Particle bed layer support structure and axial-radial reactor

A technology for supporting structures and particulate matter, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as large resistance, instability, and bed thickness, and achieve the effect of reducing flow rate, improving productivity, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

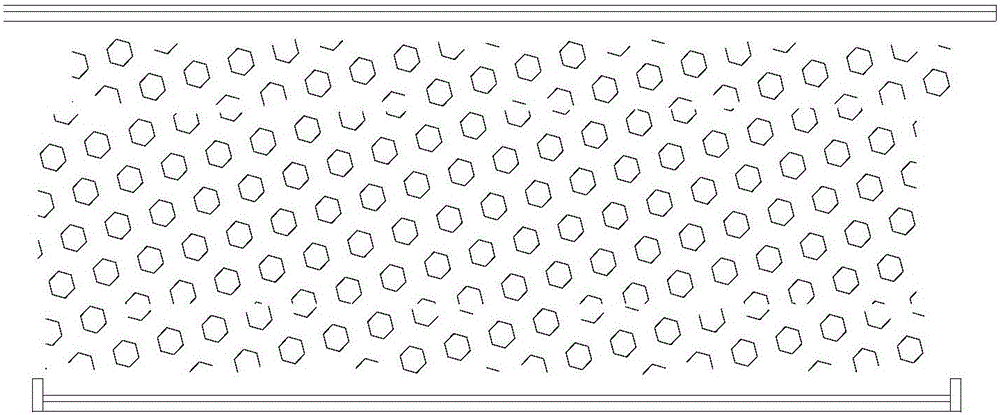

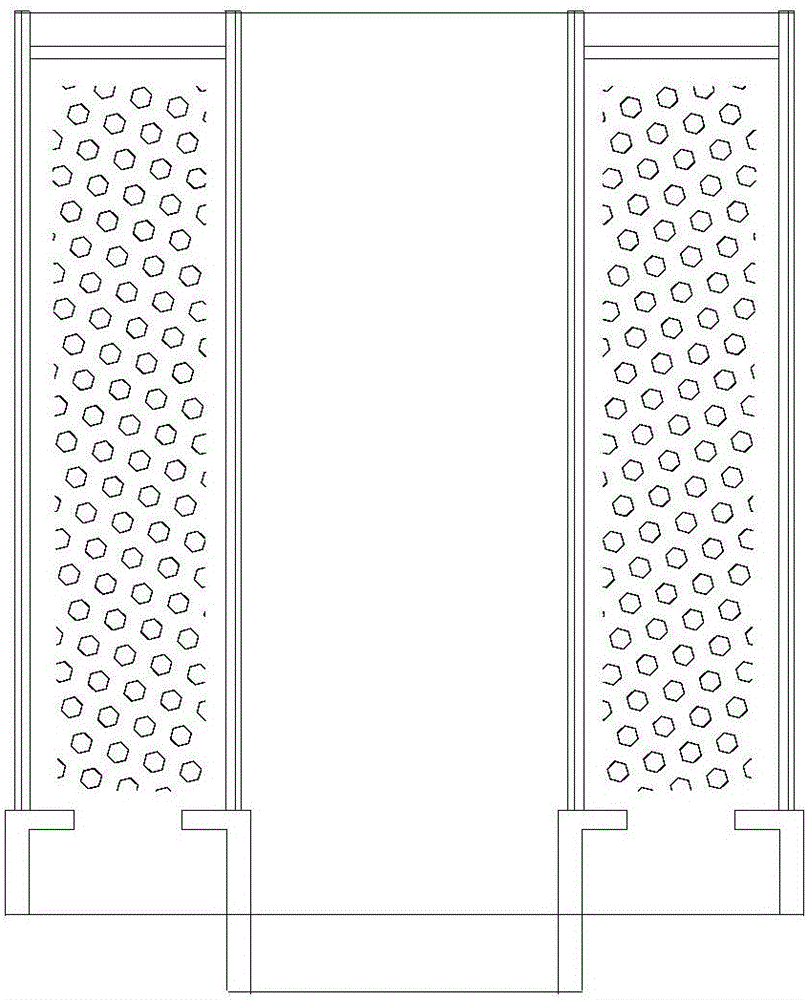

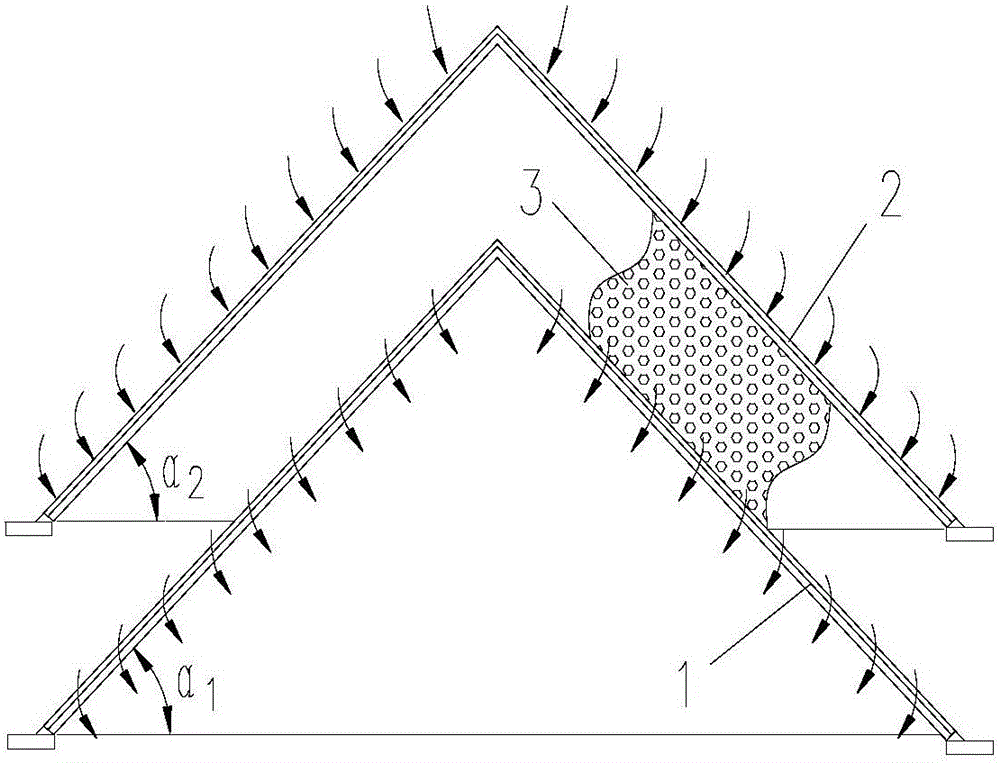

[0029] like image 3 As shown, according to one aspect of the present invention, there is provided a particulate matter bed support structure suitable for vertical reactors, vertical dryers and vertical purifiers, the support structure comprising vertically spaced support grids 1 and a compression grid 2, the support grid 1 is located below the compression grid 2, the particle bed 3 is arranged between the support grid 1 and the compression grid 2, the support grid 1 and the compression grid 2 Two conical barrels arranged coaxially and tapered upwards. The orientation words "upper and lower" used here refer to the up and down of the support structure of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com