Particulate matter bed layer support grid and radial flow reactor

A technology for supporting grids and particulate matter, which is used in the separation of dispersed particles, chemical instruments and methods, chemical/physical processes, etc., and can solve the problems of obvious scouring effect of V-shaped wire mesh, high stability and rigidity requirements, and pressure drop of distribution plate. It can reduce the corrosion and fracture tendency, increase the inlet flow area, and increase the flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example is used to illustrate the particulate matter bed support grid of the present invention.

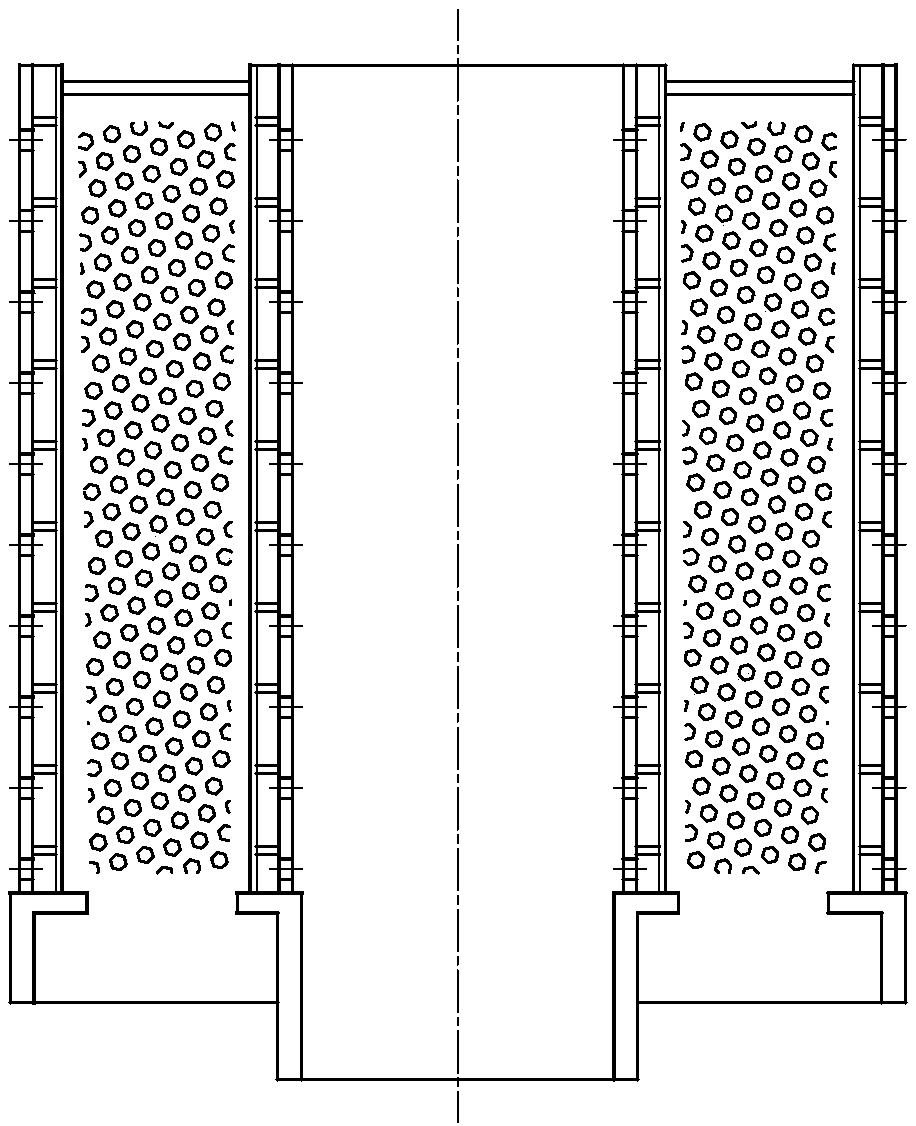

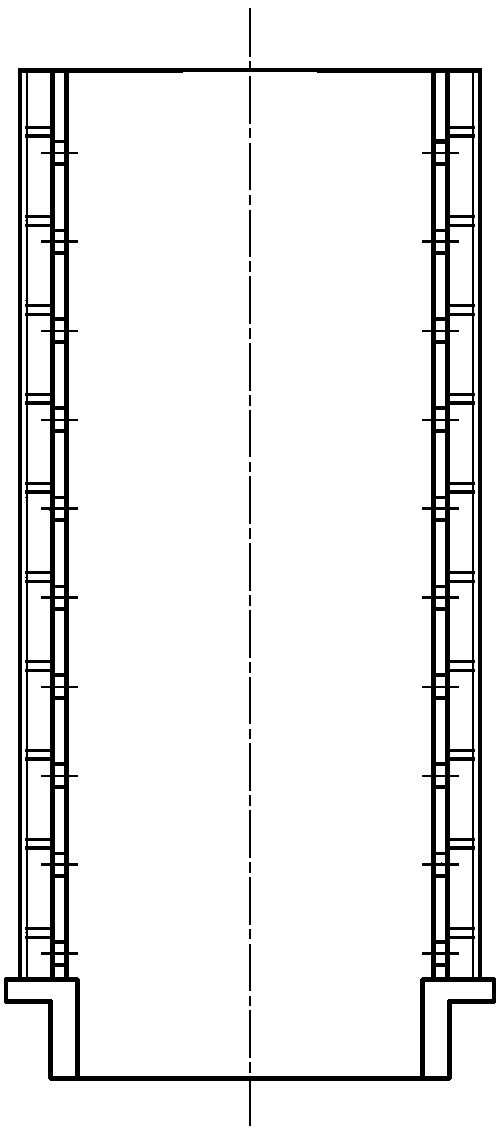

[0051] Such as Figure 3-5 As shown, the granular bed support grid is a double-layer cylindrical structure, which includes a grid tube 1-1 arranged radially, a support rod 1-2, a distribution tube 1-3, and connections at the ends Plate 1-4, the support rod 1-2 is located between the grid cylinder 1-1 and the distribution cylinder 1-3, and the distribution cylinder 1-3 and the grid cylinder 1-1 are welded on the support rod.

[0052] The grid cylinder 1-1 is a circular cylinder composed of a V-shaped wire mesh, the sharp corner of the V-shaped wire mesh faces the distribution cylinder 1-3, and is embedded in the support rod 1-2, and is connected with the support rod 1-2 weld with the flat side facing the particulate bed.

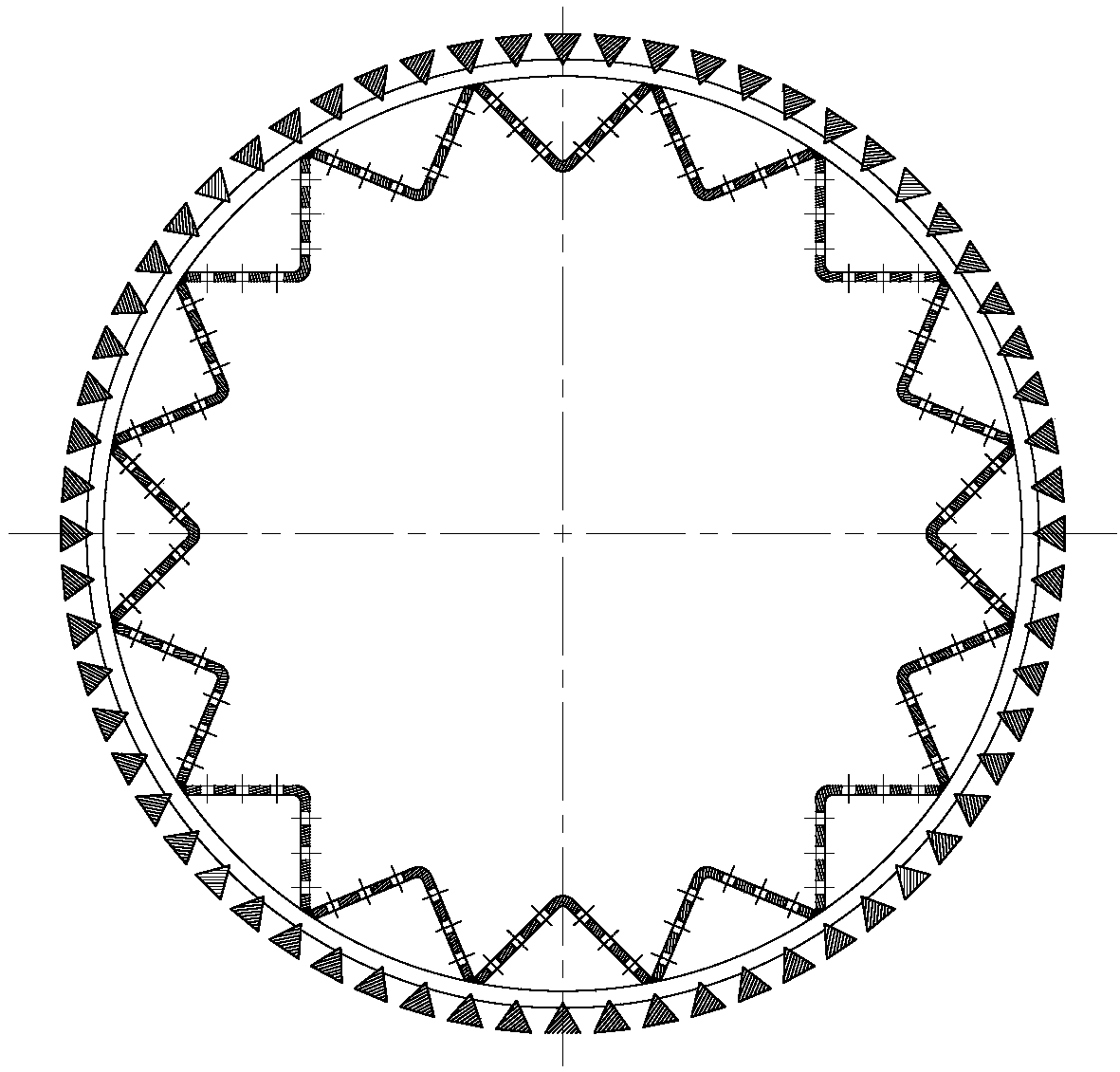

[0053] The distribution cylinder 1-3 is cylindrical as a whole, and the cylinder surface has a wave-shaped structure and is provided with uniformly...

Embodiment 2

[0058] This example is used to illustrate the particulate matter bed support grid of the present invention.

[0059] Such as Figure 6-8 As shown, the granular bed support grid is a double-layer cylindrical structure, which includes a grid tube 1-1 arranged radially, a support rod 1-2, a distribution tube 1-3, and connections at the ends Plate 1-4, the support rod 1-2 is located between the grid cylinder 1-1 and the distribution cylinder 1-3, and the distribution cylinder 1-3 and the grid cylinder 1-1 are welded on the support rod.

[0060] The grid cylinder 1-1 is a circular cylinder composed of a V-shaped wire mesh, the sharp corner of the V-shaped wire mesh faces the distribution cylinder 1-3, and is embedded in the support rod 1-2, and is connected with the support rod 1-2 weld with the flat side facing the particulate bed.

[0061] The distribution cylinder 1-3 is cylindrical as a whole, and the cylinder surface has a wave-shaped structure and is provided with uniformly...

Embodiment 3

[0066] This example is used to illustrate the radial flow reactor of the present invention.

[0067] Such as Figure 11 As shown, the radial flow reactor of the present invention includes an inner cylinder grid 1, an outer cylinder grid 2, a housing 4, an inlet pipe 6, a gas distributor 7, an outlet pipe 5 and a support 8, and is arranged on the The catalyst bed 3 between the inner cylinder grid 1 and the outer cylinder grid 2 .

[0068] The casing 4, the outer cylinder grille 2 and the inner cylinder grille 1 are nested sequentially in the radial direction, the inlet pipe 6 is arranged at the bottom of the casing 4, and the gas distributor 7 is located at the inlet Above the pipe 6, its axis coincides with the axes of the inner cylinder grid 1, the outer cylinder grid 2 and the casing 4, the outlet pipe 5 is arranged on the top of the casing 4, and the support 8 is arranged The inner wall and the bottom of the housing 4 are supported under the inner cylinder grid 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com