Continuous preparation equipment and process for metal glass cladded metal wire composite material

A technology of metallic glass and composite materials, applied in the direction of metal material coating process, hot-dip plating process, coating, etc., can solve the problems of limiting the application range of materials, and achieve the effect of strong material selectivity and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

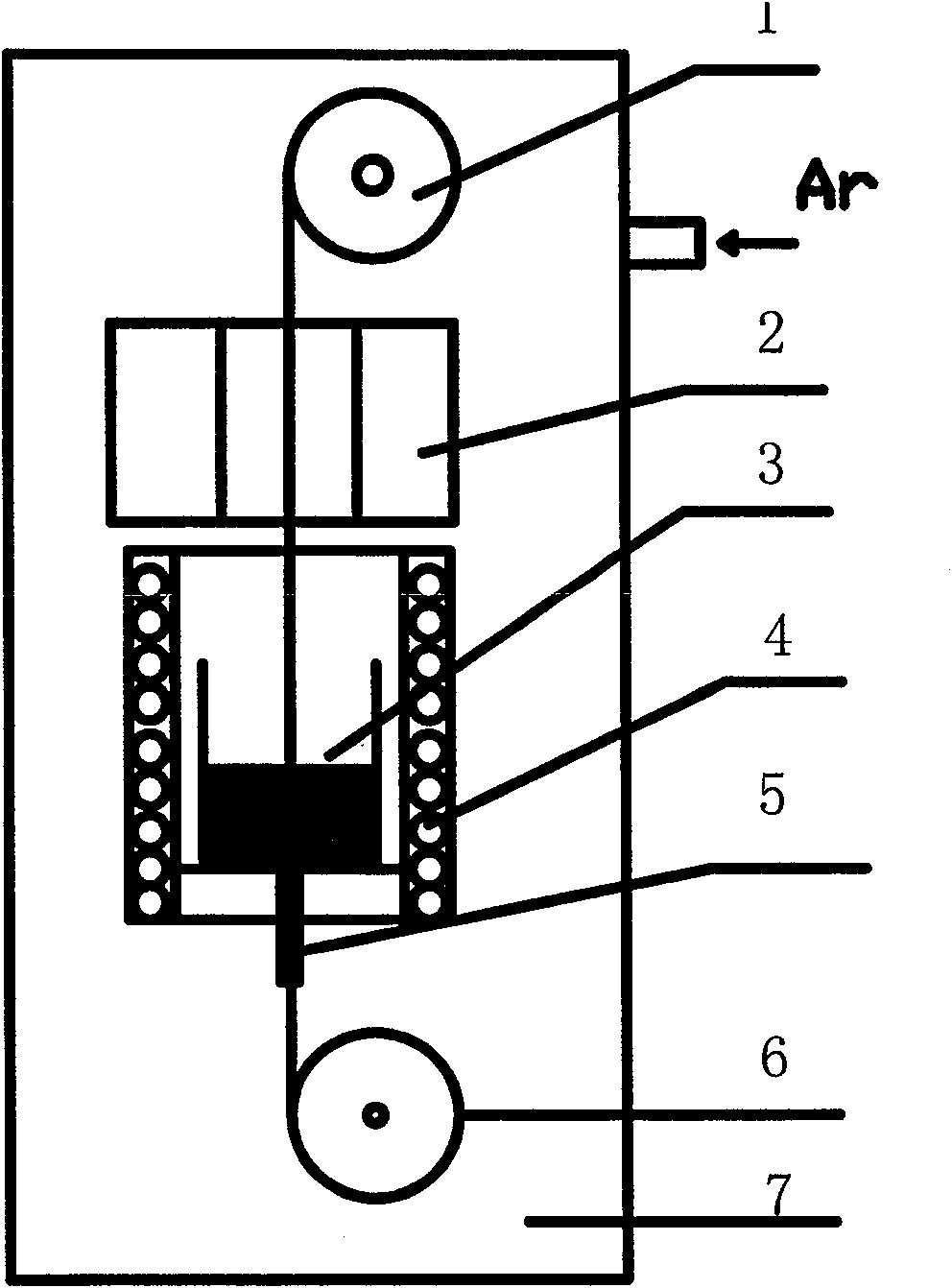

Method used

Image

Examples

Embodiment 1

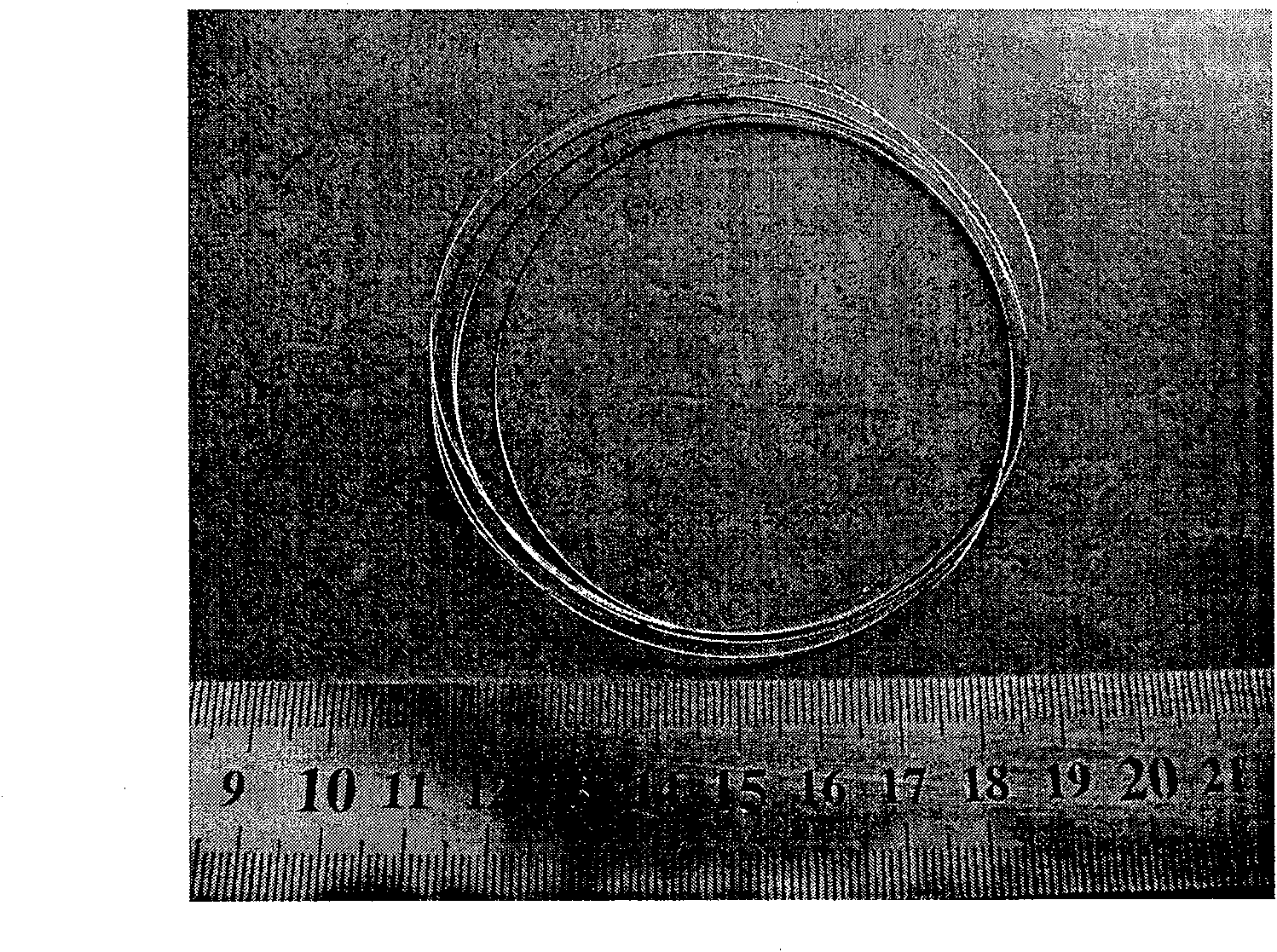

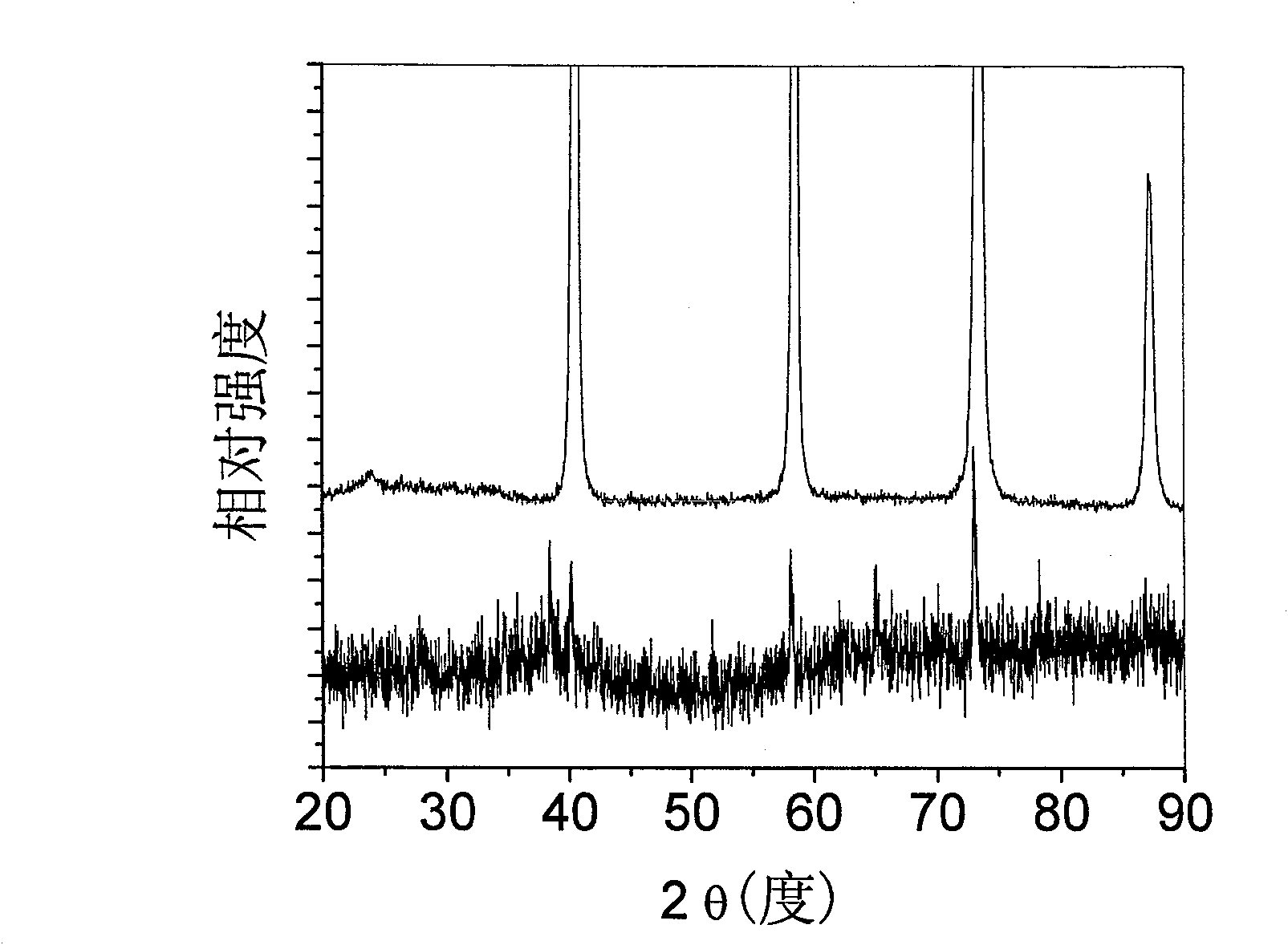

[0018] Zr, Ti, Cu, Ni and Be with a purity greater than 99.99% are arc-melted in an argon atmosphere adsorbed by titanium according to the nominal composition ratio, mixed uniformly, and cooled to obtain an ingot. The tungsten wire with a diameter of 200 μm is soaked in 40% hydrofluoric acid (HF) after being straightened to remove the surface oxide film, and then cleaned in acetone and alcohol by ultrasonic waves. The treated tungsten wire is wound on the guide wheel on the upper part of the traction mechanism, and the lead-out part together with the pulverized master alloy is put into the crucible with a small hole at the bottom. One end of the tungsten wire passes through the small hole of the crucible from the inside to the outside. Remelt the master alloy in the heating furnace and keep it warm, and then pull down the metal wire dipped in the melt at a rate of V=25mm / min driven by the motor through the traction mechanism, so that the surface is uniformly impregnated with a ...

Embodiment 2

[0020] Technical solution As in Example 1, the metal wire is made of stainless steel wire, and the continuous casting wire drawing rate V=25mm / min is adjusted to obtain a high-quality continuous casting metallic glass-coated steel wire composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic limit | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com