A device and preparation process for producing spodumene

A preparation process and technology of spodumene, applied in aluminum silicate, silicate and other directions, can solve the problem that spodumene takes away a lot of heat and is not recycled, can not greatly improve the production capacity of a single system, and reduce conduction and heat transfer. and convective heat transfer and other issues, to achieve good economic benefits and environmental protection benefits, to achieve continuous large-scale production, and to improve labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

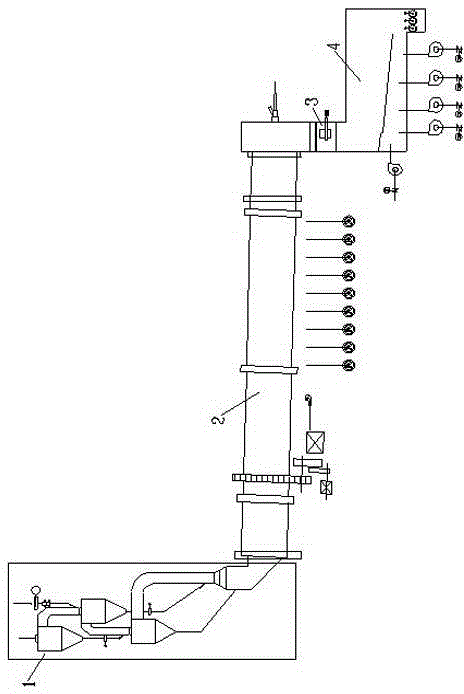

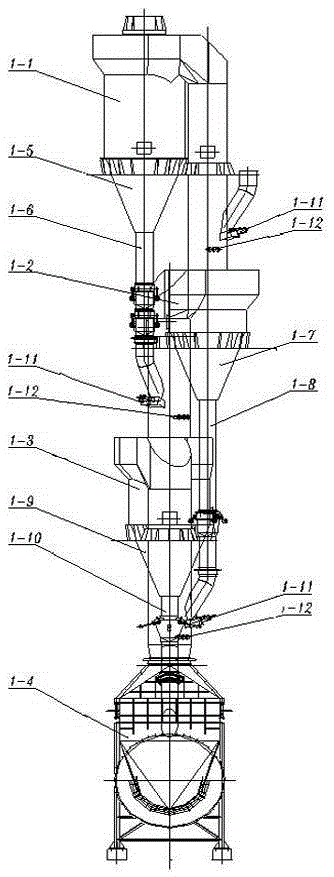

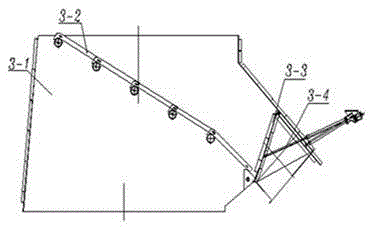

[0036] The main structure of this embodiment, a preparation device for producing spodumene such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a coarse particle suspension preheater 1, a rotary kiln 2, a material distribution valve 3 and a grate cooler 4 connected in sequence.

[0037] The coarse particle suspension preheater 1 includes a first-stage preheating cylinder 1-1, a second-stage preheating cylinder 1-2, and a third-stage preheating cylinder 1-3 connected in sequence. The first-stage preheating cylinder 1-2 and the third-stage preheating cylinder 1-3 are equipped with volute, air inlet, air outlet, air pipe elbow and air pipe straight section, and the first-stage preheating cylinder 1-1 volute The lower part is connected to the straight section of the air duct of the second preheating cylinder 1-2 through the first-level cone 1-5 and the first-level feeding pipe 1-6 in turn, and the air inlet of the first-level preheating cylinde...

Embodiment 2

[0049] The main structure of this embodiment, a preparation device for producing spodumene such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a coarse particle suspension preheater 1, a rotary kiln 2, a material distribution valve 3 and a grate cooler 4 connected in sequence.

[0050] The coarse particle suspension preheater 1 includes a first-stage preheating cylinder 1-1, a second-stage preheating cylinder 1-2, and a third-stage preheating cylinder 1-3 connected in sequence. The first-stage preheating cylinder 1-2 and the third-stage preheating cylinder 1-3 are equipped with volute, air inlet, air outlet, air pipe elbow and air pipe straight section, and the first-stage preheating cylinder 1-1 volute The lower part is connected to the straight section of the air duct of the second preheating cylinder 1-2 through the first-level cone 1-5 and the first-level feeding pipe 1-6 in turn, and the air inlet of the first-level preheating cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com