Preparation method for acidic fertilizer

A technology of acidic fertilizer and phosphoric acid, applied in ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, ammonium salt fertilizer, etc., can solve the problems of high viscosity of granular fertilizer, easy moisture absorption and hardening of products, unfavorable popularization and application, etc., and achieve reduction Effects of volatilization loss, improvement of soil structure and environment, and increase of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

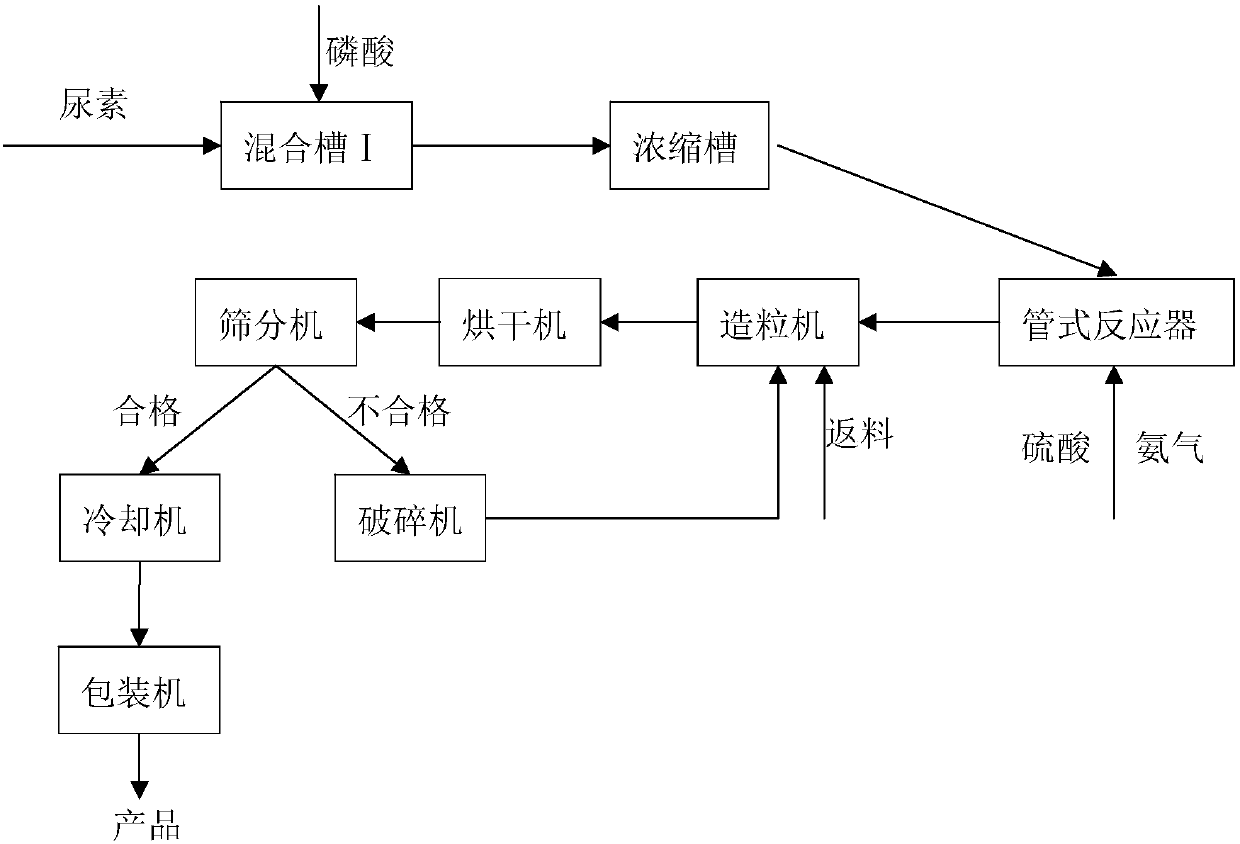

[0044] A preparation method of acidic fertilizer, comprising the steps of:

[0045] (1) Phosphoric acid and urea are added to the mixing tank I to control the P in the acid solution 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.7, and the mixture A is obtained after mixing evenly;

[0046] (2) The mixed slurry A obtained in step (1) is pumped into the concentration tank to concentrate at 85°C, and the P 2 o 5 The mass percent content is 36%, and concentrated slurry B is obtained after concentration;

[0047] (3) Pump the slurry B obtained in step (2) into the mixing tank II, add urea to the mixing tank II, and control the P in the acid solution 2 o 5 and total CO(NH 2 ) 2 The molar ratio is 1:1.4, and the mixed slurry C is obtained

[0048] (4) The slurry C obtained in the step (3) is passed into a tubular reactor, sulfuric acid is added, and ammonia gas is passed into to control P 2 o 5 The molar ratio with sulfate is 1:1, pH=2-3.5, temperature 155-165°C, after th...

Embodiment 2

[0052] A preparation method of acidic fertilizer, comprising the steps of:

[0053] (1) Phosphoric acid and urea are added to the mixing tank I to control the P in the acid solution 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.2, and the mixture A is obtained after mixing evenly;

[0054] (2) The mixed slurry A obtained in step (1) is pumped into the concentration tank to concentrate at 85°C, and the P 2 o 5 The mass percentage content is 41%, and concentrated slurry B is obtained after concentration;

[0055] (3) Pump the slurry B obtained in step (2) into the mixing tank II, add urea to the mixing tank II, and control the P in the acid solution 2 o 5 and total CO(NH 2 ) 2 Molar ratio is 1:0.6, obtains mixed slurry C;

[0056] (4) The slurry C obtained in the step (3) is passed into a tubular reactor, sulfuric acid is added, and ammonia gas is passed into to control P 2 o 5 The molar ratio to sulfate is 1:1.7, pH=2-3.5, temperature 170-175°C, after the reaction i...

Embodiment 3

[0060] A preparation method of acidic fertilizer, comprising the steps of:

[0061] (1) Phosphoric acid and urea are added to the mixing tank I to control the P in the acid solution 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.3, and the mixture A is obtained after mixing evenly;

[0062] (2) Pump the mixed slurry A obtained in step (1) into the concentration tank to concentrate at 90°C, and control P 2 o 5 The mass percent content is 41.5%, and concentrated slurry B is obtained after concentration;

[0063] (3) The slurry B obtained in the step (2) is passed into the tubular reactor, sulfuric acid is added, and ammonia gas is passed into to control P 2 o 5 The molar ratio to sulfate is 1:1.5, pH=2-3.5, temperature 160-170°C, after the reaction is complete, slurry C is obtained;

[0064] (4) spray the slurry C obtained in step (3) into the granulator for spray granulation, then transport to the dryer for drying, and then sieve, and the qualified products are packaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com