Method for continuously producing graphene aerogel microspheres

A graphene aerogel, graphene wet gel microsphere technology, applied in graphene, chemical instruments and methods, nano-carbon and other directions, can solve problems such as poor production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

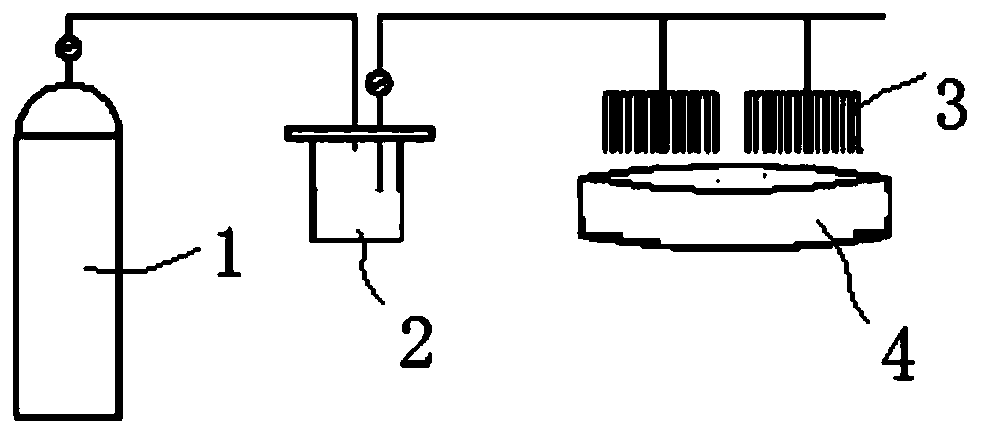

[0027] The preparation method of graphene oxide aerogel microspheres of the present invention includes the following steps: (1) liquid crystal solution preparation step; (2) graphene oxide microsphere preparation step; (3) wet gel microsphere preparation step; (4) ) Preparation steps of graphene aerogel microspheres. The details are described below.

[0028]

[0029] The graphene oxide is mixed with water to form a graphene oxide dispersion. The order of mixing is not particularly limited. According to one embodiment of the present invention, graphene oxide is added to water for dispersion to form a graphene oxide dispersion. According to another embodiment of the present invention, water is added to graphene oxide for dispersion to form a graphene oxide dispersion. The graphene oxide concentration in the graphene oxide dispersion may be 3-20 mg / ml, preferably 5-10 mg / ml, and more preferably 5-8 mg / ml. This is beneficial to improve the shell structure of graphene aerogel.

[0...

Embodiment 1

[0050] (1) Disperse graphene oxide in 10000 ml of deionized water to obtain a graphene oxide dispersion with a concentration of 5 mg / ml. Add 56 g of potassium hydroxide to the graphene oxide dispersion liquid, and ultrasonically disperse for 5 minutes to form a graphene oxide liquid crystal solution.

[0051] (2) The graphene oxide liquid crystal solution is placed in the slurry supply device 2, and the pressure supply device 1 is used to apply pressure so that the pressure of the slurry supply device 2 is 0.02 MPa, and the graphene oxide liquid crystal solution is passed through the splitter 3 (the number is 2 The number of outlets of the splitter is 10, the caliber is 2mm) is supplied to the container 4 containing the calcium chloride coagulation bath (5wt% calcium chloride aqueous solution), and it is allowed to stand for 10 minutes, and the graphene oxide microspheres sink into the container 4 At the bottom, drain the coagulation bath and add a large amount of deionized water...

Embodiment 2

[0056] (1) Disperse graphene oxide in 10000 ml of deionized water to obtain a graphene oxide dispersion with a concentration of 6 mg / ml. Add 56 g of potassium hydroxide to the graphene oxide dispersion liquid, and ultrasonically disperse for 5 minutes to form a graphene oxide liquid crystal solution.

[0057] (2) Place the graphene oxide liquid crystal solution in the slurry supply device, use the pressure supply device to apply pressure so that the pressure of the slurry supply device is 0.02MPa, and pass the graphene oxide liquid crystal solution through the splitter (the number is 2, the splitter The number of outlets is 10, the caliber is 2mm) is supplied to the calcium chloride coagulation bath (5wt% calcium chloride aqueous solution), and it is allowed to stand for 10 minutes. The graphene oxide microspheres sink to the bottom of the container. Pour out the coagulation bath and add a large amount Clean with deionized water.

[0058] (3) Add graphene oxide microspheres to 4g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com