Urea sulfate and urea phosphate fertilizer and preparation method and application thereof

A technology of urea thiophosphate and urea phosphate, applied in the field of urea thiophosphate fertilizer and its preparation, can solve the problems of easy moisture absorption and hardening of the product, unfavorable popularization and application, difficult transportation and use, etc., and achieve continuous large-scale production and preparation process Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

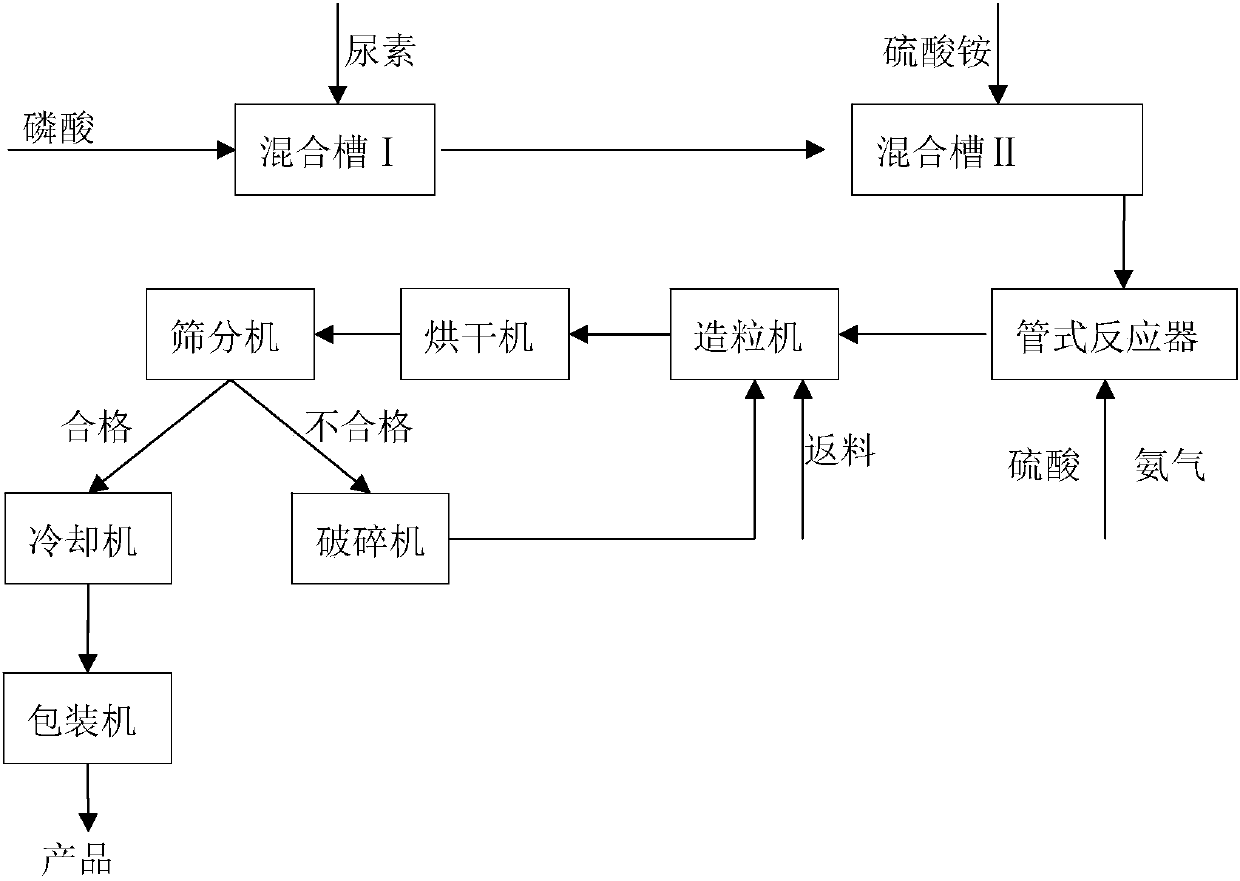

[0064] A preparation method of urea thiophosphate fertilizer, comprising the steps of:

[0065] (1) First add phosphoric acid to the mixing tank I, and add urea under constant stirring to control the P in the acid solution. 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.4, and the mixed slurry A is obtained after mixing evenly;

[0066] (2) Pump the mixed slurry A obtained in step (1) into the concentration tank, concentrate at 85°C, and control P 2 o 5 The mass percent content is 40%, and the concentrated slurry B is obtained;

[0067] (3) Pump the slurry B obtained in step (2) into the mixing tank II, add urea to the mixing tank II, and control the P in the acid solution 2 o 5 with CO(NH 2 ) 2 Molar ratio is 1:0.6, obtains mixed slurry C;

[0068] (4) Pump the mixed slurry C obtained in the step (3) into the mixing tank III, press the P in the mixed slurry 2 o 5 The content of ammonium sulfate is put into the ammonium sulfate, specifically after the ammonium sulfa...

Embodiment 2

[0073] A preparation method of urea thiophosphate fertilizer, comprising the steps of:

[0074] (1) First add the urea phosphate mother liquor into the mixing tank I, and add phosphoric acid under constant stirring to control the P in the acid solution. 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.9, and the mixed slurry A is obtained after mixing evenly;

[0075] (2) Pump the mixed slurry A obtained in step (1) into the concentration tank, concentrate at 90°C, and control P 2 o 5 The mass percent content is 43%, and concentrated slurry B is obtained after concentration;

[0076] (3) Pump the concentrated slurry B obtained in step (2) into the mixing tank II, press the P in the mixing slurry 2 o 5 The content of ammonium sulfate is put into the ammonium sulfate, specifically after the ammonium sulfate is put in, the P in the mixed slurry 2 o 5 The molar ratio of sulfuric acid and sulfate reaches 1:1.2 to obtain slurry C;

[0077] (4) The slurry C obtained in the ste...

Embodiment 3

[0081] A preparation method of urea thiophosphate fertilizer, comprising the steps of:

[0082] (1) Add phosphoric acid to the mixing tank, then add urea to control the P in the acid solution 2 o 5 with CO(NH 2 ) 2 The molar ratio is 1:0.3, P 2 o 5 The mass percent content is 43.5%; add ammonium sulfate again, press P 2 o 5 The molar ratio of sulfate to ammonium sulfate is 1:1.3, and ammonium sulfate is added;

[0083] (2) the slurry obtained in the step (1) is passed into a tubular reactor, sulfuric acid is added, and ammonia gas is passed into, and the addition of sulfuric acid is controlled to make P 2 o 5 The molar ratio to the total sulfate in the slurry is 1:1.4, pH=2-3.5, temperature 120-130°C, after the reaction is complete, the slurry is obtained;

[0084] (3) Spray the slurry obtained in step (2) into a granulator for spray granulation, then transport it to a dryer for drying, and then sieve it. After crushing, the finished product is returned to the granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com