation control of the spodumene, thereby greatly increasing the labor productivity and being better in economic benefit and environment protection benefit.

Owner:SICHUAN CALCINER TECH

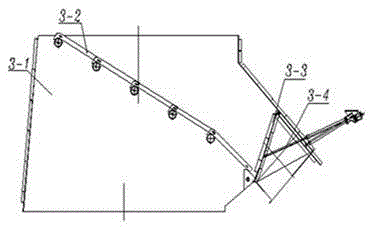

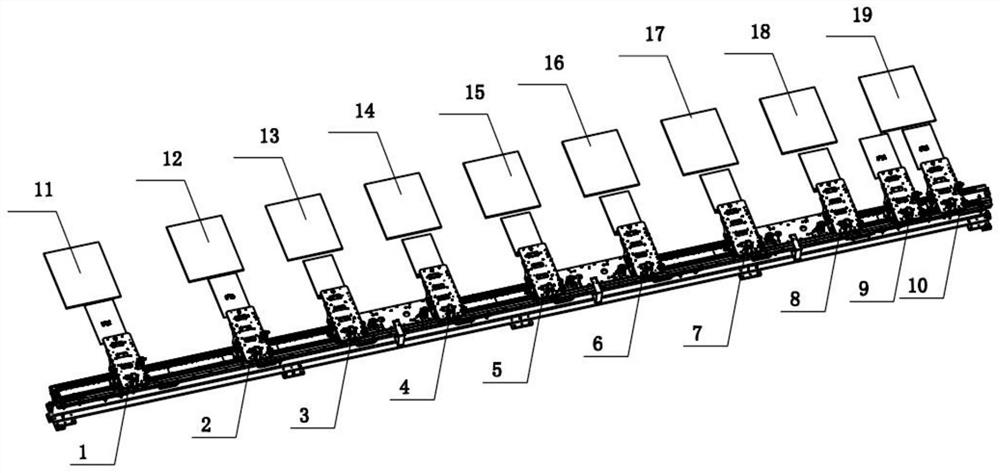

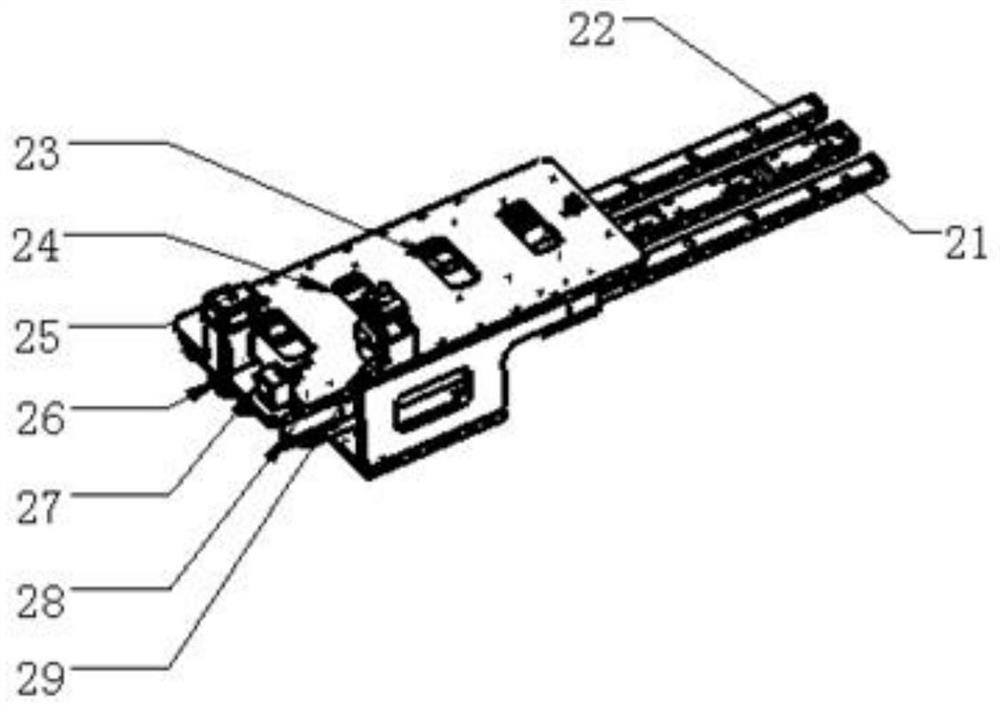

A kind of display screen ring paste synchronous handling mechanism and handling method thereof

ActiveCN108946166BAvoid deformationAchieve continuous mass productionCharge manipulationConveyor partsElectric machineSoftware engineering

Owner:SHENZHEN HONGFUHAN TECH

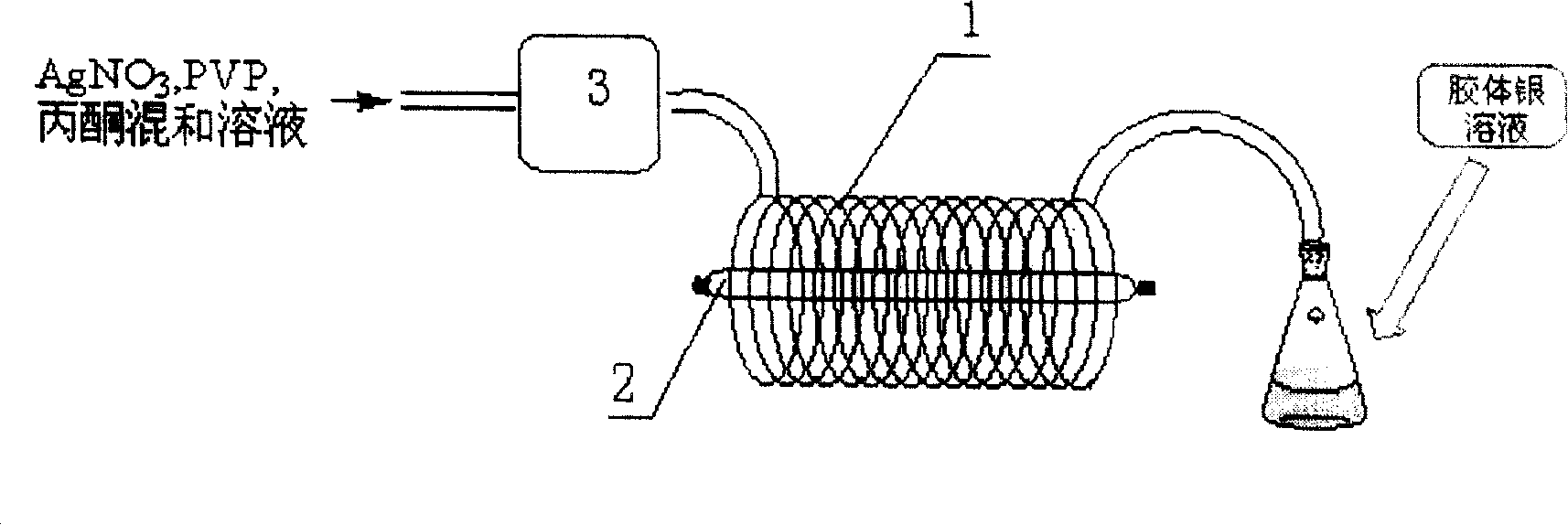

Preparation method of colloidal silver nanometer granule

InactiveCN100393455CUniform particle size distributionParticle size controllableUltravioletSilver ion

The invention discloses a making method of colloidal nanometer particle, which comprises the following steps: mixing the PVP solution and silver nitrate solution at 1-15:1 weight ratio; adding acetone in the mixing solution at 5-10:1 weight ratio for acetone and silver ion of silver nitrate; flowing the quartz snake pipe through radiating by 253.7-300 nm wavelength, irradiating by 14-2000 W ultraviolet at 0.5-60 mL / min speed. The invention doesn't produce toxic material or pollute environment, which is easy to control the grain size in the large-scale continuous production.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com