Continuous silicon carbon negative dynamic CVD sintering furnace

A sintering furnace and negative electrode technology, applied in furnaces, charge materials, rotary drum furnaces, etc., can solve the problems of intermittent production, inability to continuously feed and discharge materials, and extremely high sealing effect requirements, achieve good overall sealing, and achieve continuous mass production. Achieve the effect of continuous mass production of silicon carbon anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

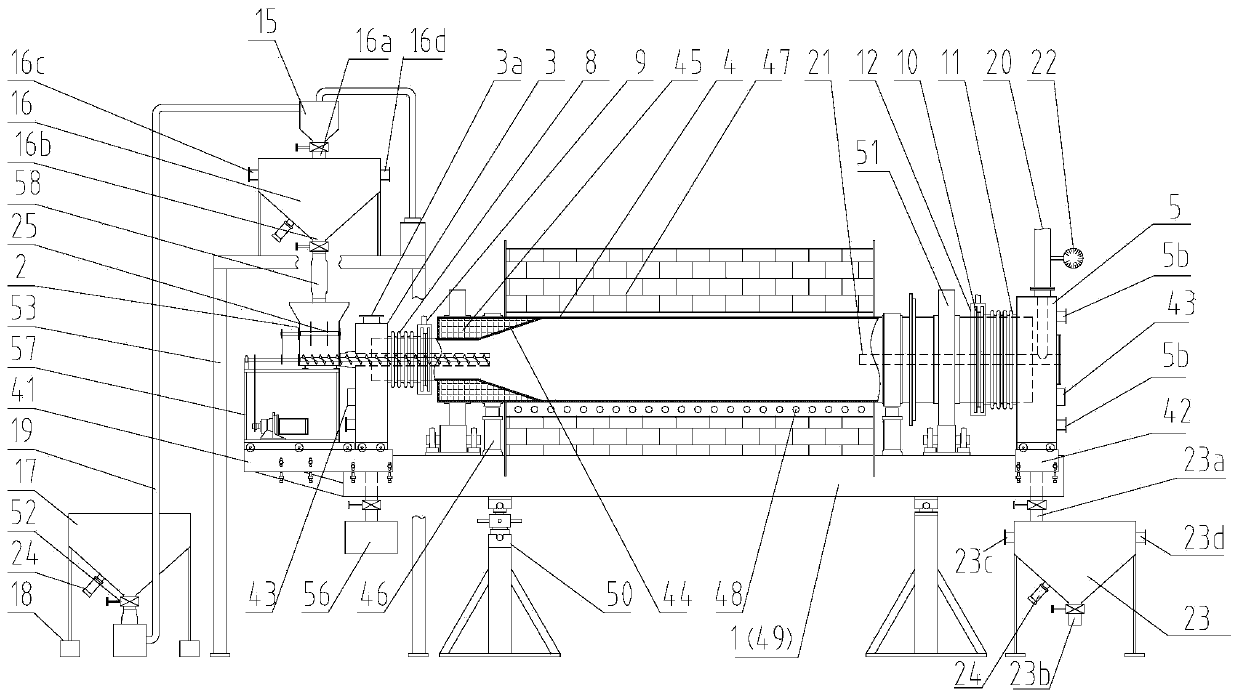

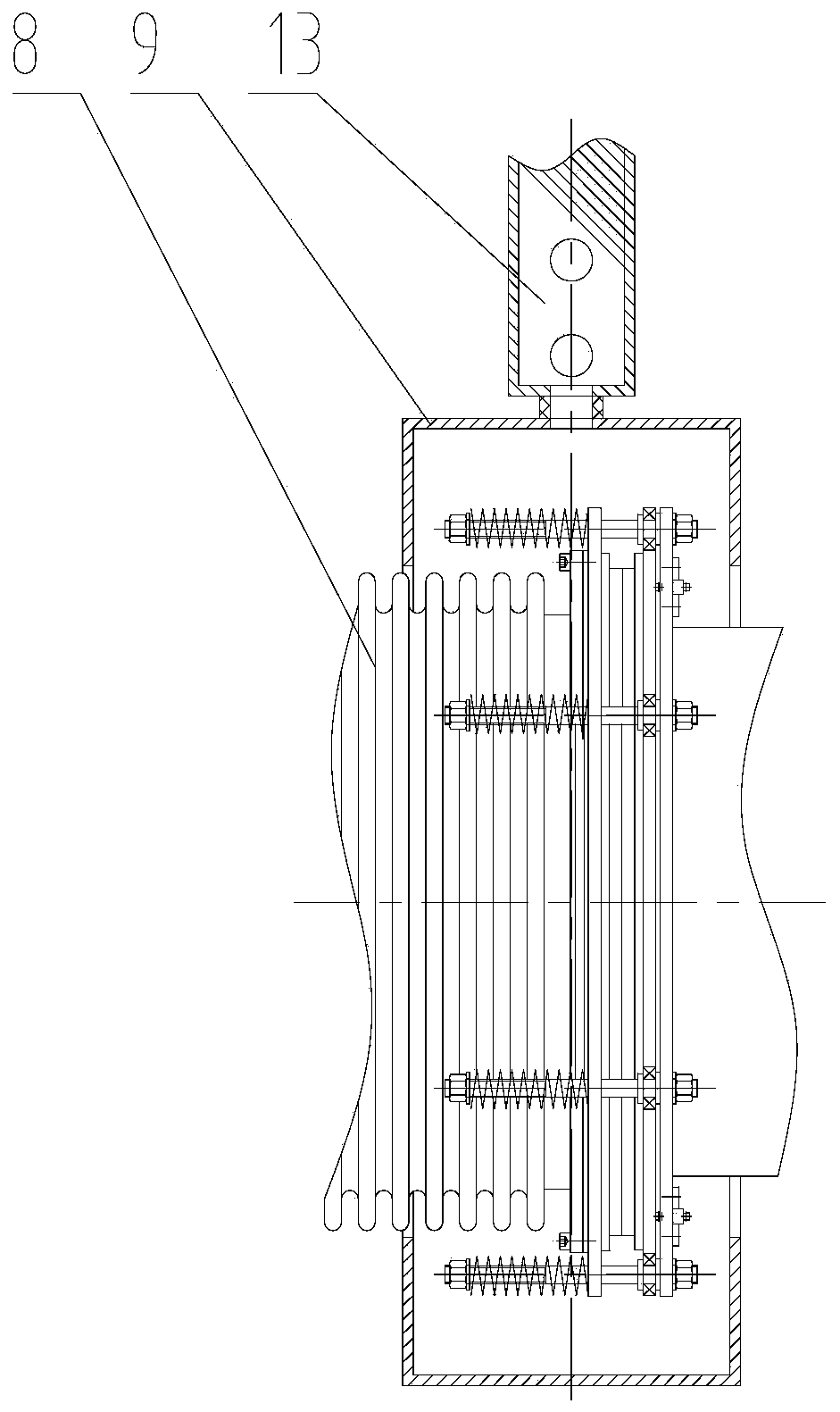

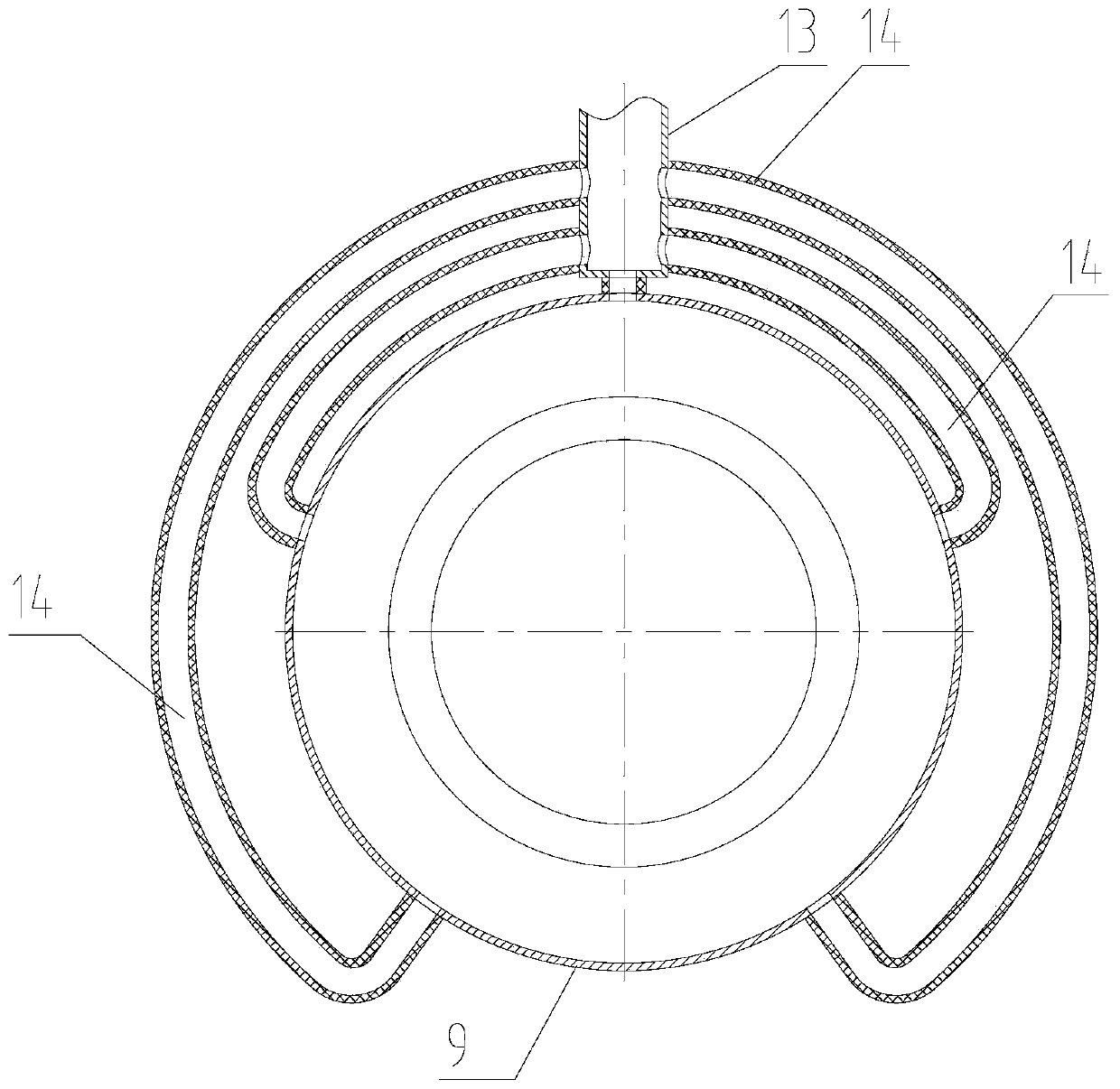

[0033] Such as Figure 1 to Figure 5 As shown, the continuous silicon carbon negative electrode dynamic CVD sintering furnace of the present embodiment includes an installation platform 1, a screw feeder 2, a furnace head cover 3, a furnace tube 4 and a furnace tail cover 5, and the furnace tube 4 is rotatably installed on On the installation platform 1, the head end of the furnace tube 4 is located in the furnace head cover 3 and the tail end is located in the furnace tail cover 5, the screw feeder 2 is sealed and docked with the furnace head cover 3 through a soft channel, and the screw feeder 2 The screw shaft 6 passes through the soft channel and the furnace head cover 3 is docked with the furnace tube 4, the furnace tail cover 5 is provided with a discharge port, and the end of the furnace tube 4 outside the furnace head cover 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com