Six-degree-of-freedom parallel mechanism containing redundant drive

A degree of freedom, driving motor technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as difficulty in meeting various motion requirements, insufficient freedom of end motion, etc., to improve kinematic performance and expand the range of rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

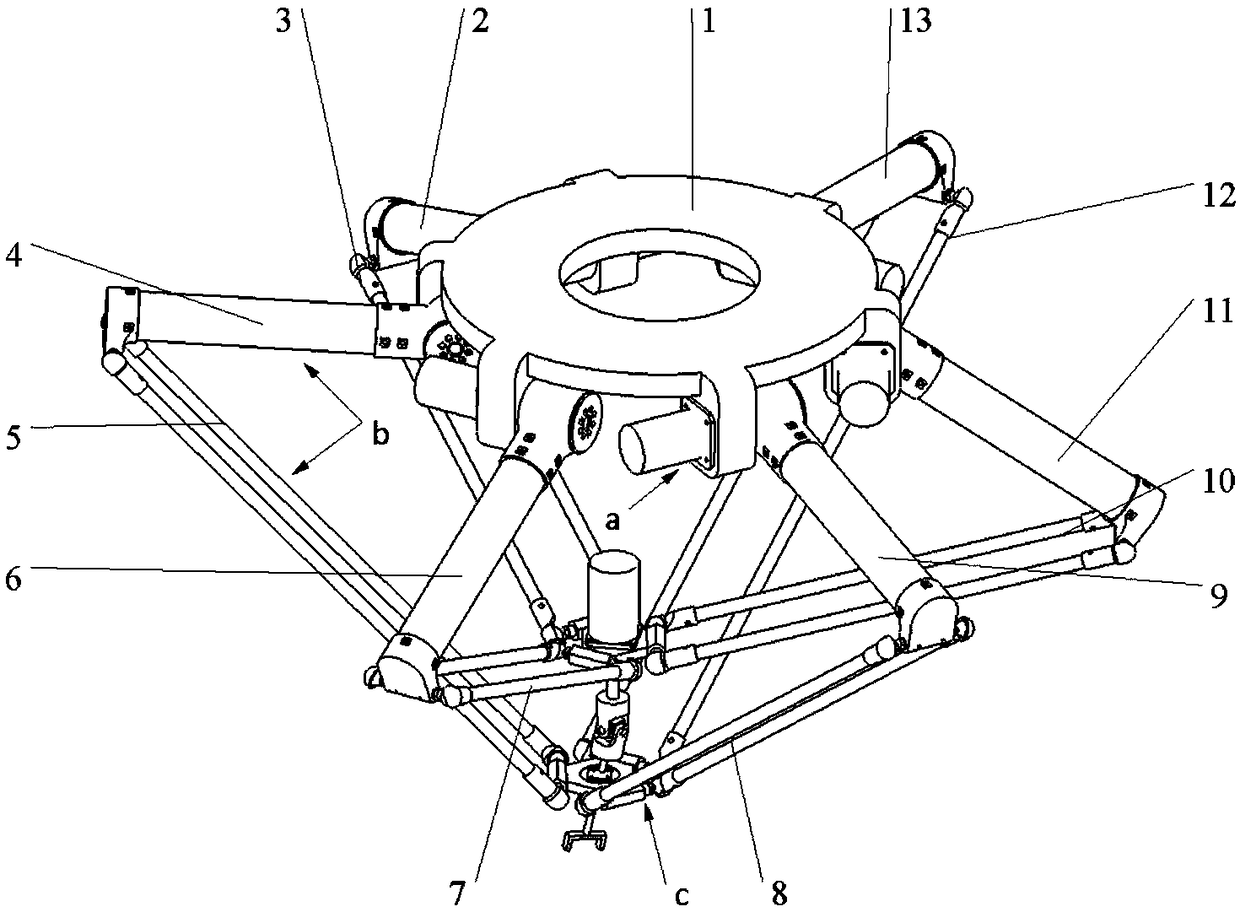

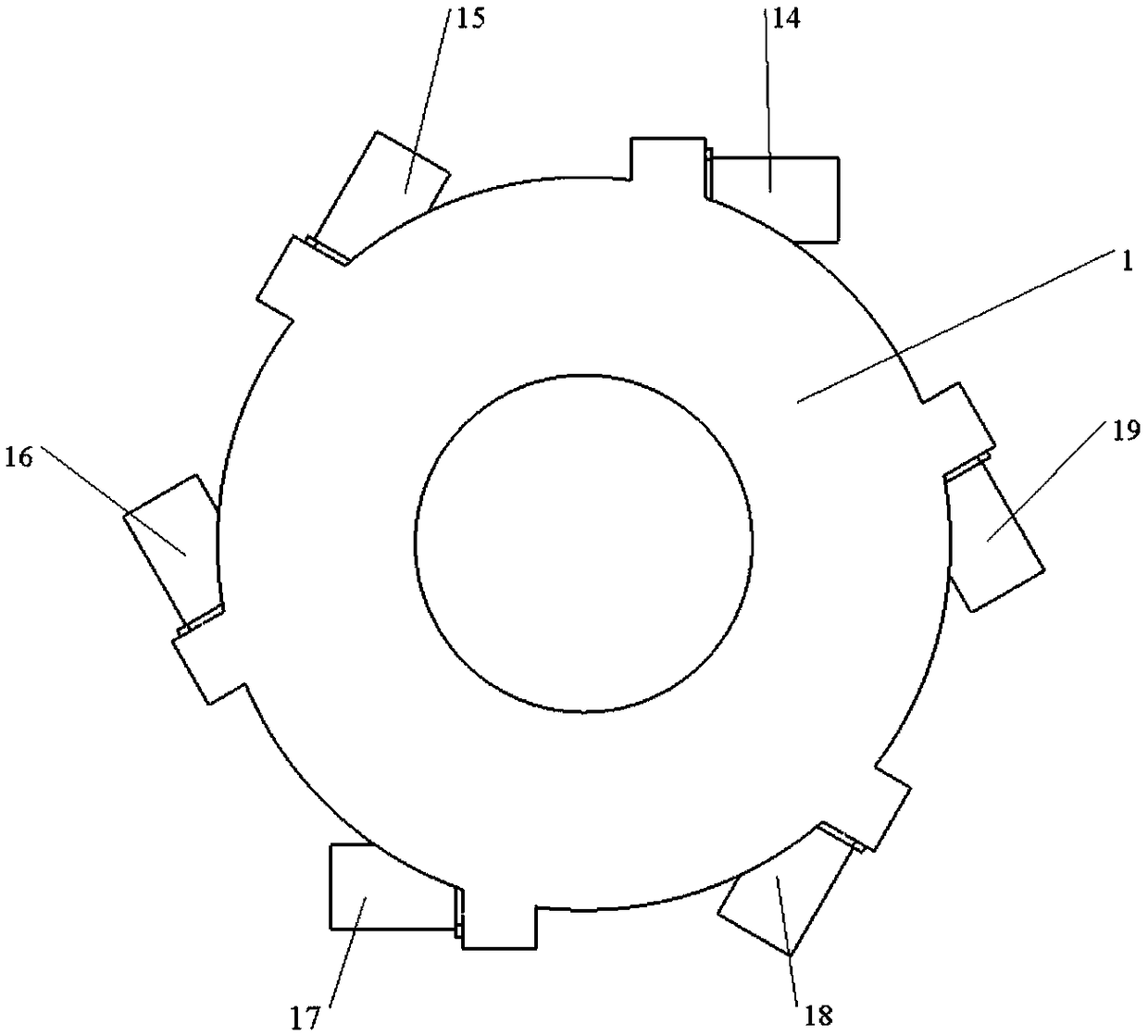

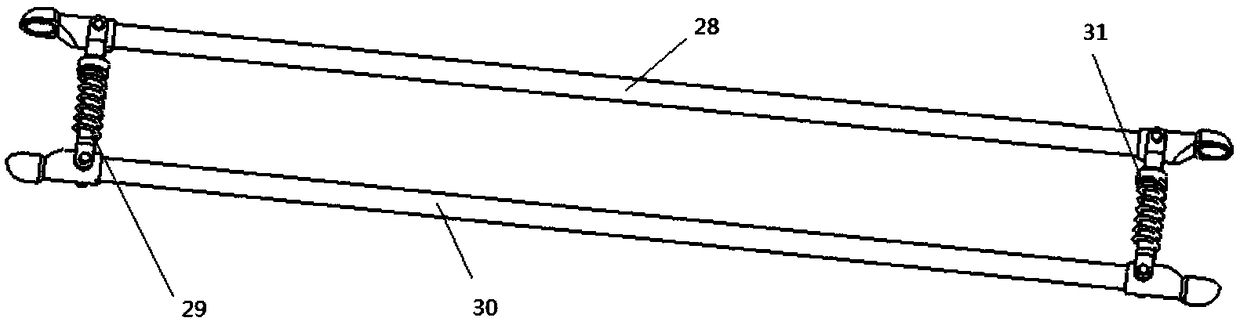

[0011] see Figure 1 ~ Figure 4 , a six-degree-of-freedom parallel mechanism with redundant drives, including two Delta parallel mechanisms sharing a static platform, the moving platforms of the two Delta parallel mechanisms are arranged in parallel up and down, and the kinematic supports of the two Delta parallel mechanisms The chains are staggered and evenly arranged. A redundant drive motor with the output shaft vertically downward is installed in the center of the upper Delta parallel mechanism actuation platform, and a movable ball forming a spherical hinge structure is installed in the center of the lower Delta parallel mechanism actuation platform. A rotating rod fixedly connected to the ball is arranged above the ball, and a terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com