Preparation method of colloidal silver nanometer granule

A silver nanoparticle and nanoparticle technology, applied in the field of preparation of colloidal silver nanoparticles, can solve the problems of uneven distribution, low light utilization rate, unfavorable production and preparation, etc., and achieve the effect of easy particle size and continuous large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

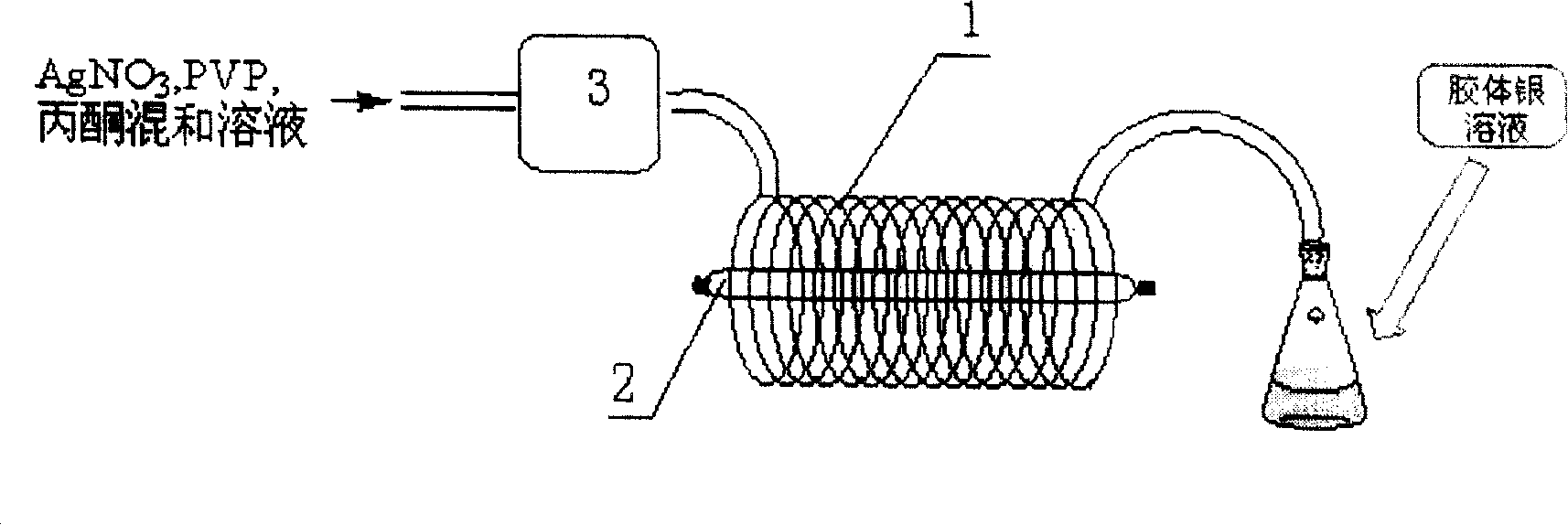

[0009] Embodiment 1: referring to accompanying drawing, at first, the K15 aqueous solution that concentration is 2mg / mL and the silver nitrate solution that concentration is 250 μ g / mL are mixed by the mass ratio of silver ion in K15 and silver nitrate as 15: 1; Then, after obtaining Acetone is added to the mixed solution, and the mass ratio of the added acetone to silver ions in silver nitrate is 8:1; finally, the mixed solution is irradiated by a 200W ultraviolet lamp 2 with a radiation wavelength of 253.7nm and a constant flow pump 3 to 30mL The flow rate of / min flows through the quartz serpentine tube 1 with a quartz tube diameter of 20 mm, a quartz tube spacing of 2 mm, and a spiral tube length of 5 cm to obtain silver nanoparticles with uniform size distribution and an average particle diameter of 10 nm.

Embodiment 2

[0010] Example 2: First, the K25 aqueous solution with a concentration of 1 mg / mL and the silver nitrate solution with a concentration of 5000 μg / mL are mixed according to the mass ratio of K25 and silver ions in silver nitrate as 8:1; then, in the obtained mixed solution Add acetone, and the mass ratio of the added acetone to silver ions in silver nitrate is 10:1; finally, the mixed solution is irradiated by a 100W ultraviolet lamp with a radiation wavelength of 300nm and flows through the quartz crystal at a flow rate of 2mL / min. The diameter of the tube is 2 mm, the distance between the quartz tubes is 5 mm, and the length of the spiral tube is 160 cm, so that silver nanoparticles with uniform size distribution and an average particle size of 20 nm can be obtained.

Embodiment 3

[0011] Embodiment 3: first, the K30 aqueous solution that is 0.5mg / mL is mixed with the silver nitrate solution that concentration is 3000 μ g / mL by K30 and the mass ratio of silver ion in silver nitrate is 5: 1; Then, in the mixed solution that obtains Add acetone to the solution, the mass ratio of the added acetone to the silver ions in the silver nitrate is 5:1; finally, the mixed solution is irradiated with ultraviolet light with a radiation wavelength of 253.7nm and a power of 1200W with a constant flow pump at a flow rate of 10mL / min. Silver nanoparticles with a uniform size distribution and an average particle diameter of 15 nm can be obtained through a quartz serpentine tube with a diameter of 18 mm, a distance between the quartz tubes of 20 mm, and a spiral tube length of 30 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com